Page 1

Instruction Manual

INM7700

MTL7700 Series

Shunt-diode safety barriers

Page 2

ii

INM7700-6 Jan 2010

Page 3

1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.2 MTL7700 Series – barrier ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.3 MTL7700 Series – accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3 SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.1 General requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.2 Safety checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4.2 Mounting/removing barriers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4.3 Installing accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5 WIRING CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.2 Barrier connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.3 Connections to plant earth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.4 Connections to dummy barriers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.2 Routine inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7 FAULT-FINDING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.2 Power supply check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.3 Barrier resistance test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8 EQUIPMENT AND BARRIER TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8.1 Thermocouple and RTD tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8.2 Barrier tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8.3 Tests for Active Barriers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.4 Test tables for passive barriers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

APPENDIX A: TYPICAL WIRING CONNECTIONS FOR SPECIFIC APPLICATIONS. . . . . . . . . . . . . . . . . . . 17

CONTENTS PAGE

© 2010 MTL Instruments Group plc. All rights reserved.

INM7700-6 Jan 2010

iii

Page 4

INM7700-6 Jan 2010

iv

Page 5

1

INM7700-6 Jan 2010

MTL7700 Series

Shunt-diode safety barriers

INM7700-6

Jan 2010

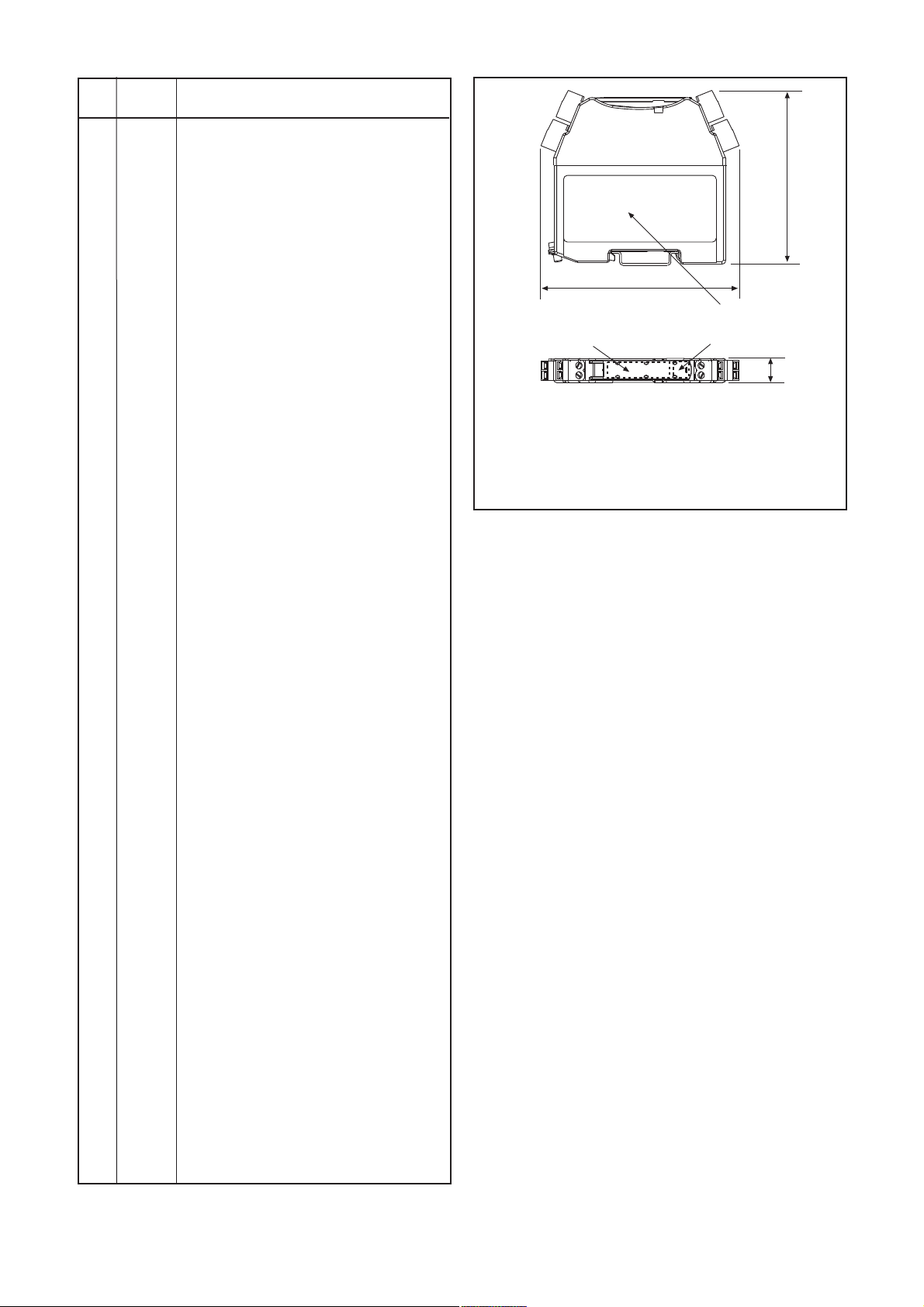

Figure 1: MTL7700 Series shunt-diode safety barriers

1 OVERVIEW

This instruction manual contains all information needed to install,

maintain, fault-find and test MTL7700 Series shunt-diode safety

barriers.

Section 3 includes a checklist of essential safety factors that must

be considered when using MTL7700 Series barriers as intrinsically

safe (IS) interfaces between safe and hazardous areas.

Read section

3 before beginning installation

. Users within the European

Community should also refer to the supplied MTL publication:

INA7700 MTL7700 Series

Instructions for Safe Use

It is assumed that all necessary system design, specification and

engineering factors have been taken into account BEFORE installation

work begins. To assist pre-planning, the following MTL publications

covering the theory, design, application, specifications and

certification of shunt-diode safety barriers are available:

AN9003 Application Note:

A user’s guide to

intrinsic safety

AN9007 Application Note:

A user’s guide to

MTL700 Series shunt-diode safety

barriers

MTL IS catalogue The MTL IS catalogue includes detailed

specifications of all MTL7700 Series

barriers and accessories

IS certificates Copies of Baseefa, FM and CSA IS

apparatus and system certificates for

MTL7700 Series barriers

If not supplied with the product, these publications are available

either from the company website (

www.mtl-inst.com

) or on request

from your local MTL office.

2 DESCRIPTION

2.1 Introduction

MTL7700 Series ‘fourth-generation’ intrinsically safe shunt-diode

safety barriers are innovative successors to the MTL700 Series.

MTL7700 Series barriers are 1-, 2- or 3-channel devices that use

intrinsically safe explosion-protection techniques to pass electrical

signals between safe and hazardous areas, whilst limiting transferred

energy to a level that cannot ignite flammable atmospheres.

Connected in series with wiring entering any hazardous area on

process plant, MTL7700 Series barriers prevent explosions in all

normally occurring explosive atmospheres – including mixtures of air

with flammable gases, vapours, dusts and fibres – if a fault or faults

develop in the safe area.

2.2 MTL7700 Series – barrier ranges

The range is based on a choice of models which, between them,

cover virtually all applications – including the protection of

installations incorporating uncertified devices known as ‘simple

apparatus’ (eg, switches, thermocouples, resistive sensors, photocells

and LEDs) or separately certified ‘energy-storing’ or ‘voltageproducing apparatus’ (eg, ac sensors, proximity detectors,

transmitters and current-to pneumatic (I/P) converters. Being

intrinsically safe, shunt-diode barriers enable maintenance work or

calibration to be carried out ‘live’ without additional precautions. To

simplify selection, several ‘key’ barriers (see table 1) are highlighted

as meeting the majority of process control requirements.

Page 6

2

INM7700-6 Jan 2010

2.3 MTL7700 Series – accessories

MTL7700 Series barriers mount directly onto DIN-rail. A

comprehensive selection of mounting, tagging, power and earthing

accessories is available. Installation details are given in section 4.3.

Essential accessories

The following are usually considered essential for mounting and

earthing MTL7700 Series barriers:

DIN-rail (eg, THR2 or THR7000)

Insulating spacers (eg, ISP7000)

Earth terminal (eg, ETL7000)

The tagging systems for individual modules and columns of barriers

are described here. They are shown below under Tagging

accessories for columns of barriers.

