INSTRUCTIONS FOR THE

LCR10 TEN INCH

CIRCULAR CHART RECORDER

LOVE CONTROLS

LOVE

®

April, 2003 Page 1 of 20 LCR10 IOM

a Division of Dwyer Instruments, Incorporated

Contents

Chapter 1 Overview

1-1 General ......................................................................................3

1-2 Model Identifi cation....................................................................3

Chapter 2 Installation

2-1 Unpacking..................................................................................4

2-2 Mounting ....................................................................................4

2-3 Case Location............................................................................5

2-4 Wiring Precautions.....................................................................6

2-5 Power Wiring..............................................................................7

2-6 Sensor Installation Guidelines ...................................................8

2-7 Thermocouple Input Wiring........................................................9

2-8 RTD Input Wiring .....................................................................10

2-9 Linear DC Input Wiring.............................................................10

2-10 Alarm Relay Wiring ................................................................10

2-11 Changing the Chart ...............................................................11

2-12 Marking Systems ...................................................................11

2-13 Replacement of Pen ..............................................................12

2-14 Battery Backup ......................................................................13

Chapter 3 Programming

3-1 Recorder Setup........................................................................14

3-2 Alarm Settings .........................................................................15

Chapter 4 Calibration

.......................................................................................................16

Chapter 5 Specifi cations

.......................................................................................................18

Chapter 6 Dimensions

.......................................................................................................19

Chapter 7 Green LED Troubleshooting Guide

.......................................................................................................20

LCR10 IOM Page 2 of 20 April, 2003

Chapter 1 Overview

1-1 General

The LCR10 is a microprocessor based 10 inch circular chart recorder.

Programmable alarm options combined with “ease of setup” provide the

fl exibility required for a multitude of recording applications.

The Ink style LCR10 is the fi rst recorder with “self documenting”

confi guration during initial setup. It can operate using standard or

competitive charts. The battery backup feature provides up to 48 hours of

recording in the event of a power loss, providing an additional degree of

protection for customer processes.

A unique setup template provides the user with an “on the spot” manual.

This setup template will also self document the current setup for quick

review by an operator.

These units are powered by a fi eld selectable 110/220VAC 50/60Hz.

supply. A 9 Volt battery allows for operation for up to 48 hours if the main

power supply fails. Standard inputs are programmable for thermocouple

types J, K, T, R, B and S as well as 4-20mA or 0-5 VDC.

Optional alarm relay is available and programmable for low, hi, or band in

latching or non-latching operation.

High accuracy, maximum fl exibility, fast response and a simple interface

are the main benefi ts of the LCR10 recorder.

1-2 Model Identifi cation

LCR10 -

Rotation:

1 = Counterclockwise

2 = Clockwise

Outputs:

0 = None

1 = 1 Relay

April, 2003 Page 3 of 20 LCR10 IOM

Enclosure:

1 = Standard

2 = NEMA 4X

3 = Platen Mount

Chapter 2 Installation

Dangerous voltages capable of causing serious injury or death

are sometimes present in this instrument.

Before installation or beginning any troubleshooting procedures,

the power to all equipment must be switched off and isolated.

More than one power disconnect may be required.

Units suspected of being faulty must be disconnected and

removed to a properly equipped workshop for testing and repair.

Component replacement and internal adjustments must be made

by a qualifi ed maintenance personnel only.

To minimize the possibility of fi re or shock hazards, do not expose

this instrument to rain or excessive moisture.

Do not use this instrument in areas under hazardous conditions

such as excessive shock, vibration, dirt, moisture, corrosive

gases or oil. The ambient temperature of the areas should not

exceed the maximum rating specifi ed in Chapter 5.

2 - 1 Unpacking

Upon receipt of the shipment remove the unit from the carton and inspect

the unit for shipping damage.

If any damage due to transit , report and claim with the carrier. Write down

the model number, serial number, and date code for future reference when

corresponding with our service center. The serial number (S/N) and date

code (D/C) are labeled on the box and the platen of the unit. Make sure

that all items are accounted for:

1: Battery (for battery backup)

2: Installation manual

2 - 2 Case Location

Upon unpacking, fi nd a suitable location to mount the recorder before

wiring power to the unit.

Select a location that is well lighted, free form dust, dirt, or corrosive

fumes. The recorder should not be located near any sources of heat or

be subjected to sudden or extreme temperature changes. It should be

mounted on a rigid support that is not subject to vibration.

