Page 1

BULLETIN NO.A-27

Magnehelic® Differential Pressure Gage

OPERATING INSTRUCTIONS

SPECIFICATIONS

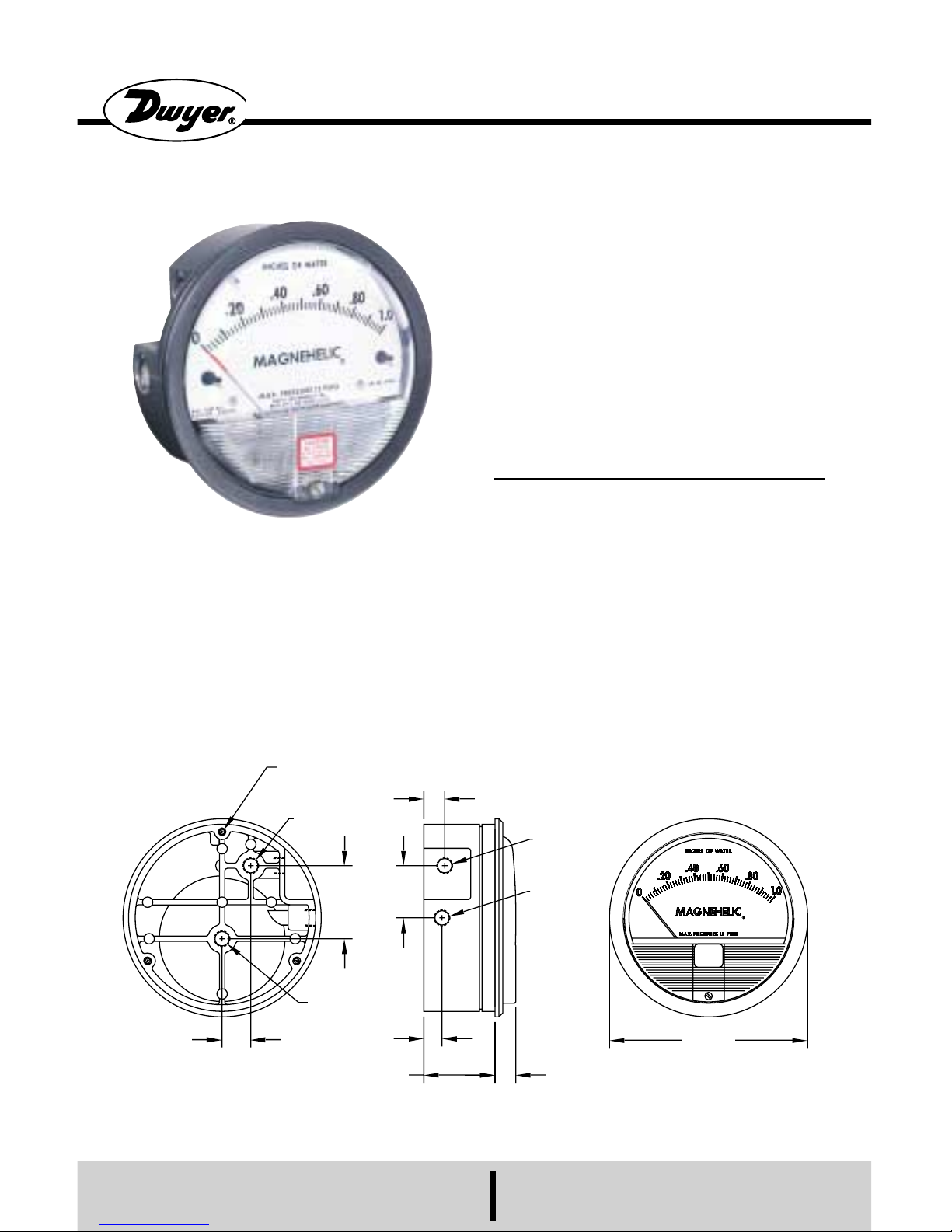

Dimensions: 4-3/4 dia. x 2-3/16 deep.

