Page 1

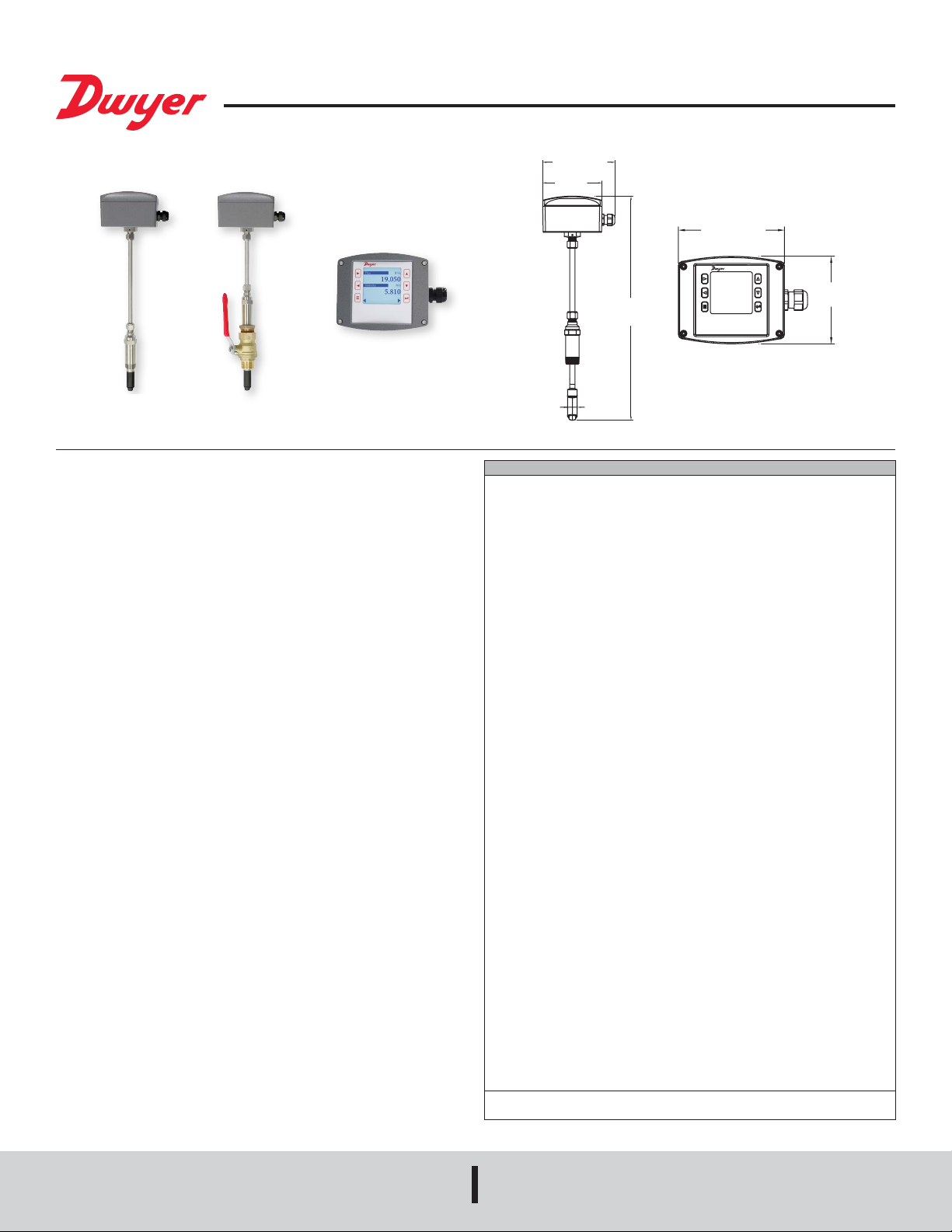

Series IEF Insertion Electromagnetic Flow Transmitter

5-53/64 [148.0]

61/64

[24.2]

22-1/64

7-3/32 [180.2]

®

Specications - Installation and Operating Instructions

5-53/64

[148.0]

[559.2]

-LCD option shown

Shown with A-IEF-VLV-BR

accessory valve

Bulletin F-IEF-F-1

4-51/64

[121.8]

The Series IEF Insertion Electromagnetic Flow Transmitter is an adjustable

insertion owmeter featuring electromagnetic technology that accurately and reliably

measures uid velocity in addition to providing several continuous signal outputs.

This series is specically designed to offer superior performance paired with simple

installation and use. One unit is adjustable to t pipe sizes from 4 to 36˝ (102 to

914 mm), and offers several output options including selectable BACnet MS/TP or

Modbus® RTU communications protocol over 2-wire RS-485 in addition to the standard

analog, frequency and alarm outputs.

FEATURES/BENEFITS

• Field congurable setup displays (-LCD integral option or remote accessory

A-IEF-DSP) allow for ultimate exibility by accommodating a variety of application

congurations with one model through multiple display congurations i.e. pipe

size, pipe material, liquid type, analog output, pulse/frequency output, alarm outputs,

communication outputs, damping, and calibration factor.

• High performance accuracy is maintained through changes in temperature, density

or viscosity.

• Setup Wizard and installation tool are simple to use allowing for quick and precise

installation.

• Accessory setup kit A-IEF-KIT ensures exact installation application depth with

included thickness gage and measuring tape.

• Long Life Cycle and minimal maintenance requirements with no moving parts to

wear or break and electrodes that discourage fouling.

• Isolation valve accessory options allow for installation in operational systems via

hot-tap kit or easy removal without system downtime.

• NIST calibration certicate included standard for Carbon Steel Schedule 40 pipes

sized 4˝ (102 mm), 6˝ (150 mm), 8˝ (200 mm), and 10˝ (250 mm) with high accuracy

option.

APPLICATIONS

• Boiler feed water

• Chilled water

• Open and closed loop condenser water

• Irrigation system

• Municipal water distribution

• Process and coolant ow

• Ground water remediation

• Chemical processing

• Pump protection

• Wastewater

• Mining

SPECIFICATIONS

Service: Compatible clean or dirty non coating, conductive liquids.

Range: 0 to 20 ft/s (0 to 6 m/s).*

Wetted Materials: Body shaft/tting: 316 SS; Electrodes: 316 SS; Electrode cap:

Polymer/Polystyrene; O-ring: Silicone.

Accuracy: IEF-HX-X: ±0.5% of reading at calibrated velocity; ±1% of reading from

2 to 20 ft/s (0.6 to 6 m/s) ±0.02 ft/s (±0.006 m/s) at < 2 ft/s (0.6 m/s). IEF-SX-X:

±1% FS.

Temperature Limits: Ambient: -20 to 160°F (-29 to 71°C); Process: 15 to 250°F (-9

to 121°C); Storage: -40 to 185°F (-40 to 85°C).

Process Connection: 1˝ NPT or BSPT with accessory full port ball valve options.

Pressure Limits: 400 psi (27.6 bar) @ 100º F (37.8°C).

Pressure Drop: < 0.1 psi at 12 ft/s in 4˝ (101.6 mm) and larger pipe.

Outputs:

(1) Analog: 4-20 mA, 0-5 V, 0-10 V or 2-10 V (display selectable);

(1) Pulse/Frequency: 0-15 V peak pulse, 0 to 500 Hz or scalable pulse output

(display selectable);

(2) Alarm: (1) Empty pipe detection or minimum/maximum velocity, (display

selectable); (1) Reverse ow output indication.

Power Requirements: 12-42.4 VDC, .25 A @ 24 VDC; 12-36 VAC.

Electrical Connection: Removable terminal blocks, model selectable 1/2˝ female

NPT conduit connection, PG 16 gland or PG 16 gland with (2) 10 ft (3 m) 9

conductor 22 AWG plenum rated cables, accessory cable lengths up to 200 ft (61

m) optional.

Display (-LCD option): 2˝ ( 5.08 cm) x 2˝ (5.08 cm) graphic LCD with backlight.

Conductivity: >20 microsiemens.

Enclosure Material: Powder coated die cast aluminum.

Enclosure Ratings: NEMA 6P (IP68) (Non display models); NEMA 4X (IP66)

(-LCD option).

Agency Approvals: BTL, CE, NSF/ANSI 61 and 372.

COMMUNICATIONS (-COM OPTION)

Type: BACnet MS/TP or Modbus® RTU communication protocol (default disabled,

display selectable).

Supported Baud Rates: 9600, 19200, 38400, 57600, 76800, or 115200 bps

(display selectable).

Device Load: 1/8 unit load.

ADDITIONAL SPECIFICATIONS

Applicable Pipe Material: Most popular plastic and metal pipes; i.e. Carbon steel,

SS, copper, UPVC/PVDF, galvanized steel, mild steel, and brass**.

Applicable Pipe Size: IEF-HX-X: 4 to 10˝ (101 to 254 mm); IEF-SX-X: 4 to 36˝

(101 to 914 mm).

Diameter Length Requirements: >10 upstream, >5 downstream.

Glycol: 0 to 100% display selectable.

*For max owrates >10 ft/s (3 m/s) order option -CC.

**Brass ttings and pipe not suitable for use with NSF certied models.

Modbus® is a registered trademark of Schneider Automation, Inc.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

1

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Page 2

MODEL CHART

THUMBSCREW

BODY

RULER

Example IEF -L N -CND -LCD IEF-LN-CND-LCD

Series IEF Insertion electromagnetic ow transmitter

Accuracy L

G

S

F

I

E

T

H

Process

Connection

Electrical

Housing

Connector

Options LCD

Note: For CC option, must provide completed conguration paperwork.

ACCESSORIES

Model Description

A-IEF-KIT

A-IEF-DSP

A-IEF-CBL-50

A-IEF-VLV-BR

A-IEF-VLV-SS

A-IEF-INGD

A-IEF-PA

Safety Information

WARNING

• Only qualied professionals equipped with the necessary required trade skills

should install, remove or service this product in any way. Failure to follow the

proper installation procedures could lead to death or permanent injury.

• This product is intended to be installed in pressurized pipe applications. In this

event, product will be under pressure, caution should be taken to properly vent

system prior to installation or removal of the unit. Failure to do so could result in

equipment damage and/or serious bodily injury.

CAUTION

N

B

CND

PG

10

Setup kit (includes setup display, thickness gage and measuring

tape)

Setup display

Plenum rated cable 50 ft (15.2 m)

1-1/4˝ full port isolation valve brass

1-1/4˝ full port isolation valve 316SS

Installation alignment kit

AC wall adapter

Standard accuracy < 10˝ (250 mm) pipe;

1% FS

Standard accuracy > 10˝ (250 mm) pipe;

1% FS

Standard accuracy 4 to 36˝ (100 to 900

mm) pipe; 1% FS

High accuracy 4˝ (100 mm) pipe; 1% of

reading

High accuracy 6˝ (150 mm) pipe; 1% of

reading

High accuracy 8˝ (200 mm) pipe; 1% of

reading

High accuracy 10˝ (250 mm) pipe; 1% of

reading

High accuracy 4 to 10˝ (100 to 250 mm)

pipe; 1% of reading

1˝ male NPT

1˝ male BSPT

1/2˝ female NPT conduit connection

without cable

PG gland without cable

PG gland with 10’ cable

Integral LCD display

COM

BACnet or Modbus® communication

protocol (display selectable)

NIST

Six point NIST traceable calibration

certicate

FC

Factory calibration certicate for 0.5% of

reading at single point

CC

Custom congured for specic installation

OPERATING PRINCIPLE

• Per Faraday’s Law of electromagnetic induction, a voltage is induced in a

conductor when it passes through a magnetic eld, and the induced voltage will be

directly proportional to the velocity of the conductor.

• The Series IEF Flow Transmitter generates pulsating magnetic elds in the probe

to induce a voltage into a conductive uid owing through the pipe.

• Electrodes located on the probe measure the induced voltage. Electronics and

rmware within the enclosure convert the voltage to velocity and ow rate while

using various outputs to convey the data to connected systems (i.e. display

devices, data acquisition systems, or BTU meters).

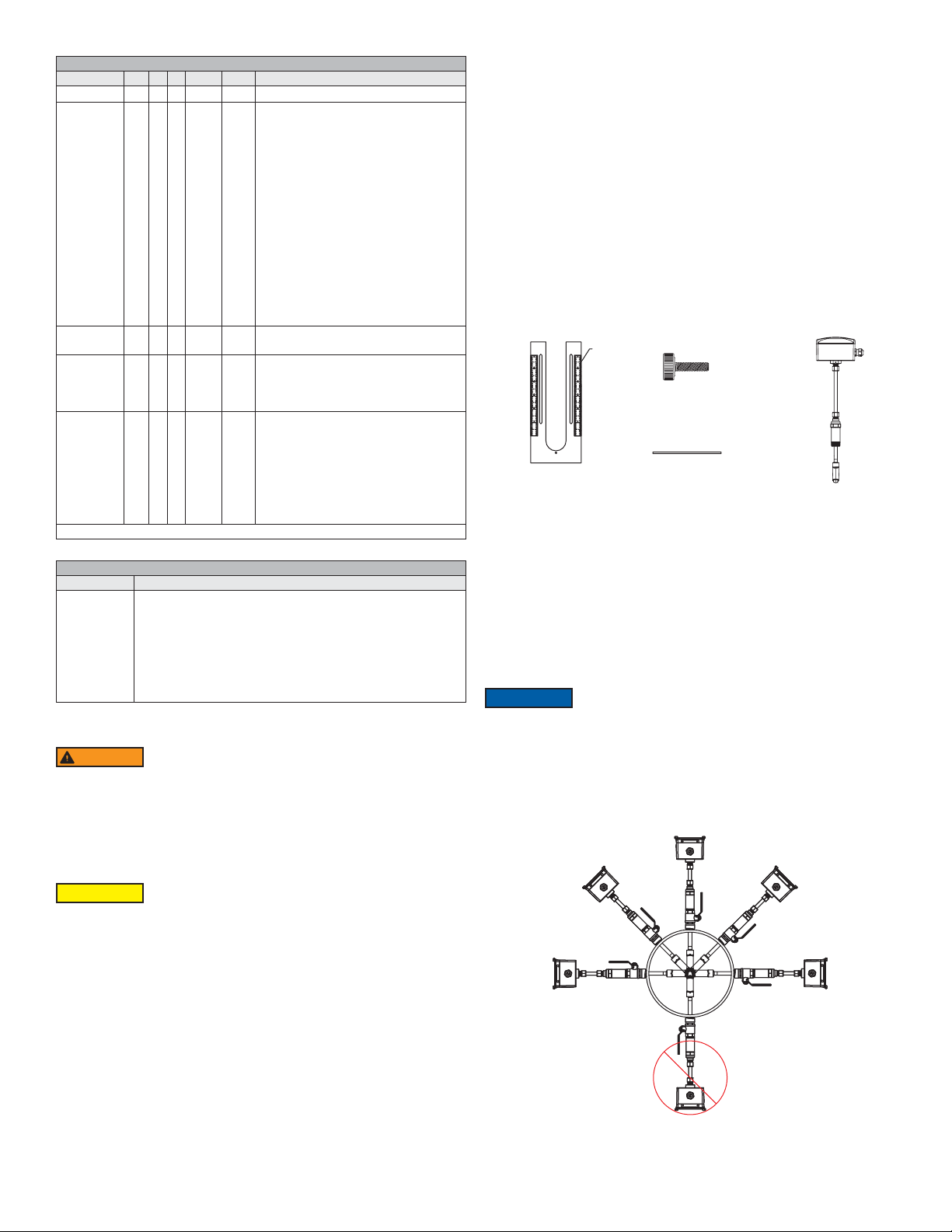

INCLUDED WITH THE FLOWMETER

Carefully unpack the shipping container of your new Series IEF Insertion

Electromagnetic Flow Transmitter and remove the following items:

• (1) Series IEF Insertion Electromagnetic Flow Transmitter

• (1) A-IEF-INGD Installation Alignment Kit:

(1) Alignment Scale

(2) Alignment Rods

(2) Thumbscrews

• (1) 3 mm Allen Wrench (not shown)

(2 PLACES)

Thumbscrews (2)

ROD

Alignment scale (1)

RECOMMENDED TOOLS

• (2) 12˝ (300 mm) adjustable wrenches

• (1) 12˝ (300 mm) pipe wrench

SETUP

Selecting Installation Location

1. Although the unit may be installed in any orientation, the ideal mounting position

is on the side of the pipe (2 o’clock or 10 o’clock position)* as this generally

minimizes possible air or sediment interference with the Series IEF. It is not

reccomended to mount the unit below the pipe (6 o’clock position).

When installing a unit with an integral display select an installation

NOTICE

location that allows for clear viewing of the display and proper

earth ground.

Insert the IEF in a pipe via a threaded Tee, Saddle, or welded integrally

reinforced branch connection outlet tting.

If a Hot-Tap option is required, use a 1-1/4˝ valve kit with proper mounting

hardware available in Model A-IEF-VLV-BR or A-IEF-VLV-SS. A 1˝ (25.4 mm)

hole in the pipe is required for proper installation.

Rods (2)

Figure 1

Series IEF

**

• Refer to Model Chart and Specications for the applicable options to your unit.