LCR10 IOM Page 4 of 20 April, 2003

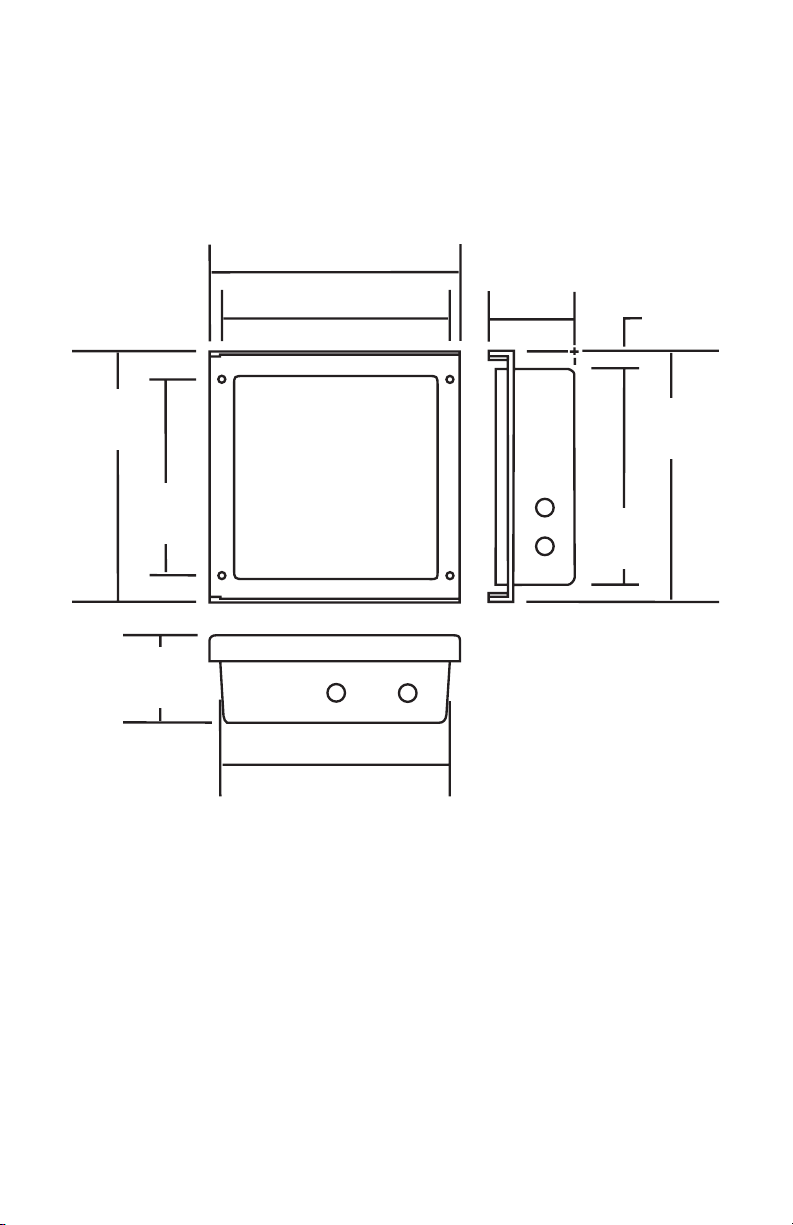

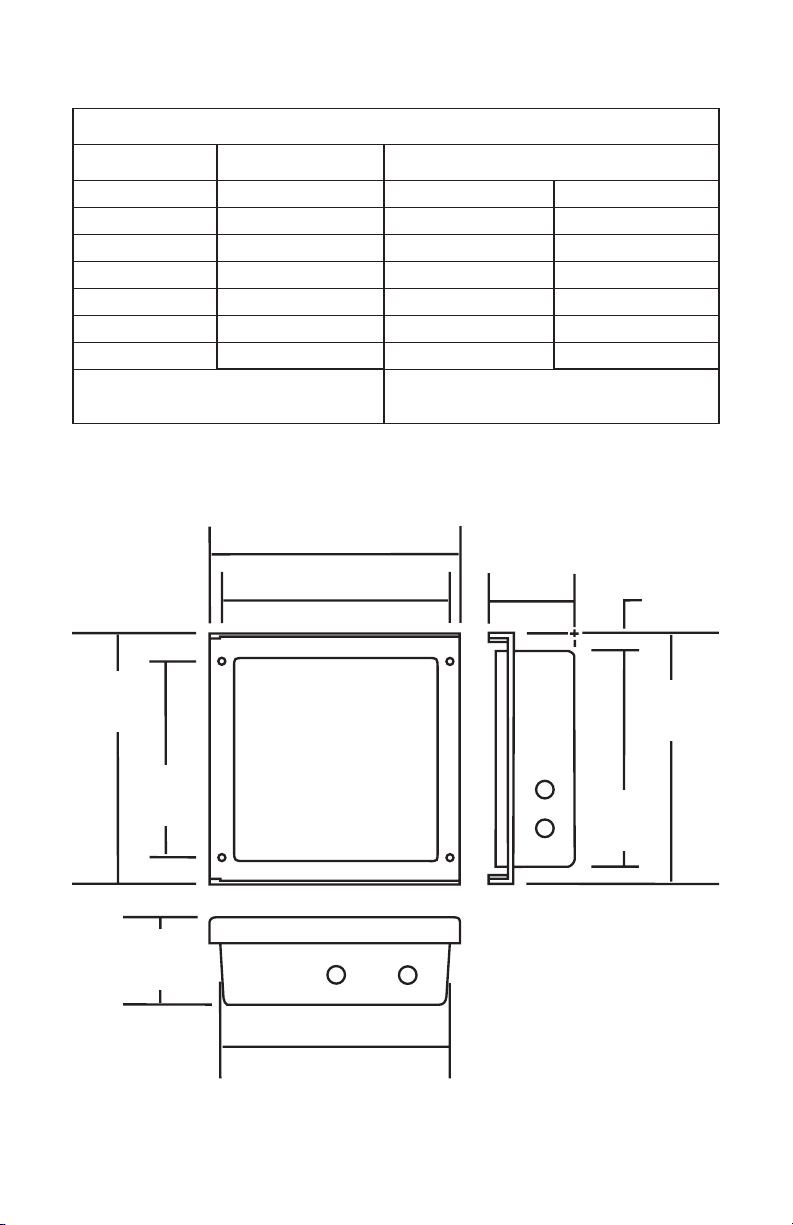

2-3 Mounting

Make panel cutout to dimension shown in Figure 2-1.

