Page 1

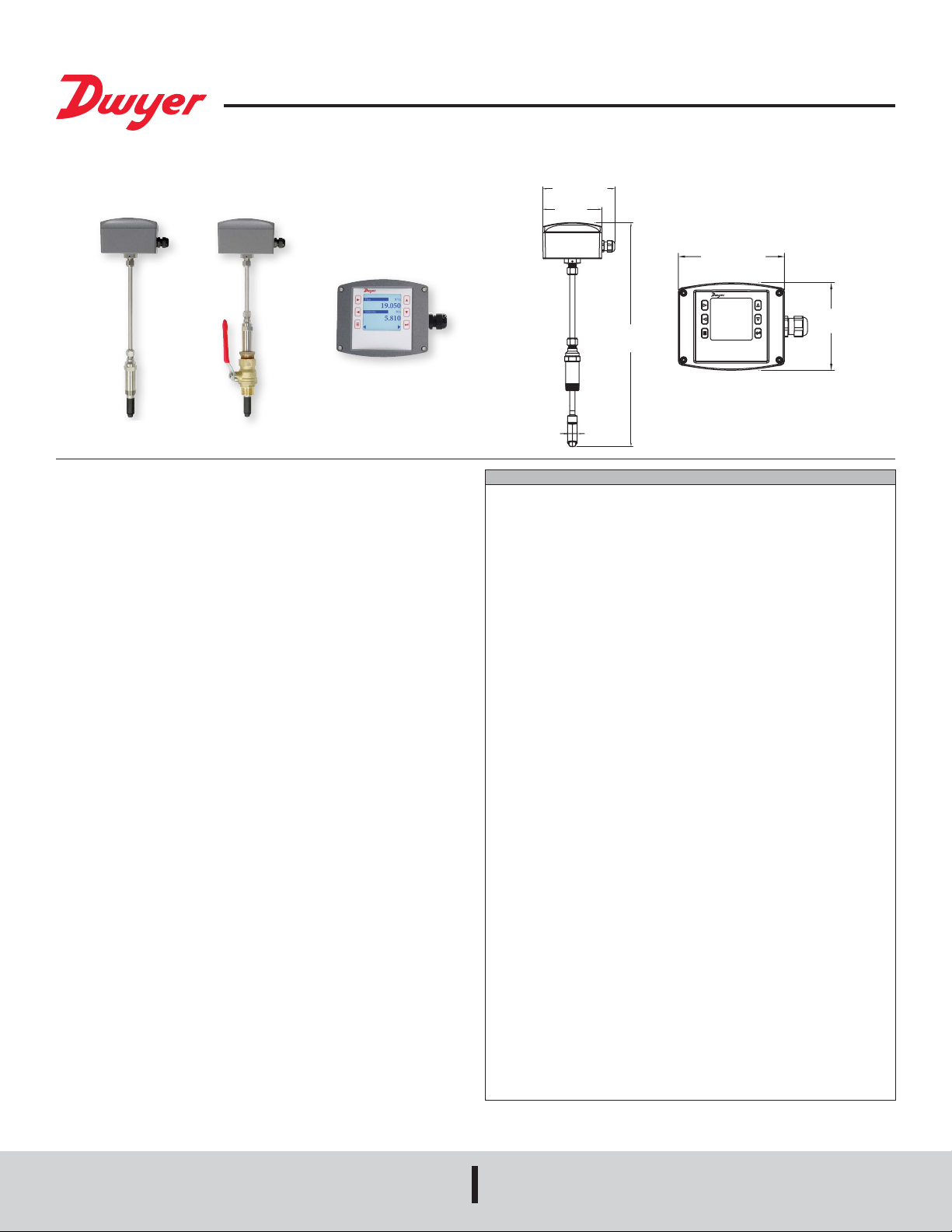

Series IEF Insertion Electromagnetic Flow Transmitter

5-53/64 [148.0]

61/64

[24.2]

22-1/64

7-3/32 [180.2]

®

Specications - Installation Instructions

For full Installation and Operating Instructions refer to Bulletin F-IEF-F at

http://www.dwyer-inst.com/Product//SeriesIEF#literature

5-53/64

[148.0]

[559.2]

-LCD option shown

Shown with A-IEF-VLV-BR

accessory valve

Bulletin F-IEF-QS

4-51/64

[121.8]

The Series IEF Insertion Electromagnetic Flow Transmitter is an adjustable

insertion owmeter featuring electromagnetic technology that accurately and reliably

measures uid velocity in addition to providing several continuous signal outputs.

