Dwyer Instruments Mark II 41-2, Mark II 41-600 Pa, Mark II 41-2-AV, Mark II 40-1-AV, Mark II 40-250-AV Installation And Operating Instructions Manual

...

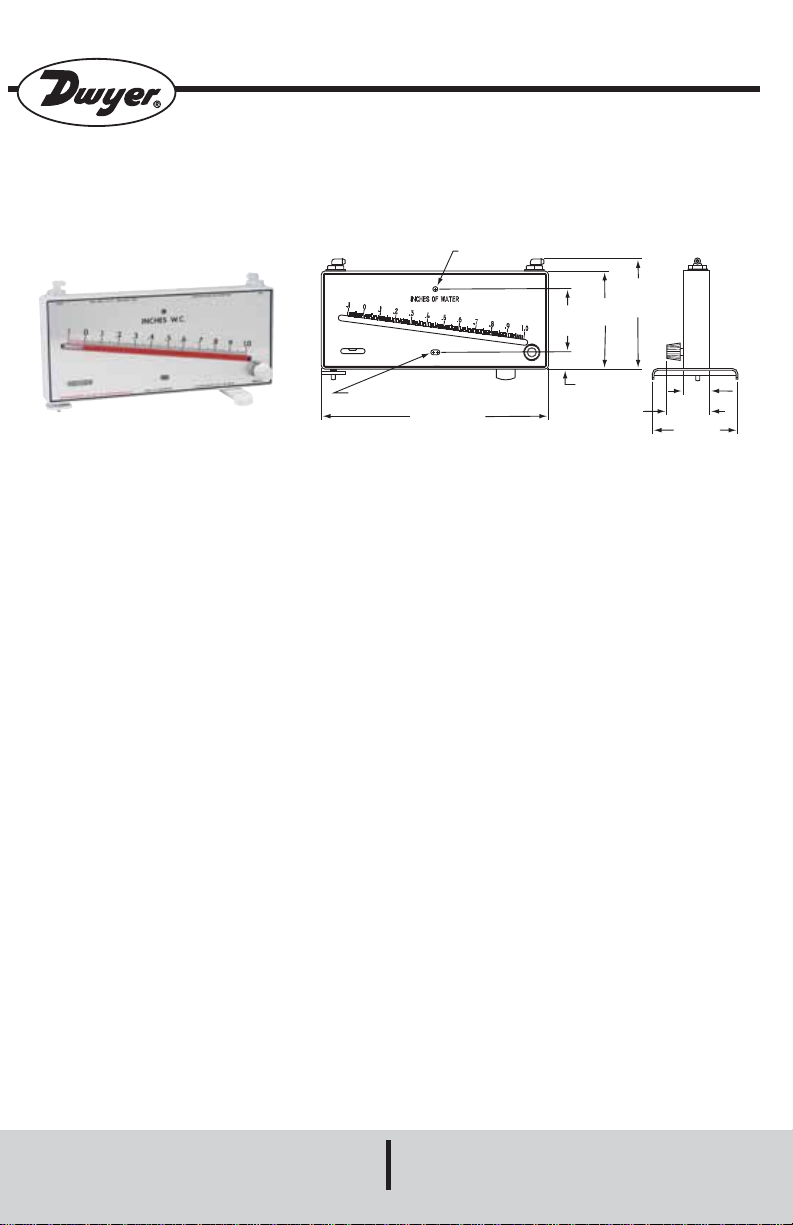

15/64 [5.95] x 13/32 [10.32] MOUNTING SLOT

10-5/8 [269.88]

5-5/16

[134.95]

MAX

4-5/8

[117.48]

2-31/32

[75.41]

25/32

[19.84]

Ø15/64 [5.95] MOUNTING HOLE

1-1/4

[31.75]

2-1/4 [57.15]

MAX

4 [101.60]

MARK II MODEL 40

Bulletin D-59

Mark II - Model 40 Molded Plastic Manometers

Installation and Operating Instructions

Dwyer Mark II - Model 40 Molded

Plastic Manometers are ideally suited

for air velocity and air filter gage applications at minimal cost. These inclined

manometers provide linear calibration

and excellent resolution throughout their

ranges. They are capable of pressure

line spaced 2-31/32˝ apart. Install the

gage with the self-tapping screws provided,

turning the screws down snug but not tight.

Adjust the position of the gage until the bubble is centered in the spirit level. Tighten the

mounting screws, checking to be sure the

instrument remained level, and re-level

as necessary.

measurements above and below

atmospheric, as well as differential pressure measurements.

