Dwyer Instruments PHOTOHELIC 3000 SGT series Specifications-installation And Operating Instructions

Page 1

SERIES 3000 SGT PHOTOHELIC

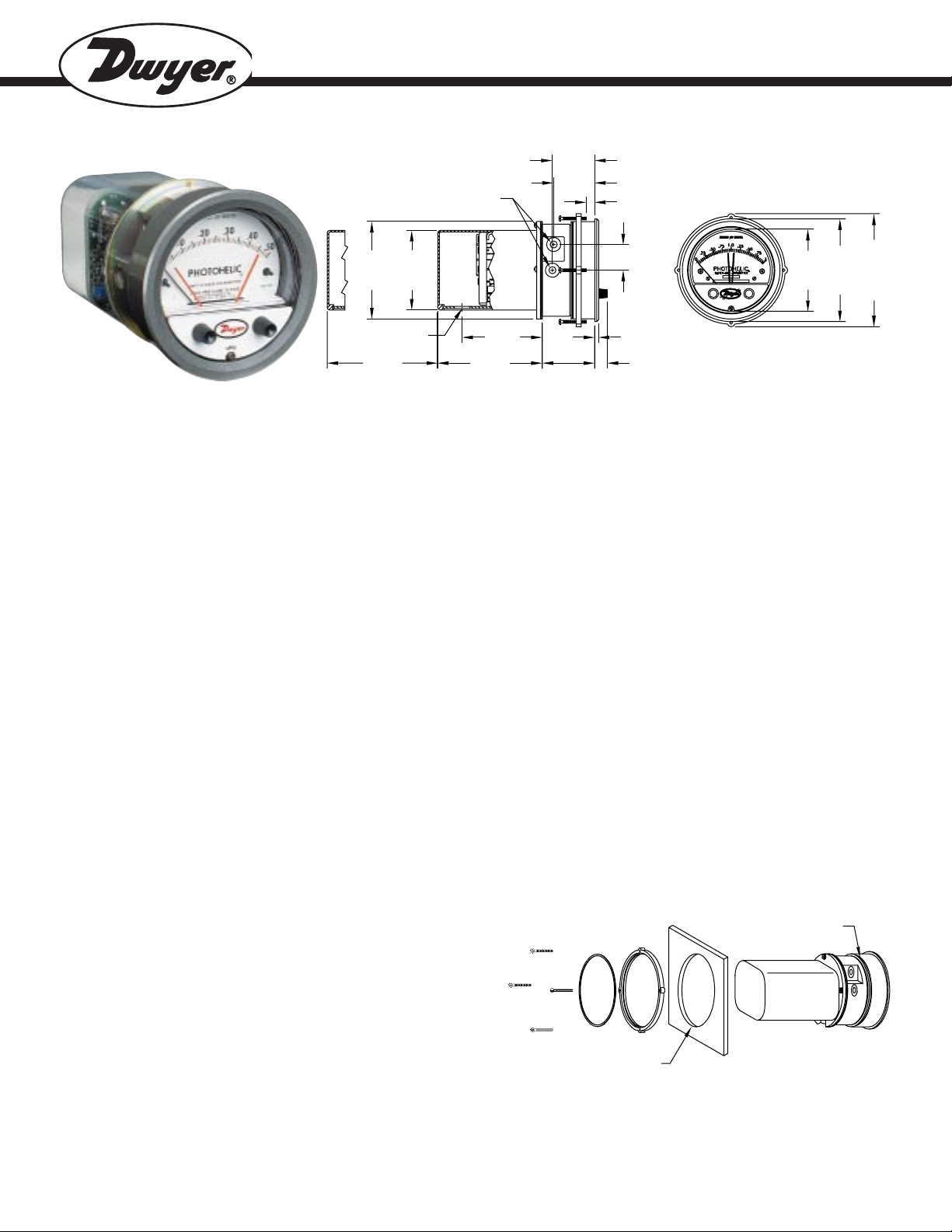

SNAP RING GROOVE

Ø4-3/4 [120.65]

MOUNTING HOLE

1/8 NPT FEMALE PNEUMATIC TAPS

2-1/16

[52.39]

2

[50.80]

PANEL 5/8 [15.88] MAX

1-1/4

[31.75]

3/16

[4.76]

5/8

[15.88]

2-1/2

[63.50]

3-7/8

[98.43]

5-1/8

[130.18]

4-3/8

[111.13]

HOUSING REMOVAL

3/4 [19.05]

CONDUIT OPENING

Ø4-3/4

[120.65]

FLANGE

3-7/8

[98.43] SQ

HOUSING

Ø4

[101.60]

FACE

5

[127.00]

0.D.