• Ensure the unit is sufciently grounded as stated in this bulletin.

• Depressurize and vent systems without Hot-tap valve prior to installation or

removal.

• Conrm the Series IEF wetted material is chemically compatible with process

media prior to installation and use.

• Do not exceed maximum temperature and pressure specications.

• Wear appropriate personal protective equipment during installation, removal and or

service of the unit.

• Altering the product construction in any way may adversely affect product operation

and voids warranty.

• Prior to attempting to wire or service the Series IEF disconnect from power.

Figure 2

2

Page 3

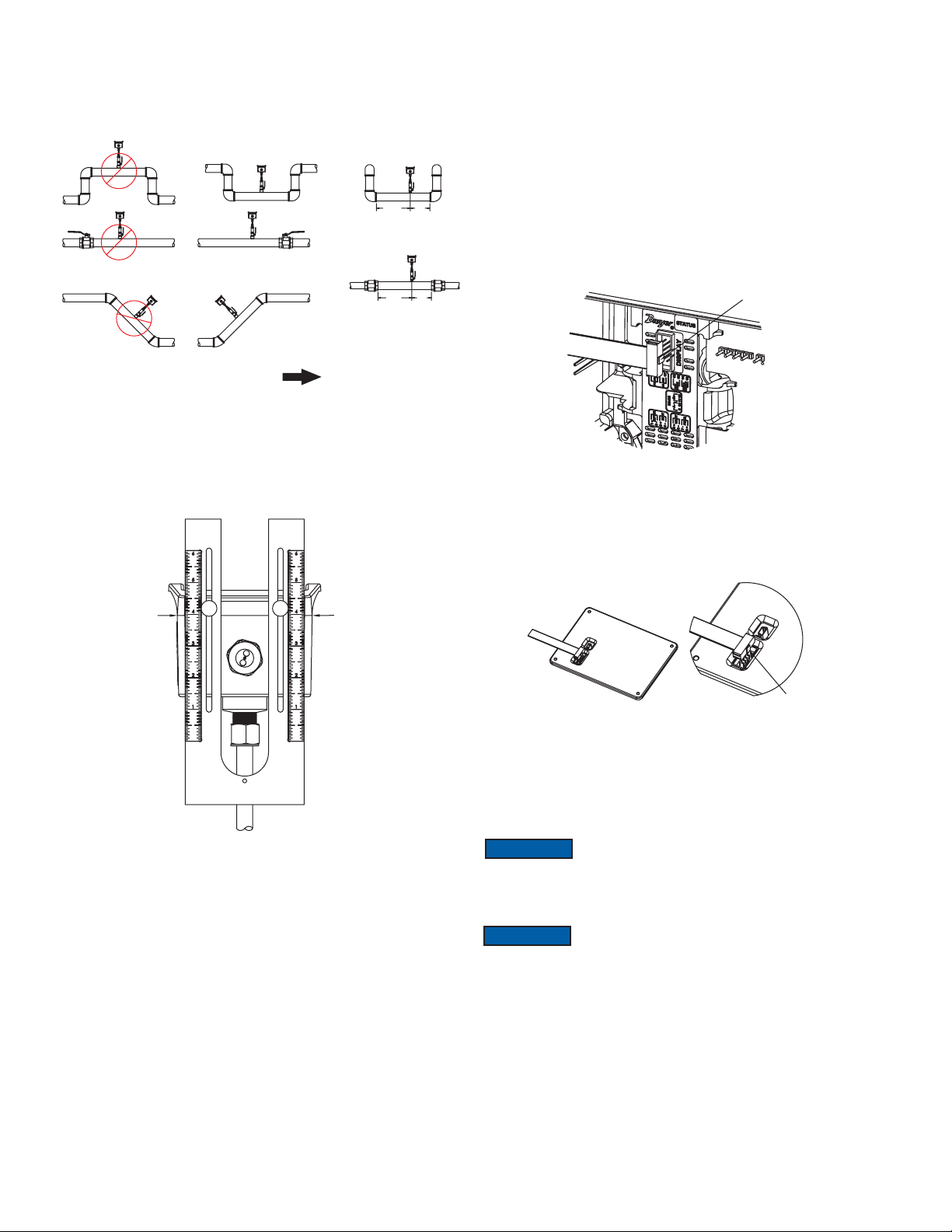

2. Select a location that will minimize ow distortion with adequate upstream and

KEYING FEATURE

KEYING FEATURE

downstream pipe diameters as displayed. Ideal installation will have a minimum

of 10 pipe diameters upstream relative to the instrument and a minimum distance

of 5 pipe diameters downstream.

NOT RECOMMENDED RECOMMENDED

5x

20x

20x

5x

FLOW DIRECTION

Figure 3

INSTALLATION

1. To prepare the meter for installation, mount the provided alignment scale to the

side of the meter with the two provided thumbscrews. The thumbscrews are to be

inserted through the alignment scale slots and into the holes in the side of the lid

as shown in Figure 4, nger tighten only. Be sure to orient the alignment scale as

shown in gure below. Actual scale setting determined in next step.

For Field Congurable Models

2. For eld conguration, a display is required (-LCD option or accessory A-IEF DSP) and needs to be powered via normal eld wiring or with the AC wall adapter

accessory A-IEF-PA ( A-IEF-DSP and A-IEF-PA are also available in the

accessory setup kit A-IEF-KIT).

3. When using the AC wall adapter and the cable is supplied, connect the red

(positive +) and black (common -) wires of the cable bundle marked “A” to the

open terminals of the AC wall adapter. This will provide temporary power to the

meter to complete the installation set up.

4. For eld wiring, refer to the wiring chart tag attached to the Series IEF to identify

the terminal block pins for positive (+) and common (-) connection.

5. Unscrew the four captured cover screws using the supplied 3 mm Allen wrench

to remove and set aside enclosure cover.

6. Insert one connector of the ribbon cable supplied in the setup kit into the

connector labeled “Display” in the middle of the unit. Be sure to orient the keying

feature/tab. See Figure 5 below:

Figure 5

7. Plug the other end of the cable into the bottom of the supplied portable display

being sure to orient the keying feature/tab as shown:

USE LID TO

ENCLOSURE

GAP AS

INDICATOR LINE

Figure 4

For Custom Congured Models (-CC Option)

2. Locate the conguration tag attached to the Series IEF to identify the value of

the alignment scale setting. Position the alignment scale such that the scale

setting is lined-up with the seam of the enclosure as shown in Figure 4. Minor

scale marks are in 1/20ths Securely tighten the thumbscrews.

3. Refer to Preparing the Unit for Installation section.

Figure 6

8. Apply power to the unit and the display will turn-on automatically. Follow the on

screen directions for entering the necessary parameters to setup the unit and

obtain the alignment scale setting value.

NOTICE

DSP, thickness gage UTG and measuring tape A-IEF-MSTP used to obtain these

measurements. When the precise pipe measurement information is known select

Option 2 High Performance setup in the Install Kit option of the display selection

When using measuring tape A-IEF-MSTP to measure pipe

NOTICE

of the pipe without insulation.

Precise pipe measurements are required for high performance

installation. The A-IEF-KIT includes setup display A-IEF-

circumference use the 100ths side to measure the circumference

3

Page 4

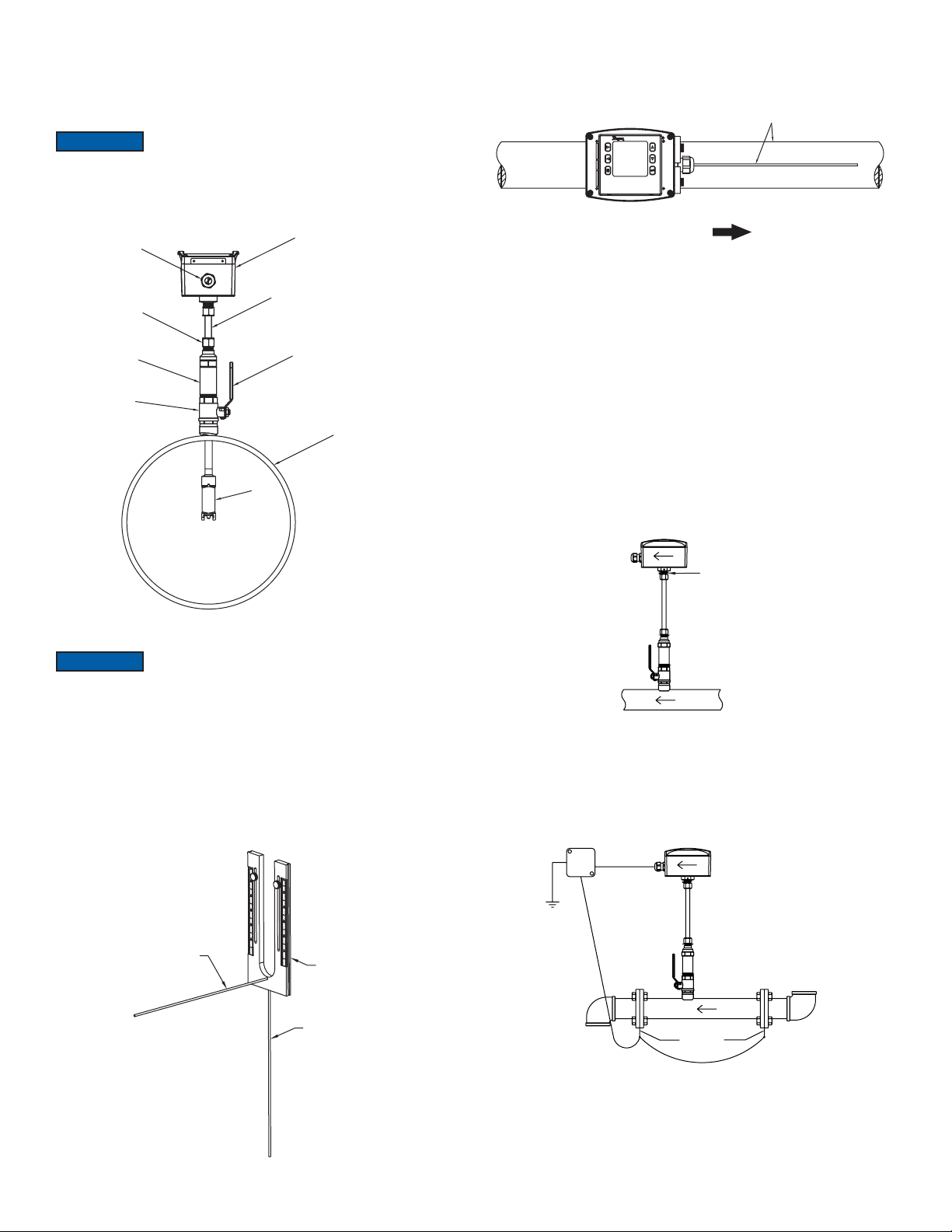

FLOW

OOL

PIPE ALIGNMENT ROD MUST

g

1

8

Preparing the Unit for installation (Refer to Figure 7)

1. Apply appropriate sealant to the process collet (5) threads such as application

suitable sealant tape or paste.

2. Install the process collet (5) in valve (6) then tighten by hand.

3. Tighten the process collet (5) with a wrench using the hex geometry until snug.

NOTICE

4. Slowly open the valve handle (7) checking for leaks.

5. If leaks occur around threaded connections, close the valve and tighten those

connections.

Use two wrenches, one to hold the valve and another wrench to

turn the process collet.

2

3. Rotate the transmitter so the pipe alignment rod is parallel with the ow in the

pipe.

BE PARALLEL WITH PIPE

FLOW DIRECTION

Figure 9

9

Figure 7

3

7

1. Enclosure

2. Cable Nut

3. Probe Shaft

4. Compression Fitting

5. Process Collet

6. Valve (optional)

7. Valve Handle (optional)

8. Pipe

9. Sensor Probe

4

5

6

Do not adjust housing compression nut at top of probe shaft (3).

NOTICE

Sensor Alignment

A depth and ow alignment installation tool is provided to ensure proper depth insertion

and ow alignment. To set the insertion depth verify the alignment scale has not moved

from its original setting based on the alignment scale value set previously.

Loosen compression nut (4) to allow the shaft (3) freedom to travel up and down and

rotate inside the process collet (5).

Install Depth and Alignment Rods

1. Remove alignment rods from sides of alignment scale by sliding them out.

2. Insert the two rods into the alignment scale as shown.

4. Slide the shaft (3) down into the process collet (5) until the depth rod contacts

the pipe. If pipe insulation is present press the rod through the insulation.

a. Tighten the nut (4) to 15 ft.-lbs (20.3 N m)

b. Remove the ow alignment rod and loosen the thumbscrews to slide the

alignment tool up to allow removal of the depth alignment rod. Store both

rods in the storage slots on the sides of the alignment scale. Tighten

thumbscrews and leave alignment tool mounted on unit for storage.

GROUNDING

Metallic Pipe

For proper operation the instrument must be earth grounded.

Connect a ground wire to meter housing via the ground lug on the housing collet.

Connect the ground wire to a known earth ground.

If the pipe is grounded, connect the ground wire to the metal pipe using suitable

devices such as grounding clamps.

Grounding lu

Figure 10

Non-Metallic Pipes

Connect a ground wire to the transmitter housing per the ground lug on the housing

collet.

Connect the ground wire to a known earth ground.

Ground the uid to earth.

ALIGNMENT ROD

Figure 8

ALIGNMENT T

DEPTH ROD

GROUNDING

RINGS

Figure 11

POWER SUPPLY

Choose a power supply with a voltage and current rating sufcient to meet the power

specications under all operating conditions.

If the power supply is unregulated, make sure the output voltage remains within the

required voltage range under all power line conditions.

4

Page 5

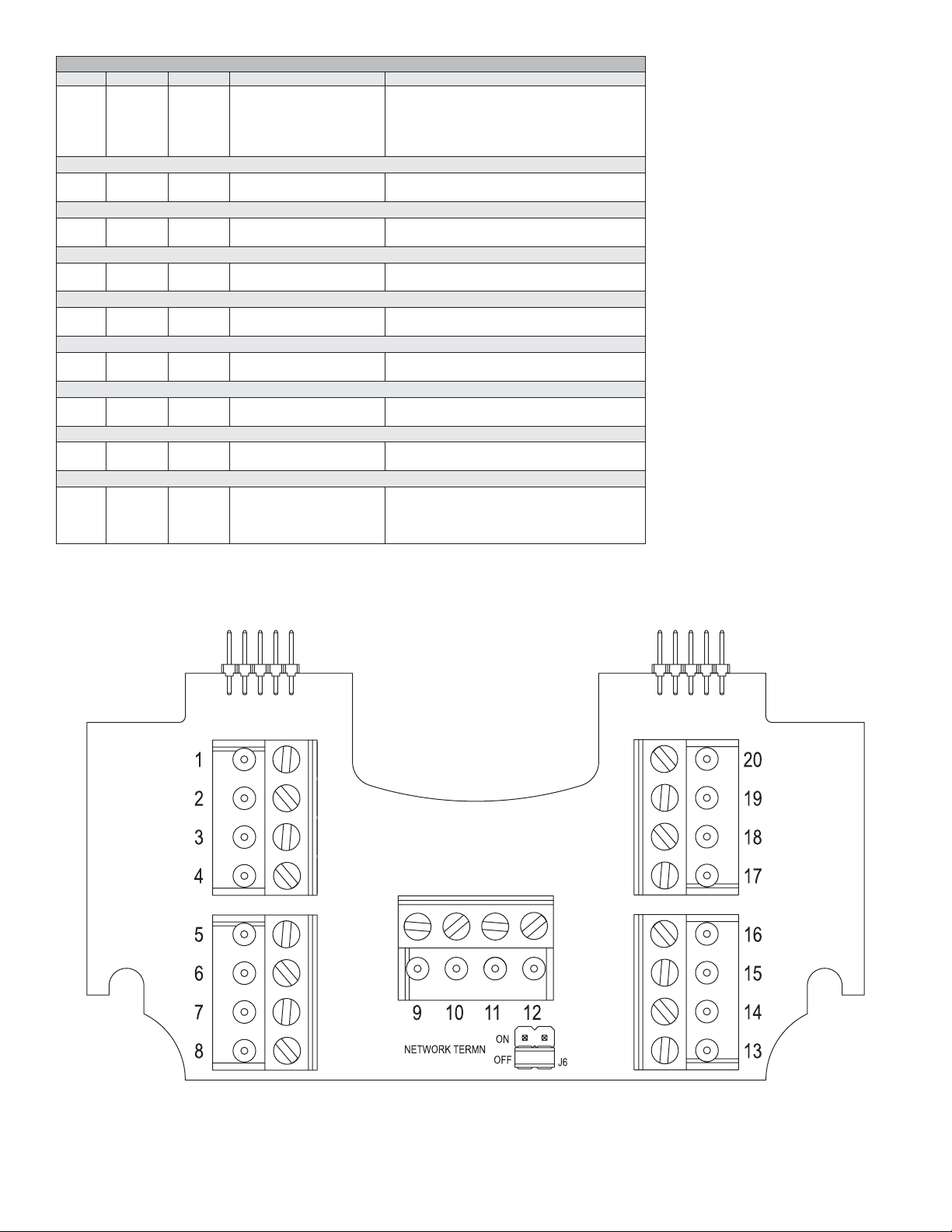

WIRING DIAGRAM

Cable Terminal # Wire Color Description Note

A

A

A

B

External

Analog Current Output

B

B

Analog Voltage Output

B

B

Frequency Output

B

B

RS-485 Communication (optional)

B

B

Reverse Flow

A

A

Alarm

A

A

Pulse

A

A

No Connection

B

B

A

A

1

2

13

14

3

4

5

6

8

7

11,12

9,10

15

16

17

18

19

20

-

-

-

-

Red

Black

Shield

Shield

-

Brown

Blue

Green

White

Violet

Grey

Orange

Yellow

Brown

Blue

Green

White

Orange

Yellow

Red

Black

Violet

Grey

Power Supply Positive

Power Supply Common

-

Earth/Chassis Ground

(+) Analog current output

(-) Analog output common

(+) Analog voltage output

(-) Analog output common

(+) Frequency output

(-) Analog output common

RS-485 (+)

RS-485 (-)

Isolated solid state output N.O.

