Page 1

Bulletin A-20-HHT

®

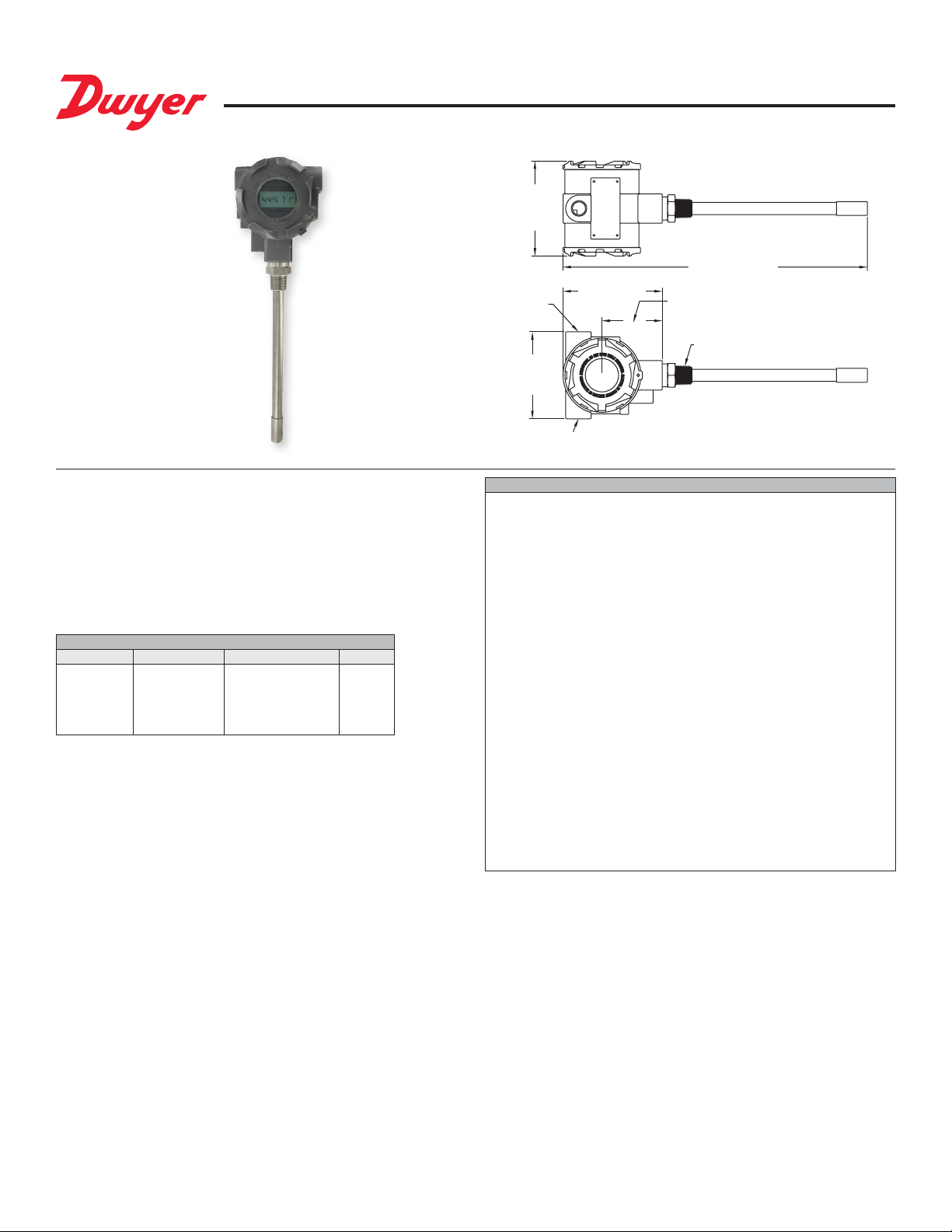

Series HHT Hazardous Area Humidity/Temperature Transmitter

Specications - Installation and Operating Instructions

4-9/32

[108.74]

