Page 1

Bulletin E-90-LPI

(

)

Series LPI Loop Powered Indicator

Specifications - Installation and Operating Instructions

SWITCH

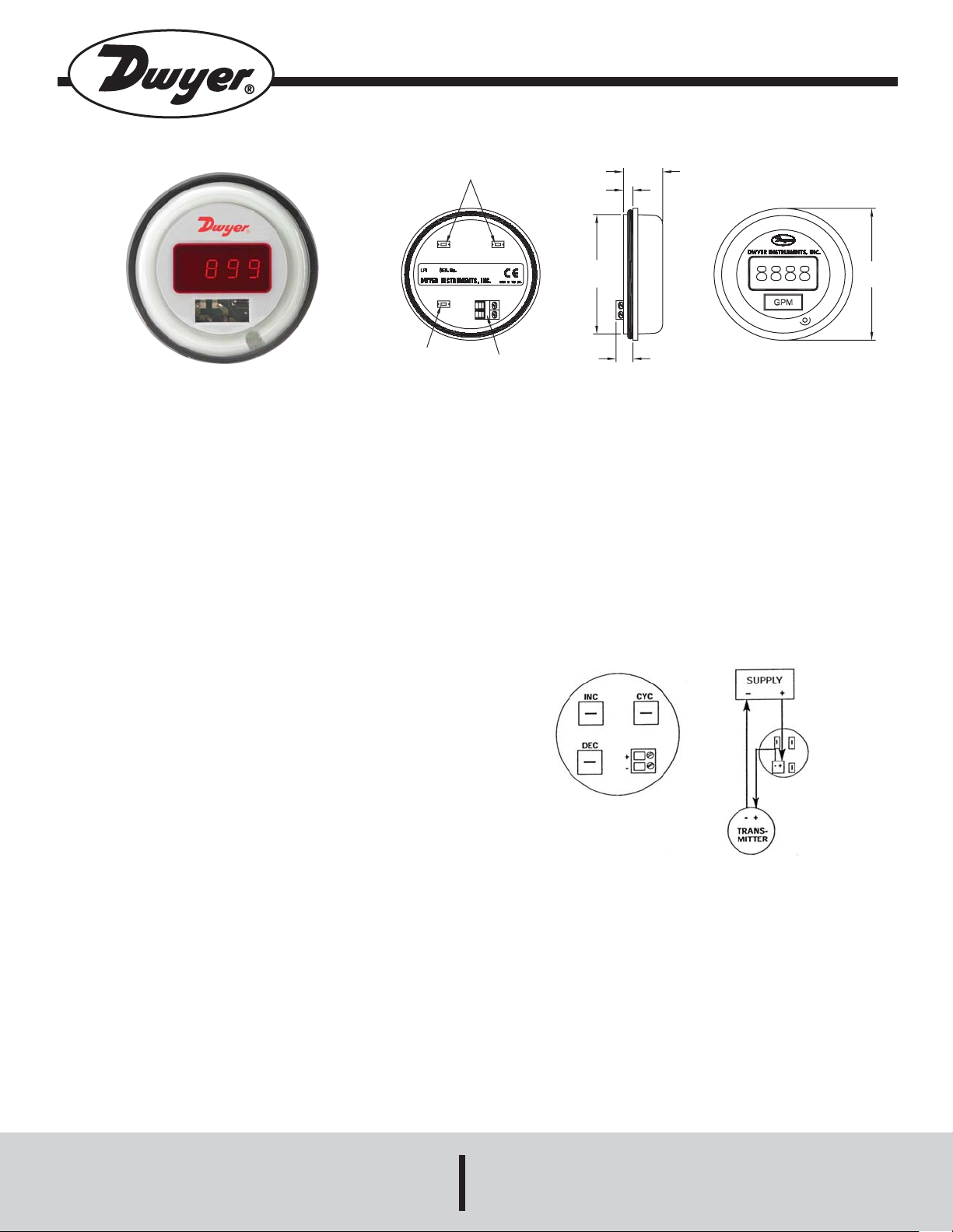

The Series LPI is a loop powered indicator with a 4-digit red

LED display. The Series LPI accepts a 4-20 mA input signal and

displays the associated process variable. The instrument configuration settings are selectable via a simple to use menu system,

which is navigated by the use of three push-button keys located

on the rear of the display. The entire assembly is sealed into a cap

that fits directly onto the connecting heads.

Please inspect the packaging and instrument thoroughly for any

signs of transit damage. If the instrument has been damaged,

please notify your supplier immediately.

INSTALLATION

The maximum current rating for this device is 100 mA for 1

minute. Exceeding this value will destroy the device. Fuse protection of the current loop to which this device is connected is highly recommended.

This unit must only be series connected to 4 to 20 mA current

loop. This device will be destroyed if connected directly across

any supply with a current output greater than 100 mA.