Weight: 1 lb. 2 oz.

Finished: Baked dark gray enamel.

Connections: 1/8 NPThigh and low pressure

taps, duplicated, one pair side and one

pair back.

Accuracy: Plus or minus 2% of full scale, at

70°F. (Model 2000-0, 3%; 2000-00, 4%).

Pressure Rating: 15 PSI (0,35 bar)

Ambient Temperature Range: 20° to 140°F

(-7 to 60°C).

Standard gage accessories include two 1/8

NPT plugs for duplicate pressure taps,

two 1/8 NPTpipe thread to rubber tubing

adapters, and three flush mounting

adapters with screws.

Caution: For use with air or compatible

gases only.

For repeated over-ranging or high cycle rates,

contact factory.

Not for use with Hydrogen gas. Dangerous

reactions will occur.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361 U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Lit-by-Fax: 888/891-4963

11/16

[17.46]

1/8 NPT LOW

PRESSURE

7/16

[11.11]

1-11/16

[42.86]

1/2

[12.70]

1/8 NPT LOW

PRESSURE

1/8 NPT HIGH

PRESSURE

1/2

[12.70]

1/8 NPT HIGH

PRESSURE

Ø4-1/8 [104.78] BOLT

CIRCLE FOR PANEL MOUNTING

120° APART

1-1/4

[31.75]

Ø4-3/4

[120.65]

1-3/4

[44.45]

Page 2

1.Select a location free from excessive vi-

bration and where the ambient temperature

will not exceed 140°F. Also, avoid direct

sunlight which accelerates discoloration of

the clear plastic cover. Sensing lines my be

run any necessary distance. Long tubing

lengths will not affect accuracy but will increase response time slightly. Do not restrict lines. If pulsating pressures or vibration cause excessive pointer oscillation,

consult the factory for ways to provide additional damping.

2. All standard Magnehelic gages are cali-

brated with the diaphragm vertical and

should be used in that position for maximum accuracy. If gages are to be used in

other than vertical position, this should be

specified on the order. Many higher range

gages will perform within tolerance in other

positions with only rezeroing. Low range

Model 2000-00 and metric equivalents

must be used in the vertical position only.