This series is specically designed to offer superior performance paired with simple

installation and use. One unit is adjustable to t pipe sizes from 4 to 36˝ (101.6 to

914.4 mm), and offers several output options including selectable BACnet MS/TP or

®

RTU communications protocol over 2-wire RS-485 in addition to the standard

Modbus

analog, frequency and alarm outputs.

FEATURES/BENEFITS

• Field congurable, integral or remote setup displays (-LCD option or accessory

A-IEF-DSP) allow for ultimate exibility by accommodating a variety of application

congurations with one model through multiple display congurations i.e. pipe

size, pipe material, liquid type, analog output, pulse/frequency output, alarm outputs,

communication outputs, damping, and calibration factor.

• High performance accuracy is maintained through temperature, density or viscosity.

• Setup Wizard and installation tool are simple to use allowing for quick and precise

installation.

• Accessory setup kit A-IEF-KIT ensures exact installation application depth with

included thickness gage and measuring tape.

• Long Life Cycle and minimal maintenance requirements with no moving parts to

wear or break and electrodes that discourage fouling.

• Isolation valve accessory options allow for installation in operational systems via

hot-tap kit or easy removal without system downtime.

• NIST calibration certicate included standard for Carbon Steel Schedule 40 pipes

sized 4˝ (100 mm), 6˝ (150 mm), 8˝ (200 mm), and 10˝ (250 mm) with high accuracy

option.

APPLICATIONS

• Boiler feed water

• Chilled water

• Open and closed loop condenser water

• Irrigation system

• Municipal water distribution

• Process and coolant ow

• Ground water remediation

• Chemical processing

• Pump protection

• Wastewater

• Mining

SPECIFICATIONS

Service: Compatible clean or dirty non coating, conductive liquids.

Range: 0 to 20 ft/s (0 to 6 m/s).

Wetted Materials: Body shaft/tting: 316SS; Electrodes: 316SS; Electrode cap:

Polymer/Polystyrene; O-ring: Silicone.

Accuracy: IEF-HX-X: ±0.5% of reading at calibrated velocity; ±1% of reading from

2 to 20 ft/s (0.6 to 6 m/s) ±0.02 ft/s (±0.006 m/s) at < 2 ft/s (0.6 m/s). IEF-SX-X:

±1% FS.

Temperature Limits: Ambient: -20 to 160°F (-29 to 71°C); Process: 15 to 250°F (-9

to 121°C); Storage: -40 to 185°F (-40 to 85°C).

Process Connection: 1˝ NPT or BSPT with accessory full port ball valve options.

Pressure Limits: 400 psi (27.6 bar) @ 100º F (37.8°C).

Pressure Drop: < 0.1 psi at 12 ft/s in 4˝ (101.6 mm) and larger pipe.

Outputs:

(1) Analog: 4 to 20 mA, 0 to 5 V, 0 to 10 V or 2 to 10 V (display selectable);

(1) Pulse/Frequency: 0 to 15 V peak pulse, 0 to 500 Hz or scalable pulse output

(display selectable);

(2) Alarms: (1) Empty pipe detection or minimum/maximum velocity, (display

selectable); (1) Reverse ow output indication.

Power Requirements: 12 to 42.4 VDC, .25 A @ 24 VDC; 12 to 36 VAC.

Electrical Connection: Removable terminal blocks, model selectable 1/2˝ female

NPT conduit connection, PG 16 gland or PG 16 gland with (2) 10 ft (3 m) 9

conductor 22 AWG plenum rated cables, accessory cable lengths up to 200 ft (61

m) optional.

Display (-LCD option): 2˝ ( 5.08 cm) x 2˝ (5.08 cm) graphic LCD with backlight.

Conductivity: >20 microsiemens.

Enclosure Material: Powder coated die cast aluminum.

Enclosure Ratings: NEMA 6P (IP68) (Non display models); NEMA 4X (IP66)

(-LCD option).

Agency Approvals: BTL, CE, NSF/ANSI 61 and 372 pending.

COMMUNICATIONS (-COM OPTION)

Type: BACnet MS/TP or Modbus

display selectable).

Supported Baud Rates: 9600, 19200, 38400, 57600, 76800, or 115200 bps

(display selectable).

Device Load: 1/8 unit load.

