Dwyer Instruments HM3531ALI300, HM3531DLH300, HM3531DLK300, HM3531DLF300, HM3531DLC100 User manual

...Page 1

Operating instructions

Digital handheld

pressure gauge

HM35

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Operating Instructions

Contents

Operating Elements .........................................................................................2

1 Description............................................................................................3

2 Safety information.................................................................................3

3 Operation..............................................................................................4

3.1 Switching on and off..............................................................................4

3.2 Lighting.................................................................................................5

3.3 Pneumatic connection...........................................................................5

3.4 Functions and operating modes............................................................6

3.5 Menu selection and set-up....................................................................6

3.6 Data logging..........................................................................................9

3.6.1 Data recording ......................................................................................9

3.6.2 Transfer of data to a PC......................................................................10

3.6.3 Deleting data.......................................................................................10

3.7 Communication...................................................................................10

3.7.1 IR/RS232-Protocol..............................................................................10

3.7.2 IR-Hardware of the instrument............................................................12

3.8 Battery replacement............................................................................19

3.9 Calibration...........................................................................................19

4 Specifications...................................................................................... 20

4.1 Technical data.....................................................................................20

4.2 Measuring Range and Precision.........................................................22

4.3 Measurement units .............................................................................23

4.4 Mains supply unit connection..............................................................24

5 Maintenance and storage ...................................................................24

6 Warning messages and faults.............................................................24

7 Accessories ........................................................................................25

8 Summary of technical characteristics..................................................25

1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

Operating Elements

Infra-red interface IR

Connection for pneumatic tube

Graphic display

Zero position / Exit menu

Function key

Select operating mode

Connection for 6 VDC power supply (not pre sent in Ex-models)

Hold display

Start function

Switch On/Off (> 1 s: Light on)

Please note this warning symbol in these operating instruction s!

EC Declaration of Conformity

We declare on our own responsibility that this product conforms to the following

standards:

• EN 61326-1/A1

Copyright ©

The contents of this publication may not be copied without the express permission of the

manufacturer. We reserve the right to make dimensional and design changes.

2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

1 Description

The HM35 digital pressure gauge is a pressure-me asuring instrument with an integrated

pressure sensor for the measurement of differential, relative or absolute pressures and

vacuum. Its versatile range of functions and high precision render it suitable for a wide

range of applications. Via the infrared interface (IR) and S CPI (Standard Commands for

Programmable Instruments) commands, the HM35 can communicate with a PC. Its

operation is very simple, and supports the user in his measurement tasks.

Operating modes

• Pressure measurement / Differential pressure

• Min./Max. values

• Mean value (average)

• Pressure change rate

• Data logging

Selectable configuration possibilities

• Data logging

Æ Interval time, print/transfer, deleted memory

• Configuration

Æ Measurement units, display filter, auto. switch-off time, au to zero, lighting level, etc.

• Average period (period for determining average value)

• Date and Time (real-time clock)

• Calibration

Æ Date of last calibration date, manual recalibration

2 Safety information

• The pressure values and overload levels stated on the rating plate and quoted in

these operating instructions must not be exceeded, as otherwise the pressure

sensor could be destroyed or there could be a risk of injury.

• Only use pressure hoses with a maximum loading capacity corresponding to that

necessary for the application.

• Ensure that the pneumatic hoses are securely fitted! Do not use damaged or kinked

hoses.

• Do not open up the instrument (this would void the guarantee).

• The instrument must be stored within the permissible storage temperature range.

The instrument must not be put into operation in an

explosive environment!

Wear eye protection if working with pressures > 1bar!

Find Quality Products Online at: sales@GlobalTestSupply.com

3

www.GlobalTestSupply.com

Page 5

3 Operation

3.1 Switching on and off

Switching on Briefly press the On/Off key ( ) (< 1 s)

For precise measurements, the HM35 must first be switched on for at

least 1 minute (warm-up phase).

Switching off Briefly press the On/Off key

or

automatic switch-off 3, 10 or 60 minutes after the last time key operation

(automatic switch-off does not take place during Average, Change Rate

and Data Logging measurements or in IR

Notes

• The HM35 switches on automatically when the supply voltage is connected.

• The HM35 continues to work in battery mode following an interruption of the supply

voltage

• In case of a change in temperature, the HM35 must be allowed to adapt to the new

ambient temperature for a least 30 minutes while switched off in order to attain the

best measurement accuracy.

• The day/time, battery level and accuracy will be briefly displayed at switch on:

• After switch-on, the HM35 switches to the last operational mode used, e.g.:

( ) (< 1 s),

and network operation).

• With the display filter activated, wait until the transient effect finishes (approx. 5 s).

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

4

Page 6

3.2 Lighting

Switching on Press the On/Off-key

( ) for > 1 s

Brightness control In the Menu, select the Configuration → Lighting function and

select an adjustment of Off, Level 1, Level 2 or Level 3.

Switching off Briefly press the On/Off key

( ) (< 1 s)

(switch off the instrument),

or automatic switch-off after 20 s.

With mains operation, the HM35 must be switched off manually.