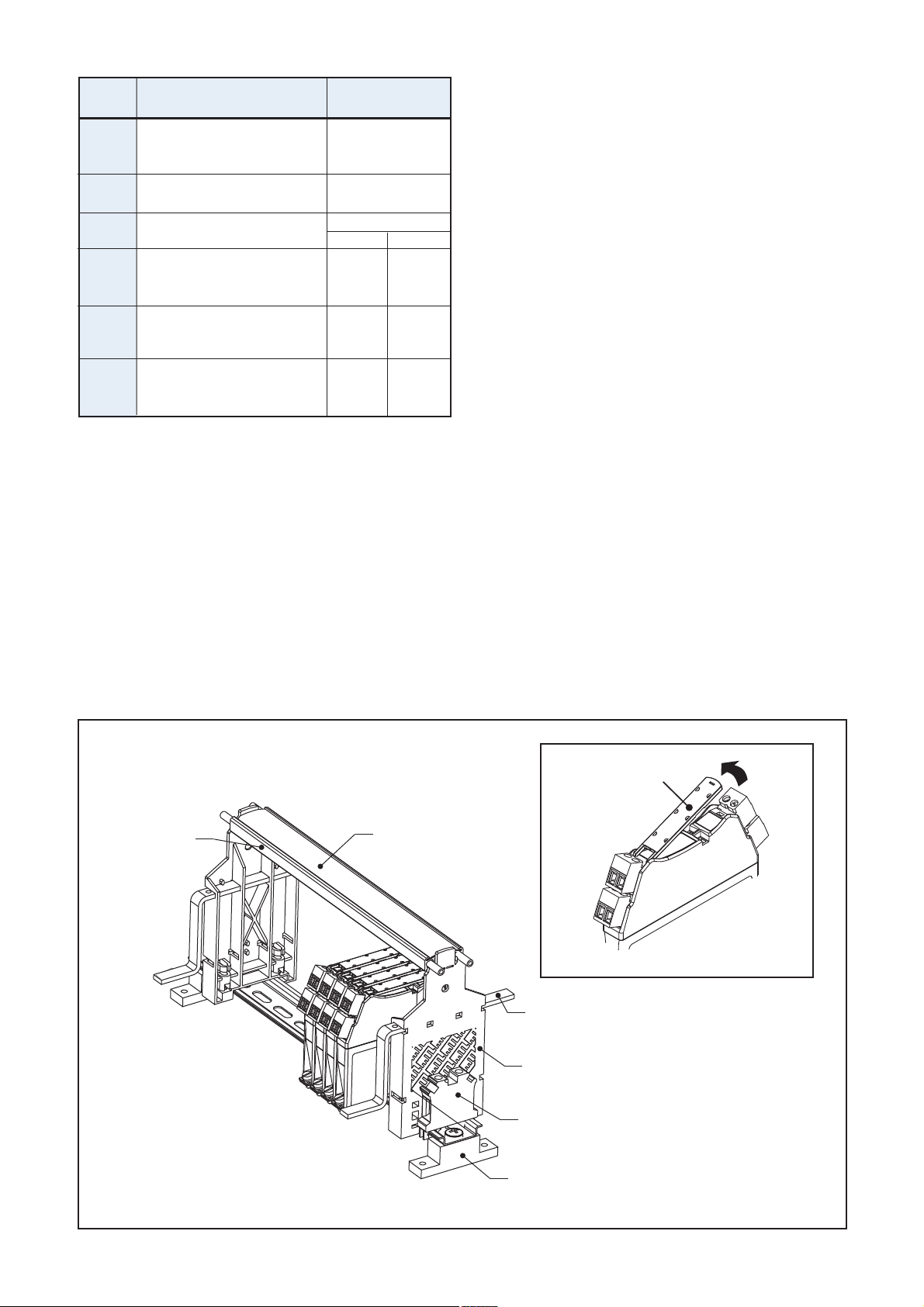

Mounting accessories (figure 2)

THR2 Standard DIN-rail, 35 x 7.5mm, (in 1m lengths)

THR7000 Nickel-plated DIN-rail, 35 x 7.5mm, for use in

potentially corrosive atmospheres (in 1m lengths)

ISP7000 Insulating spacer: attaches to the base of a DIN-

rail to isolate the IS earth from a structural earth

Tagging accessories for individual barriers (figure 2)

TH7700 Tag holder for mounting on the top of an

individual barrier

Tagging accessories for columns of barriers (figure 2)

TAG57 Tagging strips for mounting over a column of

barriers, for marking barrier locations. Supplied

(with labels) in 1m lengths for cutting to size.

TGL7700 Spare labels for use with TAG57 tagging strips:

0.5m strips, supplied in sets of 10.

IMB57 Tagging strip supports. Two needed for each

tagging strip. It can also be used as centre

support by breaking off the top end tab.

Power accessories (figure 3)

BPL7700 Power link for feeding 24V dc to a maximum of

40 barriers in a single column from an MTL7798

power feed module or MTL7799 Dummy

module.

Earthing accessories (figure 3)

ETL7000 Earth terminal providing connections for

routeing the IS earth from the DIN-rail to an

appropriate plant earth. Two recommended for

each length of DIN-rail.

TAG57

TGL7700

ERB57O

IMB57

ETL7000

ISP7000

TH7700

Figure 2: MTL7700 Series mounting and tagging accessories

Table 1: MTL7700 Series Key barriers

Type Application Key barriers

MTL

Analogue Resistance temperature detectors 7755ac

input Thermocouples, ac sensors 7756ac

(low-level) 7760ac

Analogue Controller outputs, one line earthed 7728+

output Controller outputs, neither line earthed 7787+

dc power supply

26V 20-35V

Analogue Transmitters, 2-wire, 4–20mA 7787+ 7706

input

(high-level)

Digital Switches 7787+ 7707+

(on/off) 7741-44

input

Digital Solenoids, alarms, LEDs 7728+ 7707+

(on/off)

output

Page 7

3

INM7700-6 Jan 2010

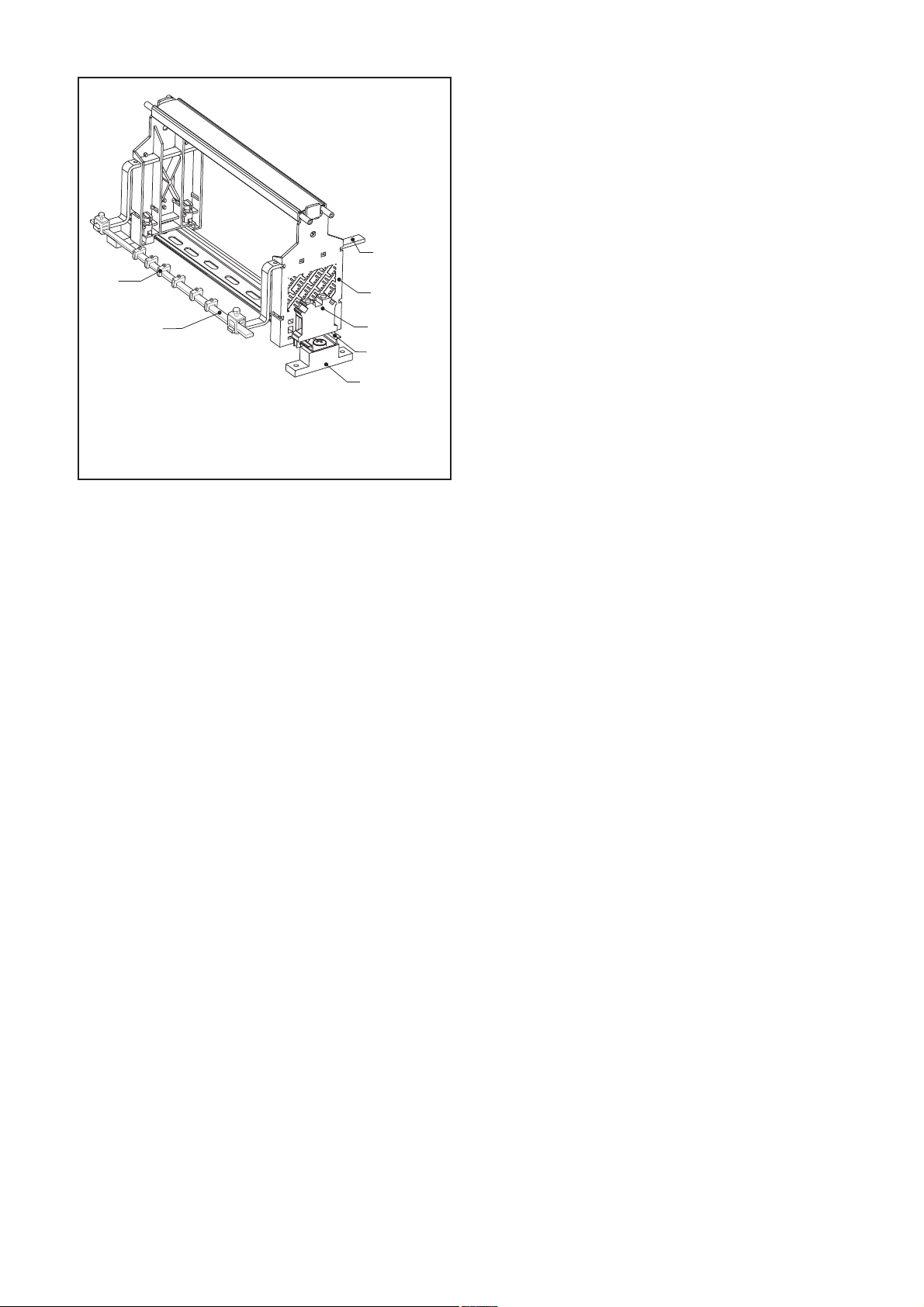

ERB57O

IMB57

ETL7000

ERL7

ETM7

ISP7000

THR2/THR7000

Figure 3: MTL7700 Series earthing accessories

Note: Module earth terminals may be used for cable

screen earth connections. See Figure 17

ERB57S Nickel-plated straight earth-rail bracket,

supplied with two push fasteners, one 14mm

earth-rail clamp and one 9mm earth clamp <

16mm2.

ERB57O Nickel-plated offset earth-rail bracket, supplied

with two push fasteners, one 14mm earth-rail

clamp and one 9mm earth clamp < 16mm

2

.

ERL7 Nickel-plated 3 x 10mm earth rail supplied in

1m lengths. Provides earthing facilities for cable

screens and 0V earth returns, additional to those

provided on the module earth foot.

ETM7 Earth terminal (5mm wide) for attachment to an

ERL7 earth rail, for terminating cable screens

and spare cable cores.

3 SAFETY CONSIDERATIONS

3.1 General requirements

All installers of shunt-diode barriers should be familiar with the

installation instructions provided by nationally accepted codes of

practice, eg, BS EN 60079-14 for the UK, or a recommended

practice, eg, ANSI/ISA-RP 12.6 for the USA.