BEZEL

5-1/2

[139.70]

O.D.

MOUNTING

RING

Northeast Controls Incorporated

P.O. Box 275 - Upper Saddle River, New Jersey 07458 USA

Tel: 201-327-7660 | Fax: 201-327-3242 | sales@nciweb.com

®

Bulletin B-36A

DIFFERENTIAL PRESSURE SWITCH/GAGE TRANSMITTER

Specifications – Installation and Operating Instructions

Fig. A

The PHOTOHELIC®Series 3000 SGT is a versatile 3-in-1

instrument combining a time-proven Magnehelic

pressure gage, low/high limit pressure switches and a 4-20 mA

pressure transmitter. It is designed to measure and control positive, negative or differential pressure of air or other non-combustible, non-corrosive gases. Gage reading is unaffected by

switch or transmitter operation. Switch set points are easily

adjusted with knobs located on gage face. Applied pressure and

switch set points are fully visible at all times. Deadband is one

pointer width, less than 1% of full scale. Each set point controls

a DPDT relay and both can be interlocked to provide variable

deadband control. The 2-wire transmitter operates independently, driven by a separate external 10-35 VDC power supply.

Separate zero and span potentiometers are provided inside the

rear electronics package for easy field adjustment.

PHYSICAL DATA

Ambient Temperature Range: 20 to 120˚F (-6.7to 49˚C)

Maximum Pressure: Model No’s. 3020SGT & 3030SGT —

11psi (75 kPa); all other units 5psi (35 kPa).

Accuracy: ±2% of full scale at 70˚F (21.1˚C) (3% on -0).

Pressure Connections: 1/8˝ NPT(F)

Case FInish: Baked dark gray epoxy enamel

Conduit Opening: 3/4˝

Standard Accessories: (2) 3/16˝ tubing to 1/8˝ NPT brass adapters for

rubber or vinyl tubing, (1) mounting ring. (1) snap ring, (4) 6-32 x 2˝

mounting screws, instructions

Compatibility: Use only with air or other non-combustible, non-corrosive gases

Weight: 4lbs., 12oz. (2.15 kg)

ELECTRICAL SPECIFICATIONS (Switches)

Power Supply: 117 VAC

Current Consumption: 5 watts average

Contact Rating: 10A @ 24 VDC or 120 VAC, 6A @ 240 VAC.

ELECTRICAL SPECIFICATIONS (Transmitter)

Power Supply: 10.0 to 35 VDC

Output Signal: 4-20 mA DC, 2-wire (limited at 38 mA)

Loop Resistance: 0-1250 ohms

Current Consumption: 38 mA DC, maximum

Span and Zero Adjustment: Multi-turn potentiometers,

internally accessible

Thermal Errors: ±1% per 50˚F typical

Warm-up Time: 10 minutes

®

differential

INSTALLATION

1. Location: Select a clean, dry, vibration-free location where

ambient temperatures will be between 20 and 120˚F (-6.7

and 49˚C). Tubing supplying pressure to the instrument can

be practically any length but long runs will increase response

time slightly.

2. Position: The PHOTOHELIC

use with scale in a vertical plane. Operation at other angles

may affect accuracy and/or require zero adjustment. Most

models can be specially calibrated at the factory for other

positions if specified at time of ordering. Ranges below 1˝

w.c. must be used only with scale vertical.

3. Mounting: Normal mounting is flush or through panel as

shown in Fig. B. Allow 4-3/8˝ space behind the unit for electrical enclosure removal. Make 4-3/4˝ diameter hole in panel.

When installing multiple units, it may be preferred to obtain a

Model 730E, 120mm chassis punch as manufactured by

Greenlee Tool Co. and available from your machine tool distributor.

Insert PHOTOHELIC

®

ing ring over the case from rear and seat the snap ring in its

groove. Thread the (4) 6-32x2˝ machine screws into mounting ring, back it against snap ring and tighten screws to back

of panel. An alternative to flush mounting is the optional A371 Surface Mounting Bracket. Unit is mounted in this

bracket as described above and bracket is then surface

mounted. Contact factory for details.

