Dwyer Instruments Magnesense II MS2-X102, Magnesense II MS2-X103, Magnesense II MS2-X101, Magnesense II MS2-X111, Magnesense II MS2-X112 Installation And Operating Instructions Manual

Page 1

Bulletin P-MS2

[88.90]

21/32

®

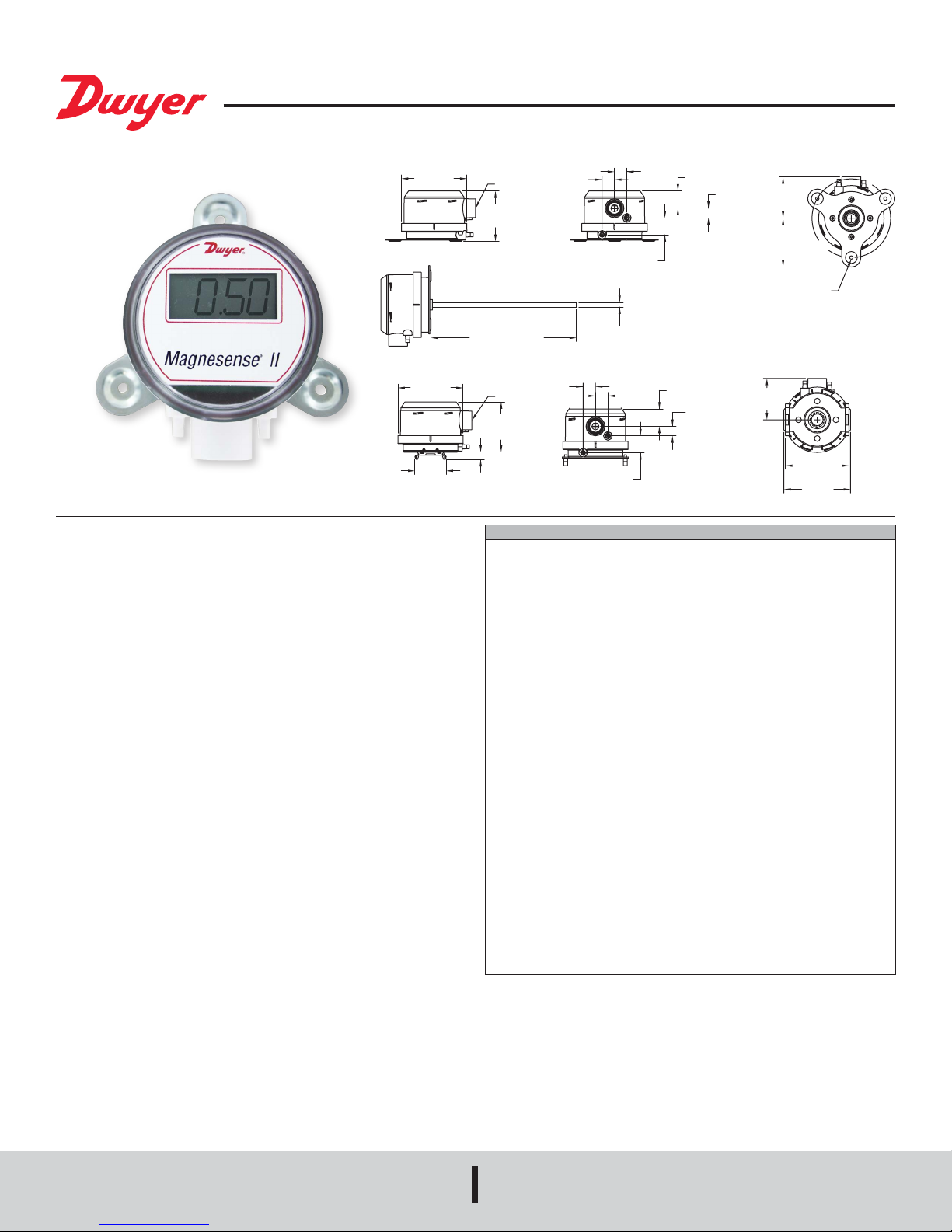

Series MS2 Magnesense® II Differential Pressure Transmitter

Specications - Installation and Operating Instructions

ø3-7/16

[ø87.31]

Duct Mount Bracket

ø3-7/16

[ø87.31]

1-41/64

[41.71]

The Series MS2 Magnesense® II Differential Pressure Transmitter combines the

proven stable Piezo sensing technology of our original Series MS with additional

features to reduce installation time and simplify ordering. In this second generation

transmitter, we have added additional eld selectable pressure ranges so that each

model can have four selectable ranges along with four additional bidirectional ranges.

When using the pluggable integral display or the portable remote display tool, both

Metric and English engineering units can be selected via on board dip switches. Dual

current and voltage outputs allow users to simultaneously take either a current or

voltage output to their building controller and have a local test circuit for verication of

the output reading. The voltage output can be selected to be either 0 to 5 VDC or 0 to

10 VDC, while the current is always 4 to 20 mA. Both the current and voltage output

can also be inverted. Alternatively, the MS2 can be ordered with either a BACnet

or MODBUS

chained together.

Like the original Series MS, the second generation transmitter can be used as a linear

pressure output or a linear velocity output with the square root extraction done in

the transmitter. Additional parameters have been included to expand the square root

capability to include ow measurements.