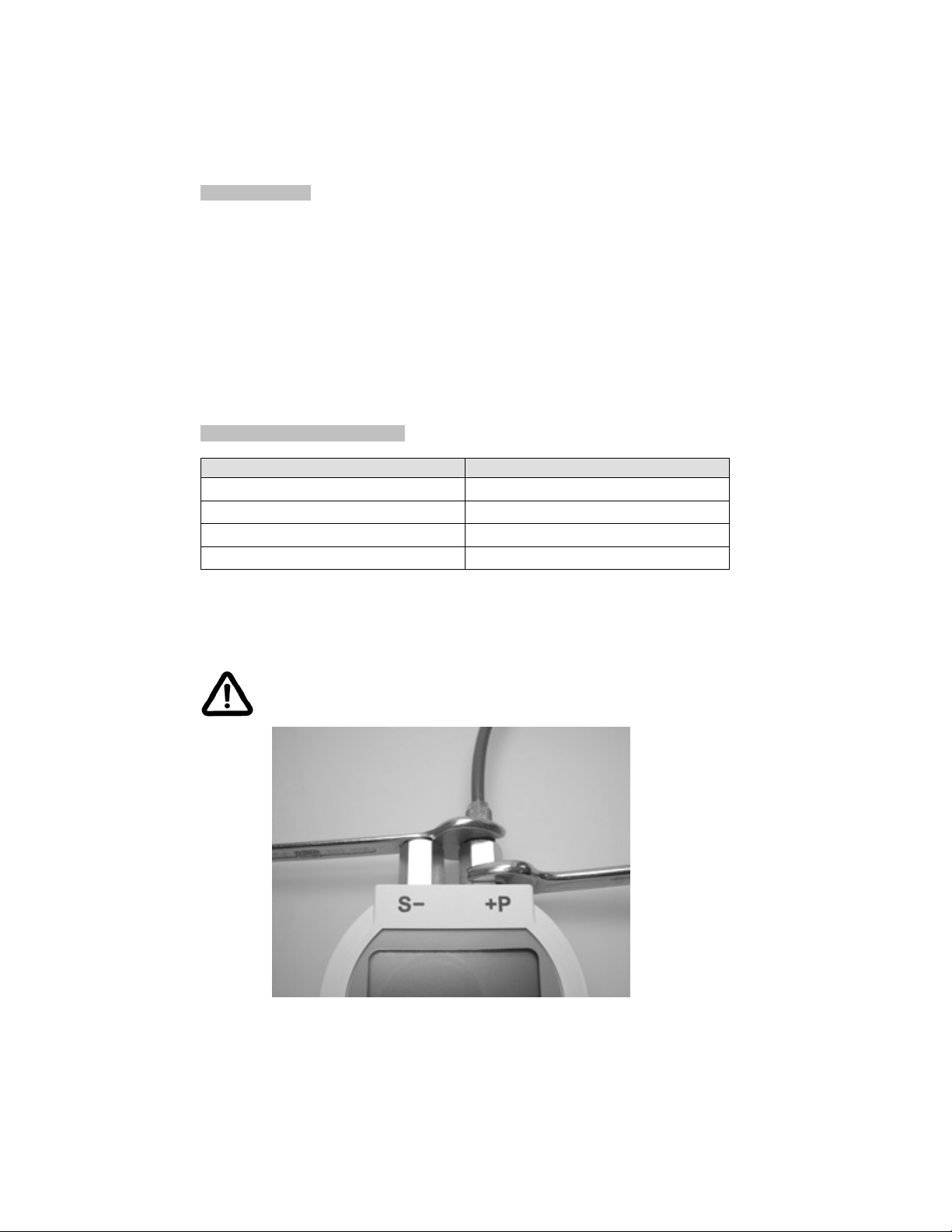

3.3 Pneumatic connection

Designation Pressure range

Hose 4/6 mm

NPT1/8“ internal 10 ... 90 bar

Plug in nipple „Rectus“ Type 20

M10 x 1 internal thread (for „Minimess“ connector) all

≤ 7,5 bar

≤ 30 bar

Ensure that the pneumatic hoses are connected correctly!

+P Higher pressure

S- Lower pressure (not availa ble with the absolute and relative pressure version)

When screwing onto a coupling, it is important to hold the

coupling steady with a wrench to prevent any turning!

Never secure by holding the casing itself!

5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

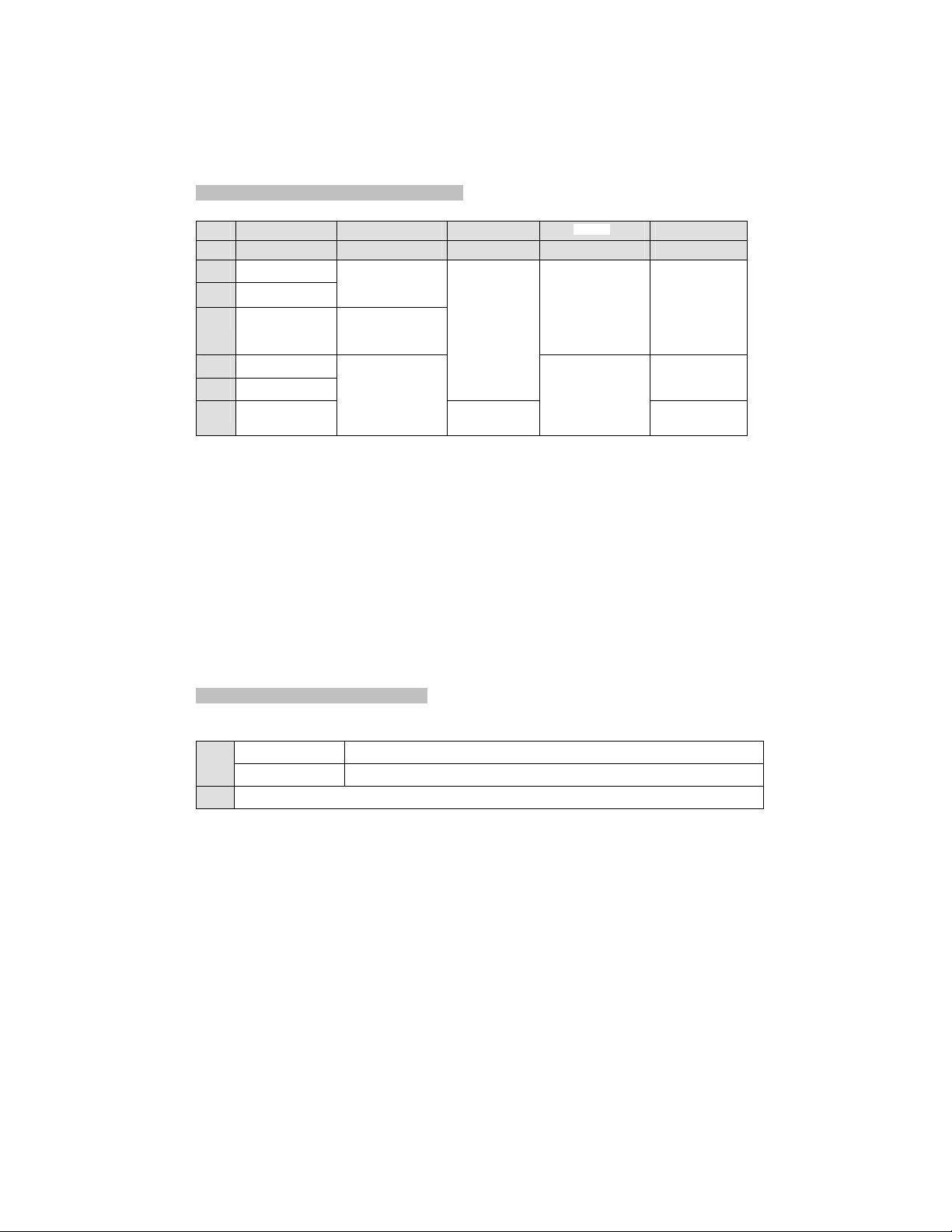

3.4 Functions and operating modes

Key clear hold

Functions

PRESSURE

DIFFERENCE

▲ MIN/MAX Sets Max/Min to

▼ AVERAGE 4)

CHANGE RATE 5)

DATA LOGGING

Zero: sets

measured value to

3)

zero

current measured

value

Sets measured

value to zero

3)

Freezes all

current

measurement

values

--

To Menu selection

1)

Stop/Menu

Start 2)

--

Starts measuring

Starts data

logging

Notes

1) Once a measurement procedure has been started, the menu selection is blocked.

2) During a measurement procedure (after Start has been pressed), you can switch

between functions. This permits, for example, the observation of the Min/Max

function during data logging.

3) The Clear key has no function in the absolute pressure instruments.

4) The AVERAGE function creates an arithmetic average value of all measured values

during the time period selected in the menu. After expiry of the time period, the

average value will be displayed.

5) Measurement of the leak rate (diff/gauge sensor) or tendency (abs. sensor). The

pressure change (CHANGE RATE) from the start time to the current time will be

displayed. The first display occurs 10 s after the start.

