Page 1

Important Points!

Product must be maintained and installed in strict accordance

with the National Electrical Code and Dwyer product catalog

and instruction bulletin. Failure to observe this warning could

result in serious injuries or damages.

In-Line Flow Switches

P2 Series

For hazardous area applications involving such things as (but

not limited to) ignitable mixtures, combustible dust and

flammable materials, use an appropriate explosion-proof

enclosure or intrinsically safe interface device.

The pressure and temperature limitations shown on the

individual catalog pages and drawings for the specified flow

switches must not be exceeded. These pressures and

temperatures take into consideration possible system surge

pressures/temperatures and their frequencies.

Selection of materials for compatibility with the media is critical

to the life and operation of Dwyer products. Take care in the

proper selection of materials of construction, particularly wetted

materials.

Life expectancy of switch contacts varies with applications.

Contact Dwyer if life cycle testing is required.

Ambient temperature changes do affect switch set points,

since the specific gravity of a liquid can vary with temperature.

Dwyer Products have been designed to resist shock and

vibration; however, shock and vibration should be minimized.

Filter liquid media containing particulate and/or debris to

ensure the proper operation of our products.

Electrical entries and mounting points in an enclosed tank

may require liquid/vapor sealing.

P2 Model Flow Switches operate reliably in any mounted attitude for which they

are calibrated. Other attitudes will slightly alter actuation settings. Unless

otherwise specified, units are calibrated in the vertical inlet port down position.

Installation . . .

- Warning The P2 is a plastic, taper-threaded instrument.

Over-tightening will result in port breakage!

All plastic NPT threads should be installed using a suitable thread sealant.

(Teflon tape or Permatex "No More Leaks"). Sealant must be kept out of unit

during installation. Improper installation to a process can result in cracking.

Install fittings or adapters onto flow switch using strap wrenches. One to two

turns past hand-tight is adequate.