Install both mounting clamps and insert the case into the panel cut out.

Dimensions are in millimeters (inches).

355.60

(14.000)

334.95

(13.187)

90.07

(3.546)

17.45

(0.687)

355.60

(14.000)

302.41

(11.906)

90.07

(3.546)

355.60

(14.000)

320.68

(12.625)

320.68

(12.625)

Figure 2-1

April, 2003 Page 5 of 20 LCR10 IOM

2-4 Wiring Precautions

Before wiring, verify the label for correct model number and options.

Switch off the power when checking.

Care must be taken to ensure that maximum voltage rating specifi ed

on the label are not exceeded.

It is recommended that power of these units to be protected by fuses

or circuit breakers rated at the minimum value possible.

All units should be installed inside a suitably grounded metal

enclosure to prevent live parts being accessible from human hands

and metal tools.

All wiring must conform to appropriate standards of good practice and

local codes and regulations. Wiring must be suitable for maximum

voltage, current, and temperature rating of the system.

Take care not to over-tighten the terminal screws.

Unused control terminals should not be used as jumper points as

they may be internally connected, causing damage to the unit.

Verify that the ratings of the output devices and the inputs as specifi ed

in Chapter 5 are not exceeded.

Electric power in industrial environments contains a certain amount of

noise in the form of transient voltage and spikes. This electrical noise

can enter and adversely affect the operation of microprocessor-based

controls. For this reason we strongly recommend the use of shielded

thermocouple extension wire which connects the sensor to the unit. This

wire is a twisted-pair construction with foil wrap and drain wire. The drain

wire is to be attached to earth ground at the sensor end only.

LCR10 IOM Page 6 of 20 April, 2003

2-5 Power Wiring

The unit is supplied to operate at 110/220VAC 50/60Hz. Check that the

installation voltage corresponds with the power rating indicated on the

product label before connecting power to the unit.

The recorder uses AC power when it is operating normally. The battery

backup option will allow the recorder to operate for approximately 48 hours

in case of a power loss.

In order to connect the recorder to the main AC power, you must fi rst gain

access to the microprocessor PC board that is mounted to the back of the

chart plate. Your recorder will have a hinged chart plate held in place by

two (2) screws located on the right hand side of the chart plate. Remove

these two screws and open the hinged chart plate. If you are not sure how

to access the back of the chart plate. See Figure 2-5 (pg. 13) for screw

location.

AC Input Terminals

T1

T2

T3

T4

110 VAC Wiring

L1

L2

T1

T2

T3

T4

220 VAC Wiring

L1

L2

NOTE: Connect Earth Ground to

terminal on rear of chart plate

near power transformer.

Figure 2-2

The AC power connections are made to terminal block location on the

back side of the chart plate of the recorder. Refer to Figure 2-2 for proper

connection to the main AC power.

This equipment is designed for installation in an enclosure

which provides adequate protection against electric shock. The

enclosure must be connected to earth ground.

Local requirements regarding electrical installation should be rigidly

observed. Consideration should be given to prevent unauthorized or

accidental access to the power terminals.

April, 2003 Page 7 of 20 LCR10 IOM

2-6 Sensor Installation Guidelines

Proper sensor installation can eliminate many problems in a control

system. The probe should be placed so that it can detect any temperature

change with minimal thermal lag. In a process that requires fairly constant

heat output, the probe should be placed close to the heater. In a process

where the heat demand is variable, the probe should be close to the work

area. Some experiments with probe location are often required to fi nd this

optimum position.

Proper sensor type is also a very important factor to obtain precise

measurements. The sensor must have the correct temperature range to

meet the process requirements. In special processes the sensor might

need to have different requirements such as leak-proof, anti-vibration,

antiseptic, etc.

Standard thermocouple sensor limits of error are 2 degrees C (4 degrees

F) or 0.75% of sensed temperature (half that for special limits of error) plus

drift caused by improper protection or an over-temperature occurrence.

This error is far greater than recorder error and cannot be corrected at the

sensor except by proper selection and replacement.

In order to connect the probe input device to the recorder, you must fi rst

gain access to the microprocessor PC board that is mounted to the back

of the chart plate.

CAUTION! DO NOT TOUCH the terminals of the transformer

while the recorder is connected to the main AC power supply.

To avoid the risk of possible electric shock, unplug or disconnect

the recorder from the main power supply before attempting to

open the recorder. Also, disconnect the 9 Volt battery to avoid

damaging the recorder and draining the battery.

The recorder has a hinged chart plate held in place by two (2) screws

located on the right hand side of the chart plate. Remove these two

screws and open the hinged chart plate. See Figure 2-5 (pg. 13) for screw

location.

LCR10 IOM Page 8 of 20 April, 2003

Note: Internal circuitry shown at

right of terminations, external

to the left.