®

RTU communication protocol (default disabled,

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

ADDITIONAL SPECIFICATIONS

Applicable Pipe Material: Most popular plastic and metal pipes; i.e. Carbon steel,

SS, copper, UPVC/PVDF, galvanized steel, mild steel, and brass.

Applicable Pipe Size: IEF-HX-X: 4 to 10˝ (101 to 254 mm); IEF-SX-X: 4 to 36˝

(101 to 914 mm).

Diameter Length Requirements: >10 upstream, >5 downstream.

Glycol: 0 to 100% display selectable.

Modbus® is a registered trademark of Schneider Automation, Inc.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Page 2

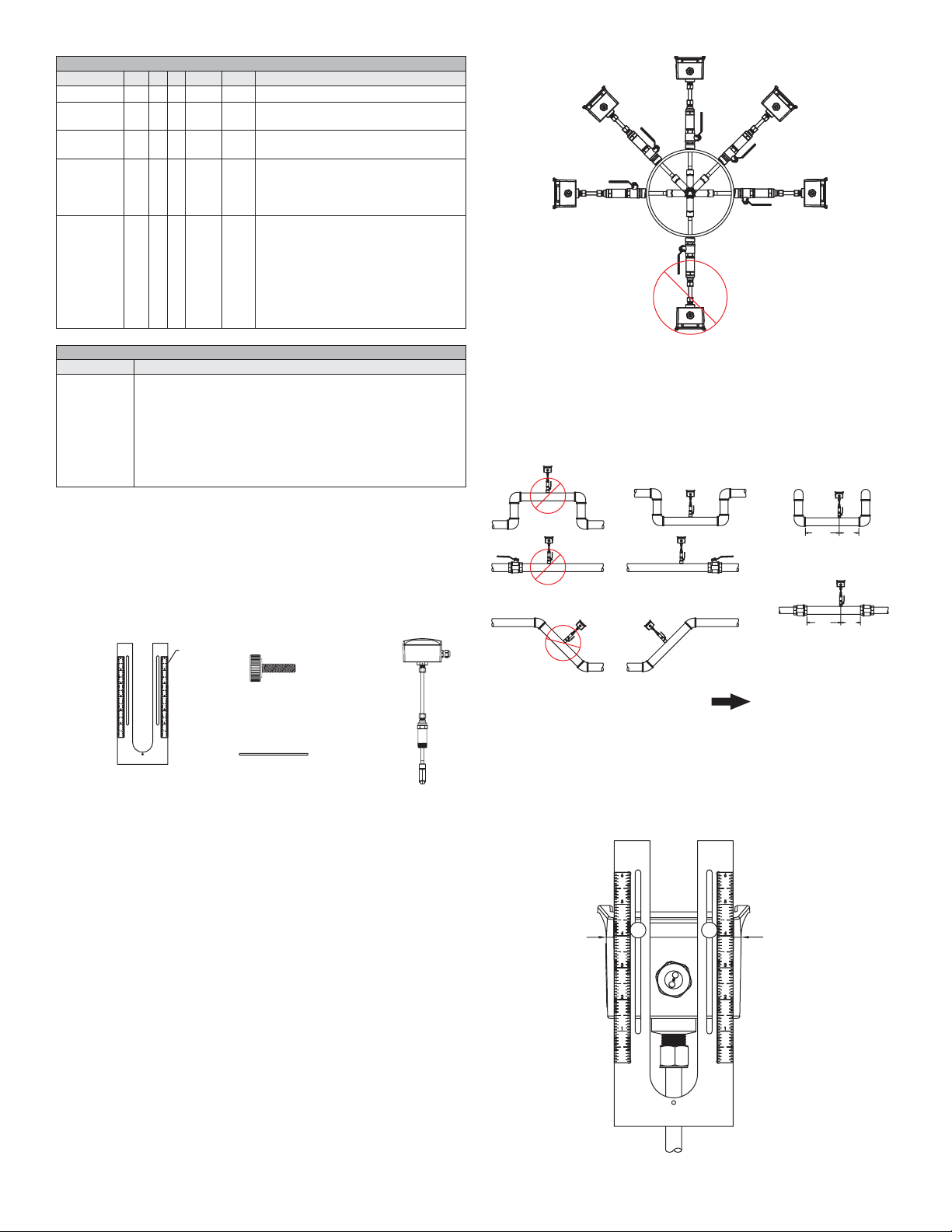

MODEL CHART

THUMBSCREW

BODY

RULER

Example IEF -H N -CND -LCD IEF-HN-CND-LCD

Series IEF Insertion electromagnetic ow transmitter

Accuracy H

Process

Connection

Electrical

Housing

Connector

S

N

B

CND

PG

10

High accuracy; 1% of reading

Standard accuracy; 1% FS

1˝ NPT

1˝ BSPT

1/2˝ female NPT

PG 16 gland

PG 16 gland with (2) 10´ (3 m) plenum

rated cables

Options LCD

Integral LCD

BACnet or Modbus

COM

®

communication

protocol (display selectable)