®

SGT is factory calibrated for

unit from front of panel, slip the mount-

Fig. B

Page 2

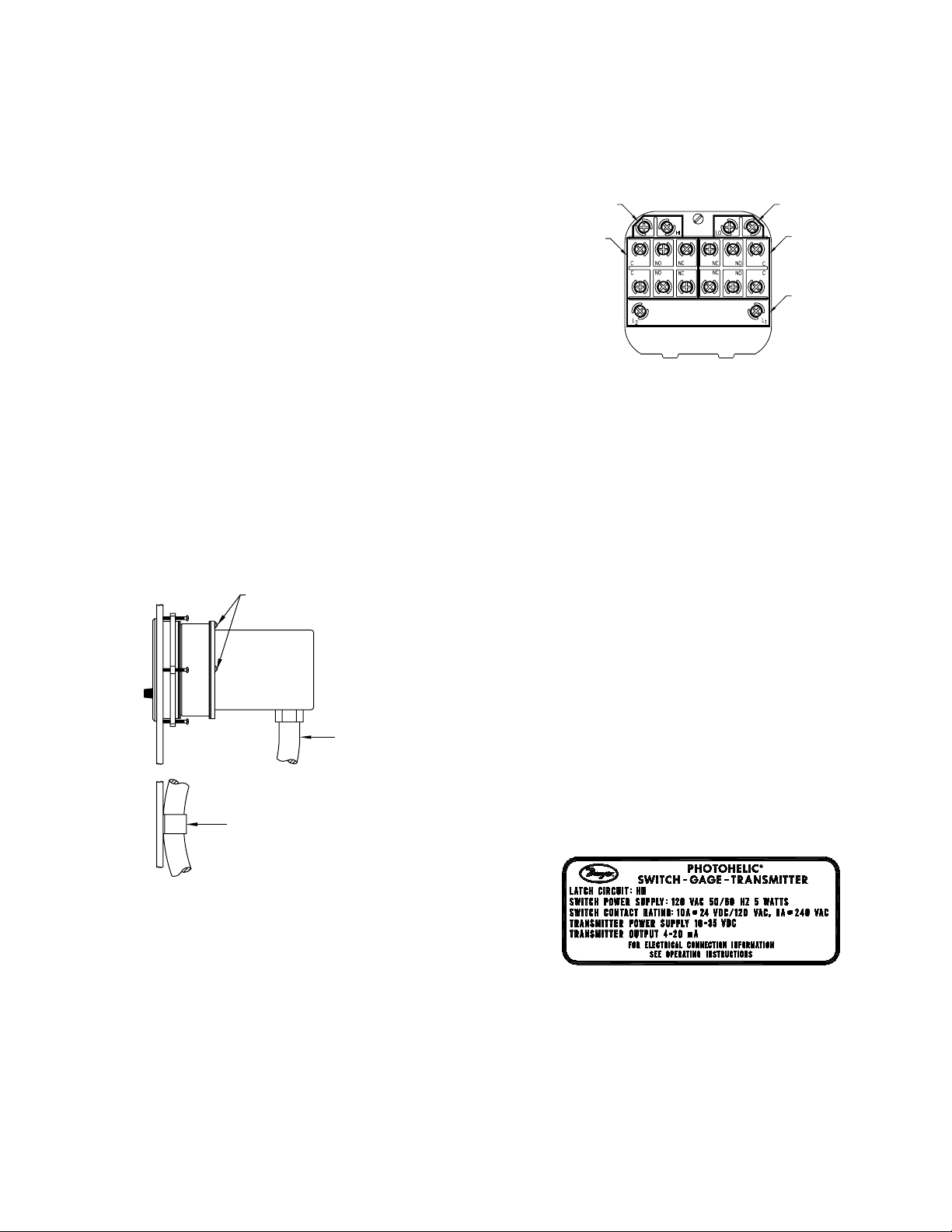

4. Zeroing & Pneumatic Connections: After unit is installed in

COVER MOUNTING

SCREWS

FLEXIBLE CONDUIT

SUPPORT CONDUIT

FROM PANEL

SECTION B

SECTION A

SECTION C

SECTION D

SECTION E

its final mounting position, use the screw at bottom of front

cover to adjust pointer for exact zero reading. This must be

done with both pressure ports open and vented to atmosphere.

(A) For positive pressure, connect tubing to HIGH PRESSURE

port and vent LOW PRESSURE port to atmosphere.

(B)For negative pressure (vacuum), connect tubing to LOW

PRESSURE port and vent HIGH PRESSURE port to atmosphere.