Optional

Relay

Connections

RTD

Relay 1

Relay 2

1

J3

1

J2

J1

1

2

3

Voltage/

Current

4

T/C

1

J3

1

1

2

3

4

2

3

1

J2

J1

1

J3

J3

1

P1

P2

Relay

Optional

J5

(Connected to

power input)

4

Figure 2-3 Input/Relay wiring - PCB layout

2-7 Thermocouple Input Wiring

Thermocouple input connections are shown in Figure 2-3. The correct type

of thermocouple extension lead-wire or compensating cable must be used

for the entire distance between the unit and the thermocouple, ensuring

that the correct polarity is observed throughout. Splices in the cable should

be avoided, if possible.

If the length of thermocouple plus the extension wire is too long, it may

affect the temperature measurement. A 400 ohms K type or a 500 ohms

J type thermocouple lead resistance will produce approximately 1 degree

C temperature error.

April, 2003 Page 9 of 20 LCR10 IOM

2-8 RTD Input Wiring

Two-wire RTD’s should be used in short lead lengths, if possible, for the

purpose of accuracy. A 0.4 ohm lead resistance of a two-wire RTD will

produce 1 degree C temperature error. RTD connection are shown in

Figure 2-4, with the compensating lead connected to terminal 4. For twowire RTD inputs, terminals 2 and 4 should be linked. The three-wire RTD

offers the capability of lead resistance compensation provided that the

three leads are of same gauge and equal length.

2-9 Linear DC Input Wiring

DC linear voltage and linear current connections are also shown in Figure

2-5. Terminal 2 = negative. Terminal 3 = positive.

2-10 Alarm Relay Connections

If your recorder has the optional relay contacts installed, then terminal

blocks J1 and J2 have been provided for connection to the relay on the

microprocessor PC board of the recorder. Refer to Figure 2-4 (page 9) for

the location of J1 and J2 on the microprocessor PC board.

CAUTION! DO NOT TOUCH the terminals of the transformer

while the recorder is connected to the main AC power supply.

To avoid the risk of possible electric shock, unplug or disconnect

the recorder from the main power supply before attempting to

access the terminals of the relay. If the recorder is installed with

the battery back-up option, disconnect the 9 Volt battery to avoid

damaging the recorder and draining the battery.

The recorder has a hinged chart plate held in place by two (2) screws

located on the right hand side of the chart plate. Remove these two

screws and open the hinged chart plate. See Figure 2-5 (pg. 13) for screw

location.

The relay is rated for the following maximum Values:

2.0 AMPS at 25VDC, 1.0 AMP at 120VAC

Warning: Damage to the recorder may result if the ratings for the

relay is exceeded.

LCR10 IOM Page 10 of 20 April, 2003

2-11 Changing the Chart

Press and releasethe CHANGE CHART button (#3), Figure 3-1 (pg. 14).

The pen will move to the left of the chart and the LED begins blinking

rapidly. Unscrew (counterclockwise) the chart “hub” knob at the center of

the chart. Remove the old chart paper and position the new one so that

the correct time line coincides with the time line groove on the left side of

the chart plate.

Refer to Figure 2-5 (pg. 13) for the location of the time line groove.

Re-attach the chart “hub” knob and screw securely (by hand) against the

chart. Press and release the CHANGE CHART button (#3). The pen will

move to the outer ring and then pause. The LED remains on. If the unit

is equipped with alarm(s) or the alarm(s) are enabled, the pen will them

move to the current alarm setpoint settings. For mor information on setting

the alarms, see Section 3.2 (pg. 15).

If the unit is not equipped with alarm(s) or the alarm(s) are disabled, the

pen will move to the current input value. Check to make sure that the pen

is marking on the chart paper. If it is not, then carefully adjust the pen arm

to establish contact with the paper.

2-12 Chart Pens

The chart pen consists of a self contained ink reservoir with a porous

plastic stylus which is fastened around the outer edge of the metal pen

arm.

A pen cap is provided to extend the life of the ink pen during shipping or

when the recorder is not in service. To remove the pen cap, gently lift the

pen arm away from the chart paper. Remove the black plastic pen cap to

expose the fi ber tip of the ink pen and gently place the pen back onto the

chart paper. Do not let the pen arm “snap” back onto the chart paper. This

will fl atten the fi ber tip of the pen and will no longer give you a fi ne line

marking on the chart paper. Place the pen cap in a safe place for future

use.

If the stylus does not touch the chart, adjustment can be made by slightly

bending the metal pen arm in the center towards the chart paper. Do

not use more pressure than is necessary to create a fi ne line marking on

the chart paper. Note: As the pen ink supply runs out, the pen color will

become lighter. This indicates that the pen should be replaced.