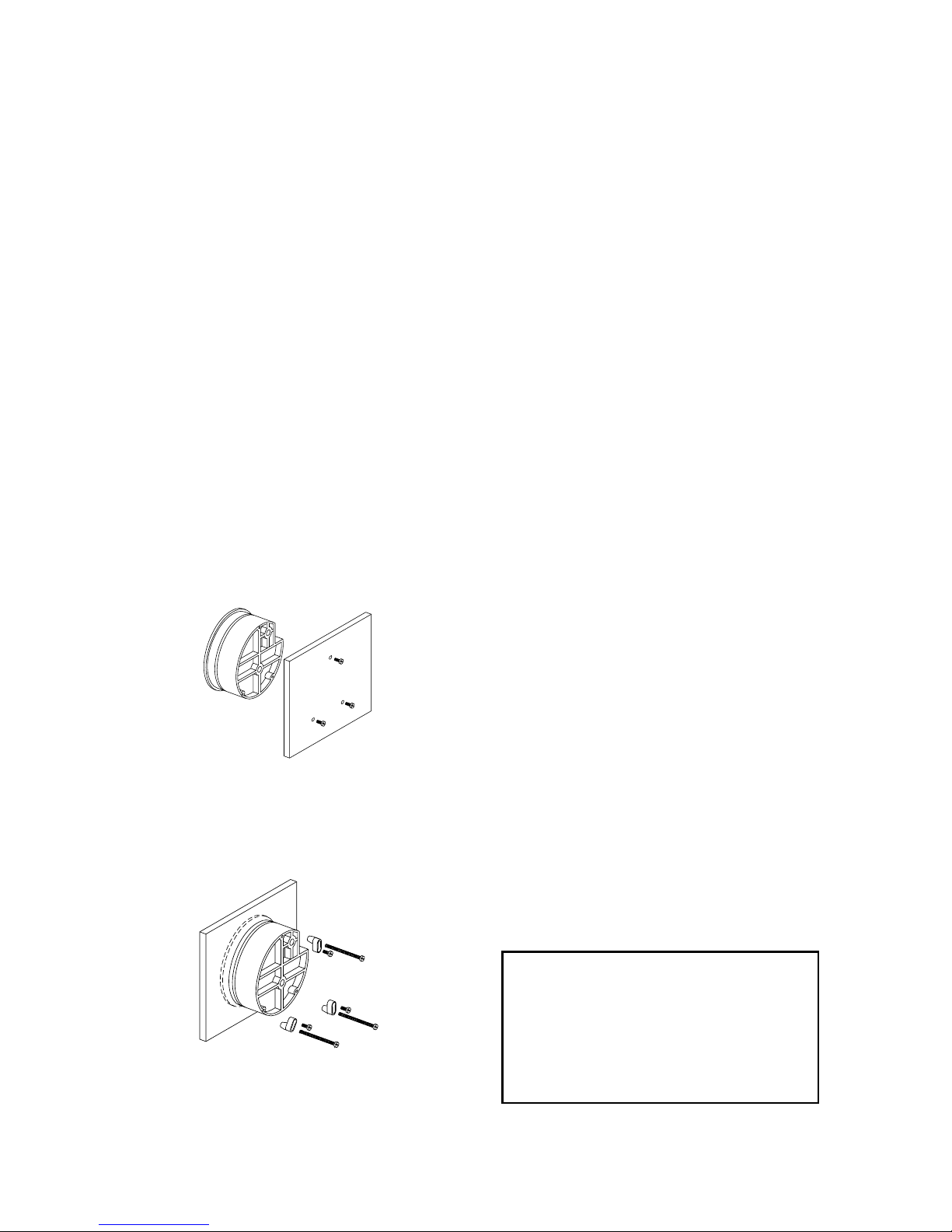

3. Surface Mounting

Locate mounting holes, 120° apart on a 41/8

⬙ dia. circle. Use No. 6-32 machine

screws of appropriate length.

4. Flush Mounting

Provide a 4-9/16⬙ dia. opening in panel.

Insert gage and secure in place with No. 632 machine screws of appropriate length,

with adapters, firmly secured in place. To

mount gage on 1-1/4

⬙-2⬙ pipe, order op-

tional A-610 pipe mounting kit.

MAGNEHELIC®INSTALLATION

5. To zero the gage after

installation

Set the indicating pointer exactly on the

zero mark, using the external zero adjust

screw on the cover at the bottom. Note that

the zero check or adjustment can only be

made with the high and low pressure taps

both open to atmosphere.

Operation

Positive Pressure:Connect tubing from

source of pressure to either of the two high

pressure ports. Plug the port not used. Vent

one or both low pressure ports to atmosphere.

Negative Pressure: Connect tubing from

source of vacuum or negative pressure to

either of the two low pressure ports. Plug

the port not used. Vent one or both high

pressure ports to atmosphere.

Differential Pressure: Connect tubing

from the greater of two pressure sources to

either high pressure port and the lower to

either low pressure port. Plug both unused

ports.

When one side of the gage is vented in

dirty, dusty atmosphere, we suggest an A331 Filter Vent Plug be installed in the open

port to keep inside of gage clean.

A. For portable use of temporary installation use 1/8

⬙ pipe thread to rubber tubing

adapter and connect to source of pressure

with rubber or Tygon tubing.

B. For permanent installation, 1/4

⬙ O.D., or

larger, copper or aluminum tubing is recommended. See accessory bulletin S-101

for fittings.