3.5 Menu selection and set-up

Navigation within the Menu selection

clear

▲▼

Brief (< 1 s) 1 level back

Long (> 1 s) Back to the function level/operating modes

Selection of Set-up/Functions

The functions shown inverted on the display will be carried out if the Function key

) is pressed.

(

The currently selected setting for values is marked with '9'. In the following table, the

default values are correspondingly marked (factory settings).

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

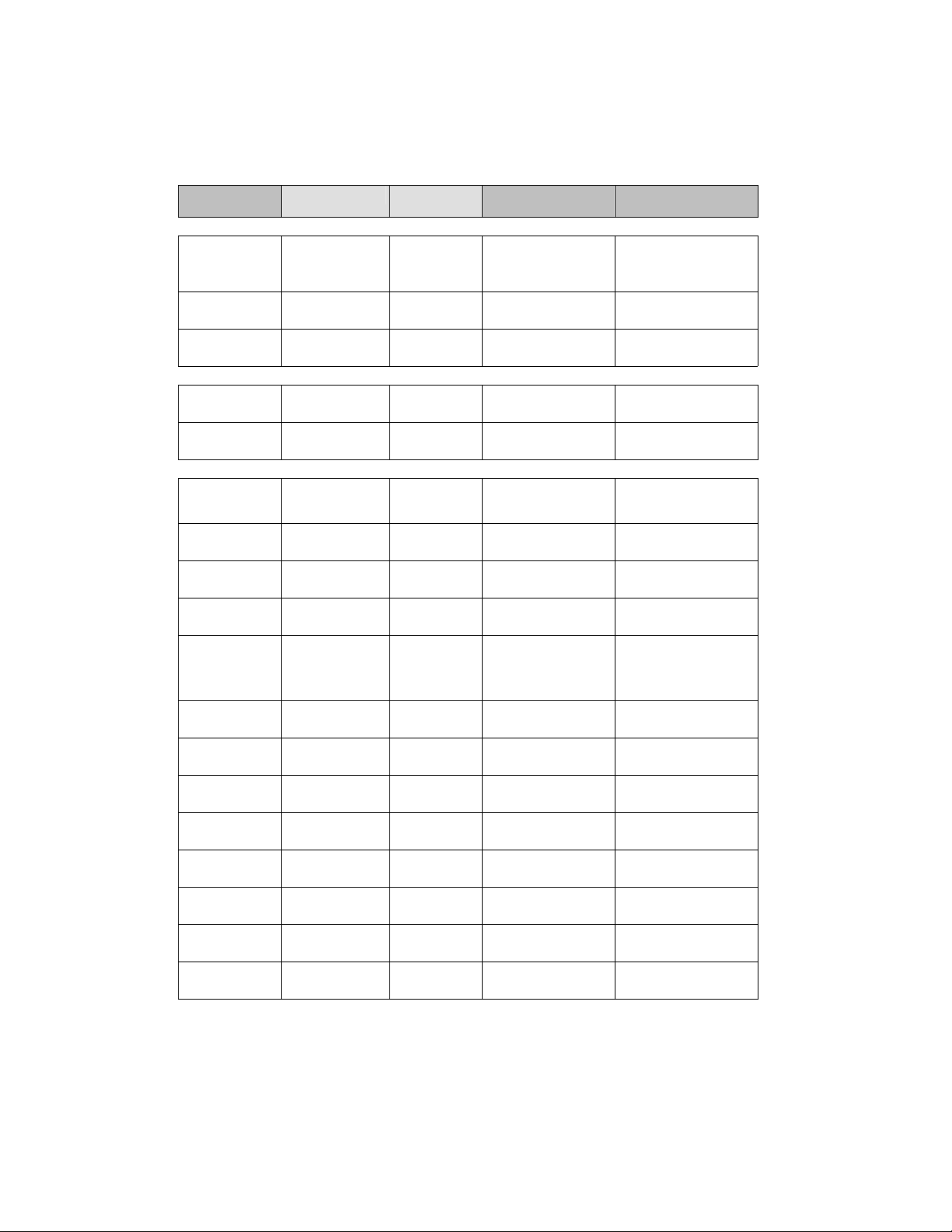

Key

Data logging

Interval Interval period

manual

25 M./s

10 M./s

1 s

9 2 s

5 s

10 s

30 s

1 min

2 min

5 min

10 min

30 min

1 h

3 h

6 h

12 h

24 h

user Set with ▲/▼/ EDIT/OK

▲ Print Data Logging

▼ Press 'Start' Print/send via IR

Clear Memory

Press 'Clear' Deletes the data memory

Configuration

Pressure Unit

9 mbar

bar

Pa

hPa

kPa

MPa

kg/cm2

kg/m2

mmHg

cmHg

mHg

inHg

mmH2O

cmH2O

mH2O

inH2O

ftH2O

psi

lb/in2

lb/ft

torr

atm

2

Notes

7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

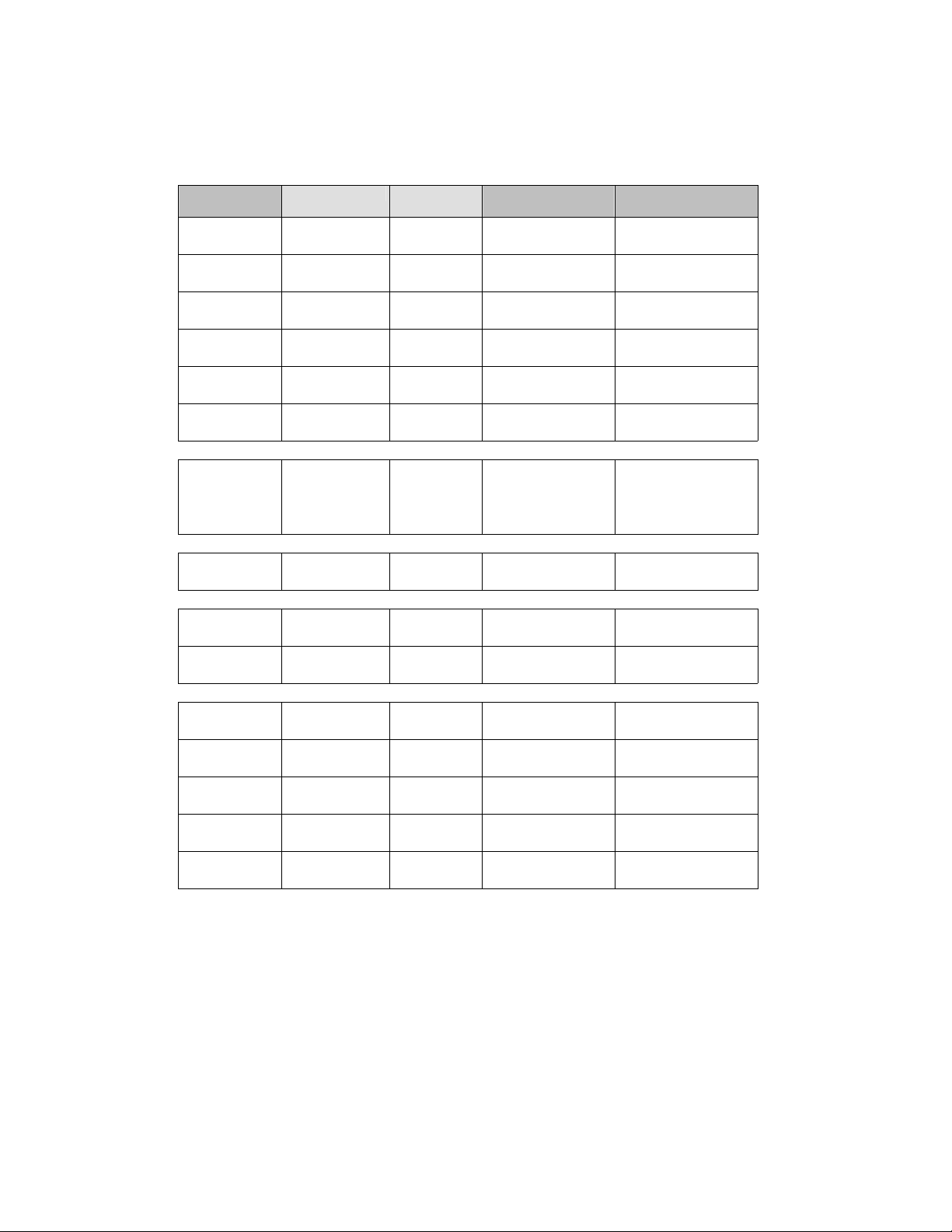

Key

Display Filter Filters the display values 1)

9 On

Off

Auto-Off Auto. switch-off

3 min

9 10 min

60 min

Auto-Zero

On Sensor auto-zeros at switch-on

9 Off

Beep Warning beeper

9 On

Off

Lighting Off

Level 1 Only Level 1 possible for Ex-models

Level 2

▲ 9 Level 3

▼ IR Interface

9 On At switch-on, the automatic

Off Automatic connection is de-activated

Average period Time period for average value

10 s

30 s

1 min

2 min

9 5 min

10 min

30 min

1 h

3 h

6 h

12 h

24 h

user Set with ▲/▼/EDIT/OK

Date & Time

dd.mm.yyyy Set with ▲/▼/ EDIT/OK

hh:mm:ss Set with ▲/▼/ EDIT/OK

Calibration

History Displays the last calibration date

Manual re-calibration Manual re-calibration of the zero

Notes

if measured value < 1% FS

connection to the PC is activated for

2 minutes

point and limit value

Note

1) With the filter function active, short-term measurement variations should be

suppressed, resulting in a steadier display. Measured values via the int erface and in

the Data Logging Memory will not be filtered.

8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

3.6 Data logging

3.6.1 Data recording

Every time that the Data Logging is started, an information header ("Header") will first be

saved: The measured values will then be saved sequentially. "Stop" will be saved after

every interruption of the logging or if manual storage is carried out. At the end of all the

data loggings, "End" will be saved. Measured values can be uniquel y identified by their

header.

Designation Example 1 Data Logging Type of Data 2)

Date

Time 12:00:00

Interval 30 s

Function PRESS

Unit mbar

01.01.2001

1000.0

1001.1

1001.5

1000.3

999.7

Stop

End

INTEGER

Header

DISCRETE

1)

Measurement series

DISCRETE

DISCRETE

FLOAT

Designation Example 2 Manual saving Type of Data 2)

Date 01.01.2001

Time 12:00:00

Interval Manual

Function PRESS