April, 2003 Page 11 of 20 LCR10 IOM

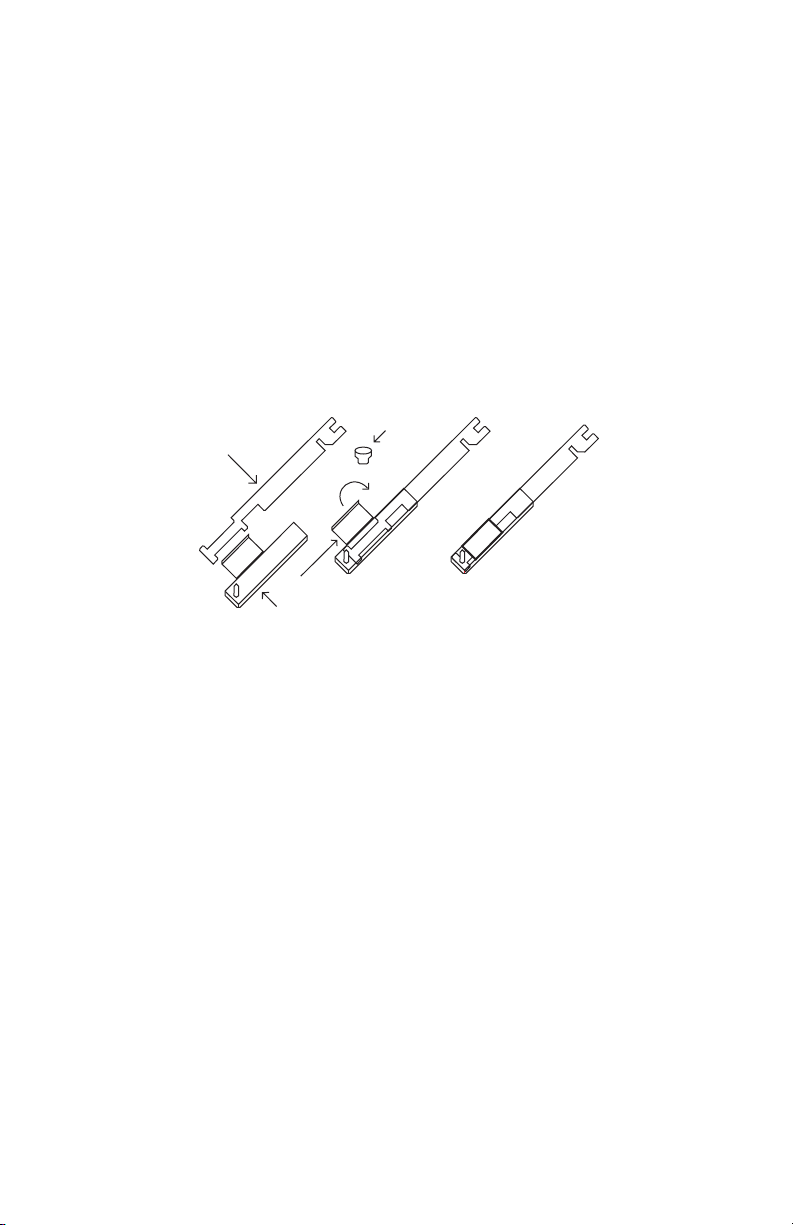

2-13 Pen Installation / Replacement

g

Recorders that are equipped with fi ber tipped cartridge pens will have a

cartridge that is color coded “red”.

The pen cartridge is securely fastened to the metal pen arm using a

special “U” clip tab.

For ease of replacement, it is suggested that the two (2) screws that hold

the pen arm be loosened and the pen cartridge and metal pen arm be

removed as an assembly. Refer to Figure 2-5, pg.13, for the location of the

pen arm screws. Unsnap the plastic “U” clip tab of the pen cartridge from

the metal pen arm, remove and discard the old pen cartridge. Replace the

new cartridge by opening the hinge and snapping it securely around the

metal pen arm. Refer to the Figure 2-4 .

Pen Cap

Pen Arm

"U" Clip Tab

Pen Cartrid

Figure 2-4 Pen Installation / Replacement

e

LCR10 IOM Page 12 of 20 April, 2003

2-14 Battery Backup

Having the 9 volt DC battery back-up in place, will allow the recorder to

continue to function normally for approximately 48 hours in the event of a

power failure.

The battery strap and battery holder are located on the front of the chart

plate (refer to Figure 2-5). In order to change the battery, you must open

the recorder case door. Note: Use only NEW 9 volt alkaline replacement

batteries.