BACnet

nodes in any segment to 32. Therefore, the transceiver may be rated at one unit load.

Fractional loads are also acceptable. The MS2 accounts as an eighth of a load on the

MSTP network.

INSTALLATION

Surface Mount:

The transmitter should be mounted on a vertical surface with the connections directed

down to prevent moisture from entering either the pressure ports or the electrical cable

entry. The diaphragm must be vertical to minimize gravity effects on the diaphragm.

Attach the mounting ange to a at surface using three #8 x 1/2˝ pan head sheet metal

screws. Do not over tighten.

®

Communications protocol that will allow the transmitters to be daisy-

®

and Modbus® Communications protocol recommend limiting the number of

[16.55]

21/32

1/2 NPT

2-41/64

[67.16]

7-41/64[194.06]

1/2 NPT

2-41/64

[67.24]

25/64

[9.97]

SPECIFICATIONS

Supported Baud Rates: 9600, 19200, 38400, 57600, 76800, 115200.

Data Size: 8.

Parity: None.

Stop Bits: 1.

Service: Air and non-combustible, compatible gases.

Wetted Materials: Consult factory.

Accuracy: ±1% FS for 0.25˝ (50 Pa), 0.5˝ (100 Pa), 2˝ (500 Pa), 5˝ (1250 Pa), 10˝

(2 kPa), 15˝ (3 kPa), 25˝ (5 kPa); ±2% FS for 0.1˝ (25 Pa), 1˝ (250 Pa), ±0.1˝ (±25

Pa), ±1˝ (±250 Pa) and all bi-directional ranges.

Stability: ±1% / year FSO.

Temperature Limits: 0 to 150°F (-18 to 66°C).

Pressure Limits: 1 psi max., operation; 10 psi burst.

Power Requirements: 10 to 35 VDC (2 wire), 17 to 36 VDC or isolated 21.6 to 33

VAC (3 wire).

Output Signals: 4 to 20 mA (2-wire), 0 to 5 VDC, 0 to 10 VDC (3-wire).

Response Time: Averaging 0 to 240 sec, 2.5 Hz sample rate, 1.5 to 228 sec for

95% step change.

Zero & Span Adjustments: Digital push buttons.

Loop Resistance: Current output: 0 to 1250Ω max; Voltage output: Min. load

resistance 1kΩ.

Current Consumption: 40 mA max.

Display (optional): 5-digit LCD.

Electrical Connections: 3-wire removable European style terminal block for 16 to

26 AWG.

Electrical Entry: 1/2˝ NPS thread; Accessory (A-151): Cable gland for 5 to 10 mm

diameter cable.

Process Connection: 3/16˝ ID tubing (5 mm ID); Max. OD 9 mm.

Enclosure Rating: IP66.

Mounting Orientation: Diaphragm in vertical position.

Weight: 8.0 oz (230 g).

Agency Approvals: CE.

[16.55]

Wall Mount Bracket

15/64

[6.00]

21/32

[16.51]

57/64

[22.60]

DIN Mount Bracket

57/64

[22.67]

21/32

[16.51]

29/32

[23.02]

[12.76]

29/32

[23.02]

1/2

[12.77]

[3] 3/16 [4.76] HOLES

EQUALLY SPACED ON A

1/2

2-11/64

[55.25]

2-9/16

[65.12]

4.115 [104.52] B.C.

2-11/64

[55.12]

3-11/32

[84.84]

3-1/2

Duct Mount:

The transmitter should be mounted away from fans, corners, heating and cooling coils

and other equipment that will effect the measurement of the pressure.

1. To mount the transmitter, drill a .562˝ (12.70 mm) diameter hold into the duct.

2. Insert transmitter probe into the duct.

3. Mark location of three mounting holes on duct using mounting ange as template.

Drill holes.

4. Attach mounting ange to duct with three #8 x 1/2˝ pan head sheet metal screws.

Do not over tighten screws.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Electrical Connection:

The Series MS2 simultaneously transmits a 2-wire 4 to 20 mA current output and

a 3-wire 0 to 5 V / 0 to 10 V voltage output via a removable European-style three

conductor terminal block. The transmitter can be wired in one of the following three

ways to utilize the current and / or voltage output. The range of the voltage output can

be selected using the on board dip switches as described in the Dip Switch Settings

section of this manual.

Modbus® is a registered trademark of Schneider Automation, Inc.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Page 2