Isolated solid state output N.O.

Isolated solid state output N.O.

Isolated solid state output N.O.

Isolated solid state output N.O.

Isolated solid state output N.O.

Do not connect

Do not connect

Do not connect

Do not connect

Connect to +24VDC or VAC transformer

Connect to 24VDC/VAC common

If used - Application Dependant

If used - Application Dependant

-

4 to 20 mA process output

Current output common

May be congured; 0 to 10 V, 0 to 5 V, 2 to 10 V, etc.

Voltage output common

0 to 500 Hz output (@ 0/15 VDC output level)

Frequency output common

On board short for daisy chain connection

On board short for daisy chain connection

50 V AC/VDC @ 100 mA maximum

50 V AC/VDC @ 100 mA maximum

50 V AC/VDC @ 100 mA maximum

50 V AC/VDC @ 100 mA maximum

50 V AC/VDC @ 100 mA maximum

50 V AC/VDC @ 100 mA maximum

-

-

-

-

The Cable column identifying cable A and B is reective of units that include factory installed cabling.

Wiring PCBA shown in Figure 12 with terminal block numbers as listed in above wiring diagram chart.

Figure 12

5

Page 6

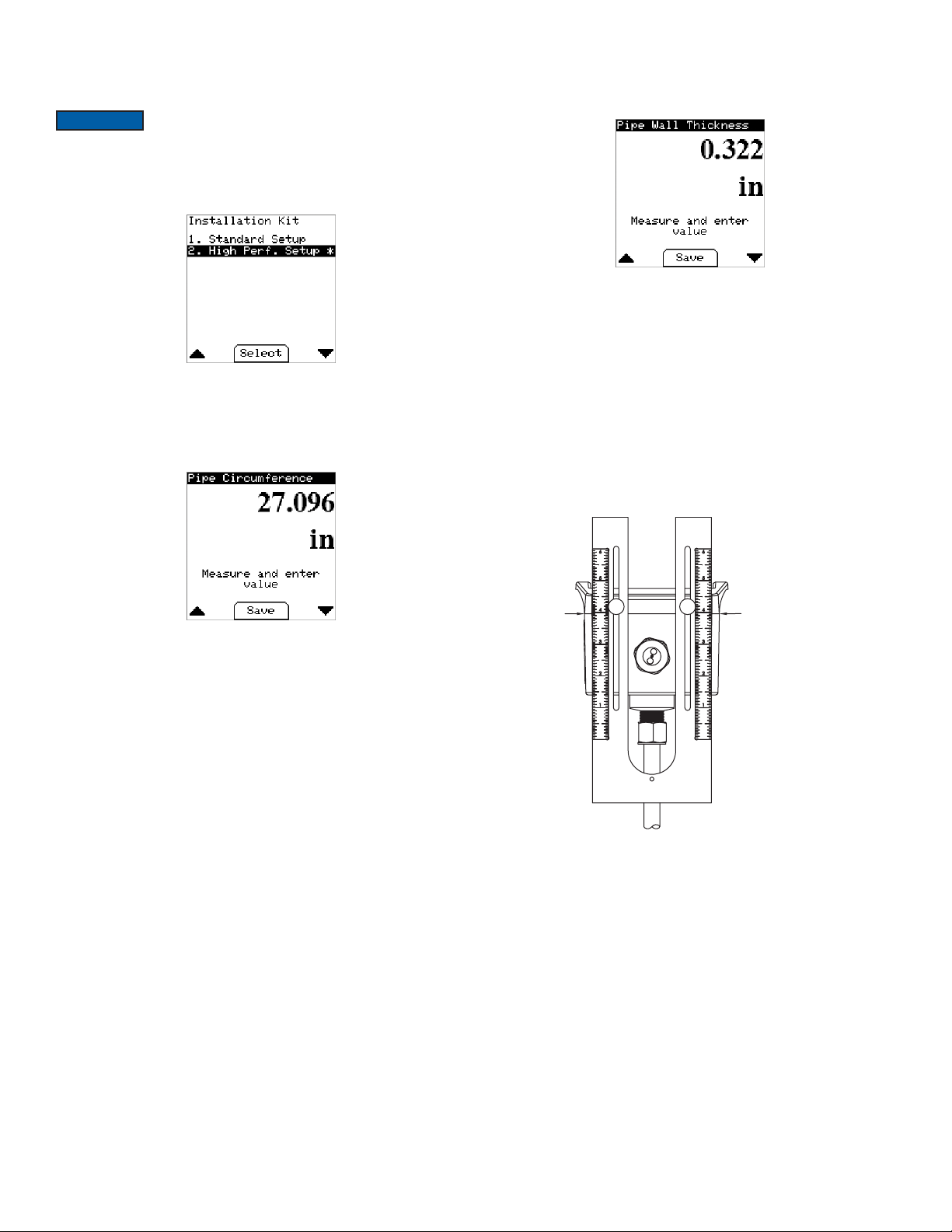

Determining probe insertion depth for models with a display

The Series IEF transmitter will calculate the probe insertion depth used with -LCD

display option or A-IEF-DSP display when the steps below are followed.

Follow the on screen directions for entering the circumference and wall thickness

dimensions. See the Electronic Control Data Setup section of this manual for more

information.

NOTICE

A-IEF-MSTP to obtain these measurements. When the precise pipe measurement

information is known, select option 2 (High Performance Setup) under the Install Kit

Menu when prompted by the display as shown below. Precise pipe measurements

are required for a high performance installation.

1. To measure the pipe circumference remove any existing insulation at the

location where the transmitter will be installed. Wrap the tape measure around

the pipe to measure the circumference at the selected location using the

100ths side of the tape. Record this measurement for entering into the unit

when the circumference measurement is requested.

It is recommended to use the A-IEF-KIT which includes a setup

display A-IEF-DSP, thickness gage UTG and measuring tape

Determining probe insertion depth for models without a display

For models without a display the following formulas allow for calculating the alignment

scale value for setting the depth of the probe into the pipe. Also included are wall

thickness charts for various pipe materials and sizes.

Pipes < 11 in (< 279 mm) diameter: 7.1625-1/2*D

Pipes 12 inches to 36 inches: 7.1625-(0.1*(D-2*WT))+WT

Where D represents the pipe outer diameter and WT represents the pipe wall

thickness, both in inches. Measurement of the outside diameter and wall thickness

can be accomplished as described in the previous section, Determining probe insertion

depth for models with a display, or similar method. Precise pipe measurements are

required for a high performance installation.

Position the alignment scale such that the alignment scale setting is lined-up with

the seam of the enclosure as shown in Figure 13. Minor scale marks are in 1/20ths

Securely tighten the thumbscrews.

2. To measure the wall thickness of the pipe use the thickness gage UTG. Following

the separate directions provided with the UTG gage and record the thickness.

This measurement will be needed to enter into the unit after the circumference

data is entered.

Figure 13

USE LID TO

ENCLOSURE

GAP AS

INDICATOR LINE

6

Page 7

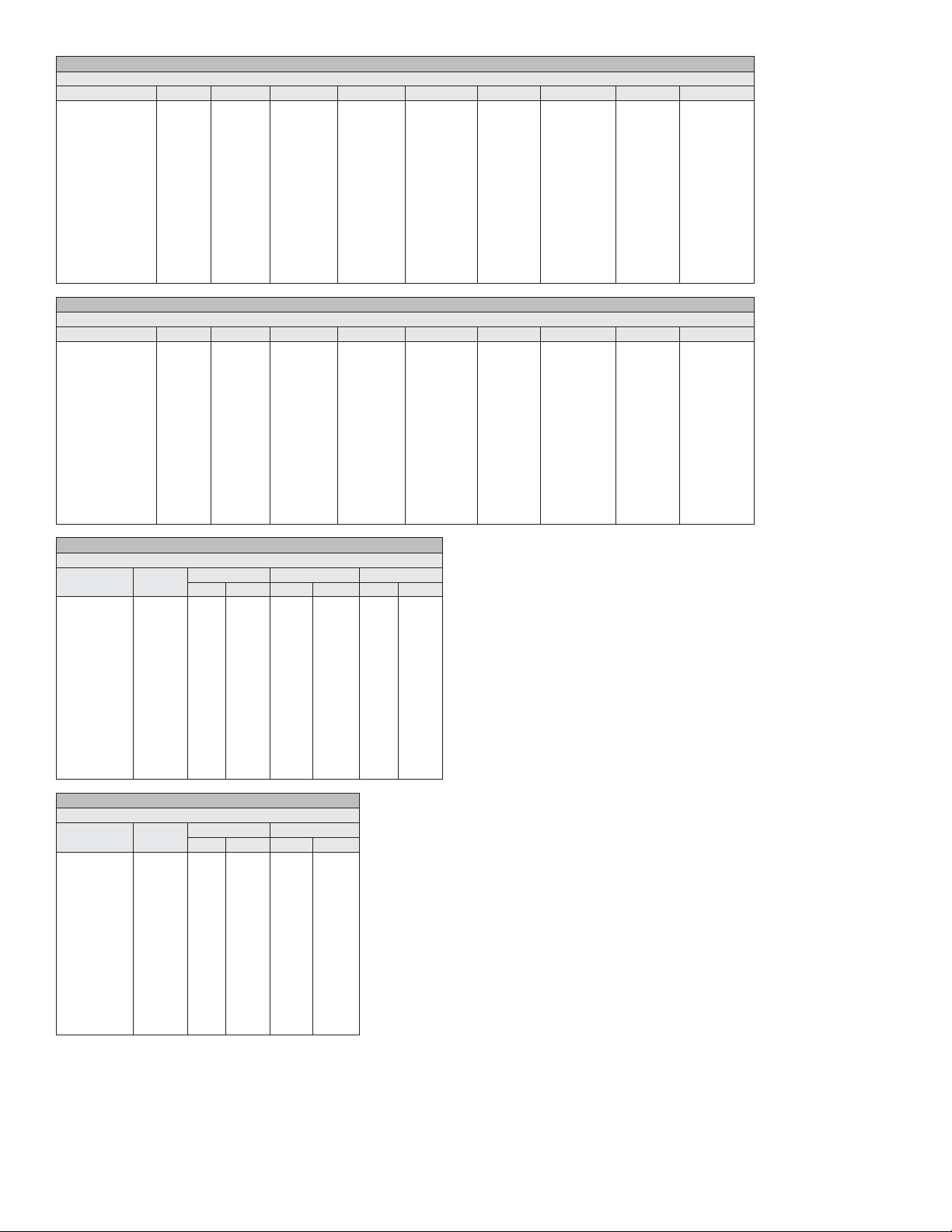

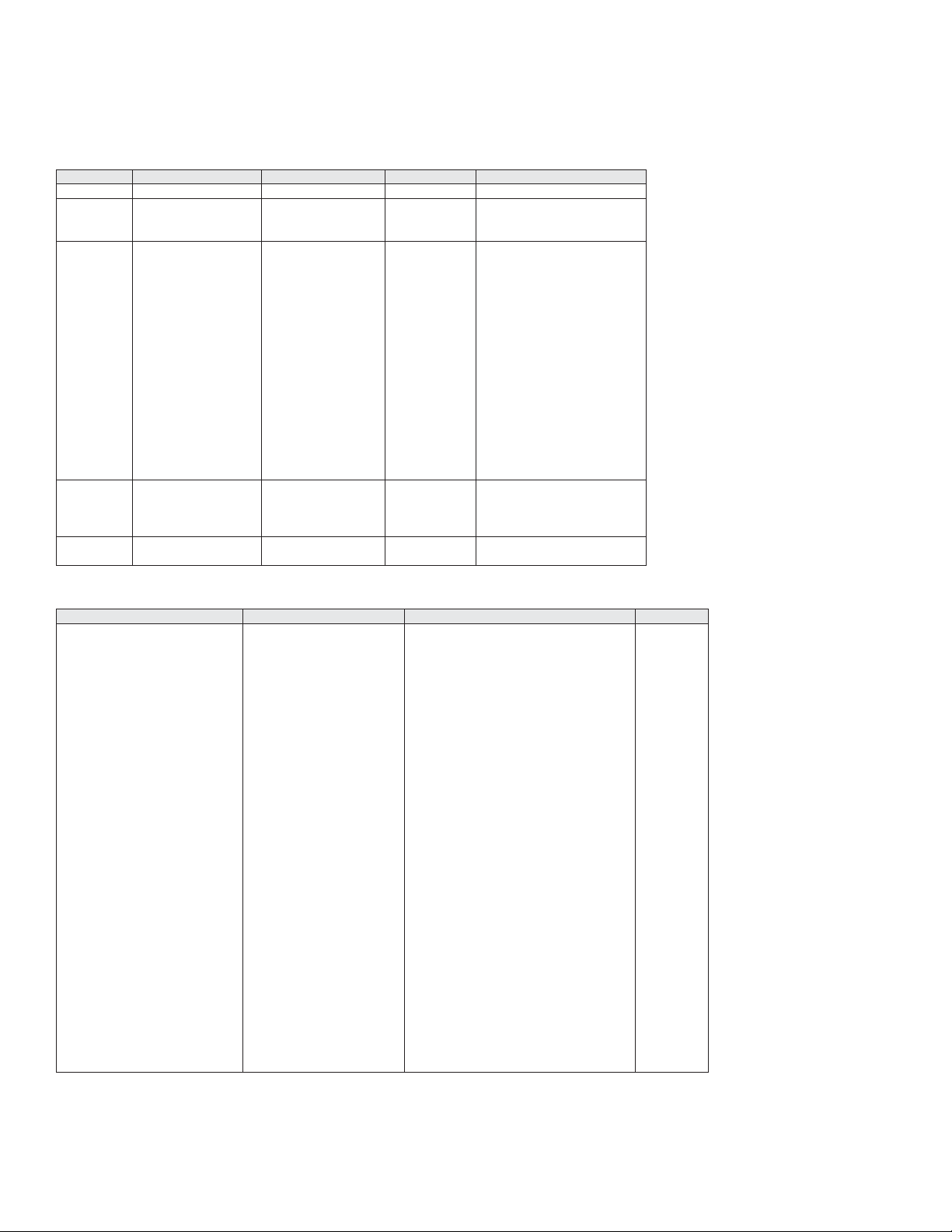

WALL THICKNESS

Carbon Steel

Pipe Diameter (in) DN (mm) SCH5 (in) SCH5 (mm) SCH10 (in) SCH10 (mm) SCH40 (in) SCH40 (mm) SCH80 (in) SCH80 (mm)

4.5

5.563

6.625

8.625

10.75

12.75

14

16

18

20

24

32

36

WALL THICKNESS

Stainless Steel

Pipe Diameter (in) DN (mm) SCH5 (in) SCH5 (mm) SCH10 (in) SCH10 (mm) SCH40 (in) SCH40 (mm) SCH80 (in) SCH80 (mm)

4.5

5.563

6.625

8.625

10.75

12.75

14

16

18

20

24

32

36

114.30

141.30

168.28

219.08

273.05

323.85

355.60

406.40

457.20

508.00

609.60

813.00

914.40

114.30

141.30

168.28

219.08

273.05

323.85

355.60

406.40

457.20

508.00

609.60

813.00

914.40

0.083

0.109

0.109

0.109

0.134

0.156

0.156

0.165

0.165

0.188

0.218

0.250

0.250

0.083

0.109

0.109

0.109

0.134

0.156

0.156

0.165

0.165

0.188

0.218

0.250

0.250

2.110

2.770

2.770

2.770

3.400

3.960

3.960

4.190

4.190

4.780

5.540

6.350

6.350

2.110

2.770

2.770

2.770

3.400

3.960

3.960

4.190

4.190

4.780

5.540

6.350

6.350

0.120

0.134

0.134

0.148

0.165

0.180

0.250

0.250

0.250

0.250

0.250

0.312

0.312

0.120

0.134

0.134

0.148

0.165

0.180

0.188

0.188

0.188

0.218

0.250

0.312

0.312

3.050

3.400

3.400

3.760

4.190

4.570

6.350

6.350

6.350

6.350

6.350

7.920

7.920

3.050

3.400

3.400

3.760

4.190

4.570

4.780

4.780

4.780

5.540

6.350

7.920

7.920

0.237

0.258

0.280

0.322

0.365

0.406

0.437

0.500

0.562

0.593

0.688

0.688

0.750

0.237

0.258

0.280

0.322

0.365

0.375

0.375

0.375

0.375

0.375

0.375

0.375

0.375

6.020

6.550

7.110

8.180

9.270

10.310

11.130

12.700

14.270

15.090

17.480

17.480

19.050

6.020

6.550

7.110

8.180

9.270

9.525

9.525

9.525

9.525

9.525

9.525

9.525

9.525

0.337

0.375

0.432

0.500

0.593

0.687

0.750

0.843

0.937

1.031

1.218

1.218

1.218

0.337

0.375

0.432

0.500

0.500

0.500

0.500

0.500

0.500

0.500

0.500

0.500

0.500

8.560

9.530

10.970

12.700

15.090

17.480

19.050

21.440

23.830

26.190

30.960

30.960

30.960

8.560

9.525

10.970

12.700

12.700

12.700

12.700

12.700

12.700

12.700

12.700

12.700

12.700

WALL THICKNESS

Copper

Pipe

Diameter (in) DN (mm)