When either port will be left open to atmosphere, we suggest

installation of optional A-331 Filter Vent Plug to keep gage

interior clean.

(C) For differential pressure, connect higher pressure to HIGH

PRESSURE port and lower pressure to LOW PRESSURE

PORT.

NOTE: If the PHOTOHELIC

®

SGT is over-pressured beyond

its full scale range, pointer could jump from full scale back to

zero and remain there until the excess pressure condition is

relieved. Users should be aware that this condition would

cause a false indication of zero pressure and subsequently

affect set-points and transmitter output signal.

Section E (L1 and L2) contains power supply connections for

the control unit transformer primary. The transformer in turn

supplies reduced voltage power for the LED, phototransistor,

amplifier unit, load relay pull-in and holding coils.

Connections must always be made to this section for the unit

to operate. Standard units require 117 VAC but options are

available for other power sources. See label on terminal

board for correct voltage and circuit style.

CAUTION: Do not apply electrical current to ter-

minals in Sections B and C.

Fig. D

Separate Ground Wire attachment is provided for by a No.

6-32 screw on the mounting bracket near the conduit opening.

SWITCH/GAGE WIRING CONNECTIONS

To make electrical connections, remove the (3) cover screws

and slide cover off. All wiring should be fed through flexible conduit attached to conduit opening at bottom of electrical package. Conduit should be attached to the panel of other suitable

support to avoid excess strain on the instrument. See Fig. C.

Fig. C

1. Low/High Set-Point Wiring Connections

The rear terminal board contains connections for low and

high set-points, holding coil circuits and line power supply.

Transmitter connections are located behind this terminal

board. See TRANSMITTER WIRING CONNECTIONS for

complete information.

Section A contains DPDT connections for the right or high

set-point and Section D contains identical connections for

the left or low set-point.

Terminals in Section B are for control of the holding coil circuit for the right, high set-point and Section C contains identical connections for the left, low set-point. These holding

coil circuits are typically used to allow latching set-points

with manual reset or for adjustable deadband operation with

one set-point wired to reset the other. See paragraphs 3 and

4 for details. Do Not Connect Line Current to Sections B or C.

2

Single Set-Point instruments are furnished with the right or

high set-point components and circuitry in place. These are

connected to Sections A and B of the terminal board. The left

or low set-point components are omitted.

2. Circuit Style: The PHOTOHELIC

®

is available with several

factory installed optional internal circuits. They are identified

as to style by a label shown in Fig. E. This label is mounted

prominently on the terminal board of each instrument. The

letter H denotes a circuit in which the relay can be made to

latch or remain energized after pressure increase to its setpoint.

The letter L denotes a circuit in which the relay can be made

to latch or remain de-energized after pressure decreases to

its set-point. Two letters are required to fully identify a dual

set-point. Two letters are required to fully identify a dual setpoint unit. Thus, circuit style HH, which is standard, is a dual

set-point circuit which has provisions for latching on presure increase to either set-point. Single relay units are identified by the letters SR followed by H for the standard unit or

L for the special low latch unit. Units for use with other than

standard 117 VAC will be so indicated on the label.

Fig. E

3. Dual Set Point Automatic Reset: Circuit Style HH is used

for simple on-off switching applications. To place in service,

connect load circuits to the appropriate terminals in Section

A (Fig. D) for the right set-point and Section D for the left setpoint. Note that the N.O. contacts are open when the gage

pressure pointer is to the left of the set-pointers. No connections are necessary in Sections B and C. Make external

ground connections as required and connect power to

Section E for the control unit. To use circuit style LL for automatic reset, a jumper wire must be installed between the

upper and lower terminals in Sections B and/or C.

Page 3

4. Dual Set Point Manual Reset: Circuit Style HH may also be

RESET

NC

NO

RESET

NC

NO

HI LO

C

NO NC NC NO C

C

NO

NC NC NOC

L

2

L

1

1/3 HP*

120 V

LOAD

RESET JUMPERS

Northeast Controls Incorporated

P.O. Box 275 - Upper Saddle River, New Jersey 07458 USA

Tel: 201-327-7660 | Fax: 201-327-3242 | sales@nciweb.com

used for manual reset applications where it is desired to have

maintained contact on either relay following pressure

increase above its set-point. Load or signal connections are

made to the appropriate terminals in Sections A and D (as in

paragraph 3 above). Connect terminals in Sections B and C

through normally closed switches or push buttons as shown

in Fig. F. Use of “dry-circuit” type switches such as Dwyer

Part No. A-601 with paladium, gold, etc. or rotary wiping

action type contacts is recommended. Make external ground

connections as required and connect power to Section E for

the control unit.