Ensure the instrument is installed with adequate protection

against the environment. IP67 rating must be maintained.

Try to avoid installing the equipment close to sources of extreme

temperature and electrical or electromagnetic interference.

SWITCHES

TERMINAL

(13/16)

(13/64)

(Ø2-5/8)

(Ø66.7)

(20.7)

(5)

(Ø2-7/8)

(Ø73)

(23/64)

8.9

SPECIFICATION @ 68°F (20°C)

Input: 4 to 20 mA.

Maximum Input Current: 100 mA for 1 minute.

Accuracy: ±0.02% of full scale.

Stability: Zero: 0.002%/°C; Span: 100 ppm/°C.

Power Requirements: 2-wire 4-20 mA loop powered.

Display: 4-digit, 7.6 mm (high) red LED.

Maximum Display Range: -1999 to 9999.

Ambient Operating Temperature: -4 to 167°F (-20 to 75°C).

Storage Temperatures: -58 to 185°F (-50 to 85°C).

Weight: 6.0 oz (170 g).

Front Panel Protection: NEMA 4X (IP65).

Agency Approvals: CE.

Wiring and switch location (viewed looking at connector)

LPI Typical Wiring

LPI

Configuration - Connect the device to a 4 to 20 mA loop, set at

any value between 4 and 20 mA. To configure the device follow

the simple configuration menus printed on the reverse side of this

sheet. Fit the correct units legend to the front panel face.

Enclosure - All external cabling/sensor entries must maintain

IP67 rating.

CONFIGURATION MENU

The prime function of the Series LPI device is to sink a 4-20 mA

current input and display the associated process variable (PV) in

appropriate engineering units.

The section below describes the menus accessible on the LPI. By

accessing these menus, the user can modify the instrument configuration in many ways. The following section refers to the configuration menu to describe how to configure the input scaling.

The instrument needs to know at least 2 co-ordinate pars to define

the relationship between mA input and display PV. The default

method is to have SCAL (scaling) set to StNd (standard). This allows

the user to edit the ENLO (engineering low) and ENHI (engineering

high) PV values that correspond to 4 mA and 20 mA input values,

respectively. The default values for ENLO and ENHI are 0 & 100,

respectively, giving a linear display range of 0-100 for 4-20 mA

input.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

Alternatively, the user may not know the exact PV values at 4 & 20

mA. You can choose AUtO scaling to solve this problem. This allows

the user to edit ENLO and ENHI PV values that correspond to LO mA

and HI mA input values, respectively. When the user accesses the

SCLO (scale low) menu entry, the display flashes IPLO (input low) to

prompt the user to apply the LO mA value. Once the correct input

signal is present and stable, the user should press ENT to store.

The user is then prompted to apply the HI mA value (in SCHI/IPHI).