4.125

5.125

6.125

8.125

10.25

12.25

14

16

18

20

24

32

36

WALL THICKNESS

PVC

Pipe

Diameter (in) DN (mm)

4.5

5.563

6.625

8.625

10.75

12.75

14

16

18

20

24

32

36

104.78

130.18

155.58

206.38

257.18

307.98

355.60

406.40

457.20

508.00

609.60

813.00

914.40

114.00

141.00

168.00

219.00

273.00

324.00

356.00

406.00

457.20

508.00

609.60

813.00

914.40

Type K Type L Type M

in mm in mm in mm

0.134

3.400

0.114

0.160

4.064

0.192

4.876

0.271

6.883

0.341

8.661

0.411

10.439

0.471

11.963

0.471

11.963

0.541

13.741

0.610

15.494

0.680

17.272

0.818

20.777

1.096

27.838

SCH40 SCH80

in mm in mm

0.237

6.020

0.258

6.550

0.280

7.110

0.322

8.180

0.365

9.270

0.406

10.300

0.437

11.100

0.500

12.700

0.562

14.274

0.593

15.062

0.687

17.450

0.874

22.200

0.968

24.587

0.125

0.140

0.200

0.356

0.411

0.459

0.459

0.513

0.568

0.623

0.732

0.950

0.337

0.375

0.432

0.500

0.593

0.687

0.750

0.843

0.937

1.031

1.218

1.572

1.754

2.895

3.175

3.556

5.080

9.042

10.439

11.658

11.658

13.030

14.427

15.824

18.593

24.130

8.560

9.520

11.000

12.700

15.100

17.400

19.000

21.400

23.800

26.187

30.937

39.929

44.552

0.095

0.109

0.122

0.170

0.308

0.356

0.398

0.398

0.445

0.493

0.541

0.636

0.826

2.413

2.768

3.098

4.318

7.823

9.042

10.109

10.109

11.303

12.522

13.741

16.154

20.980

7

Page 8

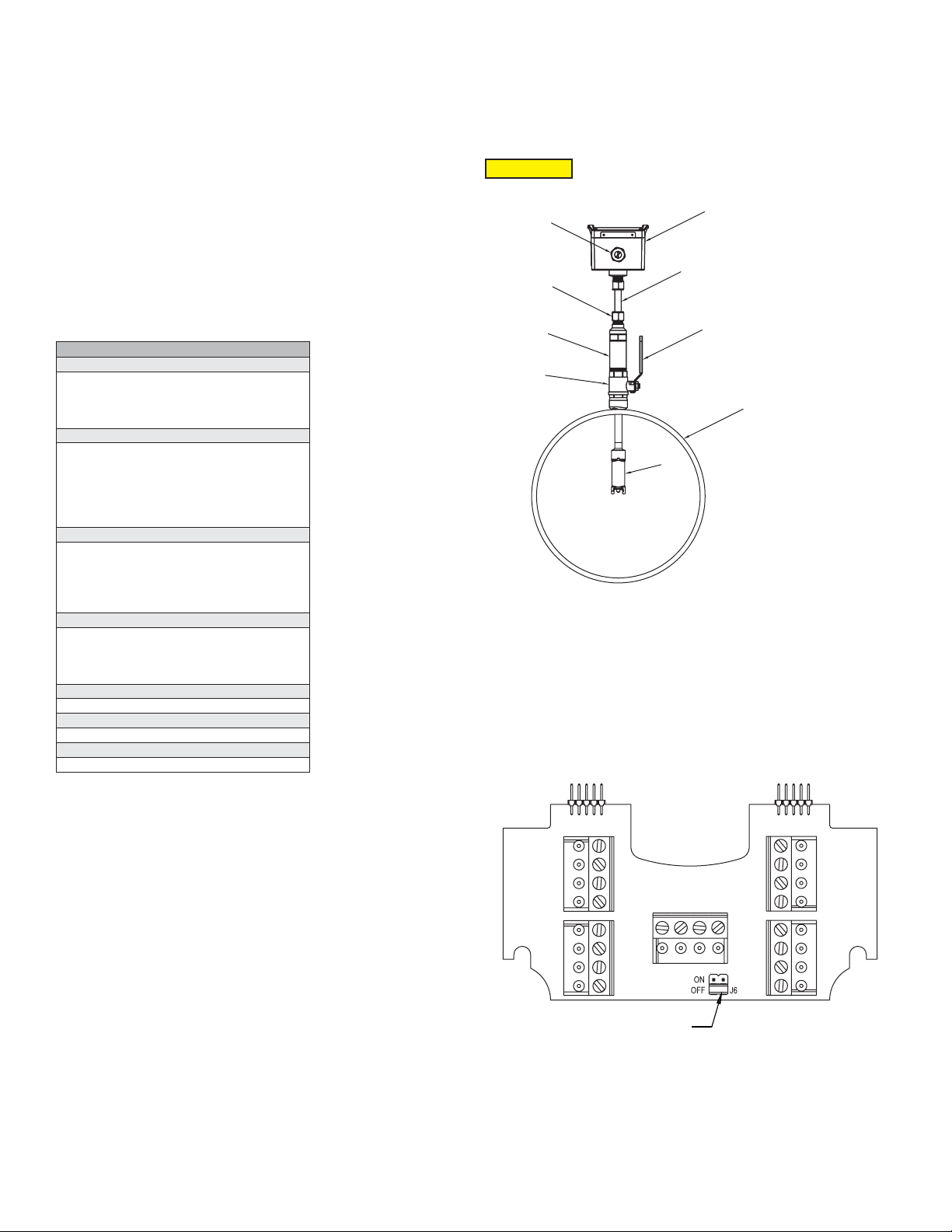

Printing out conguration values

1

8

NETWORK TERMINATION JUMPER

After installation is complete a table of conguration values can be gathered from the

transmitter to print out and insert into one of the hanging plastic envelopes for future

reference. The housing cover/display needs to be removed for access to the display

port to retrieve the table of conguration values. To do so:

1. Unscrew the four captured cover screws using the supplied 3 mm Allen wrench

to remove the enclosure cover. Leave the display cable connected to the main

unit.

2. Insert a customer supplied mini-USB cable into the USB connector on the bottom

side of the display PCB.

3. Connect the other end into a standard USB port in a laptop.

4. The Series IEF transmitter will appear as a standard USB drive on the laptop.

5. The le name with the conguration values is in the format of:

serial number.txt. The serial number can be found on the product label on the

side of the transmitter.

6. Print out the conguration values and insert into one of the hanging plastic

envelopes for future reference

7. Re-attach the housing cover/display by reinserting the four 3 mm screws.

CONFIGURATION DATA PRINT OUT EXAMPLE

[Device Information]

MeterTag=Series IEF

SerialNumber=Andrew2

ModelNumber=IEF-XX-COM-LCD

DateCode=20180101

[Setup Information]

CalibratedBy=

Date=

Units=English

VelocityUnit=ft/s

FlowUnit=ft³/s

VolumeUnit=gal

[Pipe Conguration]

LiquidType=Water

PipeMaterial=Carbon Steel

PipeCircumference=27.096 in

PipeWallThickness=0.322 in

AlignmentScaleValue=1.85

[Analog Output]

AnalogOutputType=Current 4-20mA

AnalogOutputVariable=Velocity ft/s

AnalogOutputHigh=20.00

AnalogOutputLow=0.00

[Pulse/Freq. Output Setup]

Pulse/Freq. Output=Disabled

[Alarm Output Setup]

AlarmOutput=Empty Pipe Alarm

[Communication]

CommunicationProtocol=Disabled

Removing Series IEF Transmitter

1. To remove the transmitter from an installation without a valve depressurize the

pipe and skip to step 4. If installed with a valve loosen compression tting (4) and

withdraw the transmitter shaft fully through the valve until it stops.

2. Tighten compression tting (4) snug.

3. Close valve (6) via valve handle (7).

4. Remove transmitter by unscrewing process collet (5) from value (6).

CAUTION

occur to the probe ns.

Network Termination Jumper

On the terminal block PCBA there is a jumper, J1 (see Figure 15), that enables or

disables a network termination resistor as dened below:

When the network jumper is placed in the ON position there is a 120 ohm termination

resistor in place. When the network jumper is placed in the OFF position there is no

termination resistor in place.

Default: OFF

Be sure to support the housing end of the transmitter to prevent it

from ipping while unscrewing process collet (5) as damage may

2

4

5

6

3

9

Figure 14

7

1. Enclosure

2. Cable Nut

3. Probe Shaft

4. Compression Fitting

5. Process Collet

6. Valve

7. Valve Handle

8. Pipe

9. Sensor Probe

Figure 15

8

Page 9

Communication Overview

The Insertion Magmeter supports BACnet MS/TP and Modbus® RTU over 2-wire RS-

485. Selection of protocol and conguration of serial parameters require the use of

the display.

BACNET

BACnet Object Overview

Supported BACnet Objects

Object Type Dynamically Creatable Dynamically Deletable Object Identier Object Name

Device No No 607XXX “Series IEF 607xxx”

Analog Input No No AI1

Analog Value No No AV1

Binary Value No No BV1

Bit String

Value

No No BSV1

AI2

AI3

AV2

AV3

AV4

AV5

AV6

AV7

AV8

AV9

AV10

AV11

AV12

AV13

AV14

AV15

AV16

AV17

BV2

BV3

BV4

BSV2

Velocity

Inlet Temperature

Outlet Temperature

Volume Flow

Mass Flow

Total Flow

Power

Total Energy

Heat Energy

Cooling Energy

Differential Temperature

YTD Max Power

YTD Min Power

MTD Max Power

MTD Min Power

Inlet YTD Average Temperature

Outlet YTD Average Temperature

Heat Changeover Temperature

Process Pressure

Ethylene Glycol Concentration

Reverse Flow

Empty Pipe

Reset Total Flow

Reset Energy Statistics

Flow Meter Status Flags

Energy Meter Status Flags

BACnet Objects: Device Object

Property Default Value Property Data Type Access

Object Identier

Object Name

Object Type

System Status

Vendor Name

Vendor Identier

Model Name

Firmware Revision

Application Software Version

Location

Description

Protocol Version

Protocol Revision

Protocol Services Supported

Protocol Object Types Supported

Object List

Active COV Subscriptions

Maximum APDU Length Accepted

Segmentation Supported

Local Time

Local Date

UTC Offset

Daylight Savings Status

APDU Timeout

Number of APDU Retries

Max Master

Max Info Frames

Device Address Binding

Database Revision

Property List

Serial Number

Property List

607xxx

“Series IEF 607xxx”

DEVICE(8)

Operational(0)

“Dwyer Instruments, Inc.”

607

“IEF-??-??-COM”

“?.?”

“?.?.?”

1

14

See PICS

See Table Above

See Table Above

480

NO_SEGMENTATION (3)

0

False

6000

3

127

1

Empty

1

“xxxxxxxx”

BACnetObjectIdentier

CharacterString(40)

BACnetObjectType

BACnetDeviceStatus

CharacterString

Unsigned

CharacterString

CharacterString

CharacterString

CharacterString(32)

CharacterString(32)

Unsigned

Unsigned

BACnetServicesSupported

BACnetObjectTypesSupported

BACnetArray

List of BACnetCOVSubscription

Unsigned

BACnetSegmentation

Time

Date

Integer

Boolean

Unsigned

Unsigned

Unsigned

Unsigned

BACnetAddressBinding

Unsigned

BACnetARRAY[N] of BACnetPropertyIdentier

CharacterString

BACnetARRAY[N] of BACnetPropertyIdentier

Read/Write

Read/Write

Read

Read

Read

Read

Read

Read

Read

Read/Write

Read/Write

Read

Read

Read

Read

Read

Read

Read

Read

Read

Read

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read

Read

Read

Read

Read

9

Page 10

The default object identier is 607xxx, where xxx is replaced by the MS/TP MAC

address set in the Network Address menu. The object identier value will change as

the MS/TP MAC address changes. However, if a specic object identier is written

via BACnet, then that value is stored and changes to the MS/TP MAC address will no

longer affect the object identier.

Similarly, the default object name includes 607xxx. The object name will reect the

current object identier. If a specic object name is written via BACnet, then that value

is stored and changes to the object identier will no longer affect the object name.

APDU Timeout values are rounded to the nearest second (1000ms). Values less than

500 will be rounded to 0 and Number of APDU Retries will be set to 0.

Analog Input – Velocity

Property Default Value Property Data Type Access

Object Identier

Object Name

ObjectType

Present Value

Status Flags

Event State

Reliability

Out Of Service

Units

COV Increment

Property List

COV Increment Value

Property Default Value Property Data Type Access

0.5 ft/s 0.1 ft/s 10.0 ft/s 0.1 ft/s

Supported Units:

Feet-per-second (76), Feet-per-minute (77), Meters-per-second (74), Meters-perminute (163), Meters-per-hour (164), Feet-per-hour (512)*, Feet-per-day (513)*,

Meters-per-day (514)*

AI1

“Velocity”

ANALOG_INPUT (0)

Current reading

0

NORMAL (0)

NO_FAULT_DETECTED(0)

FALSE (0)

Feet-per-second (76)

0.5

BACnetObjectIdentier

CharacterString

BACnetObjectType

Real

BACnetStatusFlags

BACnetEventState

BACnetReliability

Boolean

BACnetEngineeringUnits

Real

BACnetARRAY[N] of BACnetPropertyIdentier

Read

Read

Read

Read

Read

Read

Read

Read/Write

Read/Write

Read/Write

Read

* Non-Standard BACnet unit

Analog Value – Volume Flow

Property Default Value Property Data Type Access

Object Identier

Object Name

Object Type

Present Value

Status Flags

Event State

Reliability

Out of Service

Units

COV Increment

Property List

COV Increment Value

Default Value Minimum Value Minimum Value Increment

1.0 ft³/s 0.133 ft³/s 13.3681 ft³/s 0.1 ft³/s

Supported Units:

Cubic-feet-per-second (142), Cubic-feet-per-minute (84), Cubic-feet-per-hour (191),

Cubic-feet-per-day (248), US-gallons-per-minute (89), US-gallons-per-hour (192),

Liters-per-second (87), Liters-per-minute (88), Liters-per-hour (136), Cubic-metersper-second (85), Cubic-meters-per-minute (165), Cubic-meters-per-hour (135), USgallons-per-second (515)*, US-gallons-per-day (516)*, Liters-per-day (517)*, Cubicmeters-per-day (518)*

*Non-Standard BACnet unit

AV1

"Volume Flow"

ANALOG_VALUE (1)

Current reading

0

Normal (0)

NO_FAULT_DETECTED (0)

FALSE (0)

Cubic-feet-per-second (142)

1.0

BACnetObjectIdentier

CharacterString

BACnetObjectType

Real

BACnetStatusFlags

BACnetEventState

BACnetReliability

Boolean

BACnetEngineeringUnits

Real

BACnetARRAY[N] of BACnetPropertyIdentier

Read

Read

Read

Read

Read

Read

Read

Read/Write

Read/Write

Read/Write

Read

10

Page 11

Analog Value – Mass Flow

Property Default Value Property Data Type Access

Object Identier

Object Name

Object Type

Present Value

Status Flags

Event State

Reliability

Out of Service

Units

COV Increment

Property List

COV Increment Value

Default Value Minimum Value Minimum Value Increment

10.0 lbm/s 10.0 lbm/s 100.0 lbm/s 0.1 lbm/s

Supported Units:

Kilograms-per-second (42), Kilograms-per-minute (43), Kilograms-per-hour (44),

Kilograms-per-day (526)*, Pounds-mass-per-second (119), Pounds-mass-per-minute

(45), Pounds-mass-per-hour (46), Pounds-mass-per-day (47812)

*Non-Standard BACnet unit

Analog Value – Total Flow

Property Default Value Property Data Type Access

Object Identier

Object Name

Object Type

Present Value

Status Flags

Event State

Reliability

Out of Service

Units

COV Increment

Property List

COV Increment Value

Default Value Minimum Value Minimum Value Increment

7.48 gal 1.0 gal 100.0 gal 0.1gal

Supported Units:

Cubic-feet (79), US-gallons (83), Liters (82), Cubic-meters (80)

AV2

"Mass Flow"

ANALOG_VALUE (2)

Current reading

0

Normal (0)

NO_FAULT_DETECTED (0)

FALSE (0)

Pounds-mass-per-second(119)

10.0

AV3

"Total Flow"

ANALOG_VALUE (2)

Current reading

0

Normal (0)

NO_FAULT_DETECTED (0)

FALSE (0)

US-gallons (82)

7.48

BACnetObjectIdentier

CharacterString

BACnetObjectType

Real

BACnetStatusFlags

BACnetEventState

BACnetReliability

Boolean

BACnetEngineeringUnits

Real

BACnetARRAY[N] of BACnetPropertyIdentier

BACnetObjectIdentier

CharacterString

BACnetObjectType

Real

BACnetStatusFlags

BACnetEventState

BACnetReliability

Boolean

BACnetEngineeringUnits

Real

BACnetARRAY[N] of BACnetPropertyIdentier

Read

Read

Read

Read

Read

Read

Read

Read/Write

Read/Write

Read/Write

Read

Read

Read

Read

Read

Read

Read

Read

Read/Write

Read/Write

Read/Write

Read

Analog Value – Ethylene Glycol Concentration

Property Default Value Property Data Type Access

Object Identier

Object Name

Object Type

Present Value

Status Flags

Event State

Reliability

Out of Service

Units

Property List

Present Value

Default Value Minimum Value Minimum Value

0% 0% 100%

This value indicates the amount of Ethylene Glycol by volume in the process uid.