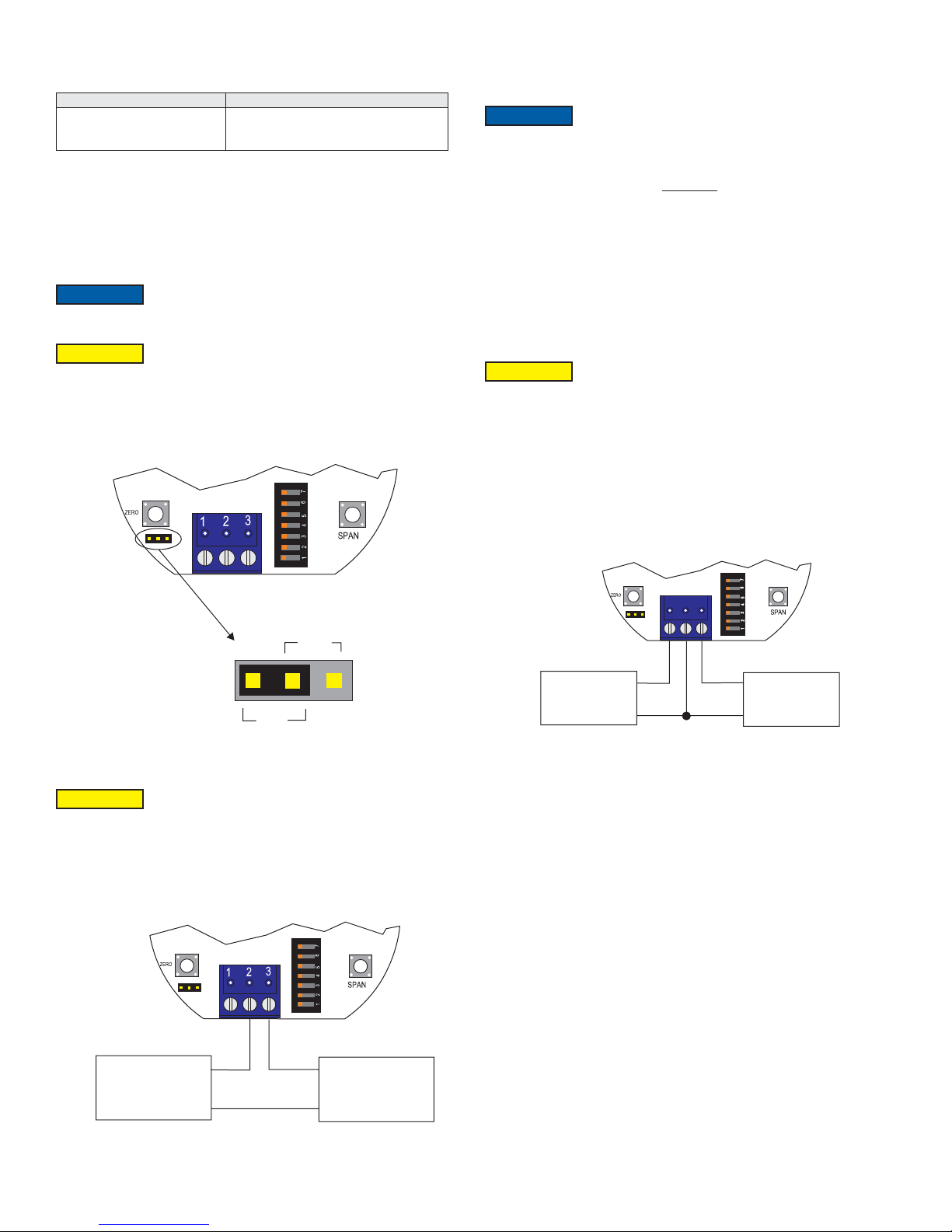

Power Supply

AC

AC/DC JUMPER

CURRENT OUTPUT WIRING

Refer to the below table for the required supply rating.

Output Type Power Supply Rating

2-wire current

3-wire voltage

Simultaneous current and voltage

10 to 40 VDC (40 mA min)

17 to 40 VDC or 21.6 to 33 VAC (40 mA min)

17 to 40 VDC (40 mA min)

Choose a power supply with a voltage and current rating sufcient to meet the power

specications under all operating conditions. If the supply is unregulated, make sure

that the output voltage remains within the required voltage range under all power line

conditions. Ripple on the supply should not exceed 100 mV.

AC/DC Jumper Selection

NOTICE

The jumper is factory set to AC. If DC power is applied while

the jumper is set to AC, no damage will occur. However, the

accuracy of the unit may temporarily be affected.

CAUTION

Powering the unit with AC power while the jumper is set to DC

may permanently damage the transmitter.

Refer to Figure 1 for the location of the AC / DC jumper. Place the shorting jumper

across either the two pins marked AC or the two pins marked DC.

The range of appropriate receiver load resistances (RL) for the power supply voltage

available is given by the formula listed below. Shielded 2-wire cable is recommended

for control loop wiring. Ground the shield at the power supply end only.

NOTICE

The receiver may be connected to either the negative or positive

side of the loop, whichever is most convenient. Should polarity

of the transmitter or receiver be inadvertently reversed, the loop will not function

properly but no damage will be done to the transmitter.

ps - 10.0

V

L =

R

20 mA DC

The maximum length of connecting wire between the transmitter and the receiver is

a function of wire size and receiver resistance. That portion of the total current loop

resistance represented by the resistance of the connecting wires themselves should

not exceed 10% of the receiver resistance. For extremely long runs (over 1,000 feet),

it is desirable to select receivers with lower resistances in order to keep the size and

cost of the connecting leads as low as possible. In installations where the connecting

run is no more than 100 feet, connecting lead wire as small as No. 22 ga. can be used.

3-Wire 0 to 10 V and 0 to 5V Voltage Operation

CAUTION

DO NOT EXCEED SPECIFIED SUPPLY VOLTAGE RATINGS.

PERMANENT DAMAGE NOT COVERED BY WARRANTY

WILL RESULT.

