Page 1

Dwyer Mark II Manometers come in a variety of ranges. Make sure the oil being used

is for the correct manometer.

Mark II #25, 27, MM-80 and M-700 Pa use

red gage oil (specific gravity 0.826).

Mark II #26, 28 and MM180 use blue gage

oil (specific gravity 1.9).

If additional oil is required, call or fax nearest

Dwyer office listed at bottom of page.

INSTALLATION

Position manometer on a vertical surface.

Drill two 1/8˝ or 9/64˝ holes on a vertical line

315/16˝ apart. Loosely mount manometer

with self-tapping screws provided. Adjust

gage until level bubble is centered in level

vial, then secure the manometer tightly.

For portable use, order optional A-612

Portable Stand.

FILLING

Turn the zero set knob counterclockwise until

it stops, then turn clockwise 3 full turns. This

puts zero in approximately the middle of the

travel adjustment in either direction. Remove

the fill plug and fill with gage fluid until fluid

reaches zero on scale. Minor adjustments

can be made to adjust zero by adjusting zero

knob. Replace fill plug. If gage is overfilled,

remove excess by inserting pipe cleaner

through the fill port to blot up excess oil.

MAINTENANCE

Check oil level regularly and adjust zero with

zero adjust knob. Be sure tubing connections are disconnected and gage is open to

atmosphere before adjusting zero.

Clean with mild soap and water. Avoid any

cleaning fluids which may result in damaging

the gage.

ACCESSORIES

Each Mark II manometer includes two tubing

connectors for 1/8˝ pipe or sheet metal

ducts, two mounting screws, 3/4 oz. bottle

of indicating fluid, red and green pointer

flags, 8´ of double column tubing and instructions.

Mark II Series Molded Plastic Manometers

Specifications - Instructions and Operation

Bulletin D-58

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Mark II Model No. 25

inclined-vertical manometer,

(shown with optional A-612 portable stand)

Page 2

FLOW

PsPt

PITOT TUBE

(SECTION

ENLARGED

TO SHOW

DETAIL)