Circuit style LL is used for manual reset applications which

require that contact be maintained following pressure

decrease below the set-point. Load connections are made to

the appropriate terminals in Sections A and D. A normally

open type manual reset switch such as Dwyer Part No. A-601

is connected to the terminals in Sections B and C. The circuit

must be reset or “armed” by momentarily closing the switch

while the black pointer is to the right of the set-point. From

that point on, the circuit will latch on pressure decrease

below the set-point and remain latched on pressure increase

until manually reset with the optional switch.

★

Note: For larger motors, use the Photohelic®in a main-

tained contact, 120 Volt Control or Push Button Circuit of

the motor starter.

Fig. G

7. Dual Set-Point Special Purpose Circuits: Circuit Style LL

may be used where manual reset following maintained contact on pressure decrease to either set-point is desired.

Circuit Styles HL and LH are combination units. For special

combinations of features, special units, and detailed instructions regarding their use, consult the factory.

8. Single Set-Point PHOTOHELIC

PHOTOHELIC

®

is furnished with the right set-point only.

®

: The single set-point

Terminals in Sections A and B (Fig. D) are connected to this

relay. Circuit Style SRH is wired for automatic reset as in

paragraph 3 above. Manual reset is accomplished by adding

a normally closed reset switch or push button to the circuit

as described in paragraph 4 above.

CAUTION: Do not apply electrical current to

terminals in Sections B and C.

Manual Reset with Circuit HH

Fig. F

5. Dual Set Point Automatic and Manual Reset Combinations:

Circuit style HH may be used with either set-point wired and

operating with automatic reset as described in paragraph 3

above and other set-point wired and operating with manual

reset as described in paragraph 4.

6. High Low Limit Control – Dual Set-Point: Circuit Style HH

may be used to control fans, dampers, pumps, etc., between

the set-points of a PHOTOHELIC

one set-point relay to reset the other as shown in the wiring

diagram Fig. G. In this typical application, the load (for

®

. To accomplish this, use

instance a fan) would be connected to the N.C. contacts of

the right set-point relay, Section A (Fig. D). On pressure rise

to the right set-point, its relay would pull in and hold even

though pressure might then fall below that set-point. If the

pressure continued to fall to the left set-point, its relay would

automatically be DE-ENERGIZED, returned to its normal

position and in so doing, open the holding coil circuit from

Section B (Fig. D). The right set-point relay would thus be

reset and the cycle could repeat.

9. Single Set-Point Special: Manual reset after actuation on

falling pressure can be obtained by using Circuit Style SRL.

Consult the factory for special units and detailed instructions

regarding their use.

10. Placing in Service: In normal operation each relay is deenergized when the pressure applied to the instrument is

below its set-point. Special low-latching units will ordinarily

have to be reset before placing on the line in normal operation.

11. Failure Mode: The PHOTOHELIC

®

circuit design provides

certain protection in the event of a loss of pressure or electrical power. In either case, both relays will de-energize,

returning to their normal “zero pressure” state. The exceptions to this are models with center zero ranges. Because the

relays on all standard models are always ener gized when the

indicating (black) pointer is to the right of their respective set

points, the relay action on loss of pressure will depend on

set-point position, since either of them could be located to

the left of zero. As an example; if the left pointer were set at

-2 in. w.c. and negative pressur e was -3 in w .c., a loss of that

pressure would allow the black pointer to return to the center and thus cause the low set-point relay to energize.

If the LED should burn out, only the left-low relay will deenergize. The right-high relay will react as if pressure were

above its set-point and will remain energized even though

pressure might be below that setting. In this situation, only

termination of electrical power will allow the right-high relay to

de-energize.