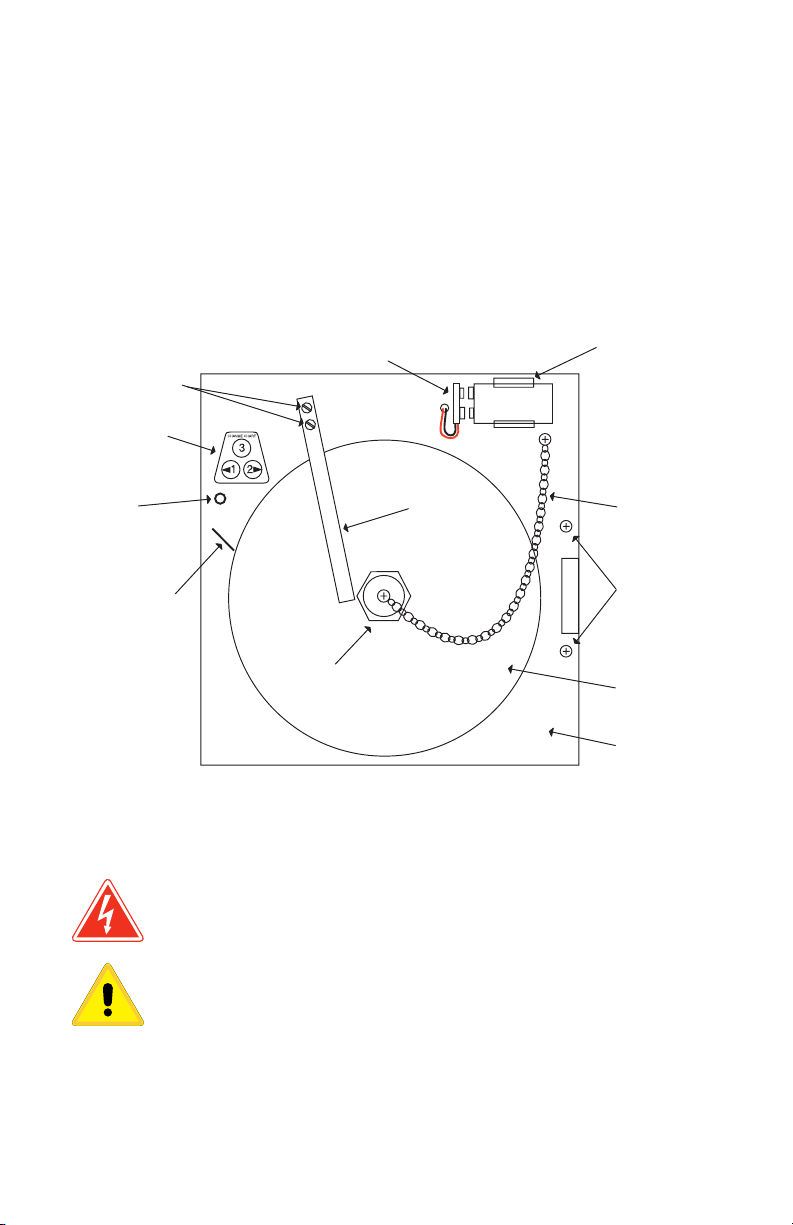

PEN ARM

SCREWS

KEYPAD

INDICATOR

LAMP

TIME LINE

GROOVE

Figure 2-5 Recorder Platen Layout/Battery Installation

CAUTION! DO NOT TOUCH the terminals of the transformer

while the recorder is connected to the main AC power supply.

To avoid the risk of possible electric shock, unplug or disconnect

the recorder from the main power supply before attempting to

access the terminals of the relay. If the recorder is installed with

the battery back-up option, disconnect the 9 Volt battery to avoid

damaging the recorder and draining the battery.

CHART

'HUB'

KNOB

BATTERY

CONNECTOR

9 VOLT

BATTERY

PEN ARM

BATTERY

HOLDER

CHART

'HUB'

CHAIN

CHART

PLATE

SCREWS

CHART

PAPER

CHART

PLATE

April, 2003 Page 13 of 20 LCR10 IOM

Chapter 3 Programming

3-1 Recorder Setup

In order to confi gure the recorder, you will need the recorder SET-UP

CHART, P/N R18-270 for CCW rotation or P/N R18-272 for CW rotation.

This chart contains the confi guration categories for the recorder (Probe

Input, Inner Chart Values, Outer Chart Values, Scale Units, Chart Rotation

Speed, Input Averaging and Relay Opotions).