Users within the European Community should also refer to the

supplied MTL publication:

INA7700 MTL7700 Series

Instructions for Safe Use

3.2 Safety checks

Table 2 itemises the essential checks that should be carried out to

ensure the safety of a barrier installation. Use the checklist to prevent

important safety considerations being overlooked when installing,

commissioning, modifying or servicing an installation of MTL7700

Series barriers. Check the list both before and after a barrier system

has been installed, the final check being made by someone other

than the person(s) who carried out the installation work. Each item in

the list is cross-referenced to the appropriate section of the manual.

For Factory Mutual (FM) based installations see also Appendix B

for FM certification information.

4 INSTALLATION

4.1 General

MTL7700 Series barriers clamp directly onto standard T-section DINrail (DIN EN 50 022). The simple mounting procedure for barriers is

described in section 4.2 and for accessories in section 4.3.

4.1.1 DIN-rail length

BEFORE mounting the barriers, make sure the rail length is sufficient

for the proposed number of barriers and for other mounting

accessories. As a guide, on a given length of DIN-rail, allow space

(length) for:

a) Barrier packing pitch: 12.6mm

b) ETL7000 earth terminals: 10mm each (minimum

of two)

c) IMB57 tagging strip support 16.0mm (minimum of

(if specified) two)

d) ISP7000 insulating spacer 14.7mm (minimum of

(if specified) two)*

e) ERB57S or O earth-rail 8 mm (minimum of two)

mounting bracket

(if specified)

* See Note in section 4.3.2

Make sure that there is sufficient clearance between the DIN-rail and

any possible obstruction (eg, other columns of barriers) to remove

barriers and install accessories such as ERB57S/O earth rails.

Provide sufficient height for IMB57 tagging strip supports and

ISP7000 insulating spacers when fitted.

As a guide, refer to figure 4 (dimensions of an individual barrier) and

figure 5 (clearances needed for accessories).

4.2 Mounting/removing barriers

MTL7700 Series barriers clamp directly onto T-section DIN-rail,

earthing the barrier through the rail.

a) Hook the hazardous-area end of the mounting/earthing clamp

over the hazardous-area flange of the DIN-rail (figure 6).

b) Push the safe-area end of the barrier firmly down by hand until

it clicks into place.

c) Check that the barrier is securely clamped into place (see notes

below).

d) To remove a barrier (figure 7), use the tip of a screwdriver (with

a blade width of 4 to 5mm, minimum shaft length 60mm) to ease

the metal clip at the base on the safe-area end outwards until the

barrier is freed and can be removed easily by unhooking the

hazardous-area end.

Notes

1: Make sure the barrier is properly clamped onto the rail to ensure

the essential earth connection. In a row of barriers, one end of an

improperly mounted barrier will stick up slightly.

2: Once an MTL7700 Series barrier is fitted, its mounting/earthing

foot grips the DIN-rail strongly in order to maintain positional stability

and create a high-integrity earth bond. The unit should not be forced

along the rail. If it is necessary to reposition a barrier, detach it from

the DIN-rail and re-attach it in the correct location. Where minor

repositioning is needed, relieve the pressure on the spring of the

mounting foot with a screwdriver and ease the unit into place.

4.3 Installing accessories

See section 2.3, figure 2 and figure 3 for brief details of the

accessories available for use with MTL7700 Series barriers. More

information and installation details (where relevant) for the various

accessories are detailed in the following sections:

Page 8

4

INM7700-6 Jan 2010

90

Hazardousarea

terminals

Safe-area

terminals

12.6

105

Installation and approval side label

Product top label

Colour-coded top label

Top label background colour codes

Red = positive barrier

Black = negative barrier

Grey = ac barrier

White = dummy barrier

Orange = power feed module

Figure 4: Dimensions (mm) of an MTL7700 Series barrier

Mounting accessories Section 4.3.1 to 4.3.

Earthing accessories Section 4.3.3, 4.3.4

Tagging accessories Section 4.3.5, 4.3.6

Power links Section 4.3.7, 4.3.8

4.3.1 DIN-rail (THR2 and THR7000)

MTL can supply both standard (THR2) and plated (THR7000) lowprofile T-section DIN-rail. Although standard DIN-rail maintains a

high-integrity earth in normal conditions, for aggressive environments

MTL provides THR7000 nickel-plated DIN-rail. Both types are

supplied in 1m lengths for cutting to size as necessary. Although there

is no strict requirement for the DIN-rail to be isolated from earthed

surfaces, it is advisable, in order to minimise the possibility of the

earth circuit being invaded by fault currents which might interact

adversely with other systems. ISP7000 insulating spacers are a

convenient method of insulating the DIN-rail. It is much easier to

install insulating spacers during the initial build, than to discover later

that an equipped and running installation must be modified.

4.3.2 Insulating spacers (ISP7000)

When used, ISP7000 insulating spacers are attached to each end of

the DIN-rail and at intervals depending upon the length of the rail. It

is recommended that spacers be mounted at 300mm intervals on lowprofile (7.5mm) DIN-rail and at 500mm intervals on high-profile

(15mm) rails – see figure 8. The spacers are provided with suitable

screws for attaching to both the DIN-rail and the mounting surface,

which will need to be suitably drilled and tapped for the purpose.

Install each spacer as follows (figure 9):

a) On the mounting surface, drill and tap two holes for M4 screws.

b) Attach the spacer to the surface with the two M4 x 16 screws

provided.

c) Drill an M6 clearance hole (6.5mm) in the centre of the base of

the DIN-rail (if not already suitably slotted)

d) Attach the DIN-rail to the spacer with the M6 x 16 screw

provided.

Table 2: Safety checklist

Item Refer to

no. section: Action

1 3.1 Before beginning installation, check that the

safety documentation confirms that the

proposed system is fully certified (if applicable)

and complies with the recommendations

contained in the relevant sections of IEC

60079-14 for the gas group, temperature

classification and area classification required.

2 4.1/6.2 Make sure the barriers are of the correct type

and polarity as specified in the safety

documentation.

3 4.1 Make sure all barriers are mounted the right

way round and are properly attached so that

the essential earth contact is made securely in

accordance with the safety documentation and

in compliance with the recommendations of IEC

60079-14.

4 5.3/6.2 Measure the resistance between the barrier

earth DIN-rail and the main power system earth

and make sure it does not exceed the maximum

permitted resistance specified in the safety

documentation.

5 4.1/6.2 Inspect carefully all cables connected between

the barriers and the hazardous-area equipment,

making sure the cables are the type specified

by the safety documentation and that they are

connected to the correct terminals.

6 5/6.2 Make sure all hazardous-area cables are well

secured and are segregated from all other

cables.

7 5 Make sure the permitted cable parameters for

hazardous-area circuits are not exceeded (see

relevant certificate or INA7700).

8 5 Make sure all hazardous-area apparatus and

cables are either earth-free or correctly bonded

with an equipotential conductor.

9 5.3/6.2 Make sure all hazardous-area cables and cable

screens are terminated correctly, the latter

preferably via earth foot on the hazardous side

of each barrier or via ERL7.

10 5.4 Make sure all unused hazardous-area cables

are terminated by a dummy barrier (MTL7799),

earth rail (ERL7) or otherwise safely connected

to earth.

11 Make sure all hazardous-area energy-storing

devices are independently and appropriately

certified.

12 4.1/ Inspect all tagging or identification labels and

4.3.5/ make sure they relate to the correct barrier

4.3.6 types, polarities and circuit loop numbers.

13 5/6.2 Inspect carefully all cables connected to the

safe-area equipment and make sure they are

connected to the safe-area terminals of the

barriers.

14 5.3 Make sure that no safe-area equipment is

supplied from (or includes) a source of potential

with respect to earth that exceeds 250V rms or

250V dc under normal or fault conditions unless

specifically permitted by the safety

documentation.

Note: One phase of a 3-phase supply of up to

440V is permitted as its value is equivalent to

250V rms.

15 Make sure all barriers are protected adequately

against moisture, dust, dirt, vibration, excessive

temperatures, physical damage and

unauthorised modifications.

Page 9

5

INM7700-6 Jan 2010

TAG57

TGL7700

ERB57O

IMB57

ETL7000

ISP7000

110mm

110mm

170mm

Figure 5: Clearance for accessories

Note: For high profile (15mm) DIN rail, add 7.5mm to vertical dimension

1

2

3

1

2

Figure 6: Clamping an MTL7700 Series barrier on to a DIN-rail

Figure 7: Removing an MTL7700 Series barrier from a DIN-rail

250mm

Low-profile rail (7.5mm)

High-profile rail (15mm)

250mm

500mm

Figure 8: Maximum DIN-rail spans between ISP7000 spacers

4.3.3 DIN-rail earth terminal (ETL7000)

See figure 10. For those applications (the majority) in which the IS

earth is NOT routed through the mounting surface, connections for

routing the IS earth from the DIN-rail to an appropriate plant earth

are made through earth terminals (ETL7000) clamped onto the DINrail. Two terminals are recommended, one at either end of a column

of barriers, to provide redundancy and to simplify earth testing

procedures.

WARNING: Apart from rare occasions when the mounting

surface carries the IS earth, the ONLY method of providing

the IS earth connection from any one column of MTL7700

Series barriers is from ETL7000 earth terminals. Never make

the plant IS earth connection to the earth screen on any

individual barrier: this is MANDATORY. See also section 5.3.