Multiple point NIST traceable calibration

NIST

certicate

Factory calibration certicate for 0.5% of

FC

reading at single point

CC

Custom congured for specic installation

ACCESSORIES

Model Description

A-IEF-KIT

Setup kit (includes setup display, thickness gage and measuring

tape)

A-IEF-DSP

A-IEF-CBL-50

A-IEF-VLV-BR

A-IEF-VLV-SS

A-IEF-INGD

A-IEF-PA

Setup display

Plenum rated cable 50 ft (15.2 m)

1-1/4˝ full port isolation valve brass

1-1/4˝ full port isolation valve 316SS

Installation alignment kit

AC wall adapter

INCLUDED WITH THE FLOWMETER

Carefully unpack the shipping container of your new Series IEF Insertion

Electromagnetic Flow Transmitter and remove the following items:

• (1) Series IEF Insertion Electromagnetic Flow Transmitter

• (1) A-IEF-INGD Installation Alignment Kit:

(1) Alignment Scale

(2) Alignment Rods

(2) Thumbscrews

• (1) 3 mm Allen Wrench (not shown)

(2 PLACES)

Thumbscrew (2)

ROD

Alignment scale (2)

Rod (2)

Series IEF

Figure 1

Figure 2

2. Select a location that will minimize ow distortion with adequate upstream and

downstream pipe diameters as displayed. Ideal installation will have a minimum

of 10 pipe diameters upstream relative to the instrument and a minimum distance

of 5 pipe diameters downstream.

5x

20x

20x

5x

FLOW DIRECTION

Figure 3

INSTALLATION

1. To prepare the meter for installation, mount the provided alignment scale to the

side of the meter with the two provided thumbscrews. The thumbscrews are to be

inserted through the alignment scale slots and into the holes in the side of the lid

as shown in Figure 4, nger tighten only. Be sure to orient the alignment scale as

shown in gure below. Actual scale setting determined in next step.

RECOMMENDED TOOLS

• (2) 12˝ (300 mm) adjustable wrenches

• (1) 12˝ (300 mm) pipe wrench

SETUP

Selecting Installation Location

1. Although the unit may be installed in any orientation, the ideal mounting position

is on the side of the pipe (2 o’clock or 10 o’clock position) as this generally

minimizes possible air or sediment interference with the Series IEF.

Note: When installing a unit with an integral display select an installation

location that allows for clear viewing of the display and proper earth ground.

Insert the IEF in a pipe via a threaded Tee, Saddle, or welded integrally

reinforced branch connection outlet tting.

If a Hot-Tap option is required, use a 1-1/4˝ valve kit with proper mounting

hardware available in Model A-IEF-VLV-BR or A-IEF-VLV-SS. A 1˝ (25.4 mm)

hole in the pipe is required for proper installation.

Figure 4

USE LID TO

ENCLOSURE

GAP AS

INDICATOR LINE

Page 3

For Custom Congured Models (-CC Option)

KEYLINE

TURE

1

8

2. Locate the conguration tag attached to the Series IEF to identify the value of

the alignment scale setting. Position the alignment scale such that the scale

setting is lined-up with the seam of the enclosure as shown in Figure 4. Minor

scale marks are in 1/20ths Securely tighten the thumbscrews.

3. Refer to Preparing the Unit for Installation section.

For Field Congurable Models

2. For eld conguration a display is required (-LCD option or accessory A-IEF DSP) and needs to be powered via normal eld wiring or with the AC wall adapter

accessory A-IEF-PA ( A-IEF-DSP and A-IEF-PA are also available in the

accessory setup kit A-IEF-KIT).

3. When using the AC wall adapter and the cable is supplied, connect the red

(positive +) and black (common -) wires of the cable bundle marked “A” to the

open terminals of the AC wall adapter. This will provide temporary power to the

meter to complete the installation set up.