1. Place the SETUP CHART on the recorder.

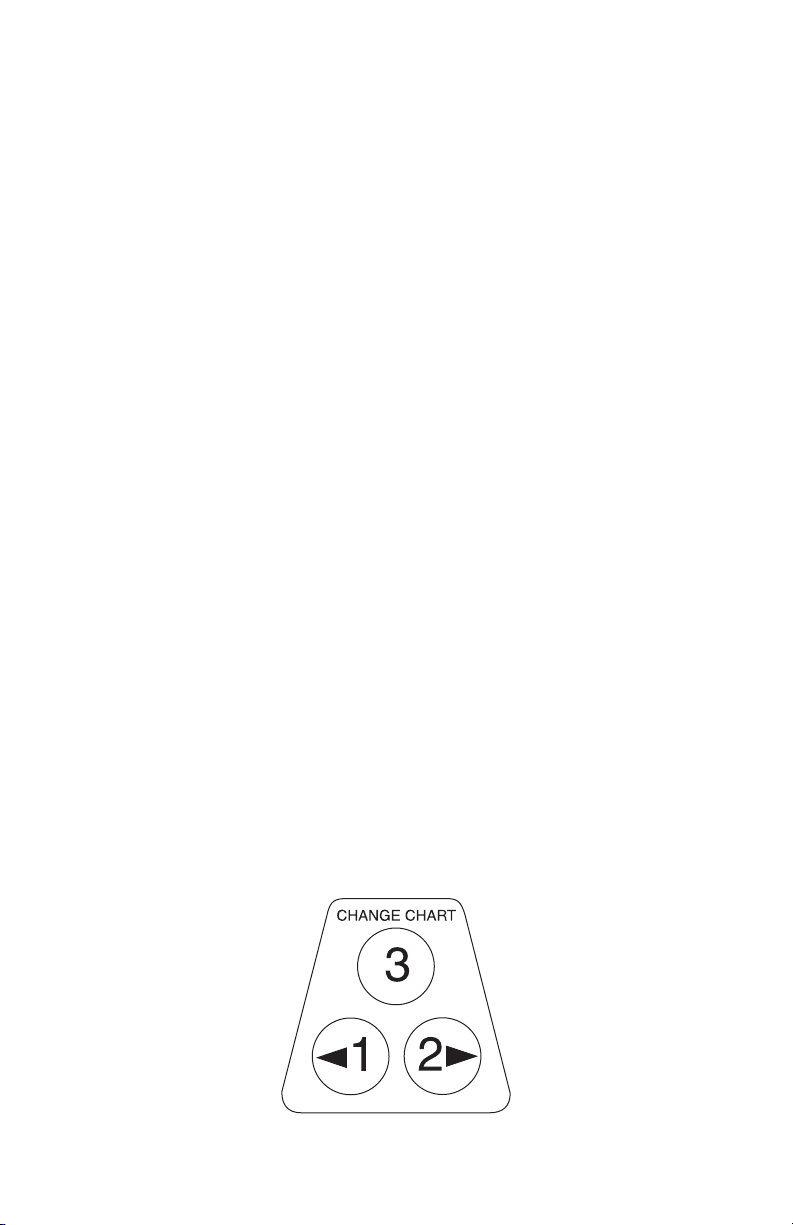

2. Press and release the CHANGE CHART key (3).

3. Wait until pen moves above scale and green LED stops fl ashing.

4. Press and hold the LEFT arrow key (1) until the LED goes off, then

release.

5. The Pen will move to the outer ring of the chart. Wait for the LED to

fl ash slowly. (.8 sec on / .8 sec off). The LED will continue to fl ash

slowly during setup.

6. Loosen the Chart Knob and rotate the chart to position the RED pen

in the middle of the START CIRCLE.

7. Tighten the chart knob. Press and release the CHANGE CHART key (3).

The Pen will move to the PROBE INPUT column on the setup chart.

8. Using the LEFT (1) and RIGHT (2) keys, move the pen to the desired

selection.

9. Press and release the CHANGE CHART key (3) to store the

selection and advance to the next category.

10. Repeat selection process until all categories are programmed. You must

press and release the CHANGE CHART key (3) after the last category.

11. After all categories are selected, the pen will move off scale and the

LED will Stop fl ashing. (Steady on)

12. Remove the SETUP CHART and save. Install an actual recording chart.

13. Press and release CHANGE CHART key (3).

14. The LED will remain on steady, the pen will stop at the 100% ring,

then move to the Alarm Setpoint Values (if enabled). The LED will

turn off when the pen reaches the alarm

Setpoint. Use RIGHT/LEFT arrow keys

to adjust alarm value(s). The LED is on

steady when the pen is recording actual

values.

Press and release the CHANGE CHART (#3)

key to begin recording.

The SET-UP CHART should be saved for

future reference.

Figure 3-1 Keyboard

Layout

LCR10 IOM Page 14 of 20 April, 2003

3-2 Alarm Settings

Alarm setpoint values are selected by positioning the pen to the actual value on

the recording chart. Alarm settings can be changed or viewed after a CHART

CHANGE, recorder setup, or during initial power up. To set the alarm setpoint

during normal recording operation, complete the following steps.

Press and release the CHANGE CHART key ( 3 on Figure 3-1). Wait until the

pen moves off scale AND the LED stops fl ashing quickly and goes to a steady

on. Press and release the CHANGE CHART key ( 3 ) again. The pen will begin

to move back onto the chart briefl y stopping at (or close to) the outermost

graduation of the chart. The Green LED remains on steady during this time.

Single Alarm Setting

When the above operation is complete, the pen will move to the current alarm

setpoint position on the chart. The green LED will go out, during this time the

alarm setpoint can be adjusted using the LEFT arrow (1) or the RIGHT arrow (2)

keys on the keypad. Once the alarm setpoiont is set, wait for the green LED to

turn on. The pen will then move to indicate the input value and the unit will begin

normal recording operation.

Band Alarm Setting

When programming the recorder for operation, the pen will move fi rst to alarm

band 1 setpoint on the chart. The green LED will go out. The alarm band 1

setpoint can now be adjusted using the LEFT arrow (1) or the RIGHT arrow (2)

keys. Once set, wait for the green LED to turn on. The active pen will then move

to the second band alarm setpoint. The green LED will go out. The alarm band 2

setpoint can now be adjusted using the LEFT arrow (1) or the RIGHT arrow (2)

keys. When pen alarm setpoints adjustments are complete, wait for green LED to

turn on. The pen will then move to the current input value and recorder will begin

normal operation.

The “Change Chart” key is the “RESET” when the recorder is programmed

for latching alarm operation. Please note that the relay will only reset if alarm

condition has been cleared.

April, 2003 Page 15 of 20 LCR10 IOM

Chapter 4 Calibration

4-1 Pen Arm Calibration

Pen calibration is a two point calibration. To check and/or adjust the

recording pen(s) calibration to the inner and outer graduations of the

chart,

Perform the following.

1. Remove power to instrument and remove the battery.

2. With all power removed, press and hold the CHANGE CHART key

(3).

While holding the CHANGE CHART key(3), re-apply power. Release

key upon applying power, either AC or battery, which ever is

convenient.

3. The pen will move off scale, The LED will fl ash rapidly. The Green

LED will then go to steady on.

4. The red pen will then move to the 100% ring. Adjust pen using the

LEFT (1) and RIGHT (2) keys to position pen on the 100% ring, if

necessary, Then Wait.

5. The Red pen will then move to the 0% ring. Adjust the pen position

using the LEFT (1) and RIGHT (2) keys, if necessary, then wait.

6. The Red pen will then move full upscale.

8. Red pen calibration is now complete. If unit has alarms enabled pens

will now go to current alarm settings. See Section 3.2. Then to actual

recording value.