Ordering Instructions:

When corresponding with the factory regarding Magnehelic

®

gage problems, be

sure to include model number, pressure

range, and any special options. Field repair

is not recommended; contact the factory

for repair service.

Page 3

Maintenance: No lubrication or periodic

servicing is required. Keep case exterior and

cover clean. Occasionally disconnect pressure lines to vent both sides of gage to atmosphere and re-zero. Optional vent valves,

(bulletin S-101), should be used in permanent installations.

Calibration Check: Select a second gage or

manometer of known accuracy and in an appropriate range. Using short lengths of rubber or vinyl tubing, connect the high pressure side of the Magnehelic gage and the test

gage to two legs of a tee. Very slowly apply

pressure through the third leg. Allow a few

seconds for pressure to equalize, fluid to

drain, etc., and compare readings. If accuracy unacceptable, gage may be returned to

factory for recalibration. To calibrate in the

field, use the following procedure.

Calibration:

1. With gage case, held firmly, loosen bezel,

by turning counterclockwise. To avoid damage, a canvas strap wrench or similar tool

should be used.

2. Lift out plastic cover and “O” ring.

3. Remove scale screws and scale assembly.

Be careful not to damage pointer.

4. The calibration is changed by moving the

clamp. Loosen the clamp screw(s) and move

slightly toward the helix if gage is reading

high, and away if reading low. Tighten

clamp screw and install scale assembly.

5. Place cover and O-ring in position. Make

sure the hex shaft on inside of cover is properly engaged in zero adjust screw.

6. Secure cover in place by screwing bezel

down snug. Note that the area under the

cover is pressurized in operation and therefore gage will leak if not properly tightened.

7. Zero gage and compare to test instrument.

Make further adjustments as necessary.

MAINTENANCE

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361 U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Lit-by-Fax: 888/891-4963

Caution: If bezel binds when installing, lu-

bricate threads sparingly with light oil or

molybdenum disulphide compound.

Warning: Attempted field repair may void

your warrenty. Recalibration or repair

by the user is not recommended. For

best results, return gage to the factory.

Ship prepaid to:

Dwyer Instruments, Inc.

Attn: Repair Dept.

102 Indiana Highway 212

Michigan City, IN 46360

Trouble Shooting Tips:

•Gage won’t indicate or is sluggish.

1. Duplicate pressure port not plugged.

2. Diaphragm ruptured due to overpressure.

3. Fittings or sensing lines blocked,

pinched, or leaking.

4. Cover loose or “O”ring damaged, missing.

5. Pressure sensor, (static tips, Pitot tube,

etc.) improperly located.

6. Ambient temperature too low. For operation below 20°F, order gage with low temperature, (LT) option.

•Pointer stuck-gage can’t be zeroed.

1. Scale touching pointer.

2. Spring/magnet assembly shifted and

touching helix.

3. Metallic particles clinging to magnet

and interfering with helix movement.

4. Cover zero adjust shaft broken or not

properly engaged in adjusting screw.

We generally recommend that gages needing repair be returned to the factory. Parts

used in various sub-assemblies vary from

one range of gage to another, and use of incorrect components may cause improper

operation. After receipt and inspection, we

will be happy to quote repair costs before

proceeding.

Consult factory for assistance on unusual

applications or conditions.

Use with air or compatible gases only.

©Copyright 2001 Dwyer Instruments, Inc. Printed in U.S.A. 4/01 FR# 12-440212-00 Rev. 3

Page 4

BULLETIN NO.A-27

Manometro Diferencial Magnehelic

®

INSTRUCCIONES Y LISTA DE PARTES

ESPECIFICACIONES

Dimensiones: diám. 120,65 mm x 55,6 prof.

Peso: 509 g.

Terminación: esmalte horneado gris oscuro.

Conexiones: 1/8 NPT para alta y baja presión,

duplicadas (atrás, a los lados).