The connection to the transmitter are made to Terminals 1, 2, and 3 on the terminal

block as shown in Figure 3. The terminal block is removable and each of the terminals

are labeled underneath the terminal block on the circuit board. Polarity is indicated by

PWR, COM, and +VOUT. When connecting using a DC power source, make sure the

AC/DC selection jumper is set for DC. If the polarity of the transmitter is inadvertently

reversed, the unit will not function properly, but no damage will be done to the

transmitter. When connecting to an AC power source, make sure the AC/DC selection

jumper is set for AC. Either lead of the supply power may be connected to PWR and

COM without affecting the operation of the transmitter or damage to the transmitter.

DC

Figure 1

2-Wire 4 to 20 mA Current Operation

CAUTION

DO NOT EXCEED SPECIFIED SUPPLY VOLTAGE RATINGS.

PERMANENT DAMAGE NOT COVERED BY WARRANTY

WILL RESULT. SIMULTANEOUS OUTPUTS ARE NOT DESIGNED FOR AC

VOLTAGE OPERATION.

The connections to the transmitter are made through terminals 2 and 3 on the terminal

block as shown in Figure 2. The terminal block is removable and each of the terminals

are labeled underneath the terminal block on the circuit board. Polarity is indicated by

+IOUT and -IOUT. The AC/DC selection jumper should be set for DC operation.

3

2

1

RECEIVER

+

_

+

POWER

_

VOLTAGE OUTPUT WIRING

Figure 3

The minimum receiver load is 1K Ω. The resistance due to the wire should be low

compared to the receiver load resistance. While the voltage at the terminal block

remains unchanged with a 10 mA current ow, resistive losses in the wiring do cause

errors in the voltage delivered to the receiver. For a 1% accurate gauge, the resistance

of the wires should be less than 0.1% of the value of the receiver load resistance. This

will keep the error caused by the current ow below 0.1%.

The output across +VOUT and COM will be either 0 to 5 V, 0 to 10 V, or the inverse

depending on the dip switch setting. See Dip Switch Setting Section for more

information.

+

_

Figure 2

+

POWERRECEIVER

_

Page 3

Simultaneous Current and Voltage Operation

VOLTAGE OUTPUT WIRING

NOT

VOL

MUST

WIRES

WIRED

ON

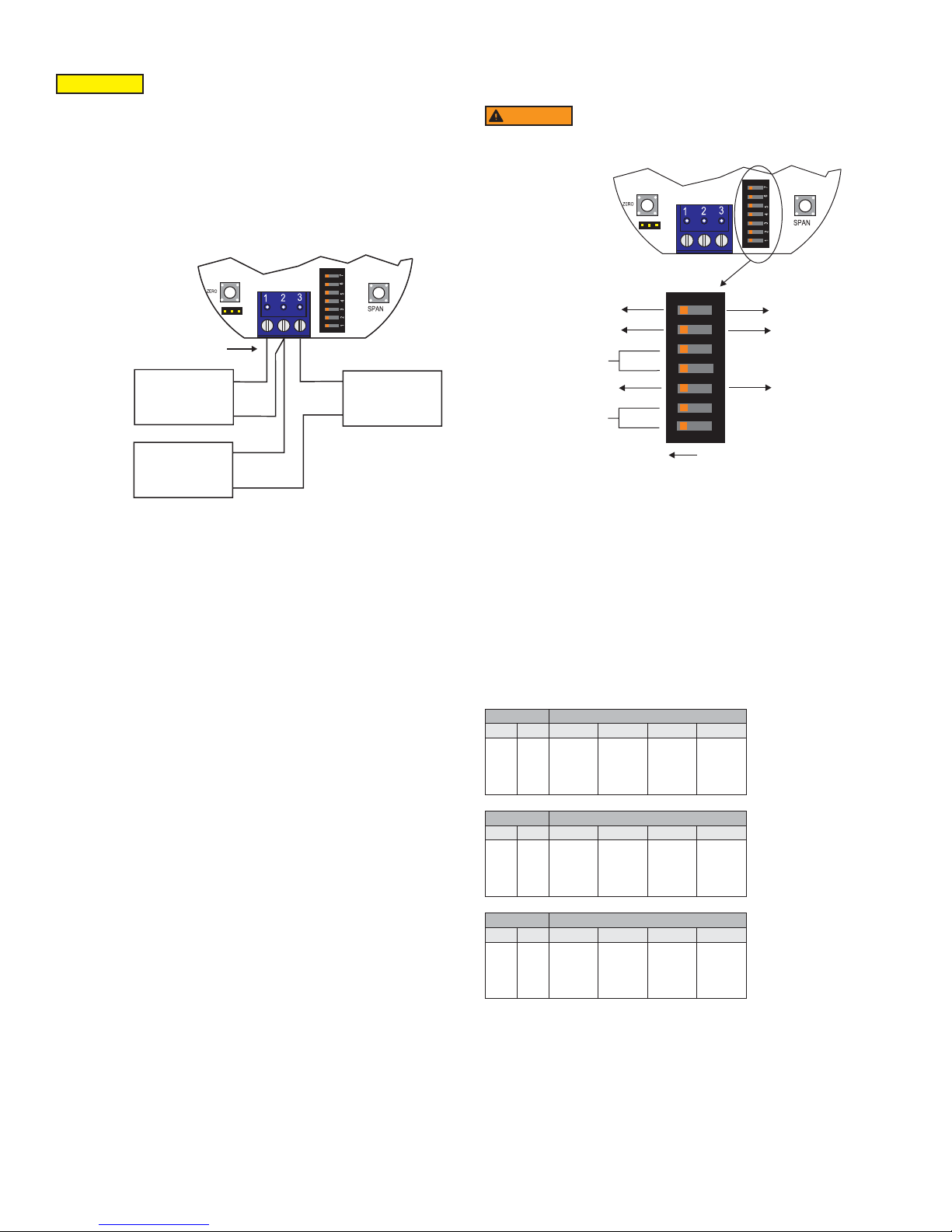

DIP SWITCH SETTINGS

CAUTION

DO NOT EXCEED SPECIFIED SUPPLY VOLTAGE RATINGS.