3

Page 4

TRANSMITTER WIRING CONNECTIONS

POSITIVE

NEGATIVE

SERIES

3000 SGT

PRESSURE

TRANSMITTER

RECEIVER

POWER

SUPPLY

10-35 VDC

SPAN ZERO

MAXIMUM VALUE (1250Ω)

RL MAX. = Vps-10.0

20 mA DC

OPERATING

REGION

1500

1400

1300

1200

1100

1000

900

800

700

600

500

400

300

200

100

50

TOTAL RECEIVER RESISTANCE (

Ω)

05

10 13 15 20 25 30 35 40

VDC

Northeast Controls Incorporated

P.O. Box 275 - Upper Saddle River, New Jersey 07458 USA

Tel: 201-327-7660 | Fax: 201-327-3242 | sales@nciweb.com

Electrical connections for the two-wire, 4-20 mA transmitter circuit are made to the small terminal block mounted behind the

larger switch/gage terminal board. Wiring should enter this area

through the 5/8″ dia. hole at bottom of electronics chassis. See

Fig. H.

Fig. H

The transmitter function of the PHOTOHELIC

independent of the low/high switch set-points and requires a

separate external power supply delivering 10.0 to 35 VDC with

minimum current capability of 40mA to power its control loop.

Refer to Fig. J for connection of the power supply, transmitter

and receiver. The range of appropriate receiver load resistance

(R

) values for various power supply voltages is defined by the

L

formula and graph in Fig. K. Shielded two wire cable is recommended for control loop wiring and the negative side of the loop

can be grounded if proffered. The receiver can be connected in

either the positive or negative side of the loop. If the polarity of

the transmitter or receiver is inadvertently reversed, the loop will

not function properly but no damage will be done to the transmitter.

®

SGT operates

Voltage Input

The PHOTOHELIC

®

SGT Transmitter can easily be adapted for

receivers requiring 1-5 VDC input. Insert a 250 ohm, 1/2 watt

resistor in series with the current loop but parallel to the receiver input. Locate this resistor as close as possible to the receiver input. Because resistor accuracy directly influences output

signal accuracy, we recommend use of a precision ±0.1% tolerance resistor to minimize this effect.

Transmitter Output Calibration

Each unit is factory calibrated to produce 4mA DC of loop current at zero pressure and 20mA DC at full scale. To check calibration use the following procedure.

1. Connect a controllable source of pressure to the high pres-

sure port and leave the low pressure port vented to atmos

phere.

2. With transmitter connected to its companion receiver and

power supply, insert an accurate milliameter ranged to

approximately 30 mA in series with the current loop.

3. Apply electrical power to the system and check for proper

operation. Slowly apply pressure and confirm that loop current increases above the 4 mA zero pressure value.

4. Span and zero controls are located behind the terminal board

as shown in Fig. L. Apply pressure until gage reads full scale

and adjust span control for 20 mA loop current.

The maximum wire length between the transmitter and receiver

Fig. L

is a function of wire size and receiver resistance. Connecting

wires should not contribute more than 10% of the receiver resistance to total current loop resistance. Where long runs (over

1,000 feet) are required, select receivers with higher resistances

to minimize size and thus cost of wiring. For runs up to 100 feet,

wire as small as 24 AWG can be used.

5. Relieve pressure and adjust the zero control for a reading of 4

mA loop current.

6. Zero and span controls are slightly interactive so steps 4 and 5

should be repeated until outputs are consistently 4 and

20mA, respectively.

7. Remove the milliameter from the current loop, make connec-

NOTE: RECEIVER MAY BE IN SERIES WITH

+ OR - LEG OF CONTROL LOOP

tions to system pressure sources and place unit in service.

Multiple Receiver Installation

An advantage of the standard 4-20 mA DC output signal used in

Series 3000 SGT switch/gage/transmitters is the compatibility

with a wide range of receivers. Devices such as the A-701

Digital Readout, a chart recorder and other process control

equipment can all be operated simultaneously. It is only necessary that all devices be designed for a standard 4-20 mA DC

Fig. J

input, the proper polarity of input connections be observed and

the combined receiver resistances not exceed the maximum for

the current loop. If any receiver indicates a negative or downscale reading, the signal input leads are reversed.

Maintenance

After final installation of the PHOTOHELIC

®

Switch/gage/transmitter no routine maintenance is necessary. A periodic check of

calibration is recommended following the procedure under

TRANSMITTER OUTPUT CALIBRATION. Otherwise, these units

©Copyright 2000 Dwyer Instruments, Inc. Printed in U.S.A. 11/00 FR#13-440202-05 Rev.1

Fig. K

are not field repairable and should be returned, freight prepaid,

to the following address if service is necessary. Be sure to

include a brief description of the problem plus any relative application information available.

Dwyer Instruments, Inc.

Attn: Repair Department

102 Highway 212

Michigan City, IN 46360

Loading...

Loading...