Exactitud: ⫾ 2% de fondo de escala a 21 °C

Mod. 2000-0 3%; Mod. 2000-00 4%

Presión máxima: 15 PSI (0,35 bar)

Temperatura: -7 a +60°C

Accesorios: Tapones 1/8 NPT para las conex-

iones duplicadas, dos adaptadores de rosca

1/8 NPT a tubo de goma; y tres adapta-

dores para montaje al ras y tornillos.

Atencion: solo para uso con aire o gases

compatibles.

Para indicaciones de sobrerango repetidas u

otras contacte a Fábrica.

Precaución para uso con hidrogeno: el imán

del instrumento puede en presencia de

hidrógeno liberar gases tóxicos y explo-

sivos. Para este caso, consulte a fábrica.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361 U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Lit-by-Fax: 888/891-4963

11/16

[17.46]

1/8 NPT LOW

PRESSURE

7/16

[11.11]

1-11/16

[42.86]

1/2

[12.70]

1/8 NPT LOW

PRESSURE

1/8 NPT HIGH

PRESSURE

1/2

[12.70]

1/8 NPT HIGH

PRESSURE

Ø4-1/8 [104.78] BOLT

CIRCLE FOR PANEL MOUNTING

120° APART

1-1/4

[31.75]

Ø4-3/4

[120.65]

1-3/4

[44.45]

Page 5

1. Seleccione un lugar libe de exceso de vi-

braciones, y donde la temperatura ambiente

no supere los 60°C. Evite luz solar directa,

para evitar decoloración de la cubierta plástica. Las conexiones de proceso pueden

tener cualquier longitud sin afectar la exactitud, pero pueden extender el tiempo de respuesta del instrumento. Si hay pulsación de

presión o vibración, consulte a fábrica sobre

medios de amortiguación.

2. Los MAGNEHELIC han sido calibrados

con el diafragma vertical, y deben ser usados

en esas condiciones. Para otras posiciones,

se debe especificar en la orden de provisión.

Los de rango elevado pueden ser usados en

diversas posiciones, pero se debe reajustar el

cero. Los modelos de la serie 2000-00 y

equivalentes métricos deben ser usados solo

verticalmente.

3. Montaje en Superficie

Perfore tres orificios separados 120° sobre

una circunferencia de 105 mm de diám. y

sostenga el instrumento con tres tornillos

6-32 de long. apropiada.

4. Montaje al Ras

Perfore un circulo de 115 mm de diám. en el

panel, y sostenga el instrumento mediante

los. Para montaje sobre caño, ordene el

adaptador A-610 apto para caños de 32 a 50

mm de diám.

INSTALACIÓN

5. Puesta a Cero Después de

Instalar

Deje las conexiones de presión abiertas a

atmósfera y ajuste a cero desde tornillo del

panel frontal.

Operacion

Presión Positiva: Conecte la tubería desde

la fuente de presión a cualquiera de las dos

conexiones de alta presión (HIGH), bloqueando la no usada; Las conexiones de baja

(LOW) presión pueden dejarse uno o los dos

abiertos a la atmósfera.

Presión Negativa: Repita el procedimiento

anterior, conectado en este caso las conexiones de baja presión (LOW). Deje las otras

conexiones abiertas.

Presión diferencial: Conecte el tubo correspondiente a la presión más positiva al

cualquiera de los conectores de alta presión

(HIGH) bloqueando el no usado, y la más

baja presión o presión negativa (vacío) al

conector de baja presión (LOW). Puede usarse cualquier conector de cada par, dejando

siempre uno bloqueado. Si se deja una

conexión abierta a la atmósfera, se recomienda el uso de un filtro tipo A-331 en el

lugar correspondiente para mantener limpio

el interior del instrumento. Para uso

portable, o instalación temporaria, uso adaptadores para rosca de tubo de 1/8⬙ a tubo

flexible, y conecte a proceso mediante una

tubería de goma o Tygon, o equivalente.

Para instalación permanente, se recomienda

el uso de tubo de cobre o aluminio de por lo

menos 1/4⬙ de diám. exterior. Vea el boletín

S-101 para accesorios.