PERMANENT DAMAGE NOT COVERED BY WARRANTY

WILL RESULT. SIMULTANEOUS OUTPUTS ARE NOT DESIGNED FOR AC

VOLTAGE OPERATION.

The connection to the transmitter are made to Terminals 1, 2, and 3 on the terminal

block as shown in Figure 4. The terminal block is removable and each of the terminals

are labeled underneath the terminal block on the circuit board. Polarity is indicated by

PWR, COM, and +VOUT. The AC/DC selection jumper should be set for DC operation.

The voltage output and the power supply must have separate wire leads that are only

joined at terminal 2 of the transmitter. Additional error may occur for the voltage output

if a single wire is used or if the wires are joined at the power supply or receiver.

- POWER AND

TAGE RECEIVER “-”

BE SEPERATE

AND BOTH

TO

_

+

CURRENT

RECEVIER

VOLTAGE

RECEVIER

+

_

_

POWER

+

SIMULTANEOUS CURRENT AND

Figure 4

For the current output, the maximum allowable loop resistance (wiring + receiver

resistance) is dependent on the power supply. The maximum loop voltage drop must

not reduce the transmitter voltage below 17 V. The maximum loop resistance can be

calculated using the following equation:

R

MAX = (VPS – 17.0) / 0.02 Where VPS is the power supply voltage

The equation uses 17.0 instead of 10.0 used in current only equation. This represents

the minimum voltage supply which is higher on the simultaneous output conguration

due to the requirements of the voltage outputs.

Shielded 4-wire cable is recommended for control loop wiring. Ground the shield

at the power supply end only. Should the polarity of the transmitter or receiver be

inadvertently reversed, the unit will not function properly, but no damage will be done

to the transmitter.

DIP SWITCH SETTINGS

DIP Switches can be located next to the terminal block as shown in Figure 5. A small

screw driver or pen can be used to change the position of the switches.

WARNING

All power should be turned off to the transmitter before adjusting

the dip switch settings to avoid electrical shock.

DIR

10V

UNITS

UNIDIRECTIONAL BIDIRECTIONAL

7

6

5

4

3

RANGE

REV

5V

2

1

Figure 5

Factory Settings

Mode = Unidirectional (except on MS2-XX1X models)

Range = Highest Range Setting (0.5, 5, or 28 in w.c.)

Units = Inches W.C.

Voltage Output Range = 10 V

Direct / Reverse Output Action = Direct

Setting the Pressure Range

Ranges are selected by adjusting DIP Switch Positions 1 and 2 according to the

below tables. The range also depends on the units selected (Refer to Setting the

Engineering Units Section) and if the input is set for unidirectional or bidirectional

(Refer to the Setting for Unidirectional or Bidirectional Section). The tables below show

the maximum full scale value for the selected range and selected units. If the unit is set

to unidirectional, the ranges are all zero based. If the unit is set for bidirectional, the

ranges will be ± the maximum full scale value shown in the tables below.

DIP Switch Full Scale Range for MS2-X101

1 2 in w.c. Pa mm w.c. kPa

OFF

OFF

OFF

ON

ON

ON

OFF

ON

0.1

0.15

0.25

0.5

25

40

50

125

2.5

4

6

10

0.025

0.040

0.050

0.125

For voltage outputs, the minimum receiver load is 1K Ω. The resistance due to the

wire should be low compared to the receiver load resistance. While the voltage at

the terminal block remains unchanged with a 10 mA current ow, resistive losses in

the wiring do cause errors in the voltage delivered to the receiver. For a 1% accurate

gauge, the resistance of the wires should be less than 0.1% of the value of the receiver

load resistance. This will keep the error caused by the current ow below 0.1%.

The output across +VOUT and COM will be either 0 to 5 V, 0 to 10 V, or the inverse

depending on the dip switch setting. See Dip Switch Setting Section for more

information.

DIP Switch Full Scale Range for MS2-X102

1 2 in w.c. Pa mm w.c. kPa

OFF

OFF

OFF

ON

ON

ON

OFF

ON

1

2

3

5

250

500

750

1250

25

50

75

125

0.250

0.500

0.750

1.25

DIP Switch Full Scale Range for MS2-X103

1 2 in w.c. Pa mm w.c. kPa

OFF

OFF

OFF

ON

ON

ON

OFF

ON

10

15

25

28

2500

3500

5000

6975

250

350

500

700

2.50

3.50

5.00

6.98

Setting for Unidirectional or Bidirectional

The Models MS2-X101 and MS2-X102 models are unidirectional only. The Bidirectional

models MS2-X103, MS2-X111 and MS2-X112 can be changed to measure pressure in

one direction at a reduced accuracy by changing the setting of DIP Switch 3.