ETL7000 terminals are attached to the rail as follows. Ensure the

same security of the earth connection to the rail as for the barriers

themselves (see section 4.2):

a) Hook the fixed end-clamp of the terminal over one flange of the

DIN-rail.

b) Press the body of the terminal downwards until the pivoting end-

clamp engages the other flange of the DIN-rail.

c) Clamp the terminal firmly into place by tightening the centre

screw.

d) Important: wire up the earth terminal as given in section 5.3.2.

Page 10

6

INM7700-6 Jan 2010

High - profile

DIN rail

OR

Low - profile

DIN rail

2 off M4 x 16

M6 X 16

50mm

62mm

14.6mm

20mm

Figure 9: Mounting ISP7000 insulating spacers

ETL7000

earth terminal

Clamping

screw

Earth terminal

screws

Figure 10: Mounting an ETL7000 DIN-rail earth terminal

TH7700

LABEL

Figure 11: Installing a TH7700 barrier tag holder

4.3.4 Earth rail assembly (ERL7/ETM7/ERB57S/O)

A screw terminals on each barrier is available for terminating cable

screens and 0V returns. An alternative is provided by an earth rail

assembly (figure 12). This consists of two IMB57’s, ERB57S or O,

mounting blocks (one for each end of a column of barriers), a length

of ERL7 earth rail (supplied in 1m lengths for cutting to size), and

ETM7 terminals for connecting cable screens or 0V returns to the rail.

Install the earth rail assembly as follows:

a) Hook the loose end-clamps of the IMB57 mounting blocks over

the flanges of the DIN-rail at each end of the row of barriers.

b) Making sure the blocks are flush with the end barriers or tagging

strip supports, clamp them firmly into place by tightening the

screws at the base of the blocks and fit 2 off ERB57O or S into

supports.

c) Slide the number of ETM7 terminals required for connections

onto the length of ERL7 rail needed for the assembly.

d) Important: wire up the earth rail assembly as given in section

5.3.3.

4.3.5 Barrier identifiers (TH7700)

TH7700 tag holders (figure 11) are clipped onto the tops ofindividual

barriers to provide transparent holders for identification labels

a) Slide the required label in between the top and lower parts of

the TH7700

b) Push the tag holder downwards until it clips into place.

c) To unclip a tag holder, lever up the far end above terminals.

4.3.6 Tagging strip assemblies(IMB57)

The tagging strip assembly (figure 12) identifies the location of

individual barriers, ensuring that they are replaced correctly after

removal for maintenance or testing. Once installed, the tagging strip

pivots upwards to provide access to, and allow removal of, individual

barriers.

Each assembly uses two tagging strip supports (IMB57), a tagging

strip (TAG57) and tag labels (TGL7700).

The assembly installation procedure is:

a)IMB57 tagging strip support. Making sure that the vertical

slots are on the hazardous-area side, hook the loose end-clamps

of each IMB57 tagging strip support over the flanges of the DINrail at each end of the group of barriers.

b) Make sure that the tagging strip support is flush with the end

barrier in the row.

IMB57 tagging strip support. Clamp firmly in place by

tightening the two screws located at the foot of each support.

c) Remove any clic rivets from the tagging strip and slide out the

label.

d) Measure the distance between the top inside faces of the two

tagging strip supports.

e) Cut the tagging strip and label to this length with a hacksaw.

f) Annotate the tagging strip label as required and slide it back

into the tagging strip. Divisions on label strips are 12.6mm

wide, the pitch of individual barriers.

g) Clip the tagging strip onto the lugs on top of the tagging strip

supports.

4.3.7 Power bus (BPL7700)

For details on using and installing a power bus, see section 5.2.3.

Note: Early versions of TH7700 are hinged on two small locating

pins. Later versions are hinged by locating the clips at the hinged end

into the rectangular appartures on the barrier body. The later design

can be retrofitted on early modules by removing the hinge pins with

a knife.

TGL7700

ERB57O

TAG57

ERL7

ETM7

14mm earth-rail

clamp

THR2/THR7000

ERB57S

in lower position

ISP7000

ETL7000

10mm earth

clamp

IMB57

Snap off extension

when using IMB57

as a central support

Figure 12: Mounting earthing and tagging accessories

Page 11

7

INM7700-6 Jan 2010

5 WIRING CONNECTIONS

5.1 General

This section describes wiring connections as follows:

a) Barrier connections Section 5.2

b) Connections to plant earth Section 5.3

c) Connections to dummy barriers Section 5.4

5.2 Barrier connections

Each barrier has 4 or 8 terminals, 2 or 4 on each side, allocated as

follows:

Safe area

Terminals 1,2,5 and 6 Safe-area power Sections

and signal lines 5.2.1 and

5.2.2

Hazardous area

Terminals 3,4,7 and 8 Hazardous-area Section

signal lines 5.2.1

Torque the screw terminals to 0.4Nm.

5.2.1 Signal line connections

Connect signal lines to the screw terminals at both sides of the barrier

(1 and 2 and/or 5 and 6 at the safe-area side, 3 and 4 and/or 7

and 8 at the hazardous-area side). The safe-area terminal 1 is also

used as a power connection when power is provided from the safe

area (see section 5.2.2 for details).

Clearly segregate hazardous-area and safe-area cabling as defined

by relevant codes of practice, and route cabling to the barriers

through clearly separated and identified conduits or trunking. Deal

with spare cable cores or screens as described in section 5.2.3.

Before making any signal connections from the hazardous area,

make sure any energy-storing devices (ie, devices NOT classified as

‘simple apparatus’) are certified as being compatible with the

barriers to which they will be connected. Check also that the

connecting cables conform with the cable types specified by the

safety documentation and that the maximum cable parameters

specified in MTL’s IS catalogue are not exceeded. In general, cable

parameters are unlikely to present problems except in installations

where cables longer than 500m are called for in IIC applications.

Do not connect barriers to safe-area equipment that is supplied from

(or contains) a source of potential with respect to earth that is greater

than 250V rms or 250V dc under normal or fault conditions, unless

this is specifically permitted by the safety documentation. This

limitation does not apply to safe-area equipment fed by a three-phase

440V neutral earth supply.

See Appendix A for examples of wiring connections for specific

applications.

5.2.2. Power supply connections general considerations

Take care that if barriers are connected to a safe-area power supply,

connections are made correctly. If the internal safety fuse blows, it will

destroy MTL7700 barriers. See Appendix A for specific connections

for individual barriers and applications.

5.2.3 Bussed Power applications and connections

When a number of barriers use a common power supply, the optional

power link (BPL7700) can be used. Typical applications include

hazardous-area switches, solenoids and 4–20mA transmitters; and

the barriers it can be used with are the MTL7706, MTL7707+,

MTL7787+, MTL7787P+ and MTL774x. See figure 14 for a typical

power link installation applied to hazardous-area switches.

Up to 40 barriers can be linked using the power links. The link itself

is supplied from a power feed module (MTL7798). The MTL7798

power feed module is provided with a trip circuit which protects the

barriers by switching off their supply if a fault (such as an

overvoltage) occurs in the power source. The state of the module is

indicated by one of two LED indicators:

a) Green ON when supply is normal and being passed

to the barriers.

b) Red ON when the trip mechanism is activated

indicating a fault.

After a fault has been indicated, the module can be reset by

disconnecting the main power supply.

Install the power links as follows (figure 13):

a) Mount an MTL7798 power feed module on the DIN-rail at one

end of the column of barriers being supplied.

b) Connect a safe-area 20–26V dc supply to terminals 5 and 6 of

the power feed module.

c) select the number of links required.

d) Lift the tag holders to gain access to the power link connectors

and insert the links (figure 13).

e) Close the tag holders.

f) To replace the barrier, lift the identifiers either side of the

appropriate barrier to check which one is linked, remove the

link, replace the barrier and re-insert the link and close the

identifiers.

WARNING

Do not remove bussed power links with power applied if

installed in FM Div 2

5.2.4 Spare cores/screens/0V returns: connections

Unused cores should be connected to 0V. Terminals on the earth foot

simplify this.

5.3 Connections to plant earth

5.3.1 General considerations

A barrier installation must be earthed properly for correct and safe

operation. Care must be taken that individual barriers are correctly

mounted so that the earth connection with the DIN-rail is secure.

An installation must, in turn, be connected to a suitable plant highintegrity earth. This should be done by connecting suitable conductors

to ETL7000 earth terminals (see section 5.3.2). It is also usually

advisable to make sure that the DIN-rail is isolated from any possible

enclosure earths by separating it from the mounting surface with

ISP7000 isolating spacers (see section 4.3.2).

BPL7700

power link

Figure 13: Power link insallation

Page 12

8

INM7700-6 Jan 2010

5.3.2 Earthing an installation

See figure 15. Connections from the DIN-rail to a suitable plant earth

are made from ETL7000 earth terminals. These clip onto the DIN-rail

as described in section 4.3.3 to make the vital earth connection with

the rail and the barriers. They are provided with two screw-clamp

terminals, to one of which a copper conductor to plant earth should

be connected. This should have a resistance no greater than 1Ω

though to increase safety and reduce interference, a resistance as

close to 0.1Ω as possible is preferable. The cross-sectional area of

the conductor should be as least 4mm

2

(12 AWG).

It is advisable to mount one ETL7000 earth terminal at each end of a

column of barriers to provide redundancy by connecting both

ETL7000 terminals to the plant earth. This makes it possible to

introduce a multimeter into one of the loops to measure loop

resistance without breaking the earth connection (figure 16) – a test

which should be done periodically. In these circumstances, resistance

for each cable loop should not exceed 2Ω.

The IS plant earth conductors should be clearly identified to warn

against unauthorised interference. Though not mandatory, it is

recommended that this should be done by winding blue insulating

tape round the conductors at intervals along their length.

WARNING

Do not use earth foot terminal as an IS earth termination.