Unit inHg

Date 01.01.2001

Time 12:00:33

Interval Manual

Function PRESS

Unit inHg

Date 01.01.2001

Time 12:01:45

Interval Manual

Function PRESS

Unit inHg

End

29.92 1st measured value 1)

Stop

29.29 2nd measured value 1)

Stop

28.00 3rd measured value 1)

Stop

Header 1st measurement

DISCRETE

Header 2nd measurement

DISCRETE

Header 3rd measurement

DISCRETE

DISCRETE

INTEGER

DISCRETE

FLOAT

INTEGER

DISCRETE

FLOAT

INTEGER

DISCRETE

FLOAT

9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

Notes

1) „Over“ (data type DISCRETE) for invalid pressure value

2) For the Data Type key, refer to the table on Page 18.

3) User-interval period will, for example, be displayed as follows, “user 01:15:00”

3.6.2 Transfer of data to a PC

(with HM35 Communication Software)

1. Install the IR (IrDA) -adapter according the instructions of the manufacturer.

2. Install the HM35 Communication Software.

3. Start the HM35 Communication Software.

4. Place the instrument max. 20 cm from the IR (IrDA)-Adapter and switch it on. Ensure

a line-of sight connection between instrument and IR-adapter!

If there is no communication with the instrument for more than 2 minutes, the IR

interface of the instrument turns off automatically! By restarting the instrument the IR

interface is reactivated.

3.6.3 Deleting data

1. In the Menu, select the Data Logging → Clear Memory function.

2. Press the Clear key.

3.7 Communication

3.7.1 IR/RS232-Protocol

COM-Port Settings

Baudrate 9600

Data bits 8

Parity no

Protocol no

Stop bit 1

Communication Protocol

Coding

The characters are transfered as ASCII-Code.

10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

Sending a command from PC to the instrument

<SCPI Command> [SP <Parameter 1>] [ , <Parameter 2> ] [ , <Parameter 3> ] [ , ... ]

HT [ * <CS> ] CR

Examples:

Setting the time to 07:08:09:

S Y S T : T i m e SP 0 7 , 0 8 , 0 9 HT * 2 5 5 CR (with checksum)

S Y S T : T i m e SP 0 7 , 0 8 , 0 9 HT CR (without checksum)

Reading the time:

S Y S T : T i m e ? HT * 1 4 2 CR (with checksum)

S Y S T : T i m e ? HT CR (without checksum)

Response from instrument to PC

<Return Value 1> [ , <Return Value 2> ] [ , <Return Value 3> ] [ , ...] HT * <CS> CR

SCPI Command: SCPI command according the table on following pages

CS: Checksum

Return Value: Response from instrument

[ ] Option

ASCII-character Hex-Code Meaning

SP 0x20 Space

HT 0x09 Horizontal Tabulation

CR 0x0D Carriage Return

* 0x2A Asterisk

, 0x2C comma

SCPI Commands

There is no difference between small and capital letters.

Checksum (CS)

The use of the checksum is optional. A * indicates a following checksum. The ASCII-

character * is included in the calculation of the checksum. The checksum is calculated

from the low byte.

Example:

Reading the date

S Y S T : D a t e ? HT *

53 59 53 54 3A 44 61 74 65 3F 09 2A

83 89 83 84 58 68 97 116 101 63 09 42

hex

dez

sum: 37D

893

low byte: 7D

hex

125

dez

hex

dez

The checksum is 125 decimal.