• When the switch is in the ON direction, the transmitter will be set for Unidirectional

and will be 0 based (i.e. 0 to 5 in w.c.).

• When the switch is in the OFF position, the transmitter will be set for Bidirectional

and will be ± the maximum of the selected range (i.e. ±5 in w.c.).

• For unidirectional units only, switch has no effect and unit will remain in unidirectional

mode.

Page 4

Setting the Engineering Units

Magnesense

®

II comes with the selection of four engineering units (in w.c., Pa, mm

w.c., or kPa). The engineering units are selected using DIP Switch 4 and 5. The units

will be displayed on the optional LCD display.

DIP Switch Units

4 5 Pressure Velocity Air Flow

OFF

OFF

OFF

ON

ON

ON

OFF

ON

kPa

mm w.c.

Pa

in w.c.

m/s

m/s

m/s

FPM

m

m

m

cfm

3

/h

3

/h

3

/h

Setting the Output Voltage Range

Voltage output can be either 0 to 10 V or 0 to 5 V depending on the position of DIP

Switch 6.

• When the switch is in the ON position, the output will be 0 to 10 V

• When the switch is in the OFF position, the output will be 0 to 5 V

Setting the Input / Output Action

The output will either directly or indirectly follow the input based on the position of DIP

Switch 7.

• When the switch is in the ON position, the output directly follows the input (i.e. output

increases as the input increases)

• When the switch is in the OFF position, the output acts in reverse of the input (i.e.

output decreases as the input increases)

Another option for models that do not have a display would be to use a Model A-435-A

remote display tool which can plug into the connector shown in Figure 7. The remote

display tool has two buttons that function identically to the buttons on the PCB.

CALIBRATION

NOTICE

There is a 5 second delay from the time the zero or span

calibration buttons is released until the time that the change in

calibration takes place. This delay is used to prevent stress related offsets on the

lower ranges.

NOTICE

The security level that is set in the Programming Menu Section

of the manual will determine which calibrations, if any, may be

adjusted by the user.

Zero Calibration

The zero calibration can be set by applying zero pressure to both the pressure ports

and pressing the zero button for 3 seconds. If either the remote or local LCD is present,

the display will read ZEro and then sequence back to the home display.

SPAN Calibration

The span calibration can be adjusted only after setting the zero adjustment. It must

be completed within 5 minutes of the last zero calibration. The span calibration button

will be ignored until the zero calibration is completed. Apply pressure to the ports of

the transmitter that is associated with the maximum output of the transmitter (20 mA,

5 V, or 10 V depending on output being used). Press and hold the span button for 3

seconds. If either the remote or local LCD is present, the display will read SPAn and

then sequence back to the home display. If the span calibration is attempted before

adjusting the zero calibration, the FAIL error message will ash on the display. On bi-

directional models, separate spans can be performed on the positive and negative

sides of the range.

LCD DISPLAY

The Magnesense

®

II can be ordered with an optional, integral LCD. If the display is

not needed for normal operation, the transmitter can be ordered without the LCD.

An A-MS2-LCD eld upgradeable display is available. It comes with a housing cover

with the overlay cut out for the display. The display will plug into the pins as shown in

Figure 6.

Figure 7

Display Error Messages

ovEr = The applied pressure is greater than the maximum span value causing an Over

Range Error.

UndEr = The applied pressure is less than the minimum span value causing an Under

Range Error.

FAiL = When the span or zero buttons are pressed, the pressure value is out of the

range to allow a correct setting. This may be due to a sensor failure or incorrect

pressure being applied.

Err1 = The sensor is damaged.

PROGRAMMING MENUS

Home Menu

During normal operation, the display will be in the Home Menu and will display the

current measured pressure and the engineering units.

Menu Access Security

While in the Home Menu, press and hold the Zero and Span buttons simultaneously

until SECUr appears on the display in order to access the other programming menus.

Upon releasing the buttons, the display will indicate the current security level.

If the current security level is the security level desired (i.e. Security Level 0), press

and hold the span button for three seconds to enter the Pressure, Velocity, or Air Flow

Menu.

If the security level is not the desired level, the security level can be changed

temporarily to a lower security level or permanently to a higher level of security by

pressing the zero button. A security code will be shown on the display and it can be

changed to one of the codes listed in the below table. The span button chooses which

digit and the zero button increments the value of that digit. Pressing and holding the

span button will store the value.

Figure 6

Security

Level Setting

0

1

2

3

Access

View Menu Edit Menu Span Zero

000

111

222

333

Yes

Yes

No

No

Yes

No

No

No

Yes

No

No

No

Yes

Yes

Yes

No

The level of access to the programming menus and the calibration is limited based on

the security level. The above table details the level of access for each security level.

Page 5

Mode Selection / Digital Dampening Menu

From the home display, pressing the span and zero button simultaneously for 3

seconds will access the Menu Security Level. If the level is set to 0 or 1, pressing and

holding the span button for 3 seconds a second time will access the Mode Selection

Menu. The display will default to Pressure when rst powered up. Pressing the zero

button will cycle to Velocity and Flow.