Make IS earth connections using an ETL7000 earth

terminal as described in section 5.3.2.

5.3.3 Earthing an earth rail assembly

On installations which include earth rail assemblies (see section

4.3.4) an earth conductor, normally copper wire with a crosssectional area of at least 4mm

2

(12AWG) must be connected

between ETM7 earth terminals located at each end of the rail and the

‘spare’ terminals on the ETL7000 terminals at each end of the column

of barriers. See figure 17.

5.3.4 Hazardous-area equipment isolation

Hazardous-area equipment and interconnections should be isolated

from earth sufficiently to be capable of withstanding a 500V isolation

test. Such tests can, however, only be undertaken when the area is

gas free so it is fortunate that most circuits can be tested at low

voltages. To do this:

a) Disconnect from the barrier any cable connected directly to earth

or returned through a barrier with a nominal voltage of less than

10V.

b) Check the resistance to earth of the safe-area terminals with a

multimeter; it should be greater than 100kΩ.

Note: some hazardous-area equipment (eg, pH and conductivity

instrumentation) is unable to withstand this insulation test. As an

alternative, in these circumstances the system can comply with the

installation requirements described in IS sketch 121. See also

12.2.4.in BS EN 60079-14.

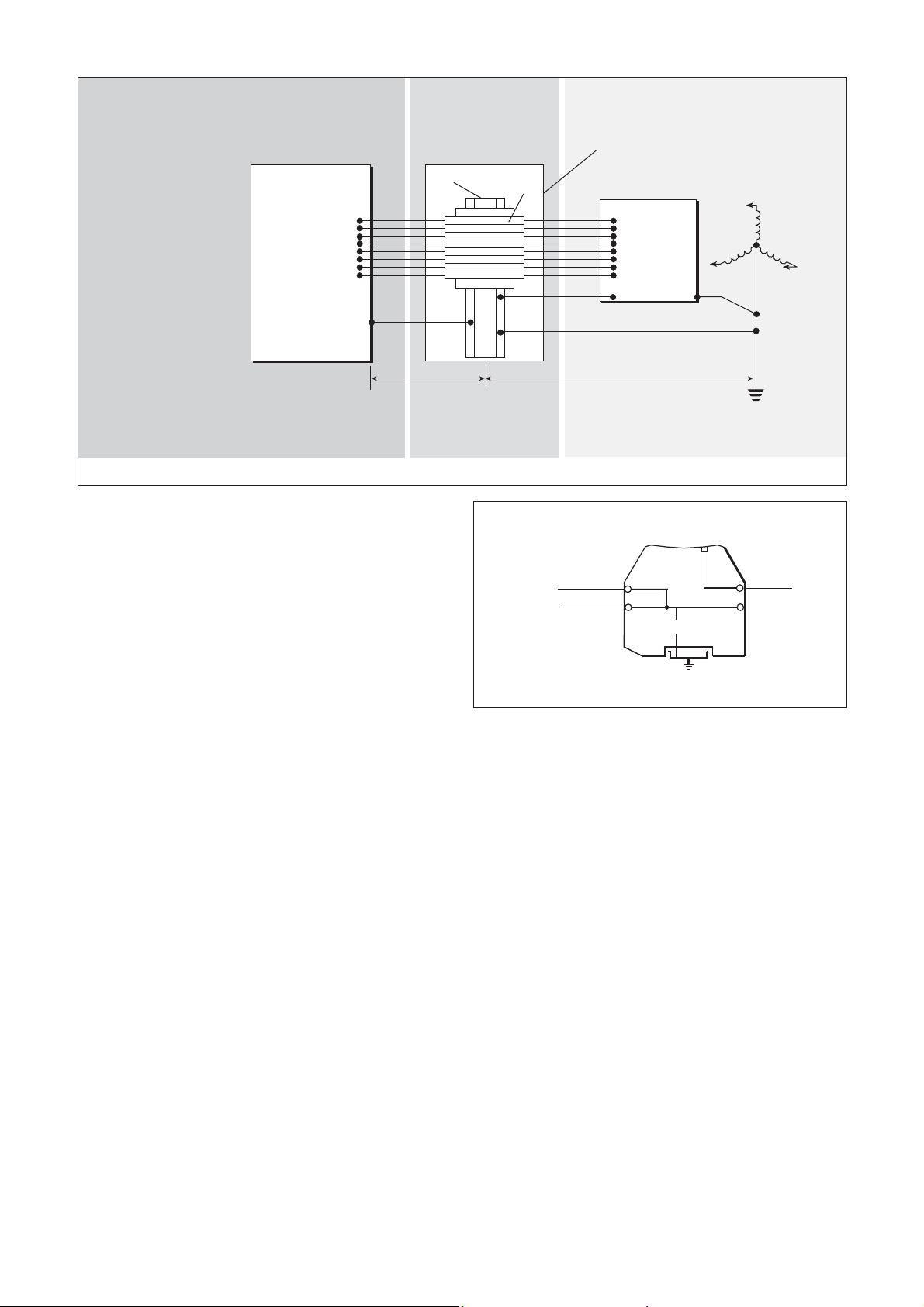

3

4

1

2

MTL7787+

MTL7787P+

Logic signal

1

5

MTL7798

(MTL7799)

3

4

1

2

MTL7706+

MTL7787+

MTL7787P+

250Ω

3

4

1

2

MTL7741

5

6

7

8

6

0V

0V

1-5V

}

Contact

signals

Power Bus

PB7700

Loop power to

opposite ends to

allow module

removal

Power

Connections

Hazardous

Area

Safe

Area

Figure 14: Typical application of the Power Bus

ETL7000 earth

terminal

To IS earth

Figure 15: Plant earth connection to ETL7000 earth terminal

ETL7000 earth

terminal

Loop

resistance

<2Ω

Local distribution transformer

Resistance meter or

bond integrity monitor

Figure 16: Earthing an installation with two conductors and

providing resistance test facilities

Page 13

9

INM7700-6 Jan 2010

5.3.5 Bonding practice when hazardous-area

equipment cannot meet prescribed insulation

standards

Where hazardous-area equipment is connected to earth (either

directly or indirectly) and/or it will not withstand a 500V insulation

test to ground or the alternative described in section 5.3.4, eg, straingauge bridges with low-voltage insulation, pH and conductivity

sensors, bare and/or earthed thermocouples, and some level

detectors, the following considerations apply:

Safety considerations

a) The pipe, vessel, or body of the hazardous-area apparatus

and/or the adjacent metallic structure must be connected to the

barrier DIN-rail (see item d) by a bonding conductor of at least

4mm2cross-sectional area for lengths of 100m or less; or at least

8mm2area for lengths between 100m and 200m.

b) Where bonding conductors are used, care must be taken to

avoid invading other intrinsically safe systems (those not using

bonding conductors) by elevation arising from currents which

may flow in the common earthing systems as a result of the

presence of the bonding conductor. Where this possibility

cannot be avoided, then barriers associated with bonded

systems should be mounted on a separate DIN-rail from those on

which other barriers are mounted. Additionally, the DIN-rails

themselves should also be earthed separately.

c) The hazardous-area equipment and/or adjacent metallic

structure bond connections must be secured against vibration

and corrosion. A terminal of the type used on ‘increased safety’

(‘e’) equipment is the mandatory solution.

d) The barrier DIN-rail connections must provide suitable

termination facilities for the bonding conductor and usual ‘earth

return’ by being equipped with separate increased safety (‘e’)

terminals.

Operational requirements

e) Figure 18 shows the 0V rail of the safe-area equipment returned

to the barrier DIN-rail by a separate insulated conductor and the

structural earths of any safe-area equipment returned separately

to the neutral star-point. This reduces interference problems but

is not essential for safety reasons.

f) In general, the use of barriers in all measurement leads reduces

the possibility of earth circulating currents causing measurement

problems.

g) Resistance from the neutral star point to ‘terrestrial earth’ – via

the buried earth mat or rods – is determined by other regulations

and is not modified or determined by the intrinsic safety

requirements, which are concerned with the plant earth only.

5.4 Connections to dummy barriers

See figure 19. The MTL7799 dummy barriers provide safe

connection facilities for unused cable cores, cable screens and 0V

returns. In addition, safe-area terminals 2 and 1 are connected

internally to provide a straight ‘feedthrough’ 24V dc supply

connection, enabling the units to be used as feed modules for use

with a power bus, useful in applications where the fault trip

mechanism of the MTL7798 is not needed.

6 MAINTENANCE

6.1 General

Circuits in all MTL7700 Series barriers are encapsulated and so

cannot be repaired. However, provided they are correctly installed

and connected (as described in sections 4 and 5 of this manual) and

the circuits they protect are not themselves defective, barrier faults are

highly unlikely to occur. Therefore, servicing of barrier installations

consists mainly of routine inspection and earth testing as described in

this section.

More information about the maintenance of barrier installations is

given in BS EN 60079 -17.

6.2 Routine inspection

At intervals not exceeding two years (more frequently for harsh

environments), make a visual check of the barrier installation.

Personnel undertaking these checks should comply with all

regulations relating to the safety of plant and personnel. Care must

be taken to prevent any inadvertent direct connection between

hazardous- and safe-area circuits and, at all times, the safety

precautions discussed in section 3 MUST be observed.