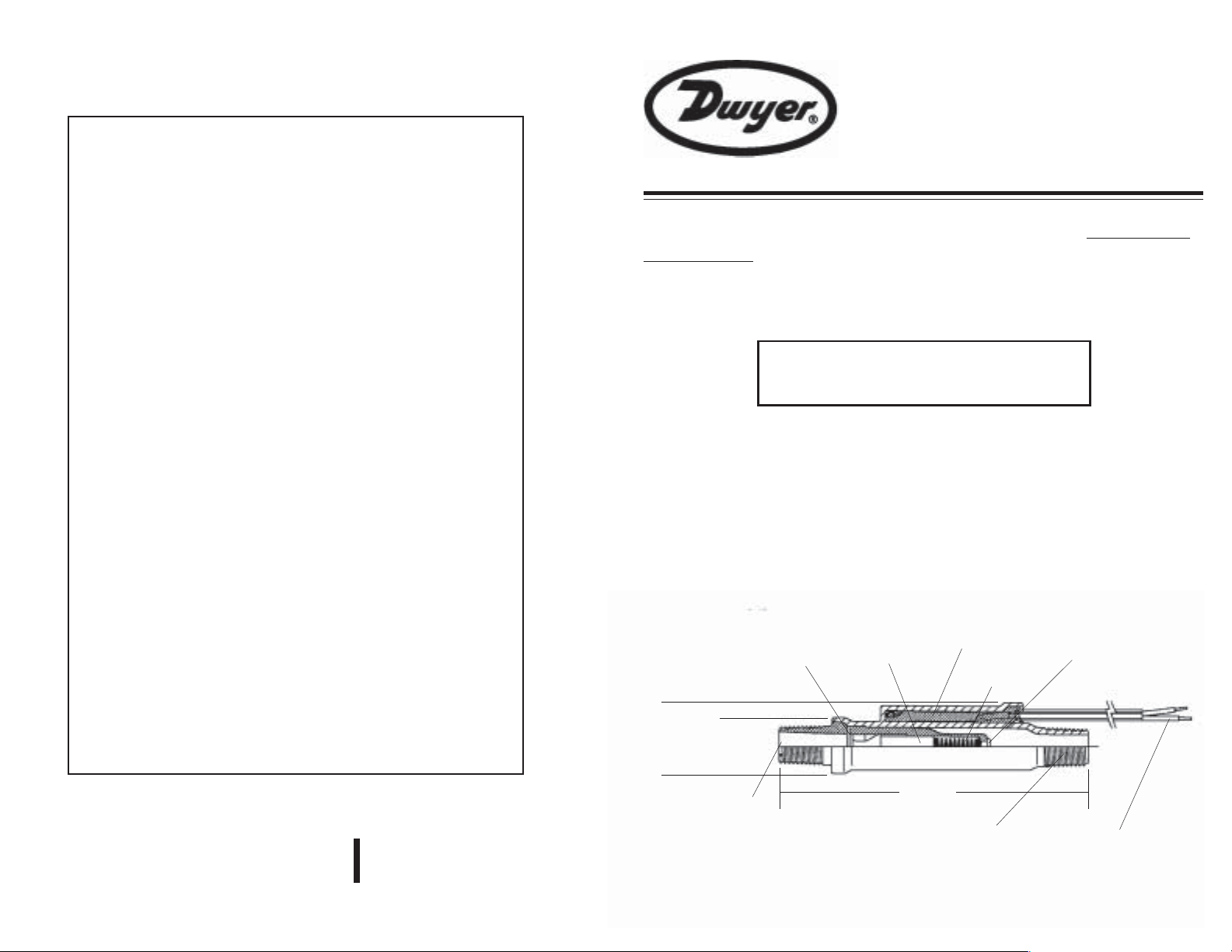

Dimensional Data . . .

Retaining

Wire

Piston

Assembly

Switch

Assembly

Spring

End Plug

Air (Gas) Flow Units

Only

Dwyer Products must not be field-repaired.

Physical damage sustained by the product may render it

unserviceable.

DWYER INSTRUMENTS,INC.

P .O.BOX 373 MICHIGAN CITY, INDIANA 46361, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

Lit-By Fax: 888/891-4963

www.dwyer-inst.com

e-mail: info@dwyer-inst.com

1"

(25.4 mm)

.78" dia.

(19.7 mm)

Inlet

4.10"

(104.3 mm)

Mechanical

Port Thread

Typ. 1/4" NPT

or R 1/4"

Outlet

- #22 AWG PVC Lead Wire

(1/4" NPT)

- Conductor PVC Cable

(R 1/4")

Page 2

Specifications . . .

Wetted Materials (FDA or NSF-Compliant)

Housing and Barbs

Piston

Spring and Stop Pin

Pressure Rating

Operating Temperature

Required Filtration

Switch, See "Switch Ratings"

Electrical Termination

Noryl

Noryl

316 Stainless Steel

150 PSI @ 70oF

50 PSI @ 212oF

212oF (100°C), Max.

50 Micron or Better

SPST, N.O. Pilot Duty 20 VA,

120-240 VAC or VDC

No. 22 AWG, 18" L., PVC Lead Wires

(1/4"NPT )

No. 22 AWG, 18" L., PVC

2-Conductor Cable (R 1/4")

®

®

and Epoxy

P2 Flow Switches Can Be

Mounted In Various Attitudes. . .

Note: Flow settings are based on a

vertical position (inlet port down), using

water at +70°F on increasing flow. Some

variation in set point actuation will occur in

other mounting orientations.