If no alarms are enabled pen will then go directly to actual recording

values and begin normal operation.

Each time the chart paper or fi ber tip pen cartridge is changed, you

should make sure that each pen stops at the inner and outer most

temperature graduations of the chart paper. Otherwise, this pen offset

can cause the unit to record an incorrect value on the chart.

Figure 4-1

LCR10 IOM Page 16 of 20 April, 2003

4-2 Probe Offset Adjustment (pen offset)

This recorder has been accurately calibrated at the factory. Before making any

adjustments, this instrument should be in service for 24 hours.

Thereafter, if any adjustment is required, perform the following procedure.

1. Place a Certifi ed Test indicator alongside the recorder’s sensor

probe in a monitored controlled condition.

2. Once the input has leveled out, compare the position of the pen

on the recorder to the reading on the test device.

3. If an adjustment is required, depress and hold either the LEFT (1) or

RIGHT (2) arrow key. The pen will begin to move after approximately

ten (10) seconds. Using the LEFT arrow (1) or RIGHT (2) arrow keys,

position the pen on the chart to correspond to the value of the test

device. Once the corrected value is obtained no further keystrokes are

required.

After the calibration check is complete, the recorder will return to normal

recording mode within 10 seconds.

April, 2003 Page 17 of 20 LCR10 IOM

Chapter 5 Specifi cations

Input:

Thermocouple: Type J, K, T, R, S, B.

RTD: 100 Ohm Platinum DIN Curve (0.00385 ohms per ohm per

degree C)

Process: 0 to 5 VDC, 250 Ohms impedance.

4 to 20 mA across 250 Ohms.

Cold Junction Accuracy: ±0.2°C @ 25°C ambient.

Cold Junction Error: ±0.2°C @ 25°C ambient.

Input Filtering: Programmable, 0, 2, 4, 8, 16, 32, 64, 128 seconds.

Recording:

Chart Size: 254 mm (10 inches)

Recording Accuracy: ±0.5% of span (100 division span)

Sensor Break: Full scale pen < 10 seconds.

Chart Speed: Programmable, 4, 8, 12, 24, 48, 72, 168 hour rotation

(168 hours = 7 days).

Output Relay: Form C (DPDT), 1A @ 240VAC Resistive.

Power:

Line Voltage: 110/220 VAC ±10%, 50~60 Hz.

Common Mode Rejection: >120db @ 60 Hz.

Normal Mode Rejection: 85dB @ 60 Hz.

Power Consumption: 15 VA maximum.

Backup Battery: 9 Volt alkaline (IEC 6LR61 or equivalent).

Operational and Physical:

Operating Temperature: 0 to 60°C (32 to 140°F)

Storage Temperature: -40 to 65°C (-40 to 150°F)

Humidity: 0 to 90% RH (non-condensing)

Vibration: 0.3 to 100 Hz @ 0.2g

Mounting: ±20 degrees of vertical, ±10 degrees of horizontal.

Dimensions: See drawing.

Panel Ratings: NEMA 12X standard, NEMA 4X optional

Moldings: Fire retardant Noryl w/ acrylic window.

Weight: 3.2 kg (7.0 pounds) maximum.

LCR10 IOM Page 18 of 20 April, 2003

Input Ranges

Input Signals

SENSOR TYPE RANGES

Thermocouple J -130 to 760°C -202 to 1400°F

Thermocouple K -130 to 1360°C -202 to 2498°F

Thermocouple T -200 to 400°C -328 to 752°F

Thermocouple R 0 to 1650°C 32 to 3002°F

Thermocouple S 0 to 1650°C 32 to 3002°F

Thermocouple B 100 to 1824°C 212 to 3315°F

RTD 100 Ohm Plt. DIN -210 to 440°C -346 to 824°F

DC Voltage: 0 to 5 VDC, linear.

DC Current: 4-20mA, linear.

0 to 100% of the chart span.

Chapter 6 Dimensions

Dimensions are in millimeters (inches).

355.60

(14.000)

334.95

(13.187)

90.07

(3.546)

17.45

(0.687)

355.60

(14.000)

355.60

(14.000)

302.41

(11.906)

320.68

(12.625)

90.07

(3.546)

320.68

(12.625)

April, 2003 Page 19 of 20 LCR10 IOM

7 - GREEN LED Troubleshooting Guide

7 - 1 LED LIGHT SEQUENCE GUIDE

1.) LED on steady and pen(s) within chart range, unit is recording

normally.

2.) LED on steady and pen(s) above 100% ring indicates unit is in

“CHART CHANGE” mode.

Action: Press and release “CHART CHANGE” key to return to normal

recording mode.

3.) LED fl ashing RAPIDLY and pen(s) within chart range indicates

battery voltage is low.

Action: Replace battery.

4.) LED fl ashing RAPIDLY and pen(s) at 0 or 100 % ring indicates that

input sensor(s) are in a break condition.

Action: Check or replace sensor, validate setup information for

sensor.

5.) LED fl ashing slowly (.8 sec.. On/ .8 sec. off) indicates the unit is in

setup mode.

Action: Complete setup procedure of recorder.

6.) LED not on indicates no power to unit.

Action: Check to see if AC present on power terminals. Check and /

or replace battery.

LCR10 IOM Page 20 of 20 April, 2003

Loading...

Loading...