INSTALLATION

Mount the

Stationary Applications:

Mark II manometer on a convenient vertical

surface. The installation should not be

exposed to strong chlorine atmospheres or

solvents such as benzene, acetone, carbon

tetrachloride, etc. The instrument is suitable

for total internal pressures of up to 15 psi

(100 kPa) and ambient temperatures of

150°F (65°C). DO NOT EXCEED THESE

LIMITS. At the mounting location selected,

drill two 9/64˝ diameter holes on a vertical

DWYER INSTRUMENTS, INC.

P.O. BOX 373 Fax: 219/872-9057 e-mail: info@dwyer-inst.com

MICHIGAN CITY, INDIANA 46361,U.S.A

SPECIFICA T IONS

Accuracy

: ±3% of full scale.

Maximum Internal Working Pressure:

15 psi (100 kPa).

Maximum Working Temperature: 150°F

(65°C).

Scale Length: Approx. 8-1/4˝ (21 cm).

Weight: 10 oz (283.49 g).

Accessories: 3/4 oz. gage oil, mounting

screws, 1/8˝ NPT tubing adapters, washers, nuts, red and green pointer flags, (2)

4-1/2 ft.

Phone: 219/879-8000 www.dwyer-inst.com

lengths 3/16˝ I. D. vinyl tubing.

Portable Applications: For portable

use, a molded plastic swing-away foot and

leveling screw are provided. Referring to the

picture on the first page of this bulletin,

secure the swing-away foot to the bottom of

the gage, using the plastic screw in the

tapped hole on the right-hand side. Install

the plastic leveling screw in the tapped hole

on the bottom left side of the manometer. In

use, the swing-away foot is positioned perpendicular to the gage. With the manometer

in operating position, the leveling screw is

adjusted until the bubble is centered in the

spirit level. For storage, the swing-away foot

can be rotated to a position in line with the

gage body.

FILLING

T urn the zero adjust knob fully counter clockwise until it stops; then turn it clockwise

approximately four full turns so as to center

the adjustment to allow room for adjusting

either side of zero. Unscrew the entire low

pressure (right) shut-off connection fitting. A

3/4˝ wrench is required. Also, remove the

cork, disc, and “O” ring. Vent the left connector by turning the elbow 1 - 2 turns

counterclockwise. Slowly fill gage with fluid

provided until fluid rises in the indicating

tube to the vicinity of zero on the scale.

Nearly all the oil provided will be required to

fill the gage. Replace the cork, disc, “O” ring

and the low-pressure shut-off

connection fitting.

OPERATION

The Model 40 manometer is provided with

convenient shut-off tubing connections to

prevent loss of oil when transporting the

gage. To use the gage, turn each barbed

tubing connection counterclockwise 1-2

turns from the closed (fully clockwise) position. Rotate the zero adjustment for an exact

zero reading and the gage is ready for use.

In stationary installations, these steps need

only be performed upon initial installation. In

portable use, each time the gage is used the

connections must be opened, the gage leveled and zeroed; prior to storage, the gage

connections must be closed.

Pressure Connection: Two 4-1/2˝

lengths of plastic tubing are included with

the gage along with two adapters for connection of the tubing to 1/8˝ NPT fittings or

sheet metal ducts. The tubing from the high

pressure pickup should be connected to the

high pressure (left) barbed connection at the

top of the gage. The tubing from the low

pressure pickup should be connected to the

low pressure (right) barbed fitting. Stick-on

red and green arrows are provided to indicate the appropriate range of readings for

the particular application. The 1/8˝ NPT

tubing adapters can be used as static pressure sensors in sheet metal ducts by drilling

a 7/16˝ diameter hole in the duct and

mounting the adapter in the hole, placing

one of the washers on each side of the duct

wall and securing the 1/8˝ NPT nut.

CAUTION

USE .826 SPECIFIC GRAVITY RED

GAGE OIL FOR MODEL #’S 40-1, 40-1AV, 40-250 Pa, 40-250 Pa-AV, and 4025 mm. Use 1.910 SPECIFIC GRAVITY

BLUE GAGE OIL FOR MODEL #’S 412, 41-2-AV, 41-600 PA, 41-60 mm.

TYPICAL APPLICATIONS

Draft Gage: Run iron pipe, 1/8˝ or larg-

er in size, from the source of the draft to a

point within 4-1/2˝ of the manometer.

Provide a means for periodic clean-out to

remove any soot accumulation. Using one

of the lengths of tubing provided, make the

connection from the pipe to the low pressure (right) fitting on the gage.

Loading...

Loading...