Command:

S Y S T : D a t e ? HT * 1 2 5 CR (with checksum)

S Y S T : D a t e ? HT CR (without checksum)

11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

Return Value

Command processed:

Return Value = o k

Example for response: o k HT * 1 3 CR

Error

Return Value Meaning

er-001 RS232 Protocol checksum Error

er-110 Header Error; Too short

Header Error; Too many subnodes

Header Error; Query not at leaf node

Header Error; Multiple querys

Header Error; Characters after query

Header Error; Too long

er-113 Undefined Header; Undefined command

er-109 Missing parameter

Missing parameter; Boolean expected

Missing parameter; String expected

Missing parameter; Discrete expected

Missing parameter; Not of expected type

er-101 Invalid character; Terminator expected

er-108 Invalid parameter; Out of bounds

Invalid parameter; Too long

er-203 Command Protected

er-999 EEProm Read/Write Error

er-002 Fatal Command Execution Error

Example: Checksum Error

Response: e r – 0 0 1 HT * 200 CR

After command with response value

Example: reading time (07:08:09)

Response: 0 7 , 0 8 , 0 9 HT * 1 9 5 CR

After every command wait for the response of the instrument (max. 680 ms).

3.7.2 IR-Hardware of the instrument

The hardware of the IR-connection of the instrument is compatible with IrDA- Standard

1.0.

IR (IrDA)- Adapter

A passive IrDA- adapter has to be use d which is compati ble to IrD A- Standard 1.0. The

IrDA adapter ACT-IR220Lplus is available as accessory.

The following explanations apply to this type:

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

Initialisation

Remarks

ACT-220L/220L+ are programmed by toggling

1

the control lines RTS and DTR. These lines

DTR

RTS

min. 50msec

Setting the baudrate

Remarks

DTR

RTS

min. 0.5usec

Control commands

The control commands are largely defined by the Standard Commands for

Programmable Instruments (SCPI).

may not be low at the same time during

0

operation. In this condition the ACT-

1

220L/220L+ goes in power down mode. If

DTR and RTS are low at the same time or in

0

an undefined condition, both lines must be set

high for at least 50 ms to leave the power

down mode.

Before setting the baudrate the

1

ACT-220L/220L+ has to be initialised

according Initialisation. The baudrate is set

0

to 9600 bps according the opposite diagram.

1

A PC usually needs more than 0.5 us for an

I/O-Instruction.

0

13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

Command Sub-node 1 Sub-node 2 Transfer Parameters Parameter

MEASure

:PRESsure? --- ---

:TEMPerature? --- ---

UNITs

:PRESsure? --- ---

SYSTem

:DATE? --- ---

:TIME <hh>,<mm>,<ss> INTEGER

:TIME? --- ---

:ERRor [:NEXT]? --- ---

:PRESsure <interval> INTEGER

:PRESsure <unit> DISCRETE

:DATE <yyyy>,<mm>,<dd> INTEGER

Data Type

:VERSion? --- ---

:BEEPer :STATe <state> BOOLEAN

:BATTery? --- ---

:RANGe? --- ---

:TOLerance? --- ---

:IDENt? --- ---

:SET :FILTer <state> BOOLEAN

:ZERO --- ---

14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

Parameter

x

(

)

limits

0, 10, 25 <value> FLOAT Continuous transfer of

Feedback data Feedback data

type

Description Remarks

measured values

Continuous measurement

with 10 or 25 M/s.

Stops with Interval=0

--- <value> FLOAT Query measured

--- <value> FLOAT Query sensor

mbar, bar,.... atm --- --- Pressure unit input

--- <unit> DISCRETE Query pressure unit E.g., mbar, bar,.... atm

yyyy: 2001 ...2099

mm: 1...12

dd: 1... x

--- <yyyy>,<mm>,<dd> INTEGER Query date yyyy: year, mm: month

0...23, 0...59, 0...59 --- --- Input time hh: hours, mm: minutes

--- <hh>,<mm>,<ss> INTEGER Query time hh: hours, mm: minutes

--- <Error_number>,

--- <version> FLOAT SCPI query and firm-

ON, OFF --- --- Beeper enable / disable

--- --- Input date yyyy: year,

"<Error_description>

(;<Devicedependent info>)"

INTEGER,

STRING

pressure value

temperature

Query SCPI Error Queue STRING with ‚fixed text‘

ware versio n

Individual value

°C, individual value

mm: month

dd: day

dd: day

ss: seconds

ss: seconds

and optional ‚free text’,

separated by a semicolon,

maximum 255 digits

e.g. '2001.0' , ‘FW:300’

--- <value> INTEGER Query battery state Range 0...100, value in %

--- <range> STRING

--- <tolerance> STRING Query sensor tolerance e.g. '0.05 %FS'

--- <type, MOD, S/N> STRING Query instrument

ON, OFF --- --- Set filter for display

--- --- --- Zero measure pressure

Query sensor

measurement range

in mbar

identification

value (ZERO)

e.g. "1,000 mbar“

e.g. "HM3500DLH200,

MOD00A,1234567“

15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

Command Sub-node 1 Sub-node 2 Transfer parameter Parameter data type

SYSTem :SET :AOFF <time> DISCRETE

:OFF --- ---

:AZERo <state> BOOLEAN

:INTerval <interval> DISCRETE

:AVERage <interval> DISCRETE

:CONFig :IRDA <status> BOOLEAN

DIAGnostic :ERRors? --- ---

DISPlay

MEMory :COPY :DLOG? --- ---

:BRIGhtness <level> DISCRETE

:DELete :ALL --- ---

*CLS

*IDN?

*STB?

*TST?

*RST

--- ---

--- ---

--- ---

--- ---

--- ---

16

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

Parameter

enu

limits

3min, 10min, 60min --- --- Set auto Off time

--- --- --- Switch off instrument

ON, OFF --- --- Enable/disable auto zero

Feedback data

Feedback data

type

Description Remarks

25M./s, 10M./s,

1s ... 24h

10s, 30s ... 24h --- --- Set time period for

OFF --- --- Set auto IrDA connection

--- <err>,<err>,<err>... INTEGER Query the BIT-Error

<message> DISCRETE Query the BIT-error

OFF, level 1,

level 2, level 3

--- <data> diverse Select Memory Data

--- --- --- Delete Memory Data

--- --- --- Delete Status and Error

--- <type, MOD, S/N> STRING Query instrument

--- <data> INTEGER Query Status Byte

--- --- Set interval time for Data

Logging

Average

memory

memory

--- --- Brightness setting for

LCD backlight

Logging (cyclic)

Logging

Memory

identification

Similar to Menu

Similar to Menu

Variable amount of

Feedback data, err: 0...255

If Error memory deleted:

'No Errors!’

EX-instrument only OFF

and Level 1, similar to

M

Complete reading,

Format: see 3.6.1

See SYST:IDENT?

--- <data> INTEGER Initiate a Self-Test

--- --- --- Reset command

17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

Data Type Key

Designation Description Example

INTEGER Decimal number, whole numbers only 123

FLOAT Floating-point number 123.45

I-FLOAT Floating-point number, transferred as an INTEGER.

This means that it will not be transferred in the floating-point

format, but as an INTEGER – value coded according to the IEEE-

754 standard.

DISCRETE Discrete values, do not use “ in the text, similar to Menu selection mbar

BOOLEAN Boolean values: ON or OFF (similar to DISCRETE) ON

STRING Character string "ABCDE“

3242721280

(corresponds to -12.5)

Notes regarding control commands

• Cyclical commands Commands that last longer are processed cyclically.