TAG57

TGL7700

ERB57O

IMB57

ETL7000

ISP7000

ERL

(optional earth rail)

Cable screens

using earth rail

Cable screens

using module

terminals

ETM7

Figure 17: Earthing and screening using module earth terminals or earth rail alternative

Page 14

10

INM7700-6 Jan 2010

Check that:

a) Barriers are of the types and polarities specified in the safety

documentation.

b) The barriers are attached securely and correctly to the DIN-rail

to make sure the earth connection is safe.

c) There are no apparent signs of damage or corrosion to the

barriers, the ETL7000 earth terminals, the plant earth

connections, and, if fitted, any earth rail assemblies.

d) All hazardous-area and safe-area cable connections are made

correctly and the terminals properly tightened.

e) Interconnecting cables are of the type and rating specified by

the safety documentation and that they are not frayed or

otherwise damaged.

f) All earth returns and cable screens from the hazardous area are

connected to earth either through a barrier, a dummy barrier or

an earth rail.

g) Visually examine the earth conductors and make sure they are

not damaged in any way and that their terminations are secure

and free from corrosion.

h) Using a low-voltage low-current test meter (ie, a meter with an

output not exceeding 3V and 50mA), measure the resistance

between the DIN-rail and the neutral star-point of the supply and

make sure it does not exceed 1Ω. Record the reading and

compare it with readings taken during previous inspections. A

consistent reading repeated over a long period of time is a

reassuring sign indicating a sound earth return which is likely to

remain so. If two earth conductors are used as described in

section 5.3.2, the loop resistance should be measured as

described in that section and the reading should not be greater

than 2Ω.

WARNING: do not try to carry out a high-current earth

resistance test unless it is confirmed by the authority in

charge of the plant that the plant is gas-free.

7 FAULT-FINDING

7.1 Introduction

Most barrier-protected systems are relatively simple and their

operation is easy to check. However, when fault finding is necessary,

it must only be undertaken after checking with plant personnel

responsible for safety that it is safe to proceed.

The fault-finding procedures described in this section call for the use

of a digital multimeter – this being the most common type used.

However, other types can be used provided their characteristics when

measuring silicon diodes are known.

Many digital multimeters include a diode test function which is useful

when diode chains are included in the test. These usually operate by

passing 1mA through the diode and measuring the voltage across it.

When measuring more than two diode drops in series, note that the

full-scale range of some multimeters is only 2V on the diode test

range. With three or more diode drops it is therefore possible that the

meter may indicate over-range. In the test tables (tables 4 to 10),

section 8, any drop of more than 4V is indicated as infinity (∞).

Zener diodes and ordinary silicon diodes have a typical forward

voltage drop of approximately 0.6V/diode. Diode return paths with

Schottky diodes have a typical voltage drop of <0.3V for each diode

in the chain, eg, MTL7787+, 7787P+.

Figure 20 depicts a typical switch-status transfer circuit protected by

an MTL7787+ barrier which illustrates some of the fault-finding

techniques discussed in this section. To determine the serviceability of

MTL7700 Series barriers, follow the steps described in sections

7.2 to 7.3.

Hazardous-area

equipment

incapable of

withstanding

insulation test

Safe-area

equipment

0V

Local

distribution

transformer

1Ω maximum

Safe area

Hazardous area

(Zone 2)

or safe area

Hazardous area

Zone 0, 1 or 2

Bonding conductor

<100m: 4mm

2

minimum

100 200m (maximum): 8mm

2

minimum

Enclosure

DIN-rail

Barriers

Figure 18: Bonding practice where hazardous-area equipment cannot meet required standards of insulation from earth

1

2

3

4

MTL7799

Unused cable

cores and

screens

24Vdc

Bussed power

Figure 19: MTL7799 dummy barrier connections

Page 15

11

INM7700-6 Jan 2010

7.2 Power supply check

Check that the power supply to an individual barrier circuit (or to an

MTL7798 power feed module or an MTL7799 dummy barrier

sourcing the power bus ) is functional and that the voltage across the

supply with respect to earth is correct. For example, in Figure 20 the

presence of 24V on terminal 1 and 12V on terminal 2 when the

switch in the hazardous area is closed confirms the serviceability of

almost the complete circuit.

7.3 Barrier resistance test

To test the resistance of a barrier on site, refer to figure 20 and carry

out the following procedure:

a) Unplug hazardous-area cables from terminals 3 and 4.

b) Unplug safe-area cables from terminals 1 and 2.

WARNING: Take care when handling safe-area cables;

the relay contacts in figure 20 for example could be

carrying mains voltage.

c) Measure the end-to-end resistance of the barrier by connecting a

digital multimeter (set to a suitable Ω range) between terminals

1 and 3. The reading should typically be slightly less (eg 1–3%

lower) than the maximum end-to-end resistance listed in tables 4

to 10 for the appropriate barrier type or approximately 10–20%

higher than the figure specified in the safety description.

d) Check the functioning of the diode-return channel (MTL7787+,

7787P+, only) by selecting the diode test function on the

multimeter and connecting it between terminals 4 (+ve) and 2

(–ve). This measures the forward voltage drop of the Schottky

diodes in the chain: the reading should be less than 0.9V.

Repeat the test with the connections reversed (ie, terminals 4

(–ve) and 2 (+ve) for an expected reading of ∞ for the reverse

voltage drop.

e) Tests c) and d) confirm the continuity of both barrier channels. If

either channel is open-circuit it is most likely that the fuse has

blown. The safe-area circuit should be investigated in an attempt

to discover the cause of the fault.

Note: if the barrier is removed, make sure the safe-area and

hazardous-area cables disconnected during operations a) and b)

are connected to an earth-rail, a dummy barrier or insulated

completely.

c) If it is not possible to disconnect wiring to the barrier for steps a)

and b), carry out the tests given in table 4.

8 EQUIPMENT AND BARRIER TESTS

8.1 Thermocouple and RTD tests

8.1.1 Thermocouple circuit testing

Thermocouple test and calibration equipment is rarely certified

intrinsically safe and therefore requires special authorisation before it

can be used for testing or calibrating thermocouple circuits in

hazardous areas. To overcome this problem, the thermocouple

circuits can be protected by using an MTL7760ac barrier as shown

in figure 21. This permits the thermocouple output to be measured

without needing special authorisation to use uncertified thermocouple

test equipment.

As it is seldom possible to measure accurately the temperatures of

thermocouples located in hazardous areas, a safe way of adjusting

calibration tables to compensate for plant temperatures is needed.

This can be done by disconnecting the compensating cables from the

thermocouple, shorting them together, and measuring the temperature

of the shorting point.

8.1.2 Resistance temperature detector (RTD) circuit

testing

Resistance temperature detector (RTD) circuits can be tested by

disconnecting the measuring leads from the RTD head in the

hazardous area and connecting them to a resistance box. Sometimes

it is more convenient to connect the resistance box in the safe area,

for instance at point ‘xx’ in figure 22. For the latter method, however,

the RTD must be shorted out or an allowance made for its

temperature. The effect of a negative temperature change can be

simulated by connecting the resistance box into the measurement lead

at point ‘yy’. The advantage of connecting the resistance box at the

RTD head is that any leakage can also be determined by connecting

the resistance box at point ‘yy’.

8.2 Barrier tests

8.2.1 General

MTL7700 Series barriers do not need to be subjected to routine

testing if they are in normal use. Generally, the inspection tests

described in section 6 are more than adequate. However, if the

performance of barriers is in any way suspect, then carry out the

detailed tests described in this section. Barriers which pass these tests

satisfactorily are highly unlikely to represent an unacceptable level of

risk or cause a circuit malfunction.

There are two types of test (as shown by tables 4 to 10); a simple test

using a digital multimeter to test barriers on site and a more

comprehensive bench test using a constant current source to establish

the breakdown characteristics.

Although certification requirements concentrate on pulse-current tests,

in many ways the leakage current tests described in this section are

a more satisfactory method of testing suspect diodes. If a complete

functional check of a barrier is needed, then the multimeter and

constant current tests described in sections 8.2.2 and 8.2.3 should be

made although, for most purposes, the multimeter tests should suffice.

1

2

3

4

370Ω

+24Vdc

12V

0V

400Ω

12V

relay

Plant earth via DIN-rail

30mA

MTL7787+

Figure 20: Switch-status transfer circuit using an MTL7787 barrier

1

2

3

4

1

2

3

4

Compensating cables

Safe-area

equipment

Calibration

equipment

MTL7760ac

Figure 21: Calibrating a thermocouple barrier circuit

Page 16

12

INM7700-6 Jan 2010

8.2.2 Multimeter tests

See tables 4 to 10. The use of a digital multimeter for testing barriers

is described in section 7. The tables assume that the multimeter is set

to a suitable Ω range for the end-to-end resistance tests (except for

diode return channels) and for the continuity tests; and that the

multimeter diode test function is used for the diode tests, channel

isolation tests and for the end-to-end resistance tests for diode return

channels.

8.2.3 Constant-current tests

For these tests (last column of tables 4 to 10) a constant-current

generator capable of supplying 10µA, 20mA and 40mA currents

from a 30V source is needed. Ideally, a purpose-built current

generator should be used but, alternatively, a set-up based on a

laboratory power supply and two multimeters (figure 23) will serve.

The current is measured by one multimeter and trimmed by adjusting

the output voltage of the power supply indicated on the second

multimeter.

When using a constant-current generator for testing MTL7700 Series

barriers, note the following points:

a) The current must be limited to 50mA to avoid damaging the

barriers.

b) The accuracy of the current is not critical and can vary by ±5%.

c) Test leads must be connected securely to the barrier terminals;

however, the changeover switch and current selector reduce the

need for connection changes.

d) Using a high resistance in series with the barrier gives more

stable results and makes it easier to set the required current.