Page 6

No se requiere mantenimiento específico

alguno, ni lubricación. Periódicamente, desconecte el instrumento, ventee la presión

acumulada, y reajuste el cero. Para instalaciones permanentes, se debe usar un juego

de válvulas de montaje permanente para el

venteo (vea Bol. S-101).

Verificación de Calibración: Desconecte el

instrumento de proceso, ventee a atmósfera

y deje escurrir condensados. Utilice un

manómetro de calidad y exactitud conocidas, y de rango adecuado. Conecte ambos

instrumentos en paralelo mediante una T de

conexión, y aplique presión lentamente para

igualar presiones y eliminar condensados si

los hubiera. Compare las lecturas. En caso

de discrepancias, el instrumento deberá ser

recalibrado en fábrica. Para calibración en

campo, siga el siguiente procedimiento.

1. Sujete firmemente la caja del instrumento, y afloje mediante una llave

adecuada el anillo de retención de la

máscara del mismo. Preste atención de

no dañar las partes del mismo.

2. Remueva el frente de plástico y el “O”

ring de sello.

3. Desmonte los tornillos de la escala, y la

escala con cuidado de no dañar la aguja

indicadora.

4. La calibración se efectúa moviendo la

traba luego de aflojarla. El movimiento

de la misma hacia el helicoide corrige

la indicación en exceso y viceversa.

Reapriete a traba e instale nuevamente la

escala.

5. Rearme el instrumento a su condición

original. Preste atención a que el eje

hexagonal interno (de ajuste a cero) esté

posicionado correctamente frente al

tornillo de puesta a cero.

6. Coloque la cubierta en posición y apriete

hasta fijar. La cubierta sella la cámara de

presión del instrumento, por lo que en

funcionamiento puede haber pérdidas de

no ser adecuadamente colocada.

7. Ajuste a cero y verifique la calibración.

Repita el procedimiento según sea necesario.

MANTENIMIENTO

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361 U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Lit-by-Fax: 888/891-4963

Atención: Si el anillo de retención se traba

al recolocar, lubrique ligeramente con aceite

liviano o compuesto de disulfuro de molibdeno.

Cuidado! : La recalibración en campo

puede invalidar la garantía. No se recomienda la recalibracion por parte del

usuario. En caso necesario envie el instrumento con transporte pago a:

Dwyer Instruments, Inc.

Attn: Repair Department

102 Indiana Highway 212

Michigan City, IN 46360

Localización De Fallas

• El instrumento no indica, o es lento en

reacción.

1. Conexión duplicada abierta.

2. Diafragma roto por sobrepresión.

3. Tubería de conexión perforada, con pérdidas o pinchazos.

4. Anillo de retención flojo, u “O “ ring dañado.

5. Conexión a proceso indebida o inadecuada.

6. Temperatura muy baja. Para este caso

ordene tipos LT (baja temperatura).

• Aguja indicadora fija; Puesta a cero im-

posible.

1. La escala esta en contacto con la aguja.

2. El conjunto imán/resorte están en contacto.

3. Hay partículas metálicas adheridas al

imán y bloquean la helicoide.

4. Eje de ajuste a cero de la cubierta roto, o

montado en forma incorrecta.

Se recomienda en general abstenerse de

efectuar la recalibración o reparación en

campo, y en cambio enviar el instrumento a

fábrica para su reparación. Las partes usadas

en cada subconjunto varían de acuerdo al

modelo y rango, por lo que es factible el uso

incorrecto de partes que darán lugar a resultados erróneos, o fallas inesperadas.

Los instrumentos enviados a fábrica son

reparados a nuevo, y nos complacerá enviar

un presupuesto de la reparación antes de la

misma, previa la inspección del material

remitido.

Consulte a fábrica para aplicaciones inusuales

o especiales. Utilice estos manómetros solamente con aire o gases compatibles.

Loading...

Loading...