They will be automatically interrupted if a command occurs

that requires an output.

• " (Inverted commas) A STRING is identified by inverted commas and a full-stop.

These must be transferred with it (unlike DISCRETE).

• ' (apostrophe) An apostrophe is used, for example for emphasis.

The apostrophe itself will not be transferred.

• ( ) (brackets) Parameter inside rou nd brackets are optional

The brackets themselves will not be transferred.

• , (comma) The comma is used to separate arguments. The next

argument must follow immediately after the comma

(no SPACE, ASCII-Code 32

dez

).

18

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

3.8 Battery replacement

• Open the battery compartment and insert 3 x 1,5 V Mignon cell AA, IEC LR6.

Always replace all three batteries at the same time!

Ensure correct polarity!

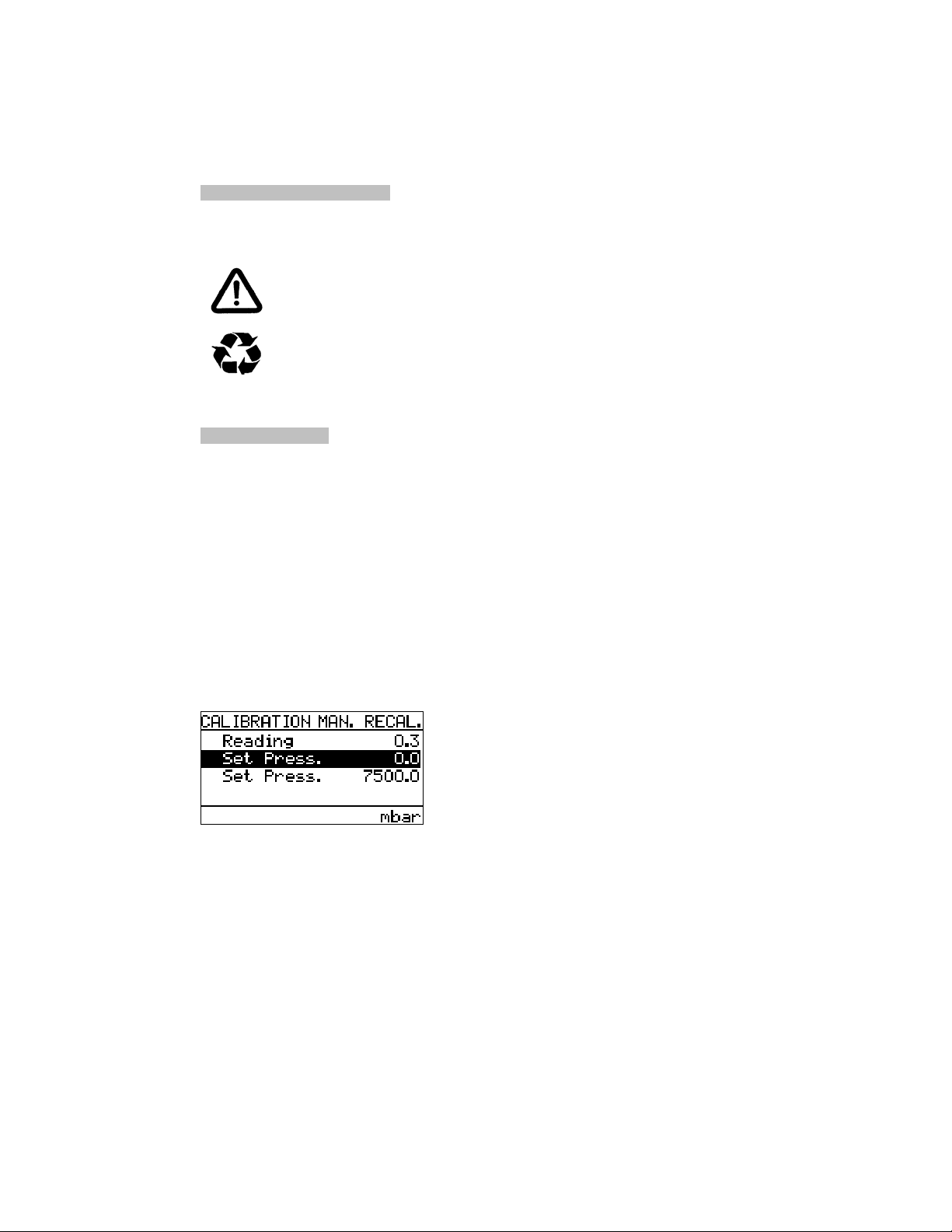

3.9 Calibration

Re-calibration may only be carried out by specialist staff and with the corresponding

pressure standards.

We recommend that you have the HM35 re-calibrated at least once a year, and, in case

of highest demands for precision, several times a year.

Manual re-calibration

• In the Menu, select the Calibration → Manual Calibration function.

Zero point (Offset)

1. Open the pressure connection or, with the absolute pressure unit, set the given

2. Press the Function key (

Î the zero point will be re-calibrated.

Dispose of used batteries in accordance with environmental

regulations

pressure value to the normal pressure.

!

)