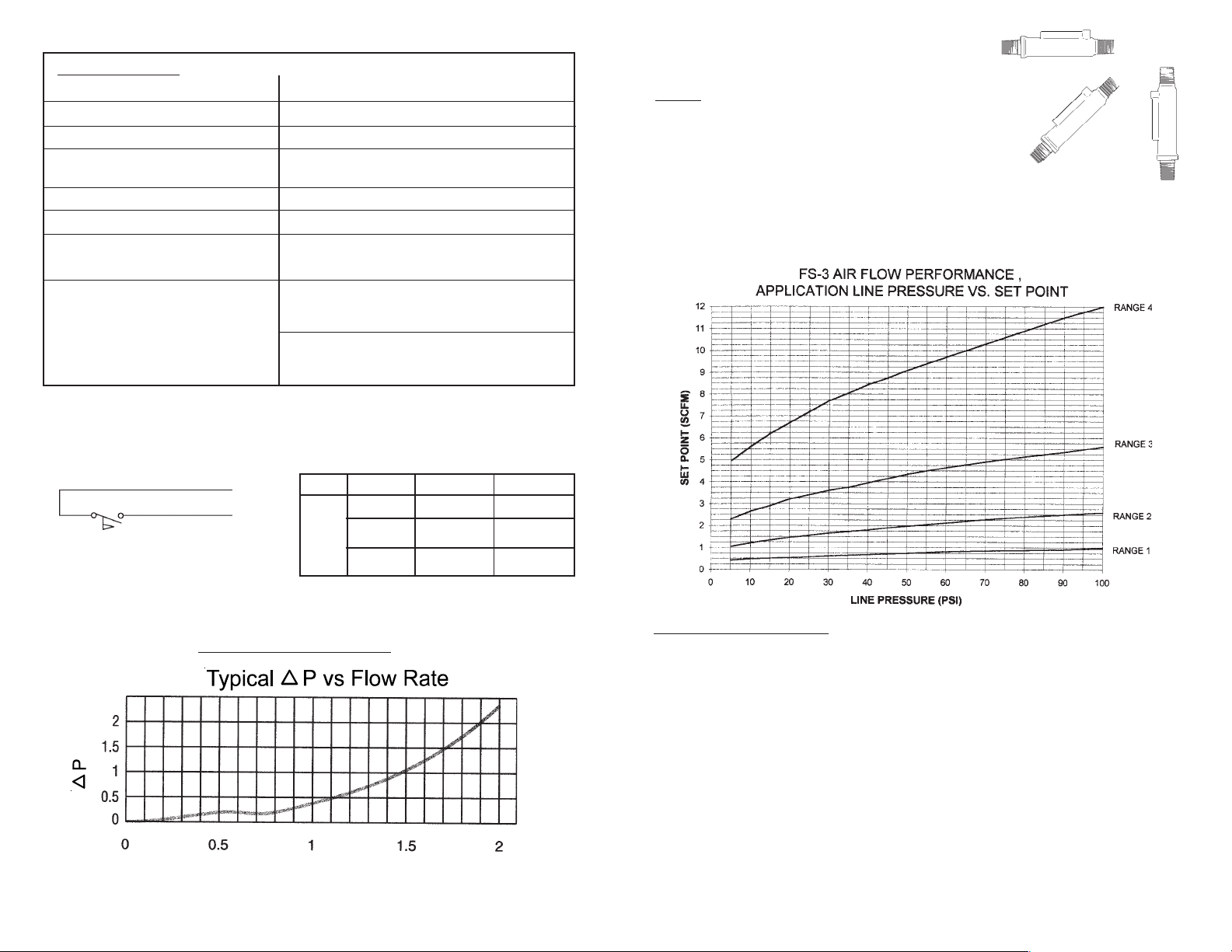

There are four standard air flow models of the FS-3. Set point will vary

with line pressure, as shown in the graph below.

Wiring Diagram . . .

Normally Open

Pressure Drop Data

(PSI)

Switch Ratings

Max. Resistive Load

VA

20

Flow Rate (GPM, Water)

Volts

0-30

120

240

Amps AC Amps DC

.4

.17

.08

.3

.13

.06

MAINTENANCE/REPAIR

Regular maintenance of the total system is recommended to assure sustained

optimum performance. These devices are not field repairable and should be

returned to the factory if recalibration or other service is required. After first obtaining a Returned Goods Authorization (RGA) number, send the unit freight prepaid

to the following. Please include a clear description of the problem plus any application information available.

Dwyer Instruments, Inc.

Attn: Repair Department

102 Highway 212

Michigan City, IN 46360

Loading...

Loading...