AV17

“Ethylene Glycol Concentration”

ANALOG_VALUE (2)

0

0

Normal (0)

NO_FAULT_DETECTED (0)

FALSE (0)

Percent (98)

BACnetObjectIdentier

CharacterString

BACnetObjectType

Real

BACnetStatusFlags

BACnetEventState

BACnetReliability

Boolean

BACnetEngineeringUnits

BACnetARRAY[N] of BACnetPropertyIdentier

Read

Read

Read

Read/Write

Read

Read

Read

Read/Write

Read

Read

11

Page 12

Binary Value – Reverse Flow

Property Default Value Property Data Type Access

Object Identier

Object Name

Object Type

Present Value

Status Flags

Event State

Reliability

Out Of Service

Property List

This value indicates whether or not the direction of the process ow is reversed relative

to the arrow mark on the product label.

Present Value: Inactive (0) – Process uid ow direction not reversed, Active (1) –

Process uid ow direction reversed.

This object supports COV notications.

Binary Value – Empty Pipe

Property Default Value Property Data Type Access

Object Identier

Object Name

Object Type

Present Value

Status Flags

Event State

Reliability

Out Of Service

Property List

BV1

“Reverse Flow”

BINARY_VALUE (5)

Current Value

0

NORMAL (0)

NO_FAULT_DETECTED(0)

FALSE (0)

BV2

“Empty Pipe”

BINARY_VALUE (5)

Current Value

0

NORMAL (0)

NO_FAULT_DETECTED(0)

FALSE (0)

BACnetObjectIdentier

CharacterString

BACnetObjectType

BACnetBinaryPV

BACnetStatusFlags

BACnetEventState

BACnetReliability

Boolean

BACnetARRAY[N] of BACnetPropertyIdentier

BACnetObjectIdentier

CharacterString

BACnetObjectType

BACnetBinaryPV

BACnetStatusFlags

BACnetEventState

BACnetReliability

Boolean

BACnetARRAY[N] of BACnetPropertyIdentier

Read

Read

Read

Read

Read

Read

Read

Read/Write

Read

Read

Read

Read

Read

Read

Read

Read

Read/Write

Read

This value indicates whether or not the meter detects process uid at the location of

the probe.

Present Value: Inactive (0) – Process uid detected, Active (1) – Process uid not

detected

This object supports COV notications.

Binary Value – Reset Total Flow

Property Default Value Property Data Type Access

Object Identier

Object Name

ObjectType

Present Value

Status Flags

Event State

Reliability

Out Of Service

Property List

Writing a value of 1 to the present value of this object will reset the value of Total Flow

to 0. Writing a value of 0 has no effect.

BV3

“Reset Total Flow”

BINARY_VALUE (5)

Inactive (0)

0

NORMAL (0)

NO_FAULT_DETECTED(0)

FALSE (0)

BACnetObjectIdentier

CharacterString

BACnetObjectType

BACnetBinaryPV

BACnetStatusFlags

BACnetEventState

BACnetReliability

Boolean

BACnetARRAY[N] of BACnetPropertyIdentier

Read

Read

Read

Read/Write

Read

Read

Read

Read/Write

Read

12

Page 13

BitString Value – Status Flags

Property Default Value Property Data Type Access

Object Identier

Object Name

ObjectType

Present Value

Status Flags

Event State

Reliability

Out Of Service

Property List

BSV1

“Status Flags”

BITSTRING_VALUE (39)

{FFFFFFFF FFFF}

0

NORMAL (0)

NO_FAULT_DETECTED(0)

FALSE (0)

BACnetObjectIdentier

CharacterString

BACnetObjectType

BitString

BACnetStatusFlags

BACnetEventState

BACnetReliability

Boolean

BACnetARRAY[N] of BACnetPropertyIdentier

Read

Read

Read

Read

Read

Read

Read

Read/Write

Read

This object provides a means for the meter to convey additional error status to a

BACnet client. See the table below for a denition of each bit.

Bit Meaning

0

Error: Reading/Writing Non-voltaile storage

1

Reserved

2

Error: Process measurement error

3

Error: Meter recovered from watchdog reset

4

Error: Factory conguration invalid

5

Error: Wiring board not installed/detected

6

Error: Power Supply board not installed/detected

7

Reserved

8

Error: Measurement board not installed/detected

9

Error: Excitation board not installed/detected

10

Error: Calibration Data Invalid

11

Error: Process Temperature Probe Failure

BACnet Services

Device Communication Control Service (DM-DCC-B)

This device supports the Device Communication Control Service BIBB. The optional

time duration in minutes is also supported. This device is congured with a password

that must be provided to successfully execute this command. The password is “Dwyer”.

Reinitialize Device Service (DM-RD-B)

This device supports the Reinitialize Device Service BIBB. The supported device

states are COLDSTART and WARMSTART. All other states return error. This device

is congured with a password that must be provided to successfully execute this

command. The password is “Dwyer”.

SubscribeCOV Service (DS-COV-B)

This device supports the SubscribeCOV Service BIBB to allow easy monitoring of

input data.

Up to seven (7) concurrent subscriptions

Conrmed and Unconrmed COV Notications

Fixed lifetime value up to 86400 seconds (24 hours).

Indenite lifetime supported.

TimeSynchronization Service (DM-TS-B) and UTCTimeSynchronization Service

(DM-UTC-B)

This device supports both time synchronization services for easy time management

and update.

When using UTCTimeSynchronization, day light savings will not be applied

automatically. The daylight_savings_status property of the device object must be

written appropriately to adjust for daylight savings time.

MODBUS

®

Modbus® Functions

The device supports the following functions

Function Name Function Code

Read Holding Registers

Read Input Registers

Write Single Register

Write Multiple Registers

03

04

06

16

Modbus® Registers

Input Registers

Register Description Data Type Range

0001-0002

0003-0004

0005-0006

0007-0008

0009

0010

0011 - 0012

8001 - 8016

8017 - 8020

8021 - 8028

8029 - 8032

Velocity

Volume Flow

Mass Flow

Total Flow

Reverse Flow

Empty Pipe

Flow Meter Status

Model Number

Flow Meter Serial Number

Flow Meter Firmware Version

Flow Meter Date Code

32bit Float

32bit Float

32bit Float

32bit Float

Unsigned 16bit Integer

Unsigned 16bit Integer

Unsigned 16bit Integer

String

String

String

String

See BACnet “Flow Meter Status Flags”

Example: “IEF-HN-10-COM”

“xxxxxxxx”

“x.x.x”

“xxxx”

The String data type is read as a

stream of ASCII characters with the rst

character sent in the MSB of the rst

register and the second character sent

in the LSB of the rst register and so on.

If the string is shorter than the allotted

size, the remaining bytes will be zero

padded.

13

Page 14

Holding Registers

Register Description Data Type Range

0001 – 0020

0021

0022

0023

0024-0025

0026

0031

0046

Device Name: A string, up to 40 characters long, that will be displayed on the LCD (if

present). When reading or writing, all 20 registers must be requested. Strings less than

40 characters shall be 0 padded.

Velocity Unit: Selects the unit of velocity for the value in the velocity register. See

Table 1.

Flow Unit: Selects the unit of ow for the value in the Flow register. See Table 2.

Volume Unit: Selects the unit of volume for the value in the Total Flow register. See

Table 3.

Reset Total Flow: When a value of 1 is written to this register, the value in the Total

Flow register is reset to 0. Writing a value of 0 has no effect. This register will always

return a 0 when read.

Reset Device: When a value of 1 is written to this register, the device will perform a

warm reset after 5 seconds. Writing a value of 0 has no effect. This register will always

return 0 when read.

VELOCITY UNIT VALUES

Value Unit

*0

1

2

3

4

5

6

7

VOLUME FLOW UNIT VALUES

Value Unit

*0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Device Name

Velocity Unit

Volume Flow Unit

Volume Unit

% Ethylene Glycol

Concentration

Reset Total Flow

Mass Flow Unit

Reset Device

Feet-per-second (ft/s)

Feet-per-minute (ft/min)

Feet-per-hour (ft/hr)

Feet-per-day (ft/day)

Meters-per-second (m/s)

Meters-per-minute (m/min)

Meters-per-hour (m/hr)

Meters-per-day (m/day)

Table 1

Cubic-feet-per-second (ft3/s)

Cubic-feet-per-minute (ft3/min)

Cubic-feet-per-hour (ft3/hr)

Cubic-feet-per-day (ft3/day)

Gallons-per-second (gal/s)

Gallons-per-minute (gal/min)

Gallons-per-hour (gal/hr)

Gallons-per-day (gal/day)

Liters-per-second (L/s)

Liters-per-minute (L/min)

Liters-per-hour (L/hr)

Liters-per-day (L/day)

Cubic-meters-per-second (m3/s)

Cubic-meters-per-minute (m3/min)

Cubic-meters-per-minute (m3/min)

Cubic-meters-per-day (m3/day)

Table 2

String

Unsigned 16bit integer

Unsigned 16bit integer

Unsigned 16bit integer

32bit Float

Unsigned 16bit integer

Unsigned 16bit integer

Unsigned 16bit integer

0 – 7

0 – 15

0 – 3

0 – 100

0 or 1

0 – 7

0 or 1

VOLUME UNIT VALUES

Value Unit

0

Cubic-feet (ft3)

*1

Gallons (gal)

2

Liters (L)

3

Cubic-meters (m3)

Table 3

MASS FLOW UNIT VALUES

Value Unit

*0

Pounds-mass-per-second (lb/s)

1

Pounds-mass-per-minute (lb/min)

2

Pounds-mass-per-hour (lb/hr)

3

Pounds-mass-per-day (lbm/day)

4

Kilograms-per-second (kg/s)

5

Kilograms-per-minute (kg/min)

6

Kilograms-per-hour (kg/s)

7

Kilograms-per-day (kg/day)

Table 4

Multi-Address Support

Multi-Address support allows a register to be read or written to using different byte

orientations specied by the address range. For example, input register 0003 can

also be read at 2003, 4003 and 6003 with different byte orientations as listed in Table

7. Registers that do not have multi-address support are only available in Big-Endian

byte orientation (Modbus® standard).

Float/32bit Values 16Bit Values

Byte Order Address Range MSB LSB MSB LSB

Big-Endian

Byte Swap

Word Swap

Little-Endian

1-2000

2001-4000

4001-6000

6001-8000

Register 1 Register 2 Register 3

A

B

C

D

B

A

C

D

D

D

A

C

B

A

C

B

B

A

A

B

B

A

B

A

* Default unit

14

Page 15

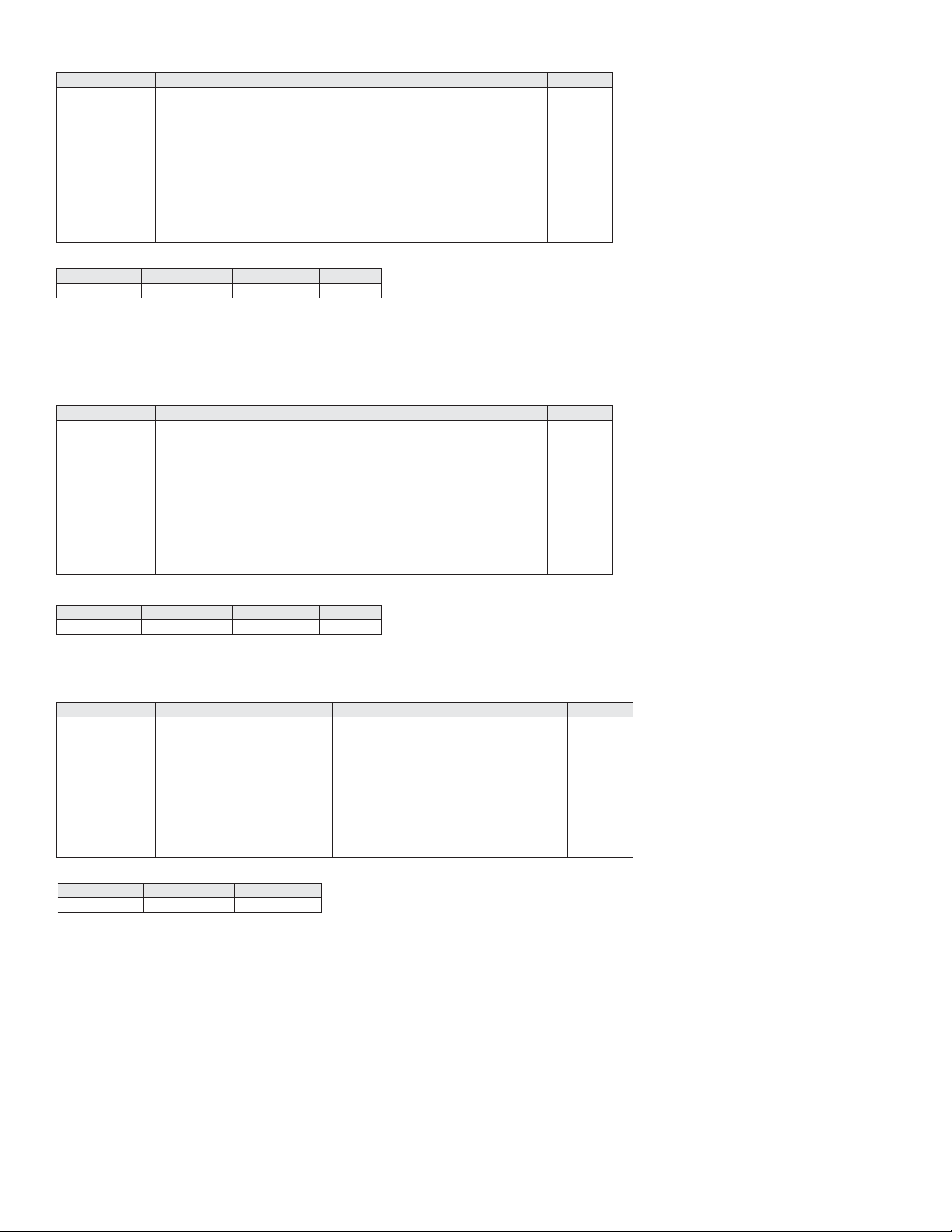

Electronic Control Setup -LCD Display Option or A-IEF-DSP Accessory

Basic information

1. Turn on the power to the Display/Menu.

NOTICE

2. If a Transmitter is NOT congured, a main conguration wizard starts.

3. If the Transmitter is congured, the process data is displayed.

At power ON, the Dwyer Logo, Serial Number and Firmware

Version of the Transmitter is displayed.

Main Conguration Wizard

1. Language Selection:

• At the Language Screen elect the Language:

NOTICE

• If necessary, select another language by moving the highlighted bar with

the UP /DOWN Arrows and press the Enter Button to select the

Language.

The menu default language is English.

SERIAL

NUMBER

Navigation Basics

1. The UP /DOWN buttons change the selected option or increase or

decrease the current value.

2. The RIGHT button advances the display to the next menu without

changing the current setting.

3. The LEFT button returns the display to the previous menu without

changing the current setting.

4. The ENTER button accepts the selected setting or value and advances to

the next menu.

5. The MENU button transitions the display to the main menu. Any unsaved

changes will be lost.

FIRM

WARE

VERSION

2. Unit System Selection Menu:

• This option determines which units will be available in future menus.

• The Default is English

• If necessary, select a different Unit of measure by moving the highlighted

bar with the UP /DOWN Arrows and press the Enter button to

select he Unit.

3. Velocity Unit Menu:

• This option determines how the calculated volume velocity is displayed.

• The Default is Feet-Per-Second.