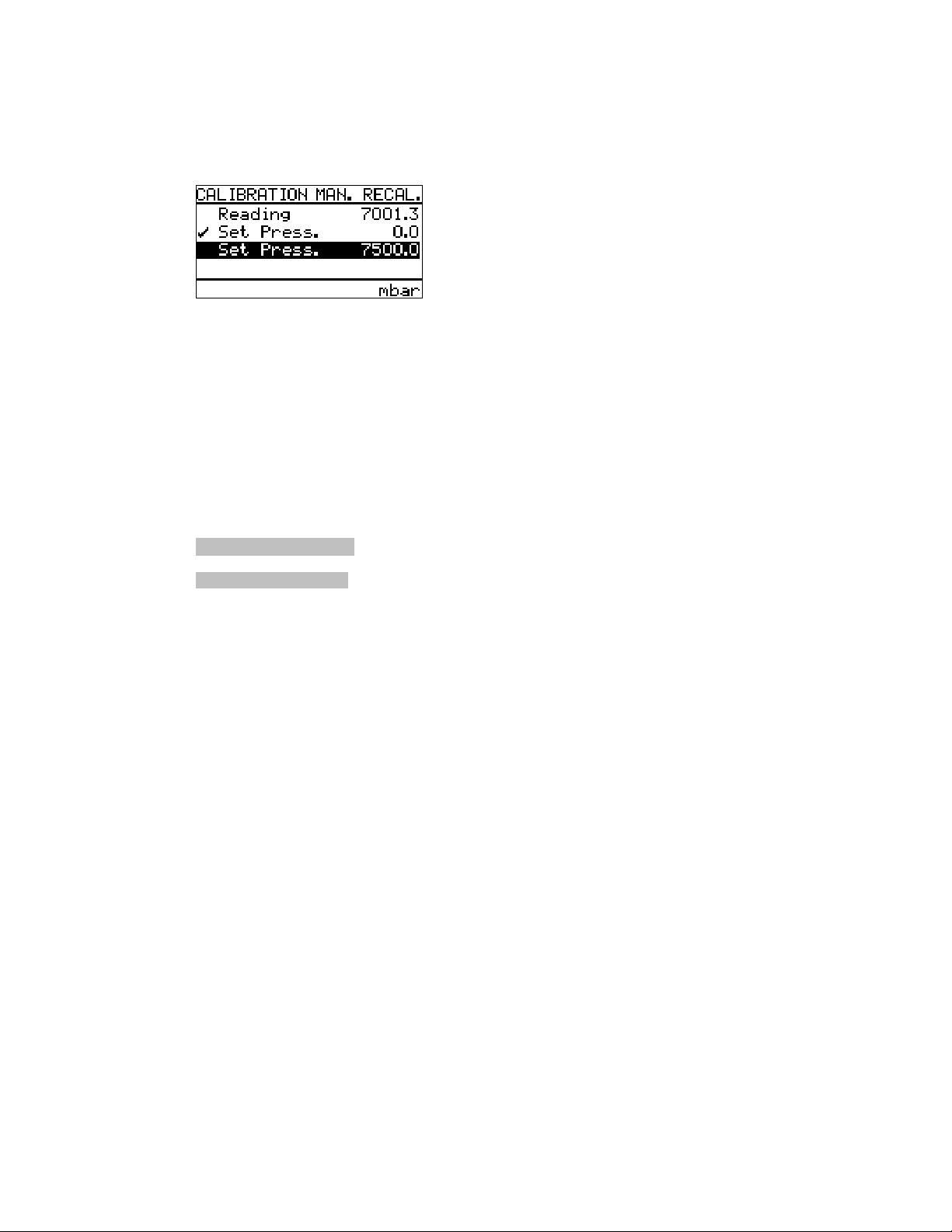

Full-scale value

1. Set the given pressure value to the normal pressure.

2. Press the Function key (

Î the full-scale value will be calibrated and the HM35 returns to normal operation.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

)

19

Page 21

Notes

• The calibration is always carried out in mbar.

• The calibration must take place at a stable room temperature of 22 °C ± 2 °C.

• A calibration value will only be accepted if it lies within ± 5 % of the full-scale

value of the HM35.

• With the pressure connections open, it is possible to only re-calibrate the zero point.

• The date of the last calibration will be stored in the Calibration History.

• In case of manual re-calibration, the previous measurement will become invalid.

You should always carry out a complete accuracy check afterwards.

4 Specifications

4.1 Technical data

Measuring media Instrument air or inert gases

Media-compatibility all me dia that is compatible with stainless steel 18/8

(DIN 1.4305)

Linearity, hysterisis and according to measuring range and use

repeatability accuracy See Table 4.2

Units according to measuring range and use

See Table 4.3

Operating temperature 0 °C to 50 °C

Storage temperature -20 °C to 60 °C

Humidity max. 95 % rH. (non-condensing)

Case protection IP 54

Power supply • 3 x 1,5 V Mign on-cell AA, IEC LR6 or accumulator

• regulated 6 VDC plug-in mains supply unit

(min. 6, max. 9 VDC

Current consumption < 25 mA

without display light, IR and beeper

Battery life approx. 90 hours

Infra-red interface serial IR-protocol

Measuring rate max. 25 measureme nts/s (Data log ging, IR)

5 measurements/s (normal operation)

Display rate 2 measurements/s

20

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

Memory size max. 10’742 measurements

Memory interval manual,

10, 25 measurements/s

1, 2, 5, 10, 30 s

1, 2, 5, 10, 30 min

1, 3, 6, 12, 24 h

user-defined (user)

Average period 10, 30 s

1, 2, 5, 10, 30 min

1, 3, 6, 12, 24 h

user defined (user)

Display LCD graphic display 128 x 64 points

Background lighting

Pneumatic connection 4/6 mm hose (M8 x 0,5) or NPT 1/8"

Plug in nipple „Rectus“ Type 20

M10 x 1 inner thread (for connector „Minimess“)

Case dimensions 200 x 93/58 x 39/28 mm

Weight including batteries approx. 300 g

21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

4.2 Measuring Range and Precision

The measured values display works in the range from -10 % to 110 % of the

measurement range.

Measuring

rage

1)

0 ... 10 inH2O d,g 0.0001 50 inH2O 245 psi

0 ... 28 inH2O d,g 0.001 140 inH2O 245 psi

0 ... 80 inH2O d,g 0.001 600 inH2O 245 psi

0 ... 120 inH2O d,g 0.001 600 inH2O 245 psi

0 ... 200 inH2O d,g 0.001 1600 inH2O 245 psi

0 ... 14.5 psi d,g 0.0001 58 psi 245 psi

0 ... 15.9 psi a 0.0001 58 psi -0 ... 29 psi a,d,g 0.001 100 psi 245 psi

0 ... 100 psi a,d,g 0.001 245 psi 245 psi

0 ... 145 psi d,g 0.001 390 psi 390 psi

0 ... 245 psi d,g 0.01 390 psi 390 psi

0 ... 500 psi g 0.01 1000 psi -0 ... 1000 psi g 0.01 2000 psi -0 ... 1300 psi g 0.01 2000 psi --

Unit Pressure type Resolution Max.

Loading

Max.

static pressure

Measuring

range

Inert gases Media compatibility

% FS % Rdg. % FS % Rdg.

2) 2)

0 ... 10 inH2O 0.1 / 0.2 -- -- --

0 ... 28 inH2O 0.05 / 0.1 / 0.2 0.1 -- -0 ... 80 inH2O 0.1 / 0.2 -- -- -0 ... 120 inH2O 0.05 / 0.1 / 0.2 0.1 -- -0 ... 200 inH2O 0.1 / 0.2 -- -- -0 ... 14.5 psi 0.05 / 0.1 / 0.2 0.1 0.1 / 0.2 -0 ... 15.9 psi 0.1 / 0.2 -- -- -0 ... 29 psi 0.05 / 0.1 / 0.2 0.1 0.1 / 0.2 -0 ... 100 psi 0.05 / 0.1 / 0.2 0.1 0.1 / 0.2 -0 ... 145 psi 0.1 / 0.2 -- 0.1 / 0.2 -0 ... 245 psi 0.05 / 0.1 / 0.2 0.1 0.1 / 0.2 -0 ... 500 psi -- -- 0.1 / 0.2 0.1

0 ... 1000 psi -- -- 0.1 / 0.2 0.1

0 ... 1300 psi -- -- 0.1 / 0.2 0.1

Unit Accuracy

1) a = absolute pressure

d = differential pressure

g = relative pressure

2) 0.1 % Rdg., but not less than 0.03 %FS.