FACTORY DEFAULT PROCEDURE

In order to reset all of the menu settings back to their factory programmed values,

press and hold both the span and zero buttons simultaneously for 10 seconds until

FACt is displayed on the LCD. Upon releasing the buttons, the unit will be factory

defaulted. Since resetting the transmitter will wipe out all changes, it is necessary to

zero (and possibly span) the transmitter before taking measurements.

Once the desired Mode is displayed, pressing and holding the span button for three

seconds will save the selected mode and display the digital dampening or averaging

parameter. This parameter stabilizes the output and the display by averaging the

readings. There are 2.5 readings taken each second and the user can select the

number of seconds that they would like to average up to 240 seconds. The display and

the output will continue to update at a rate of 2.5 updates per second, but the moving

average is used for these updates.

PRESSURE MODE

Maximum Output Adjustment

If the Pressure Mode was selected, pressing and holding the span after adjusting the

digital dampening will enter the Pressure Mode. In this menu, the maximum output

pressure (POH) can be adjusted to any pressure between the lowest dip switch range

to the highest dip switch range. If the dip switch settings are preferred over manually

setting the range, the POH parameter can be set to off.

VELOCITY MODE

K-Factor Adjustment

If the Velocity Mode was selected, pressing and holding the span after adjusting the

digital dampening will enter the Velocity Mode and the transmitter will display the

engineering unit that has been selected by the dip switch. Pressing and holding the

span button for three seconds will enter the K – Factor adjustment. The K – Factor can

be adjusted between 0.001 to 9.999. The K-Factor can be adjusted by pressing the

span button to select the digit and pressing the zero button to increment the value of the

digit. Pressing and holding the span button for three seconds will enter the Maximum

Output Adjustment parameter.

Maximum Output Adjustment

The maximum output can be equivalent to a velocity or a pressure. After adjusting

the K-Factor, the display will indicate if the adjustment is set for pressure or velocity.

Pressing the zero button will toggle between the selections. Pressing and holding the

span button for three seconds will enter the maximum output adjustment. The maximum

output can be adjusted by pressing the span button to select the digit and pressing the

zero button to increment the value of the digit. Pressing and holding the span button for

three seconds will save this value and go to the Security Update Menu.

FLOW MODE

K-Factor Adjustment

If the Flow Mode was selected, pressing and holding the span after adjusting the digital

dampening will enter the Flow Mode and the transmitter will display the engineering unit

that has been selected by the dip switch. Pressing and holding the span button for three

seconds will enter the K – Factor adjustment. The K – Factor can be adjusted between

0.001 to 9.999. The K-Factor can be adjusted by pressing the span button to select

the digit and pressing the zero button to increment the value of the digit. Pressing and

holding the span button for three seconds will enter the Area Adjustment parameter.

MAINTENANCE/REPAIR

Upon nal installation of the Series MS2 Magnesense

®

II Differential Pressure

Transmitter, no routine maintenance is required besides zeroing the transmitter

occasionally. Besides routine calibration and installation of the LCD, the Series MS2

is not eld serviceable and it is not possible to repair the unit. Field repair should not

be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping the

product back for repair. Be sure to include a brief description of the problem plus any

additional application notes.

APPENDIX I

Air Velocity / Air Flow Calculations

Velocity is calculated using the below equation:

Velocity(fpm) = K-Factor x 4004.4 x √(Diff. Press. (in of w.c.)

Velocity in m/s is then calculated from the equation:

Velocity(m/s) = Velocity(fpm) x 0.00508

Flow is calculated using the below equation:

Flow(cfm) = Area(Ft

3

Flow (m

/h) = Flow (cfm) x 1.6992

2

) x K-Factor x 4004.4 x √(Diff. Press. (in of w.c.)

APPENDIX II

Maximum Flow

Range

in w.c.

0.5

5

28

Max Displayed Flow Max (K Factor x Area)

CFM M

5885000

5885000

5885000

3

/H CFM Mode M3/H Mode

9999000

9999000

9999000

2037.2

644.2

272.2

154.5

59.9

25.3

Area Adjustment

For Flow applications, the area is multiplied by the velocity to determine the volumetric

air ow. The area will be listed in either feet or meters depending on the dip switch

settings. The units will be indicated on the display at the time of adjustment.The area

can be adjusted by pressing the span button to select the digit and pressing the zero

button to increment the value of the digit. Pressing and holding the span button for three

seconds will enter the Maximum Output Adjustment parameter.

Maximum Output Adjustment

The maximum output can be equivalent to a ow or a pressure. After adjusting the

Area parameter, the display will indicate if the adjustment is set for pressure or ow.

Pressing the zero button will toggle between the selections. Pressing and holding the

span button for three seconds will enter the maximum output adjustment. The maximum

output can be adjusted by pressing the span button to select the digit and pressing the

zero button to increment the value of the digit. Pressing and holding the span button for

three seconds will save this value and go to the Security Update Menu.

Security Update / Save Changes Menu

The Security Update Menu allows the security level to be set either higher or lower than

the current security level setting. This security level will be displayed the next time the

Menus are accessed from the home screen. Pressing the zero button cycles through

the security levels. Pressing and holding the span button for three seconds accepts

the new security level and gives the option to save all the menu changes. Pressing the

zero button will toggle between yes and no. Yes will save the changes made to all menu

items and no will discard all the changes made to all menu items. If the display is set

to yes, pressing and holding the span will save the menu items and return the display

to the Home Position.