Menu Basics

1. Option Menus:

• The current option is indicated by a highlight bar. The highlight bar is

moved with the UP and DOWN buttons.

• The active option is indicated by an asterisk (*) symbol to the far right of the

option name.

2. Value Menus:

• The active value is always displayed when the menu is displayed.

• To reset a changed value to the active value, use the LEFT button to

return to the previous menu, then the RIGHT button to advance to the

value menu again.

3. Press & Hold the UP or DOWN button to continuously increase or

decrease the value.

Note: The value will be increased or decreased by a larger amount the longer

the button is held.

4. Volume Flow Unit Menu:

• This option determines how the calculated volume ow is displayed.

• The Default is Cubic-Feet-Per-Second.

15

Page 16

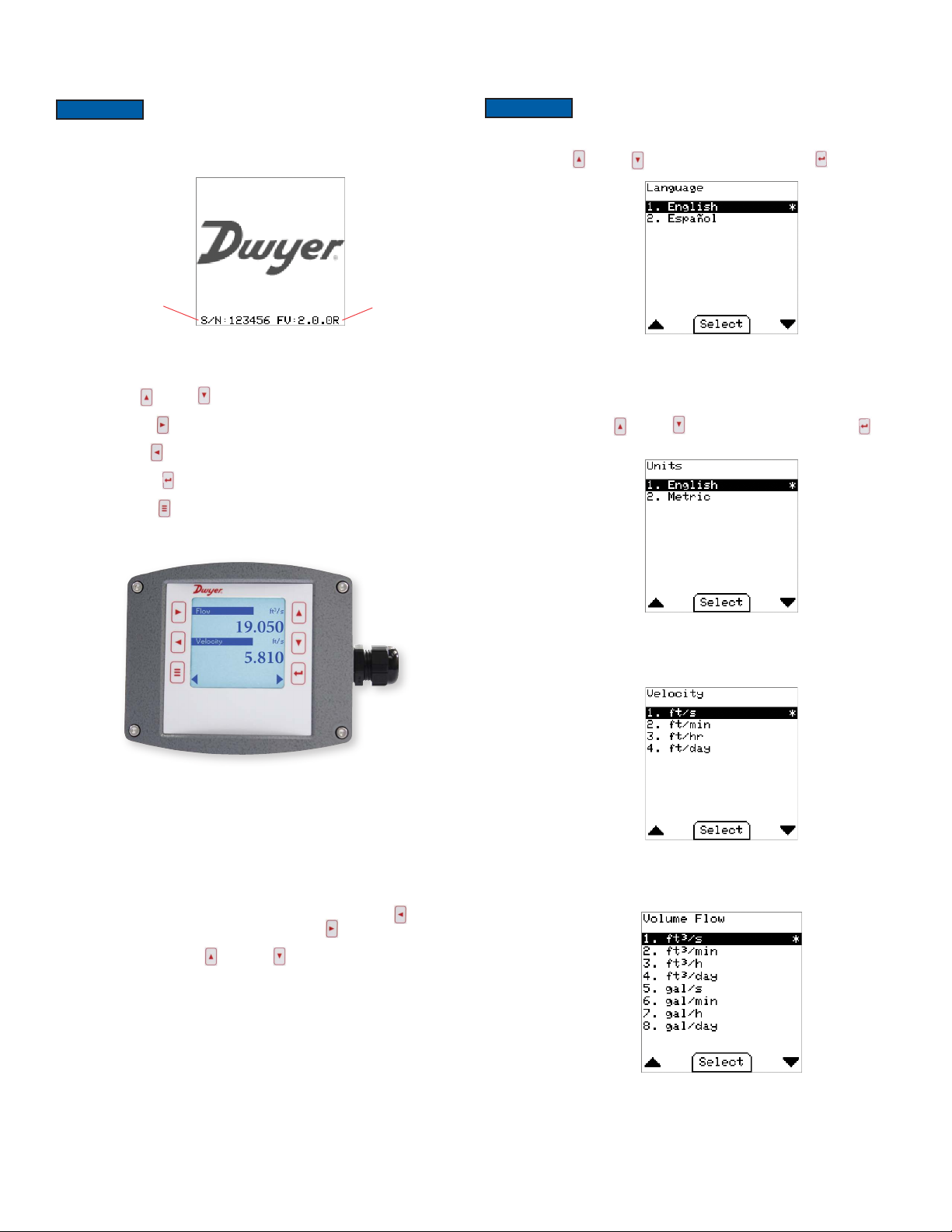

5. Mass Flow Unit Menu

• This option determines how the calculated mass ow is displayed

• The Default is pounds-mass-per-hour (lbm/h)

6. Volume Unit Menu:

• This option determines how the totalized ow is displayed.

• The Default is Gallons.

Pipe Conguration Wizard

1. Pipe Material Menu:

• This option helps determine the pipe dimensions as well as account for

different material properties.

• The Default is Carbon Steel

a. Pipe Circumference Menu (High Performance):

• This value is the outside circumference of the pipe where the Transmitter

is installed.

• The circumference can be measured with the tape included in the high

performance installation kit.

• Default: 27.096in (~8in diameter)

b. Wall Thickness Menu (High Performance):

• This value is the pipe wall thickness where the Transmitter is installed.

• The thickness can be measured with the gauge included in the high

performance installation kit.

• Default: 0.322in

2. Install Kit Menu (High Performance):

• This option determines how the pipe dimensions will be collected.

• If a high accuracy Transmitter was purchased, then a high accuracy

installation kit must be used to ensure correctness.

• Default: High Performance Setup.

3. Install Kit Menu (Standard):

• Nominal Pipe Size Menu

• Select the diameter of the installation pipe from the list of standard pipe

diameters. If your nominal diameter is not listed or you have actual OD data,

select Other and enter the pipe diameter directly.

• Default: 8 in

a. Install Kit Menu (Standard):

• Wall Thickness Menu:

• Select the wall thickness of the installation pipe from the list of standard

pipe wall thicknesses.

• If your wall thickness is not listed, select Other and enter the pipe wall

thickness directly.

• The options available depend on the pipe material selected.

• Default: Varies with selected pipe material.

16

Page 17

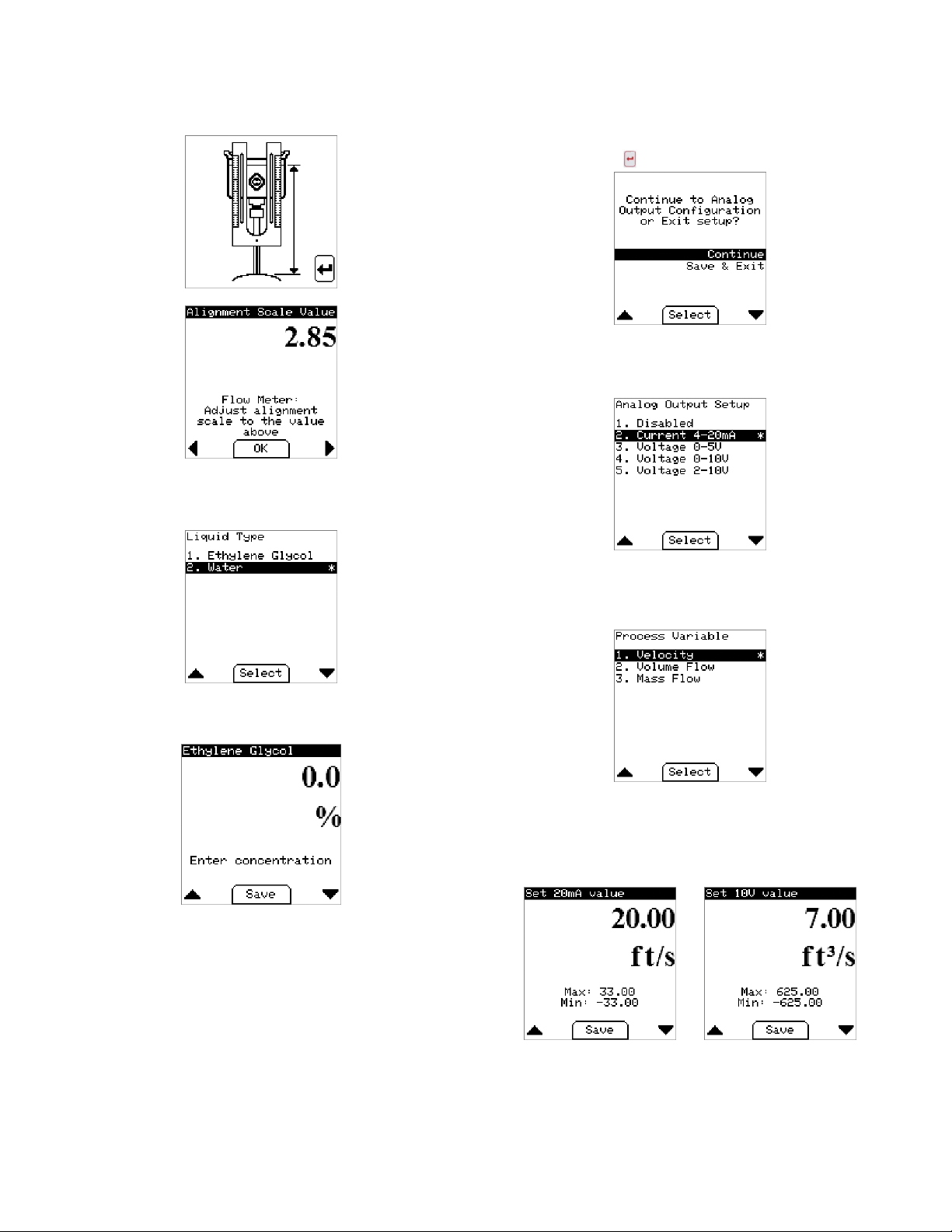

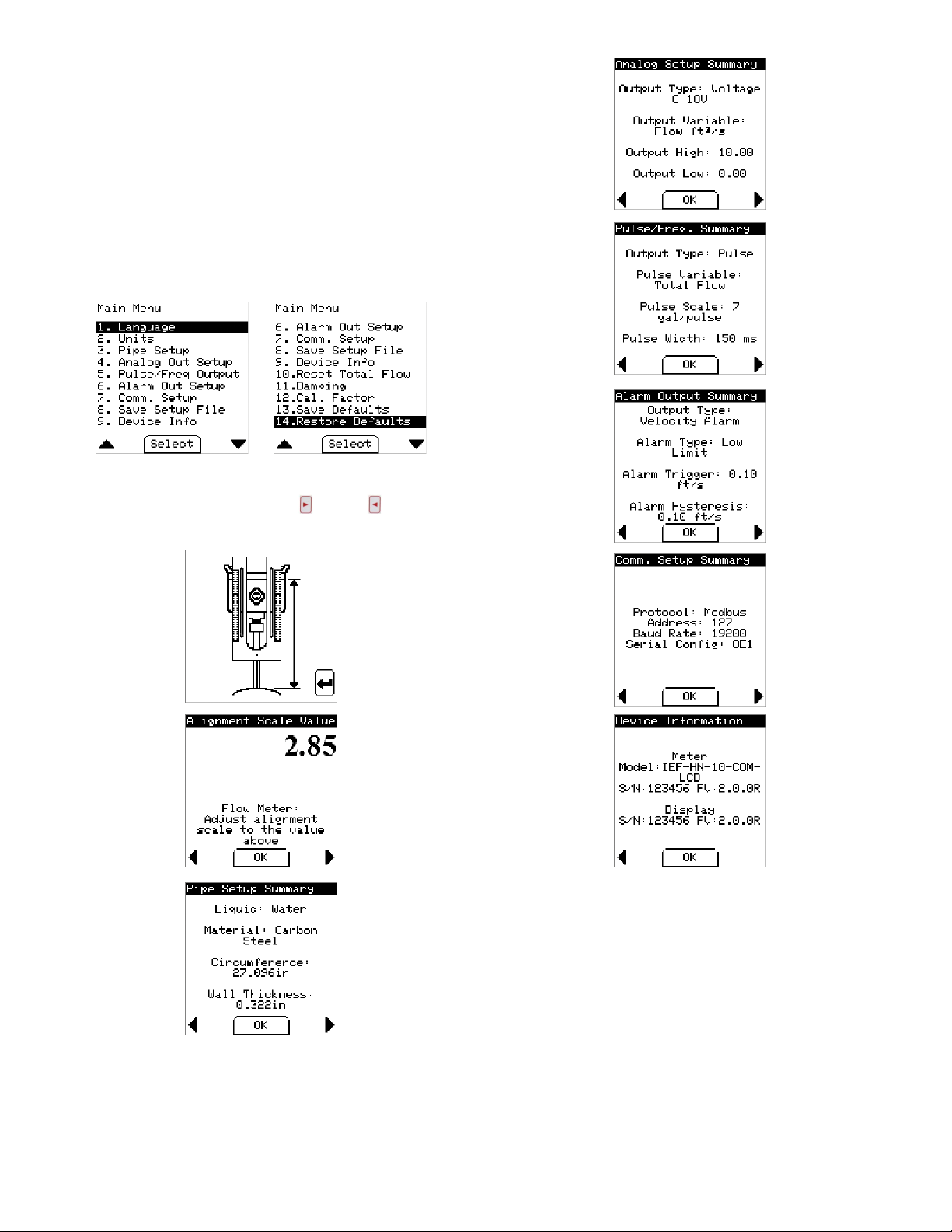

4. Pipe Insertion Depth Display:

• This screen shows the calculated insertion depth based on the values

previously entered.

• Using the installation alignment kit provided with the IEF, set the depth

to the value displayed:

5. Liquid Type Menu:

• This option species the process liquid to be measured.

• Default: Water

7. Continue to Analog Conguration Wizard Question:

• If Continue is selected, the next menu displayed will be in the Analog

conguration wizard.

• If Save & Exit is selected, the settings and values entered during the Pipe

conguration wizard will be stored and put into effect.

• Then the display will show process data. Regardless of selection, the

ENTER button must be used to choose either option.

• Default: Continue

8. Analog Conguration Wizard:

• Analog Output Setup Menu:

• This option determines the type of analog output from the Transmitter.

• Default: Current 4 to 20mA

• If Ethylene Glycol is selected, the next menu will allow the concentration to

be entered.

• Default: 0%

6. Pipe Conguration Summary Display: High Performance:

• This screen shows a summary of the settings entered in the pipe

conguration wizard when a high performance installation kit is used.

High performance Setup

9. Process Variable Menu:

• This option determines which variable is output on the analog signal.

• Default: Velocity

10. Analog Output High Menu:

• This value determines the process value at which the analog output will be

at maximum (e.g. 20 mA, 10 V, 5 V).

• Default: 20.0 ft/s.

17

Page 18

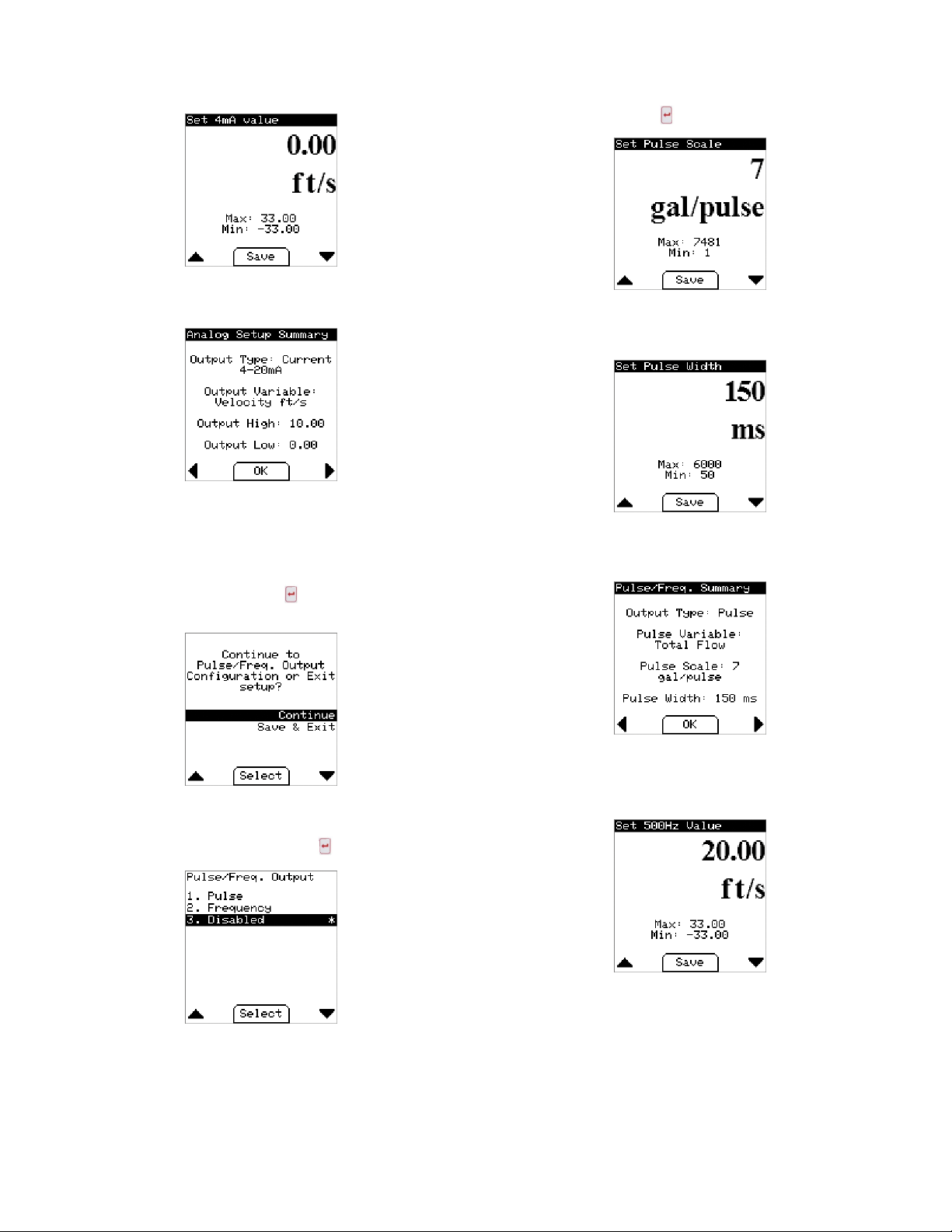

11. Analog Output Low Menu:

• This value determines the process value at which the analog output will be

at minimum (e.g. 4mA, 0V).