8.3 Tests for Active Barriers

8.3.1 Tests for the MTL7706+

Comprehensive testing requires specialised equipment, beyond the

scope of on-site tests. However, an effective test which will confirm

that the unit is operating correctly is shown in figure 24. Ammeter 1

measures the transmitter simulator current of between 4 and 20mA

flowing from terminal 4 and the safe-area load current flowing to

terminal 4 simultaneously. Since these two currents are equal and

opposite, the resulting reading on the ammeter should be virtually

zero. Ammeter 2 verifies the presence of the 4–20mA transmitter

signal.

1

2

3

4

5

7

Bridge supply

Measurement

Safe-area

equipment

MTL7756ac

Variable

resistance

Measurement

Variable

resistance

yy x

x

Figure 22: Calibrating an RTD barrier circuit

To barrier on test

Digital

multimter

(current)

Digital

multimter

(voltage)

current

selector

current limited

to 30mA

2-channel laboratory power supply

0 - 30V

variable

0 - 30V

variable

+ -

+ -

Changeover

switch

40mA

20mA

10mA

3MW

1.5kW

750W

Figure 23: Constant-current test circuit using a power supply

and digital multimeters

1

2

3

4

A1

A2

Transmitter

simulator

4-20mA

250W

+20 to

35Vdc

MTL7706+

+

+

_

_

Figure 24: MTL7706+ test circuit

8.3.2 Tests for the MTL7707+

Since this unit incorporates a built-in protection circuit, it has to be

tested in a different manner to an ordinary shunt-diode barrier.

Referring to figure 25, set the transmitter simulator to 4mA and to

20mA, and check that the ammeter reads approximately the same

value. Then, having set the simulator to 20mA, check that the voltage

between terminals 1 and 3 is less than 8.5V and between terminals

2 and 4 is less than 1.6V.

Figure 25: MTL7707+ test circuit

1

2

3

4

A

MTL7707+

Transmitter

simulator

4-20mA

+20 to

35Vdc

250W

+

_

Page 17

13

INM7700-6 Jan 2010

Input Output Line Fault

Open circuit Open Closed

Short circuit Closed Closed

620Ω Closed Open

10KΩ Open Open

8.3.3.2 Testing MTL7742 Barriers

The MTL7742 is a single channel switch/prox input barrier with an

open collector solid state interface to the safe area equipment. To

verify correct operation proceed as follows:

a) Connect the barrier as shown in figure 27.

b) Check that the LED is on when the input switch is closed, and off

when the input switch is open.

8.3.3.3 Testing MTL7743 Barriers

The MTL7743 is a dual channel switch/prox input barrier, each

channel with a relay interface to the safe area equipment. To verify

correct operation proceed as follows:

a) Connect the barrier as shown in figure 28.

b) With an ohmeter, check that the output contacts (terminal 1 & 2)

close when the input switch for channel 1 is closed.

c) Repeat the procedure for channel 2.

8.3.3.4 Testing MTL7744 Barriers

A dual channel version of the MTL7742, this module provides two

solid state interfaces for prox/switch inputs. To verify correct

operation proceed as follows:

a) Connect the barrier as shown in figure 29.

b) Connect power via the power bus

c) Check that the LED is on when the input switch is closed for

channel 1, and off when the input switch is open for channel 1.

d) Repeat the procedure for channel 2.

8.3.3.5 Testing MTL7745 Barriers

This module is a single channel interface for prox/switch inputs with

line fault detection. To verify correct operation proceed as follows:

a) Connect the barrier as shown in figure 30.

b) With an ohmeter, check the status of the output contacts

according to Table 3

3

4

1

2

MTL7742

5

6

7

8

Bussed Power

24V

Vs+

Vs-

}

2KΩ

Figure 27: Test circuit for MTL7742

3

4

1

2

MTL7745

5

6

620W10kW

24V

Bussed Power

Line Fault

Output

Vs+

Vs

Figure 30: Test circuit for MTL7745

Table 3 Test conditions for MTL7745

3

4

1

2

MTL7743

5

6

7

8

Bussed Power

24V

Vs+

Vs

Channel 1

Channel 2

Channel 1

Channel 2

Figure 28: Test circuit for MTL7743

3

4

1

2

MTL7744

5

6

7

8

Bussed Power

24V

Vs+

Vs-

2KW

2KW

Channel 1

Channel 2

Channel

1

Channel

2

Figure 29: Test circuit for MTL7744

8.3.3 Tests for MTL774x

The MTL774x range are switch/prox input barriers with a choice of

changeover relay contacts or a solid state switch acting as the safe

area interface. Relay contacts provide a universal interface capable

of switching a wide range of signals including ac, low level and high

level voltages. Phase reversal is achieved by connecting the normally

open or normally closed contacts as required. The solid state switch

variants can be configured to switch from a power rail or down to

ground and makes these barriers ideal for high switching frequency

applications.

When testing bus powered barriers use either an MTL7798 Power

Feed module or an MTL7799 dummy barrier for direct ‘feed-through’

connection of a 24V dc supply.

8.3.3.1 Testing MTL7741 Barriers

The MTL7741 is a single channel switch/prox input barrier with

changeover relay contacts acting as the safe area interface. To verify

correct operation proceed as follows:

a) Connect the barrier as shown in figure 26.

b) With an ohmeter, check that the output contacts (terminal 5 & 6)

close when the input switch is closed.

3

4

1

2

MTL7741

5

6

7

8

Bussed Power

24V

Vs+

Vs

Output

Figure 26: Test circuit for MTL7741

Page 18

14

INM7700-6 Jan 2010

BARRIER DATA MULTIMETER TESTS CONSTANT-CURRENT TESTS

MTL Safety End-to-end Diode Diode Terminal Terminal

model Description Resistance Test Test Voltage Voltage

No.

ΩΩ

+ve -ve @ 10μμA @ 20mA

V

ΩΩ

mA Min Max Min Max Min Max

7710+ 10 50 200 62 75 ∞ Vf

z

x 1 6 9.5 6.6 9.7

7715+ 15 100 150 110 119 ∞ Vf

z

x 1 12 13.6 12.4 13.7

7715P+ 15 50 291 59 64 ∞ Vf

z

x 1 12.6 13.3 13 13.4

7722+ 22 150 147 159 174 ∞ Vf

z

x 2 19.6 20.9 19.7 21.1

7728+ 28 300 93 311 333 ∞ Vf

z

x 2 25.9 26.5 26 26.7

7728- 28 300 93 311 333 Vf

z

x 2 ∞ 25.9 26.5 26 26.7

7728P+ 28 237 119 241 252 ∞ Vf

z

x 3 24.9 25.5 25 25.6

7729P+ 28 164 170 171 184 ∞ Vf

z

x 3 24.9 25.5 25 25.6

8.4 Test tables for passive barriers

Tables 4 to 10 detail the tests for all MTL7700 Series ‘passive’ barriers. In the ‘diode test’ columns, the figures adjacent to the diode description

indicate the number of forward-biased diodes used in the barrier chain. Using the multimeter diode test function and knowing the diode voltage

drop figures (approximately 0.6V for each Zener diode and 0.3V for each Schottky diode), the expected reading across the diode chain can

be determined.

BARRIER DATA MULTIMETER TESTS CONSTANT-CURRENT TESTS

MTL Safety End-to-end Diode Diode Terminal Terminal

model Description Resistance Test Test Voltage Voltage

No.

ΩΩ

+ve -ve @ 10μμA @ 20mA

V

ΩΩ

mA Min Max Min Max Min Max

7758+ 7.5 10 750 14 17 ∞ Vf

z

x 1 6 6.9 6.6 7

7758- 7.5 10 750 14 17 ∞ Vf

z

x 1 6 6.9 6.6 7

7764+ 12 1k 12 1010 1050 ∞ Vf

z

x 1 10 11.4 10.5 11.6

7767+ 15 100 150 110 119 ∞ Vf

z

x 1 12 13.6 12.4 13.7

7779+ 28 300 93 311 333 ∞ Vf

z

x 2 25.9 26.3 26 26.5

7796+ 26 300 87 311 333 ∞ Vf

z

x 2 23.9 24.4 24 24.6

7796+ (ch2) 20 390 51 401 428 ∞ Vf

z

x 2 18.3 18.8 18.4 19

7796- 26 300 87 311 333 Vf

z

x 2 ∞ 23.9 24.4 24 24.6

7796- (ch2) 20 390 51 401 428 Vf

z

x 2 ∞ 18.3 18.8 18.4 19

7788+ 28 300 93 311 333 ∞ Vf

z

x 2 25.9 26.4 26 26.6

7788+ (ch2) 10 50 200 62 75 ∞ Vf

z

x 1 6 9.5 6.6 9.7

7788R+ 28 300 93 311 333 ∞ Vf

z

x 2 25.9 26.4 26 26.6

7788R+ (ch2) 10 50 200 62 75 V

r

V

r

0 0 6.2 6.8

Table 4: Single channel polarised barriers

Table 5: Dual channel polarised barriers

Note: Vfzis the voltage dropped by a forward biased zener diode - 0.6V typically

V

r

is the voltage dropped by the sense and current limit resistors - 3.2V for a typical 1mA test current

Page 19

15

INM7700-6 Jan 2010

Table 6: Single channel

BARRIER DATA MULTIMETER TESTS CONSTANT-CURRENT TESTS

MTL Safety End-to-end Diode Diode Terminal Terminal

model Description Resistance Test Test Voltage Voltage

No.

ΩΩ

+ve -ve @ 10μμA @ 20mA

V

ΩΩ

mA Min Max Min Max Min Max

7728ac 28 300 93 311 333 ∞∞25 26.7 25.6 27.2

BARRIER DATA MULTIMETER TESTS CONSTANT-CURRENT TESTS

MTL Safety End-to-end Diode Diode Terminal Terminal

model Description Resistance Test Test Voltage Voltage

No.