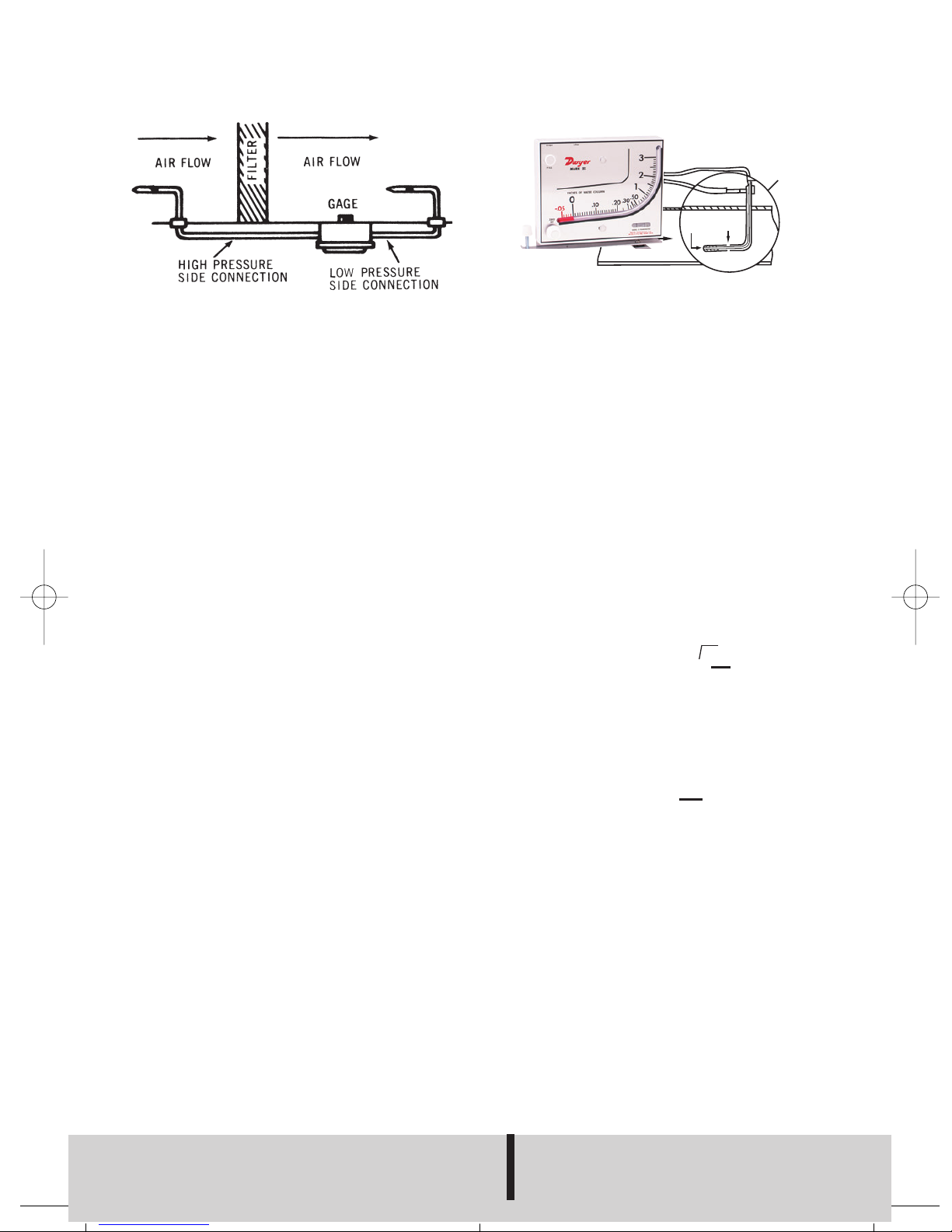

AIR FILTER GAGE

Mount gage within 3 ft. of filter bank. Install

tubing adapters on each side of filter. Run

tubing from clean side of filter to positive

pressure side of gage (left fitting). Run

downstream side to low pressure side of

gage (right fitting). Install green and red

arrows adjacent to indicating tube to indicate filter condition.

AIR VELOCITY METER

A pitot tube should be used for air velocity

readings. Install the pitot tube and gage

carefully to ensure accuracy. Select a location for the pitot tube with al least four diameters of smooth straight sections of duct

both upstream and downstream. Install

pitot tube in the center of duct with tip

directed into air stream. Connect the right

angle (leg parallel to tip) to negative (right fitting) and straight pitot tube connection to

positive (left connection) of gage. The velocity reading shown on the gage is the center

or maximum velocity. For average velocity

across the full area, multiply by a factor of

0.9.

No’s. 27 and 28 require pitot tube at additional cost. See Bulletin F-41-F.

The velocity indicated is for dry air at 70°F,

29.9˝ barometric pressure and a resulting

density of 0.075 lb/ft

3

. For variation from

these standard conditions, corrections may

be based upon the following data.

AIR VELOCITY CALCULATIONS:

Air Velocity = 1096.2

where Pv = velocity pressure in inches of

water

D = Air density in lb/ft

3

Air Density = 1.325 x

where P

B = Barometric Pressure in inches

of mercury

T = Absolute Temperature (indicat-

ed temperature °F plus 460)

Flow in cu. ft. per min. = Duct area in square

feet x air velocity in ft. per min.

PITOT TUBE SENSES TOTAL AND STATIC PRESSURES. MANOMETER

MEASURES VELOCITY PRESSURE-(DIFFERENCE BETWEEN TOTAL AND

STATIC PRESSURES).

PB

T

Pv

D

√

APPLICATIONS MARK II MANOMETER

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

©Copyright 2004 Dwyer Instruments, Inc.

FR# 67-440215-00 Rev. 11

Printed in U.S.A. 1/04

Page 3

INSTALACION

Instale el Mark II en una superficie vertical

adecuada. El ambiente debe estar libre de

vapores de sustancias cloradas, o solventes

tales como benceno, acetona, tetracloruro

de carbono, etc. El instrumento soporta

presiones internas de hasta 10 PSI, o 0,703

bar, y temperaturas de hasta 140°F ó 60°C.

NO EXCEDA ESTOS LÍMITES!

Perfore dos orificios de 3,6 mm en línea vertical, separados por 100mm, e instale el

instrumento con los tornillos autorroscantes

provistos con él. Sin apretar demaslado,

coloque el instrumento vertical con ayuda

del nivel incluido en la parte inferior derecha

del mismo. Verifique que ha quedado vertical y repita el proceso si es necesario. Para

uso portable, use el soporte vertical tipo A-

612.

LLENADO

Gire en sentido antihorario la perilla de

ajuste de cero hasta que se detenga; gírela

nuevamente pero en sentido horario unas

tres vueltas, de modo de dejar la posibilidad

de ajuste en cualquier dirección. Retire el

tapón de llenado y comience a llenar el

manómetro lentamente hasta ver el líquido

en las cercanías del cero de la escala.

ATENCION: Use solamente aceite rojo

de peso específico 0,826 para los modelos 25; 27; MM-80 y M-700Pa. Use

solamente aceite azul de peso específico 1,9 para los modelos 26; 28 y MM-

180.

Adjuste exactamente el cero del instrumento girando la perilla según corresponda, y

reponga el tapón de llenado. Si el ajuste

preciso es imposible por exceso de llenado,

retire nuevamente el tapón y extraiga el

exceso introduciendo un limpiador de

tubos, que absorba el exceso.