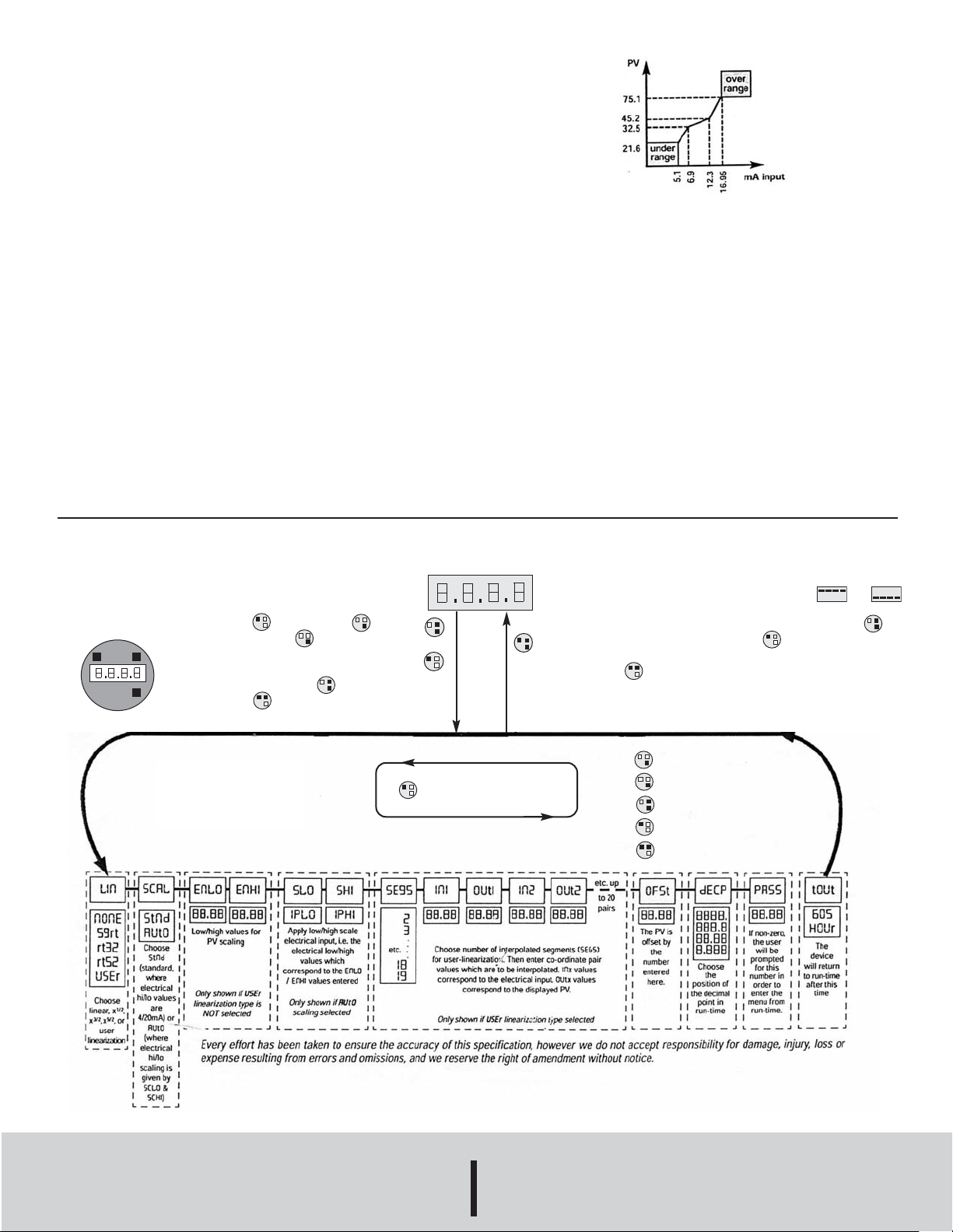

The user can choose LIN (linearization type) to NONE, 59rt, rt32, rt52

or USEr.

• NONE is the default, and sets a straight linear relationship

between mA input and PV. The input will go under/over-range

at 3.8/21.5 mA.

• 59rt (square root), rt32 (root 3/2) and rt52 (root 5/2) set a X1/2,

X3/2, or X5/2 relationship, intended for flow applications where,

for example, the flow is proportional to the square root of level.

The input will go under/over-range at 3.8/21.5 mA.

• USEr allows user-defined linearization using up to 20 co-ordinate

pairs. For example, if the user wanted to apply a 3-segment set

of interpolated co-ordinate points as shown below, you would

select LIN = USEr, then set StGS = 3. The user would then set the

mA interpolation points as IN1, IN2, IN3, IN4 = 5.1, 6.9, 12.3, 16.95.

The corresponding PV interpolation points would be set as OUt1,

OUt2, OUt3, OUt4 - 21.6, 32.5, 42.5, 75.1. The input would then

go under/over-range at 5.1/16.95 mA.

Once the input has been scaled using any of these methods, the

user can choose to apply a constant offset to the PV, using the

OFSt setting. The user can also select the display resolution using

the dECP setting. A menu access passcode can be set using the

PASS setting. The menu timeout period can be changed using the

tOUt setting.

MAINTENANCE

Apart from configuration this equipment requires no maintenance.

If recalibration is required please contact your supplier for further

information. Any cleaning of the instrument should be carried out

using a mild detergent and a soft cloth. No solvents or abrasive

cleaner should be used.

The Series LPI Loop Powered Indicator is not field serviceable and

should be returned if repair is needed (field repair should not be

attempted and may void warranty). Be sure to include a brief

description of the problem plus any relevant application notes.

Contact customer service to receive a return goods authorization

number before shipping.

SERIES LPI CONFIGURATION MENU GUIDE

There are three buttons, which the operator must

press in various combinations in order to configure

the device. These buttons are located on the underside of the indicator’s circuit board. Viewed from the

front, the three buttons (CYCle , INCrement

CYC

and DECrement ) are

INC

shown in the diagram to the left.

Pressing 2 buttons simultaneously causes ENTer or

DEC

ESCape actions.

When cycling around menu,

the title (e.g. LIN, SCAL, etc.) is

displayed for a second, then

the menu entry is displayed

ready for editing.

Run-Time

then

CYCle around menu

If no buttons are pressed for a minute or more, the

device assumes run-time mode. The display shows

the PV (if the input is in range) or shows or

to indicate over/under range. In order to access menu

configuration mode, the user must press ENTer

followed immediately by CYCle . In order to exit

the menu and return to run-time, a user must press

ESCape .

INCrement menu entry

DECrement menu entry

ENTer to confirm entry, or:

CYCle to next menu entry

ESCape

©Copyright 2005 Dwyer Instruments, Inc. Printed in U.S.A. 8/05

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...