ΩΩ

+ve -ve @ 10μμA @ 20mA

V

ΩΩ

mA Min Max Min Max Min Max

7761ac 9 90 100 98 107 ∞∞6 8.6 6.9 8.9

7761Pac 9 350 26 361 378 ∞∞6.8 8.6 7.7 8.9

7764ac 12 1k 12 1010 1050 ∞∞10 11.6 10.8 11.9

7766ac 12 150 80 159 174 ∞∞10 11.6 10.8 11.9

7766Pac 12 75 157 84 92 ∞∞9.6 10.9 10.4 11.2

Table 7: Dual-channel ac barriers

BARRIER DATA MULTIMETER TESTS CONSTANT-CURRENT TESTS

MTL Safety End-to-end Diode Diode Terminal Terminal

model Description Resistance Test Test Voltage Voltage

No.

ΩΩ

+ve -ve @ 10μμA @ 20mA

V

ΩΩ

mA Min Max Min Max Min Max

7760ac 10 50 200 62 75 ∞∞6 9.5 6.9 9.8

7765ac 15 100 150 112 124 ∞∞12 14.1 12.7 14.4

7778ac 28 600 47 614 651 ∞∞24.0 24.4 25.4 26.0

Table 9: Dual-channel star-connected ac barriers

BARRIER DATA MULTIMETER TESTS CONSTANT-CURRENT TESTS

MTL Safety End-to-end Diode Diode Terminal Terminal

model Description Resistance Test Test Voltage Voltage

No.

ΩΩ

+ve -ve @ 10μμA @ 20mA

V

ΩΩ

mA Min Max Min Max Min Max

7755ac 3 10 300 15 19 Vf

d

x 3 Vfdx 3 1 2.1 1.8 2.4

7756ac 3 10 300 15 19 Vf

d

x 2 Vfdx 2 0.7 1.4 1.2 1.6

Table 8: 2/3 channel low voltage ac barriers

Note: Vfdis the voltage dropped by a forward biased rectifier diode - 0.6V typically

Page 20

16

INM7700-6 Jan 2010

BARRIER DATA MULTIMETER TESTS CONSTANT-CURRENT TESTS

MTL Safety End-to-end Diode Diode Terminal Terminal

model Description Resistance Test Test Voltage Voltage

No.

ΩΩ

+ve -ve @ 10μμA @ 20mA

V

ΩΩ

mA Min Max Min Max Min Max

7787+ 28 300 93 311 333 ∞ Vf

z

x 2 26.6 27.4 26.7 27.6

7787+ (ch2) 28 — — ∞ (+)

0.9V + 26 ∞ Vf

z

x 2 26.6 27.4 26.7 27.6

7787P+ 28 237 119 241 253 ∞ Vf

z

x 3 26.4 27.4 26.5 27.6

7787P+ (ch2) 28 — — ∞ (+)

0.9V + 26 ∞ Vf

z

x 2 26.6 27.4 26.7 27.6

7789+ 38 300 93 614 651 ∞ Vf

z

x 2 26.6 27.4 26.7 27.6

7789+ (ch2) 28 — — ∞ (+)

0.9V + 26 ∞ Vf

z

x 2 26.6 27.4 26.7 27.6

Table 10: Diode return barriers

Note: Vfzis the voltage dropped by a forward biased zener diode - 0.6V typically

Page 21

17

INM7700-6 Jan 2010

APPENDIX A: TYPICAL WIRING CONNECTIONS

FOR SPECIFIC APPLICATIONS.

Hazardous

Area

Safe

Area

3

4

1

2

250W4 -20mA

Power +26V

Signal

Power Bus

1-5V

MTL7706+

MTL7787+

MTL7787P+

MTL7788+

Hazardous

Area

Safe

Area

3

4

1

2

MTL7788R+

250Ω

1-5V

Power +26V

Power Bus

Figure A1: 2-wire transmitters

Hazardous

Area

Safe

Area

3

4

1

2

MTL7789+

7

8

5

6

Power +26.6V

Power +26.6V

Logic signal

Logic signal

Power Bus

Figure A5: 2-channel switch inputs

Hazardous

Area

Safe

Area

3

4

1

2

MTL7756ac

Receiver

7

5

3

4

1

2

MTL7755ac

Receiver

Figure A6: Low-level analogue inputs (RTD’s)

Figure A2: 2-wire transmitters with 250Ω conditioning

Hazardous

Area

Safe

Area

3

4

1

2

MTL7760ac

MTL7765ac

MTL7778ac

Recorder

Controller

Data logger

Computer

Compensating cable

Figure A3: Thermocouple/mV input

Hazardous

Area

Safe

Area

3

4

1

2

MTL7743

MTL7744

7

8

5

6

Logic signal

Logic signal

Power

Figure A7: 2-channel switch/proximity input

Hazardous

Area

Safe

Area

3

4

1

2

MTL7742

5

6

Logic signal

Logic signal

Power Bus

+20V - 35V

0V

Figure A8: Single channel switch/proximity input

Hazardous

Area

Safe

Area

3

4

1

2

MTL7787+

MTL7787P+

Power +26.6V

Signal

Power Bus

Figure A4: 2-wire transmitter/switch input

Page 22

18

INM7700-6 Jan 2010

Hazardous

Area

Safe

Area

3

4

1

2

MTL7728+

0V

+26V

P

I

Figure A9: Analogue output

Hazardous

Area

Safe

Area

3

4

1

2

+7V

3

4

1

2

MTL7761ac

MTL7764ac

3

4

1

2

MTL7761ac

--7V

0V

Output (mV)

Sense

+

—

Figure A13: Strain-gauge bridges

Hazardous

Area

Safe

Area

3

4

1

2

MTL7745

5

6

620Ω

10kΩ

+22.9 - 30V

LFD

COM

CH 1

Power Bus

Figure A10: Single channel switch/proximity input with Line

Fault Detect

Hazardous

Area

Safe

Area

3

4

1

2

MTL7789+

7

8

5

6

Power +26V

Power +26V

Power Bus

Figure A11: Low power digital outputs

Hazardous

Area

Safe

Area

3

4

1

2

MTL7741

5

6

7

8

NO

COM

Power Bus

22.9V - 30V

NC

Figure A12: Single channel switch/proximity input with cutout

relay

Page 23

Page 24

MTL Instruments Pty Limited

9 /12 Billabong Street

Stafford

Queensland 4053

Australia

Tel: + 61 1300 308 374 Fax: + 61 1300 308 463

E-mail: enquiries@mtlaus.com.au

MTL Canada Safety Instrumentation

#102, 4249 97 Street

Edmonton, Alberta

Canada T6E 5Y7

Tel: +1 780 485 3132 Fax: +1 780 485 3122

E-mail: cinfo@mtlnh.com

MTL Instruments China Co. Ltd.

Room 1002A, The Gateway

No 10 Yabao Road, Chaoyang District

Beijing 100020

China

Tel: +86 010 8562 5718/5720/5721 Fax: +86 010 8562 5725

E-mail: bjsales@mtl-inst.cn

MTL Instruments sarl

Les Carrés du Parc

10 rue des Rosiéristes

69410 Champagne au Mont d’Or

France

Tel: +33 (0)4 78 64 98 32 Fax: +33 (0)4 78 35 79 41

E-mail: info@mtl-inst.fr

MTL Instruments GmbH

An der Gümpgesbrücke 17

D-41564 Kaarst

Germany

Tel: +49 (0)2131 718930 Fax: +49 (0)2131 7189333

E-mail: info@mtl.de

MTL India

No. 36, Nehru Street

Off Old Mahabalipuram Road

Sholinganallur

Chennai - 600 119

India

Tel: + 91 (0)44 24501660/24501857 Fax: + 91 (0)44 24501463

E-mail: sales@mtlindia.com

MTL Italia srl

Via Cantù 11

I - 20092 Cinisello Balsamo MI

Italy

Tel: +39 (0)2 61802011 Fax: +39 (0)2 61294560

E-mail: info@mtl-inst.it

MTL Instruments KK

MT Building 3F

2-7-5 Shiba Daimon

Minato-ku Tokyo

Japan 105-0012

Tel: +81 (0)3 6430 3128 Fax: +81 (0)3 6430 3129

E-mail: sales@mtlkk.co.jp

MTL Instruments BV

MTL Instruments BV

Terheijdenseweg 465

4825BK Breda

The Netherlands

Tel: +31(0)76 7505360 Fax: +31(0)76 7505370

E-mail: info@mtlbenelux.com

Cooper Crouse-Hinds Pte Ltd

No.2 Serangoon North Avenue 5

#06-01 Fu Yu Building

Singapore 554911

Tel: +65 6 487 7887 Fax: +65 6 487 7997

E-mail: sales@mtlsing.com.sg

MTL Instruments

Villa No. 4, Sector 2-17, Street 6

PO Box 53234,

Abu Dhabi, UAE

Tel: +971 2 446 6840 Fax: +971 2 446 6841

E-mail: mtlgulf@mtl-inst.com

Measurement Technology Limited

Great Marlings, Butterfield, Luton, Beds

England LU2 8DL

Tel: +44 (0)1582 723633 Fax: +44 (0)1582 422283

E-mail: enquiry@mtl-inst.com

MTL Incorporated

3413 N. Sam Houston Parkway W.

Suite 210

Houston TX 77086

USA

Tel: +1 281 571 8065 Fax: +1 281 571 8069

E-mail: csinfo@mtl-inst.com

Group Internet home page http://www.mtl-inst.com/

Members of The MTL Instruments Group

Loading...

Loading...