Con el instrumento se suministra un tubo

plástico flexible doble de 2,4 m juntamente

con adaptadores para conexión a 1/8˝ NPT.

Conecte el tubo marcado con una línea roja

al la entrada de alta presión mas elevada a

sensar. Repita el procedimiento con el tubo

restante en la entrada de baja presión

(LOW, a la derecha), y a la presión más baja

a sensar.

MANTENIMIENTO

Verifique de tanto en tanto el nivel de aceite,

y reajuste el cero del instrumento según sea

necesario. Asegúrese de haber venteado el

instrumento desconectando los tubos de

conexión a proceso (entradas HIGH y LOW

en la parte superior del manómetro).

Uso, Instalacion y Mantenimiento

MANOMETROS DWYER MARK II

Bulletin D-58

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A.

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

RANGOS

25

26

M-80

M-180

M-700 Pa

27 *

28 *

0~3˝ C.A.

0~7˝ C.A.

0~80 mm C.A.

0~180 mm C.A.

10~0~700 Pascal

0~7.000 pie./min.

0~10.500 pie./min.

0,826 rojo

1,9 azul

0,826 rojo

1,9 azul

0,826 rojo

0,826 rojo

1,9 azul

Modelo Rango

Fluido

* Los modelos 27 y 28 requieren tubo Pitot, con

costo adicional.

Page 4

APLICACIONES MARK II MANOMETER

Agregue aceite solo si es necesario, utilizando los aceites DWYER azul o rojo según

corresponda. No utilice otros fluidos pues

podrían dañar el material. Para limpieza use

solo jabón neutro y agua, evitando solventes que puedan dañar el instrumento

(vea Instalación). Limpie la perilla con un

pincel pequeño y suave.

MEDICIÓN DE TIRO

Instale un tubo de hierro de 1/8˝ (3,2 mm) o

mayor desde el conducto a medir hasta una

distancia de 1,5 m del instrumento. Use únicamente al conector derecho (LOW). Se

debe prever la limpieza periódica para evitar

acumulación de suciedad.

INDICADOR DE PRESIÓN ESTÁTICA

Te nga en cuenta que las velocidades de aire

superiores a 100 fpm (5 m/seg.) son una

fuente de posibles errores en la medición.

Es conveniente usar sondas para presión

estática. De no ser disponibles, ingrese las

conexiones al conducto, en ángulo recto a

la corriente de aire, y deles una terminación

suave en los extremos.

INDICADOR DE OBSTRUCCIÓN DE

FILTROS

Instale el manómetro a distancia no mayor

de 1 m del banco filtrante. Conecte el lado

de descarga del filtro al conector LOW en la

parte superior del instrumento y el otro

tubo,al conector HIGH y a la presión positiva. Retire el papel protector de la flechas

autoadhesivas (roja y verde)y adhiéralas

adyacentes al tubo indicador para marcar

lecturas de filtro limpio y sucio.

MEDICION DE VELOCIDAD DE AIRE EN

CONDUCTOS

Se requiere un tubo Pitot para esta aplicación. Instálelo bien centrado dentro del

conducto, en una zona donde sea recto y

sin obstrucciones por lo menos en distancias de 4 diámetros tanto corriente arriba

como abajo del punto de inserción.

Asegúrese que la punta del tubo Pitot está

bien dirigida hacia la corriente de aire.

Conecte el tubo doble a los conectores

HIGH y LOW, de modo de conectar LOW al

conector en ángulo recto del tubo Pitot, y el

restante a HIGH. La velocidad leída es la

máxima, correspondiente al centro del conducto. Para calcular la velocidad promedio

multiplique por 0,9. Esta velocidad corresponde a aire seco, a 21°C a una presión

de 760 mmHg y de una densidad de 0,075

/cuft. Para otras condiciones se deben

aplicar factores de corrección de acuerdo a

lo siguiente:

CALCULO DE VELOCIDAD DE AIRE

Velocidad de Aire =1096,2 √ (Pv/D)

Donde Pv es la presión por velocidad en ˝

de C. Agua.

D: densidad del aire en #/pie

3

Densidad de aire = 1,325 X (Pb/T)

Para PB: presión barométrica en ˝ de

Mercurio, y T = Temperatura absoluta

(°F+460)

Caudal en pie

3

/min. = Area del conducto

(pie2) X Veloc. de aire (pie/min.)

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

FLOW

PsPt

PITOT TUBE

(SECTION

ENLARGED

TO SHOW

DETAIL)

PITOT TUBE SENSES TOTAL AND STATIC PRESSURES. MANOMETER

MEASURES VELOCITY PRESSURE-(DIFFERENCE BETWEEN TOTAL AND

STATIC PRESSURES).

©Copyright 2004 Dwyer Instruments, Inc.

Printed in U.S.A. 1/04

FR# 67-440215-00 Rev. 11

Loading...

Loading...