• Default: 0.0 ft/s

12. Analog Conguration Summary Display:

• This screen shows a summary of the settings entered in the Analog

conguration wizard.

13. Continue to Pulse/Frequency Conguration Wizard Question:

• If Continue is selected, the next menu displayed will be in the Pulse/

Frequency conguration wizard.

• If Save & Exit is selected, the settings and values entered during the Analog

conguration wizard will be stored and put into effect.

• Then the display will show process data.

• Regardless of selection, the ENTER button must be used to choose

either option.

• Default: Continue.

2. Digital Output: Pulse

• Pulse Scale Menu:

◦ This value determines the amount to totalized volume between each pulse

of the output.

◦ Default: 7 gallons/pulse

• Pulse Width Menu:

◦ This value determines the duration of the pulse when active.

◦ Default: 150 milliseconds

• Pulse/Frequency Summary Display:

• This screen shows a summary of the pulse settings entered in the Pulse/

Frequency conguration wizard.

Pulse/Frequency Wizard:

1. Pulse/Frequency Output Menu:

• This option determines the type of digital output from the Transmitter.

• Default: Disabled. If correct press the Enter Button.

• Frequency Output High Menu:

◦ This value determines the process value at which the frequency output will

be at maximum (500Hz).

◦ Default: 20.0 ft/s

18

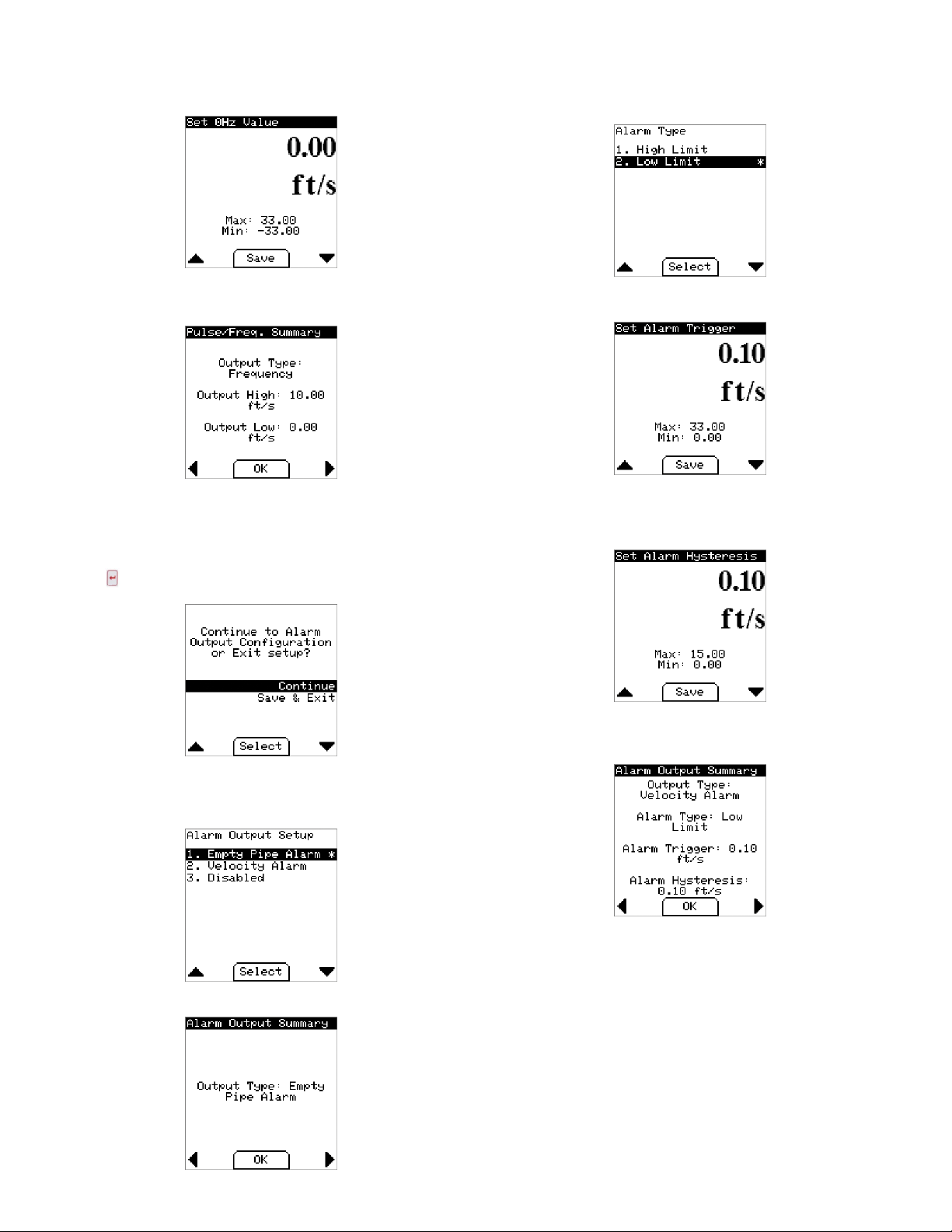

Page 19

• Frequency Output Low Menu:

◦ This value determines the process value at which the frequency output will

be at minimum (0Hz).

◦ Default: 0.0 ft/s

Velocity Alarm - Outputs:

1. Alarm Type Menu:

• This option determines how the process velocity is compared to the trigger

value.

• Default: Low Limit

3. Pulse/Frequency Summary Display:

• This screen shows a summary of the frequency settings entered in the

Pulse/Frequency conguration wizard.

4. If Continue is selected, the next menu displayed will be in the Alarm

conguration wizard.

5. If Save & Exit is selected, the settings and values entered during the Pulse/

Frequency conguration wizard will be stored and put into effect.

6. Then the display will show process data. Regardless of selection, the ENTER

button must be used to choose either option.

• Default: Continue

2. Alarm Trigger Menu:

• This value species the velocity at which the alarm is active or inactive.

• Default: 0.1 ft/s

3. Alarm Hysteresis Menu:

• This value denes a range around the trigger value to prevent excessive

switching of the alarm output.

• Default: 0.1 ft/s

4. Alarm Output Summary Display:

• This screen shows a summary of the settings entered in the Alarm

conguration wizard when velocity alarm is selected.

Alarm Wizard

1. Alarm Output Setup Menu:

• This option determines the type of alarm output.

• Default: Empty Pipe Alarm.

2. Empty Alarm Setup Menu

19

Page 20

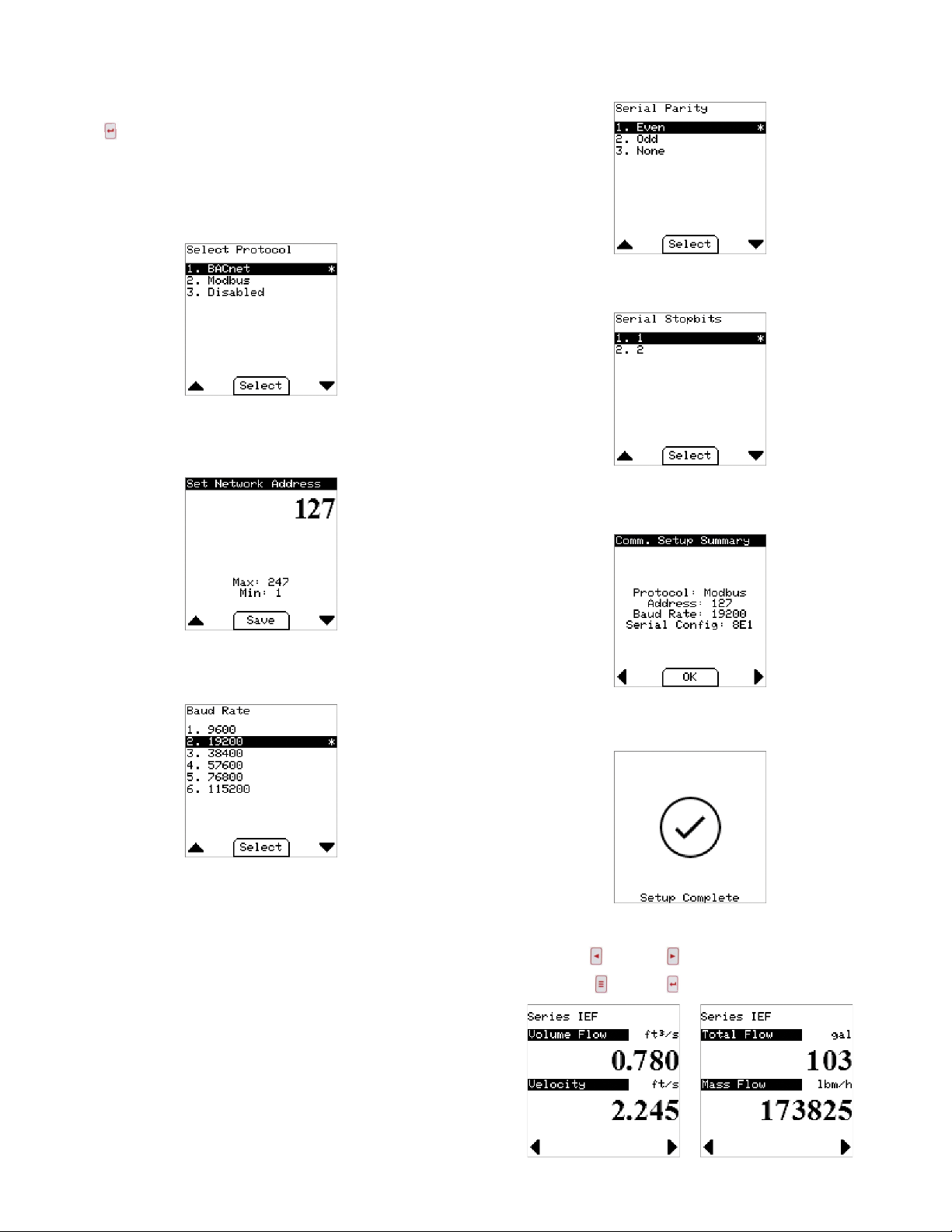

5. If Continue is selected, the next menu displayed will be in the Communication

conguration wizard.

6. If Save & Exit is selected, the settings and values entered during the Alarm

conguration wizard will be stored and put into effect.

7. Then the display will show process data. Regardless of selection, the ENTER

button must be used to choose either option.

• Default: Continue

Communication Conguration Wizard

1. Select Protocol Menu:

• This option determines the protocol used by the Transmitter over the

RS-485 interface.

• Default: Disabled.

2. Network Address Menu:

• This value sets the device address on the RS-485 bus. Address range

depends on protocol; BACnet Communications Protocol (0-127), Modbus

Communications Protocol (1-247)

• Default: 127

4. Serial Parity Menu (Modbus® Communications Protocol Only):

• This option sets the serial parity on the RS-485 bus.

• Default: Even

5. Serial Stopbits (Modus® Communications Protocol Only):

• The option sets the serial Stopbits on the RS-485 bus.

• Default: 1

®

6. Communication Summary Display:

• This screen shows a summary of the settings entered in the Communication

conguration wizard.

3. Baud Rate Menu:

• The option selects the communication speed of the RS-485 bus.

• Default: 19200 (Modbus® Communications Protocol), 38400 (BACnet

Communications Protocol)

• After the Communication Wizard is complete, the Transmitter setup is

complete:

• The display will show Setup Complete and transition to display process

Data

Process Value Display:

• This display is the default view after power on of a congured Transmitter.

When the Save & Exit option is chosen from a wizard, this is the next view.

• Use the LEFT and RIGHT buttons to toggle between Flow/Velocity and

Total Flow/Process Temperature view.

• Use the MENU or ENTER button to go to the main menu.

20

Page 21

MAIN MENU

1. Language: Change the language of the display

2. Units: Change the display units

3. Pipe Setup: Enter the Pipe setup wizard

4. Analog Output Setup: Enter the Analog Output wizard

5. Pulse/Frequency Output Setup: Enter the Pulse/Frequency wizard

6. Alarm Output Setup: Enter the Alarm Output wizard

7. Communication Setup: Enter the Communication wizard

8. Save Setup File: Save the current setup to a le.

9. Device Information: Show the summary displays from each wizard and

other Transmitter/display information.

10. Clear Flow Total: Reset totalized ow value.

11. Averaging: Congure an averaging time.

12. Calibration Factor: Congure custom velocity multiplier.

13. Save Default: Save the current settings as the user default values.

14. Restore Defaults: Restore the previously saved user settings.

Device Information

• A list of all setting summaries. Use RIGHT and LEFT to move between

the various summary pages. The last page provided information about the

Transmitter and display.

21

Page 22

Save Setup File

KEYPAD LOCKOUT SWITCH

Create a setup le containing all the options and values selected from the

wizards. This le is stored in the display and can be retrieved by connecting a

USB cable.

Restore Defaults

• This menu restores the saved user conguration to the current conguration.

This provides a means to restore the Transmitter to a known working state.

Reset Total Flow

This menu allows the totalized ow value to be reset to

Damping

• This value determines the amount of time the velocity is averaged. The

display value will reach 99% of the measured value within this time.

• Default: 30 s

Reset to Factory Default

This special menu is accessed by press & holding ENTER and MENU

buttons on the Device Information screen above. Answering Yes, will reset all

selections and values to factory default values.

NOTICE

Key Pad Lockout Feature

• For units with the LCD option a switch (shown in Figure 16) is located on

the display that allows the keypad to be “locked out” to prevent undesired key

presses that could potentially change the transmitter conguration. When the

switch is in the “locked” position the display will generate a padlock symbol in

the lower right corner as shown below.

• Default: Unlocked.

All BACnet Communications settings will be reset as well, including

the values that can only be set via BACnet Communications.

Cal. Factor

• This value sets a custom multiplier of the measured velocity.

Save Defaults

• This menu saves the current conguration as the user default values. This

provides a means to save a known good conguration before making other

changes.

Figure 16

22

Page 23

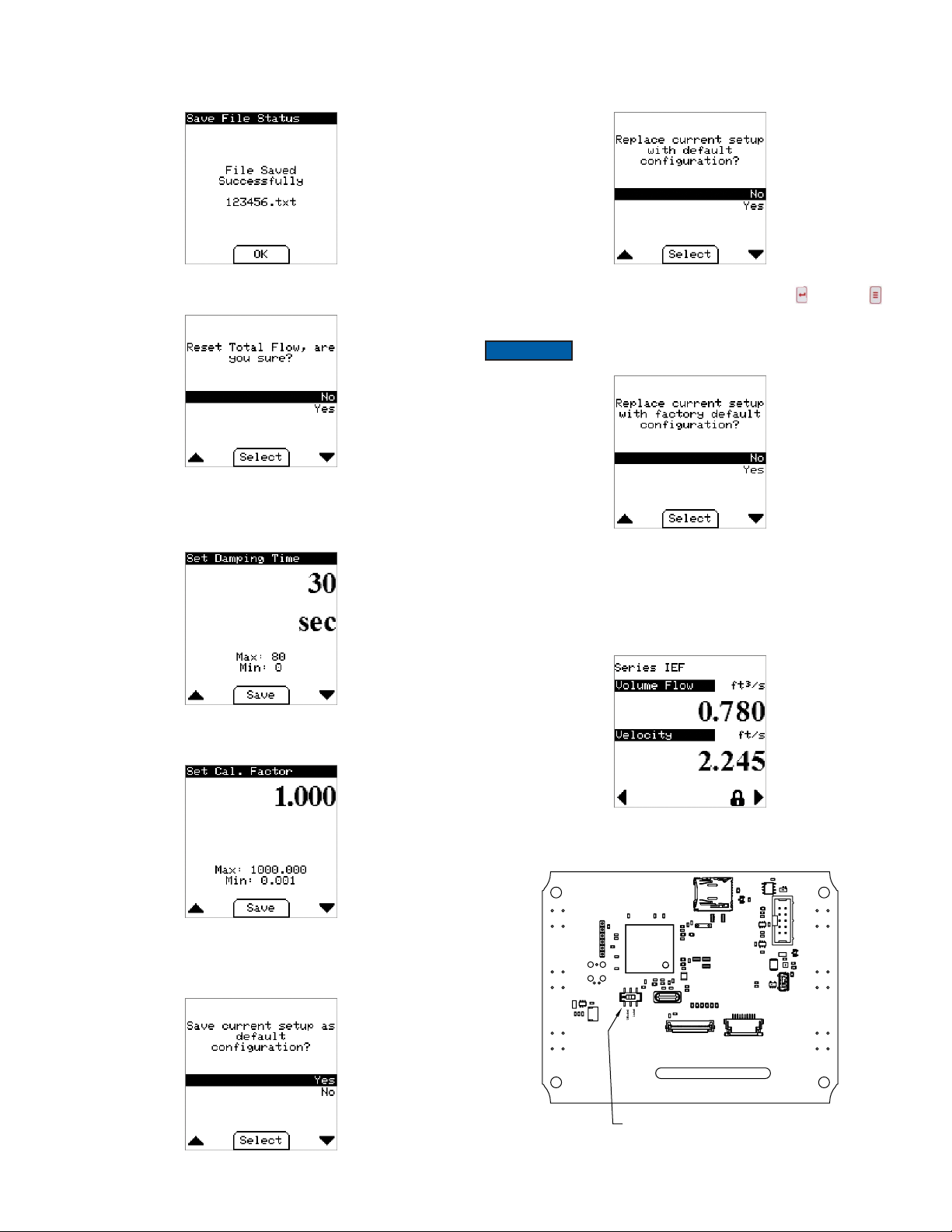

Troubleshooting Guide

A status blink code is conveyed by the blinking of the status LED (Figure 17) using

the following parameters.