4. For eld wiring refer to the wiring chart tag attached to the Series IEF to identify

the terminal block pins for positive (+) and common (-) connection.

5. Unscrew the four captured cover screws using the supplied 3 mm Allen wrench

to remove and set aside enclosure cover.

6. Insert one connector of the ribbon cable supplied in the setup kit into the

connector labeled “Display” in the middle of the unit. Be sure to orient the keying

feature/tab. See Figure 5 below:

FEA

Preparing the Unit for installation (Refer to Figure 7)

1. Apply appropriate sealant to the process collet (5) threads such as application

suitable sealant tape or paste.

2. Install the process collet (5) in valve (6) then tighten by hand.

3. Tighten the process collet (5) with a wrench using the hex geometry until snug.

NOTICE

4. Slowly open the valve handle (7) checking for leaks.

5. If leaks occur around threaded connections, close the valve and tighten those

connections.

Use two wrenches, one to hold the valve and another wrench to

turn the process collet.

2

4

5

6

3

7

Figure 5

7. Plug the other end of the cable into the bottom of the supplied portable display

being sure to orient the keying feature/tab as shown:

KEYLINE

FEATURE

Figure 6

8. Apply power to the unit and the display will turn-on automatically. Follow the on

screen directions for entering the necessary parameters to setup the unit and

obtain the alignment scale setting value.

NOTICE

DSP, thickness gage UTG and measuring tape A-IEF-MSTP used to obtain these

measurements. When the precise pipe measurement information is known select

Option 2 High Performance setup in the Install Kit option of the display selection

When using measuring tape A-IEF-MSTP to measure pipe

NOTICE

of the pipe without insulation.

Precise pipe measurements are required for high performance

installation. The A-IEF-KIT includes setup display A-IEF-

circumference use the 100ths side to measure the circumference

9

Figure 7

Do not adjust housing compression nut at top of probe shaft (3).

NOTICE

1. Enclosure

2. Cable Nut

3. Probe Shaft

4. Compression Fitting

5. Process Collet

6. Valve (optional)

7. Valve Handle (optional)

8. Pipe

9. Sensor Probe

Page 4

Sensor Alignment

FLOW

OOL

PIPE ALIGNMENT ROD MUST

g

A depth and ow alignment installation tool is provided to ensure proper depth insertion

and ow alignment. To set the insertion depth verify the alignment scale has not moved

from its original setting based on the alignment scale value set previously.

Loosen compression nut (4) to allow the shaft (3) freedom to travel up and down and

rotate inside the process collet (5).

Install Depth and Alignment Rods

1. Remove alignment rods from sides of alignment scale by sliding them out.

2. Insert the two rods into the alignment scale as shown.

GROUNDING

Metallic Pipe

For proper operation the instrument must be earth grounded.

Connect a ground wire to meter housing via the ground lug on the housing collet.

Connect the ground wire to a known earth ground.

If the pipe is grounded, connect the ground wire to the metal pipe using suitable

devices such as grounding clamps.

Grounding lu

ALIGNMENT ROD

Figure 8

3. Rotate the transmitter so the pipe alignment rod is parallel with the ow in the

pipe.

FLOW DIRECTION

Figure 9

4. Slide the shaft (3) down into the process collet (5) until the depth rod contacts

the pipe. If pipe insulation is present press the rod through the insulation.

ALIGNMENT T

DEPTH ROD

BE PARALLEL WITH PIPE

Figure 10

Non-Metallic Pipes

Connect a ground wire to the transmitter housing per the ground lug on the housing

collet.

Connect the ground wire to a known earth ground.

Ground the uid to earth.

GROUNDING

RINGS

POWER SUPPLY

Choose a power supply with a voltage and current rating sufcient to meet the power

specications under all operating conditions.

If the power supply is unregulated, make sure the output voltage remains within the

required voltage range under all power line conditions.

Figure 11

a. Tighten the nut (4) to 15 ft.-lbs (20.3 N m)

b. Remove the ow alignment rod and loosen the thumbscrews to slide the

alignment tool up to allow removal of the depth alignment rod. Store both

rods in the storage slots on the sides of the alignment scale. Tighten

thumbscrews and leave alignment tool mounted on unit for storage.

Printed in U.S.A. 12/18 FR# 444458-01 Rev. 2©Copyright 2018 Dwyer Instruments, Inc.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Loading...

Loading...