22

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

4.3 Measurement units

The following units of measurement can be selected depending on the measuring range:

Measurement

ranges

1) 1) 1) 2) 1) 2) 1) 2)

0 ... 10 inH

0 ... 28 inH2O • -- • • • -- -- • • • -0 ... 80 inH2O • • • • • -- • • • • •

0 ... 120 inH2O • • • • • -- • • • • •

0 ... 200 inH2O • • • • • -- • • • • •

0 ... 14.5 psi • • • • • -- • • • • •

0 ... 15.9 psi • • • • • -- • • • • •

0 ... 29 psi • • • • • -- • • • • •

0 ... 100 psi • • • • • -- • • • • •

0 ... 145 psi • • -- • • • • • • • •

0 ... 245 psi • • -- • • • • • • • •

0 ... 500 psi • • -- • • • • • • • •

0 ... 1000 psi • • -- • • • • • • • •

0 ... 1300 psi • • -- • • • • -- • • •

Measurement

ranges

1) 2) 1) 3) 1) 3) 1) 3) 1) 3) 1) 3) 1) 1) 1) 1) 1)

0 ... 10 inH2O • • • • • • • • • • --

0 ... 28 inH2O • • • • • • • • • • --

0 ... 80 inH2O • • • • • • • • • • •

0 ... 120 inH2O • • • • • • • • • • •

0 ... 200 inH2O • • • • • • • • • • •

0 ... 14.5 psi • • • • • • • • • • •

0 ... 15.9 psi • • • • • • • • • • •

0 ... 29 psi • • • • • • • • • • •

0 ... 100 psi • • • • • • • • • • •

0 ... 145 psi • • • • • • • • • • •

0 ... 245 psi • • • • • • • • • • •

0 ... 500 psi • • • • • • • • • • •

0 ... 1000 psi • • • • • • • • • • •

0 ... 1300 psi • -- • • • • • • • • •

1) In relation to the acceleration due to gravity of 9,81 m/s

mbar bar Pa hPa kPa MPa kg/

O • -- • • • -- -- • • • --

2

in

Hg mmH2O

cm

H2O m H2O

in

H2O

ft

H2O

kg/

cm2

m2 mmHg cmHg mmHg

(psi)

2

lb/ft

psi lb/in

2

torr

(mmHg

)

2

atm

2) at 0 °C 3) at 4 °C

Conversion factors

1 mbar = 0,0010 bar 1 mbar = 10,1974 mmH2O (at 4 °C)

1 mbar = 100 Pa 1 mbar = 1,01974 cmH2O (at 4 °C)

1 mbar = 1,0 hPa 1 mbar = 0,0101974 mH2O (at 4 °C)

1 mbar = 0,1 kPa 1 mbar = 0,40147 inH2O (at 4 °C)

1 mbar = 0,00010 Mpa 1 mbar = 0,033456 ftH2O (at 4 °C)

1 mbar = 0,00102 kg/cm2 1 mbar = 0,01450 psi

1 mbar = 10,20 kg/m2 1 mbar = 0,01450 lb/in2

1 mbar = 0,75006 mmHg (at 0 °C) 1 mbar = 2,08854 lb/ft2

1 mbar = 0,075006 cmHg (at 0 °C) 1 mbar = 0,75006 torr

1 mbar = 0,00075 mHg (at 0 °C) 1 mbar = 0,00099 atm

1 mbar = 0,02953 inHg (at 0 °C)

23

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

4.4 Mains supply unit connection

The unit can be operated from a regulated

plug-in mains supply unit.

Input 100 - 240 V, 50 - 60 Hz

Output 6 VDC ± 10 %, 1,5 W

5 Maintenance and storage

The HM35 requires no maintenance. It can be cleaned with a damp cloth. Do not use

cleaning agents containing solvents!

See the relevant chapters for battery replacement und re-calibration.

During longer storage, remove the batteries from the instrument.

Do not drop below or exceed the admissible storage temperatures of -20 °C to 60 °C!

6 Warning messages and faults

Code Fault / Display Possible cause Correction

Does not switch on Power supply missing Possibly replace the batteries.

Battery possibly inserted incorrectly.

Possibly plug in power supply

correctly.

Instrument inaccurate

No change of the measured

14

13

06

04

15

07

05

No IR communication

value

PRESSURE

OUT OF RANGE!

PRESSURE

OUT OF RANGE!

TEMPERATURE

OUT OF RANGE!

TEMPERATURE

OUT OF RANGE!

REF. VOLTAGE

FAILURE!

NOT CALIBRATED! Incorrect calibration of the

LOW BATTERY! Battery voltage too low Replace batteries

• Re-calibration carried out

inaccurately

• Not zeroed

• Natural aging of the pressure

sensor

Excess pressure on sensor Send instrument to the manufacturer

Measurement range has been

exceeded by more than 10 %.

• Excess pressure on sensor

• Electrical fault

Pressure sensor exposed to

temperature outside permissible

range (< -5 °C or > 55 °C)

Used outside permissible

temperature range

Internal reference voltage error Send instrument to the manufacturer

instrument

• Line-of-sight connection

interrupted

• Separation too large

• PC-configuration

• Re-calibrate

• Vent and press Zero

• Have it re-calibrated

for repair.

Set up the permissible measurement

pressure.

Send instrument to the manufacturer

for repair.

Observe permissible operating

temperature and temperature of the

medium.

Observe permissible operating

temperature.

for repair.

Send instrument to the manufacturer

for repair.

• Re-establish line-of-sight

connection

• Max. distance 50 cm

• Check IR connection

24

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

7 Accessories

Standard 3 x 1,5 V b atteries IEC LR6

Operating instructions

SCS Test certificate

Options 6V mains supply unit 100 - 240 V, 50 - 60 Hz, 1,15 A

Leather case with carrying strap

Service-Set (transport case)

Hand pump

Infrared RS232 serial adapter

NPT 1/8" adapter

„Rectus“ adapter, type 20

Communication software for MS-Windows® (95/98, 2000, XP)

8 Summary of technical characteristics

Characteristics HM35 Remarks

Basic functions

1 pressure sensor installed

Absolute pressure

Differential pressure

Relative pressure

Vacuum (relative under-pressure)

for inert gases

Media compatibility rel./abs.

Measuring ranges / Accuracy See separate table

Calibrated temperature range 0 ... 50 °C

Measuring functions

Pressure / Differential pressure

Min/Max

Average

Change Rate

Other functions

Set-up/Configuration

Unit switchable

Display filter

Auto-off

Record interval

Average period

Display rate 2 M/s

Max. measurement rate 25 M/s Approx..

Date / Time (real time)

Analogue bar display

Real time data logging

Data logging / manual rec ord

Print record

Number of records 10742 Max.

Zeros with key

Automatic zeroing

Hold

Display accuracy at start-up

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

The instrument is only calibrated

in the over-pressure range

Average per time period

Tendency / leak rate

Free choice

Free choice

25

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

Characteristics HM35 Remarks

Low battery display

Acoustic signal

Self-test

Housing

Hand-held

Splash proof IP54

Connections

Tube 4/6 mm

NPT1/8“ internal

Plug-in nipple „Rectus“ Type 20

M10 x 1 internal thread

Power supply socket

Display

Graphic display

Lighting

Automatic contrast adjustment

Power supply

Battery

External plug-mounted power module

Digital interfaces

Infrared interface

SCPI protocol

Environmental conditions

Operating temperature 0 ... 50 °C

Storage temperature -20 ... 60 °C

Humidity max. 95 %r.F.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

For out-of-range / fault operation

For „Minimess“ 1215

Reduced brightness in Ex-version

for temperature changes

Standard Commands for Programmable

M8 x 0,5

Instruments

Non-condensing

Trademark Windows is property of Microsoft Corporation.

26

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...