A blink is dened as the LED is ON for 200ms followed by the LED being OFF for

200ms.

If a status code has a tens digit, the tens digit blink code is created and then

followed by a 750ms delay OFF time. Then the ones digit blink code is created.

After a blink code is displayed, there is an OFF time of 2 sec before the blink code

is displayed again.

If more than one condition is true, the condition with the highest code will be

displayed.

Example: Item 3, Invalid Factory Conguration with a blink code of 11.

There would be a state of the LED being ON for 200 msec, then OFF for 200 msec,

then OFF for 750 msec, then ON for 200 msec, then OFF for 200 msec followed by

off for 2 sec before repeating this sequence.

Status

LED Blink

Item Condition

1

Invalid value

2

Empty pipe

3

Invalid factory conguration

4

NV access failed

5

NV write failed

6

Wiring board not installed

7

Flyback board not installed

8

Analog front end board not installed

9

Coil driver board not installed

10

Process temperature fault

11

Factory variable unlocked

12

Failure to measure process

13

Communication failure

Code Description Corrective Action

1

2

11

12

13

21

22

24

25

26

33

n/a

n/a

Invalid calibration (Value display on LCD)

The probe is not submerged in the process uid

The factory non-volatile conguration is invalid

The meter failed to read its non-volatile memory

The meter failed to write its non-volatile memory

The wiring board was not detected

The Flyback board was not detected

The Analog Front End board was not detected

The Coil Driver board was not detected

Temperature sensor not responding

The factory variables are unlocked and can be modied

Critical Error! Failed to measure process. (On-screen only)

Communication with the meter has failed. Settings not saved to

meter (On-screen only)

14

Communication failure

n/a

Communication with meter has failed. Attempting to re-establish.

Please wait … (On-screen only)

15

Communication failure

n/a

Critical Error! Failed to access settings in non-volatile storage.

(On-screen only)

16

Settings not saved

17

Settings not saved

18

Settings not saved

n/a

n/a

n/a

Error: File Not Saved! Access Denied (On-screen only)

Error: File Not Saved! Storage Media Timeout (On-screen only)

Error: File Not Saved! Storage Media Not Ready (On-screen

only)

19

Settings not saved

n/a

Error: File Not Saved! Storage Media Not Found (On-screen

only)

20

Settings not saved

21

Indicator display failure

n/a

n/a

Error: File Not Saved! Unknown (On-screen only)

Meter not congured! The meter must be congured with a setup

display before an indicator display can be used.

STATUS LED

Figure 17

Return to factory, calibration required

Ensure the pipe is properly lled, ensure proper

installation depth

Return to factory, conguration and calibration

required

Return to factory for repair

Return to factory for repair

Return to factory for repair

Return to factory for repair

Return to factory for repair

Return to factory for repair

Return to factory for repair

Power cycle, reset, or send lock command to

meter

Power cycle, reset via BACnet/Modbus

®

Disconnect and reconnect display

Disconnect and reconnect display

Power cycle, reset via BACnet/Modbus®,

consult factory

Disconnect and reconnect display,

replace SD card on display PCBA

Disconnect and reconnect display,

replace SD card on display PCBA

Disconnect and reconnect display,

replace SD card on display PCBA

Verify SD card is fully inserted into SD card

socket on display PCBA

Disconnect and reconnect display,

replace SD card on display PCBA

Congure the meter with a setup display

Item 1 Display

Item 10 Display Item 13 Display

23

Item 12 Display

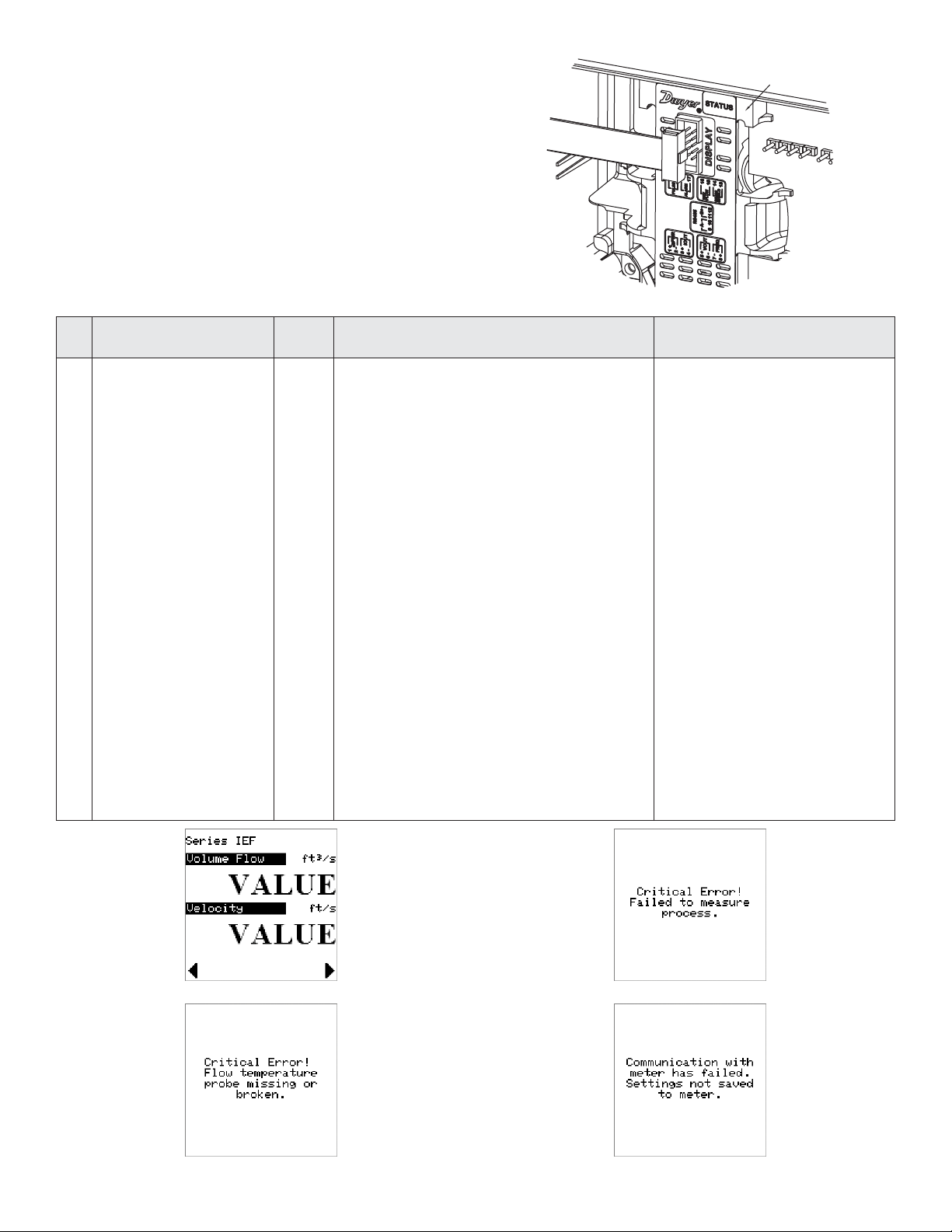

Page 24

Item 14 Display

Item 17 Display

Item 15 Display

Item 16 Display

Item 18 Display

Item 19 Display

Item 20 Display

24

Item 21 Display

Page 25

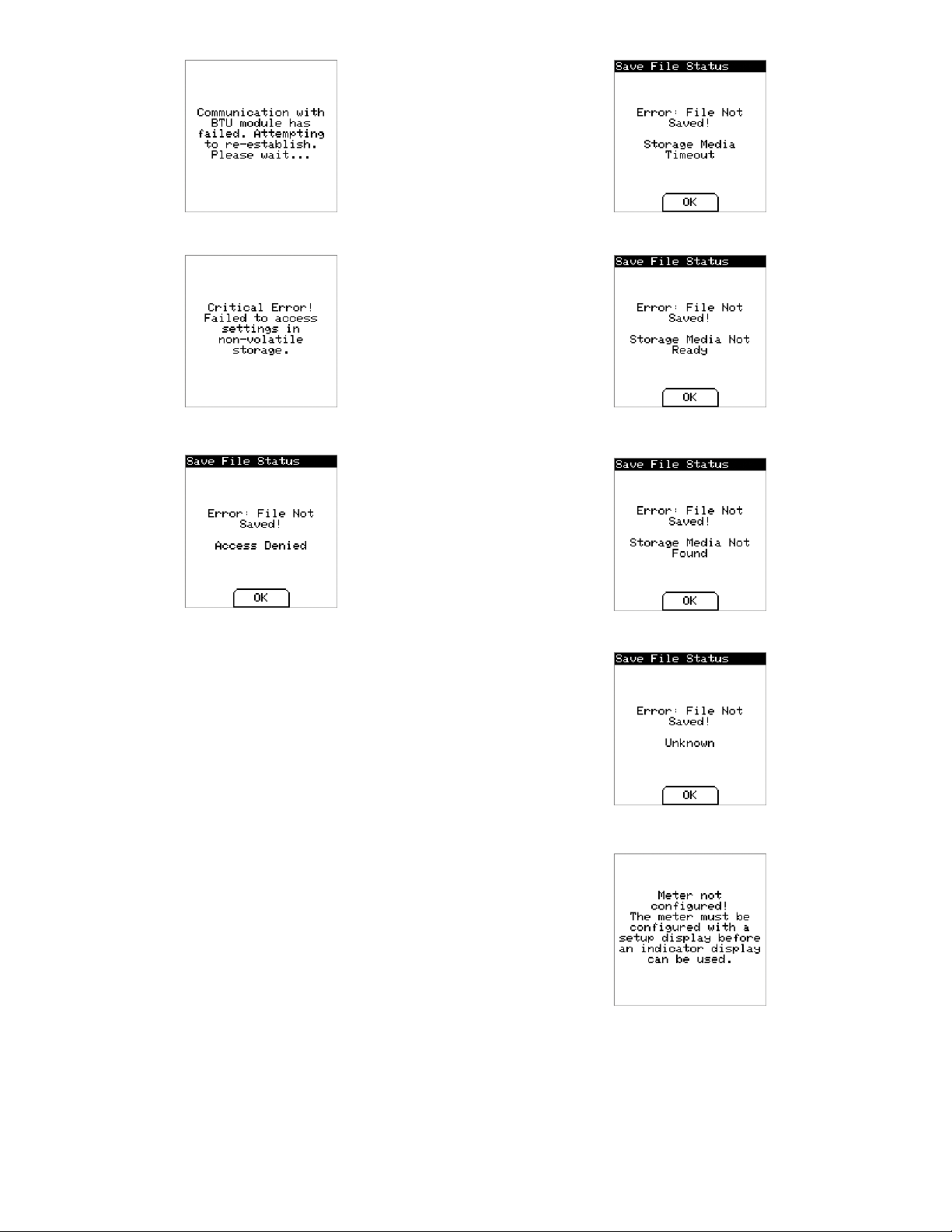

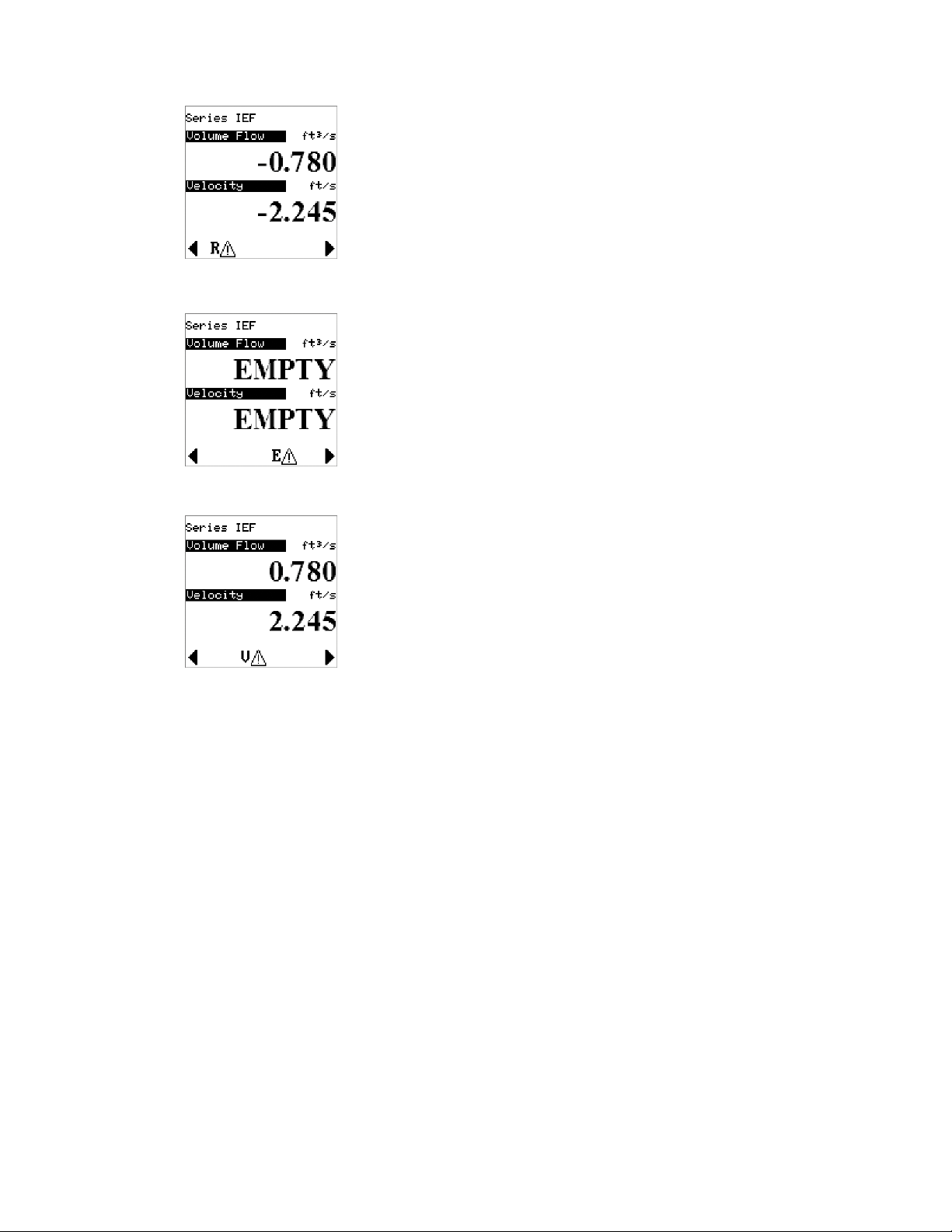

Flow Condition Warnings:

If a reverse ow condition exists an “R” with an exclamation mark in a triangle will

appear as shown below:

If an empty pipe condition exists an “E” with an exclamation mark in a triangle will

appear as shown below:

If velocity alarm condition exists a “V” with an exclamation mark in a triangle will

appear as shown below:

MAINTENANCE/REPAIR

Upon nal installation of the Series IEF, no routine maintenance is required, however

if recalibration is desired the unit must be returned to Dwyer Instruments, Inc. to be

calibrated. Contact customer service to receive a Return Goods Authorization number

before shipping you product back for calibration. The Series IEF is not eld serviceable

and should be returned if repair is needed. Field repair should not be attempted and

may void the warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sale” in our catalog or on our website. Contact

customer service to receive a Return Goods Authorization number before shipping

your product back for repair. Be sure to include a brief description of the problem plus

any relevant application notes.

25

Page 26

NOTES

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________