Page 6

APPENDIX III

BUTTON PRESS LEGEND

MODE

PRESSURE

OR

TO"PRESSURE, VELOCITY, OR FLOW"MENUS

Quick Start Guide

MENU FLOW CHART

ZERO

PRESS ZERO BUTTON

=

SPAN

PRESS SPAN BUTTON

=

ZERO

PRESS AND HOLD ZERO BUTTON

=

SPAN

PRESS AND HOLD SPAN BUTTON

=

ZERO

PRESS AND HOLD ZERO AND SPAN BUTTONS

=

SPAN

MENU CONVENTIONS

IN HOME POSITION:

ZERO

CALIBRATE UNIT TO ZERO PRESSURE.

SPAN

CALIBRATE UNIT TO SPAN PRESSURE.

ZERO

ENTER MENU DISPLAY

SPAN

DISPLAY IS NOT NECESSARY

IN MENU DISPLAY:

SPAN

SEQUENCES TO NEXT MAIN MENU ITEM, AND IF A MENU ITEM IS CHANGED TEMPORARILY SAVES THE SELECTION

ZERO

SEQUENCES THROUGH SUB MENU SELECTIONS OR INCREMENTS DIGITS

SPAN

SEQUENCE TO NEXT DIGIT. ACTIVE DIGIT WILL BLINK.

BLINKING DIGIT

=

3

SECURITY LEVEL

SELECTION

SELECTION

, VELOCITY,

FLOW

ADJUST AV ERAGING

0.0

in

C

W

ZERO

SPAN

SECUr

SEC 0

SPAN

PrES

SPAN

000

A

VG

SPAN

HOME POSITION

WHILE BUTTONS ARE

PRESSED

WHEN BUTTONS ARE

RELEASED DISPLAYS CURRENT

SECURITY LEVEL

ZERO

TO CHANGE

SECURITY LEVEL

IF SECURITY IS SET TO

0,1, OR 2

S 345

SPAN

LoCK

ZERO

ZERO

SPAN

INCREMENT

DIGIT

SELECT

DIGIT

uEL

HOLD 7

SECONDS

ZERO

SPAN

INCREMENT

ZERO

DIGIT

SELECT

SPAN

DIGIT

IF SECURITY IS SET TO 3

PRESS ANY KEY

OR WAIT 5 SECONDS

ZERO

FLo

FACTORY SETTINGS

RESTORED, THEN RETURNS

TO HOME POSITION

FACt

SECURITY LEVEL

0

1

2

3

HOME POSITION

ZERO

SPAN SPANSPAN

SETTING

000

111

222

333

0.0

in

C

W

TO SELECT MODE

Page 7

FROM AVERAGING MENU

PRESSURE MODE MENU

SWITCH

FROM

VELOCITY MODE MENU

AND SAVE " MENU

SELECT

SET

VELOCITY

PoH

ADJUST PRESSURE

OUTPUT HIGH

"

AdJ

SELECTED UNITS

DISPLAYED

"

P

MENUS

TO " UPDATE SECURITY

AND SAVE " MENU

FROM AVERAGING MENU

Unit

SPAN

UPON RELEASE

PoH n

SPAN

THIS MENU DEPENDS ON

DIP SWITCH SETTING

FP

M

SPAN

PoH = DIP SWITCH FULL SCALE SETTING

SET PoH TO DESIRED VALUE

ZERO

PoH Y

SPAN

288

in

W

SPAN

UNITS SELECTED

OR

Unit

M

S

BY DIP SWITCH

SETTING

C

ZERO

INCREMENT

ZERO

DIGIT

SELECT

SPAN

DIGIT

UNITS SET BY DIP

WILL BLINK

ADJUST DISPLAY

K FACTOR

MAXIMUM OUTPUT

BY PRESSURE OR

ADJUST VELOCITY

OUTPUT HIGH

diSP

K

o AdJ

uoH

TO " UPDATE SECURITY

SPAN

UPON RELEASE

SPAN

UPON RELEASE

SPAN

UPON RELEASE

d1000

SPAN

AdJ

SPAN

0233

FP

M

FPM OR M/S BASED

ON DIP SWITCH SETTING

0233

SPAN

K

ZERO

u

K

K

M

S

ZERO

SPAN

ZERO

SPAN

AdJ

INCREMENT

DIGIT

SELECT

DIGIT

INCREMENT

DIGIT

SELECT

DIGIT

P

ZERO

SPAN

TO PoH , PRESSURE

MODE MENU

Page 8

FROM " UPDATE SECURITY

AND SAVE " MENU

UPDA

LEVEL

TE SECURITY

SAVE CHANGES

©Copyright 2018 Dwyer Instruments, Inc. Printed in U.S.A. 6/18 FR# 444021-00 Rev. 8

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

SEC 0

SPAN SPAN

SAuE

in

W

C

HOME POSITION

0.0

ZERO

SEC 1 SEC 2

UPON RELEASE

SPAN

ZERO

no

Phone: 219/879-8000

Fax: 219/872-9057

ZERO

SEC 3

SPAN

ZERO

ZERO

SPAN

YES

ZERO

SPANSPAN

www.dwyer-inst.com

e-mail: info@dwyermail.com

Loading...

Loading...