13-23/32 [347.98]

1/2 NPT

3-29/32

[99.22]

4-15/32 [113.51]

1/2 NPT

2-23/32

[69.06]

1/2 NPT

The Series HHT Hazardous Area Humidity/Temperature Transmitter takes

accurate measurements in the harshest of environments. The transmitter is offered

in explosion-proof and intrinsically-safe versions depending on the applications

requirements. The explosion-proof model is offered with 4 to 20 mA outputs for humidity

only. The intrinsically-safe version is offered with 4 to 20 mA output for humidity and

temperature. Both versions have an optional two line alphanumeric display to show the

current humidity and temperature.

The Series HHT humidity/temperature transmitter is excellent for offshore HVAC

applications, dust and grain applications.

MODEL CHART

Model Protection Description Display

HHT-EU

HHT-IU

HHT-IT

HHT-EU-LCD

HHT-IT-LCD

Explosion-Proof

Intrinsically Safe

Intrinsically Safe

Explosion-Proof

Intrinsically Safe

Humidity

Humidity

Humidity/Temperature

Humidity

Humidity/Temperature

No

No

No

Yes

Yes

SPECIFICATIONS

Relative Humidity Range: 0 to 100% RH.

Temperature Range: -40 to 140°F (-40 to 60°C).

Accuracy: ±2% 10-90% RH, ±0.9°F at 72°F (±0.3°C at 25°C).

Hysteresis: ±1%.

Repeatability: ±0.1% typical.

Temperature Limits: -40 to 140°F (-40 to 60°C).

Storage Temperature: -40 to 176°F (-40 to 80°C).

Compensated Temperature: -40 to 140°F (-40 to 60°C).

Power Requirements: For intrinsically safe models HHT-IX, 9.5 to 28 VDC. For

explosion-proof models HHT-EX, 16.5 to 28 VDC.

Output Signal: 4 to 20 mA, 2 channels for humidity/temperature models (loop

power on RH).

Response Time: 15 s.

Electrical Connections: Screw terminal block.

Conduit Connection: 1/2 female NPT.

Drift: <1% RH/year.

RH Sensor: Capacitance polymer.

Temperature Sensor: Solid state band gap.

Housing Material: Aluminum.

Display: Optional 2 line alpha numeric, 8 characters/line. Temperature display is

°F/°C selectable.

Display Resolution: RH: 0.1%: Temperature 0.1°F (0.1°C).

Weight: 2 lb 8 oz (1134 g).

Agency Approvals:

DIP / II, III / T5 Ta = -40°C to 60°C; TYPE 4X, IP66; IS / I, II, III / 1 / ABCDEFG / T4

Ta = -40°C to 60°C - 03-001467-00; ENTITY; TYPE 4X, IP 66; I / 0 / AEx ia / IIC / T4

Ta = -40°C to 60°C - 03-001467-00; ENTITY; TYPE 4X, IP 66, CE.

FM Approved to: XP-IS / I / 1 / BCD / T5 Ta = -40°C to 60°C,

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Wiring Diagram – Humidity Only

NON-HAZARDOUS SIDEHAZARDOUS SIDE

GROUND THIS SIDE OF CABLE ONLY

MODEL

INTRINSICALL

EXAMPLE USING PEPPERL

BARRIER SYSTEM

HAZARDOUS SIDE

NON-HAZARDOUS SIDE

MODEL HHT-IU, RH ONLY

INTRINSICALL

EXAMPLE USING MTL

SYSTEM

Explosion Proof Installation Notes:

1 . Install in accordance with any applicable national electric code.

2. Plug unused conduit openings. Plug must engage a minimum of 5 threads.

3. Use conduit seal within 18 inches of conduit entry.

4. Disconnect power before servicing.

5. Control equipment voltage on hazardous side is 250 Vrms/DC maximum.

6. Do not substitute any components. The intrinsic safety of the sensor may be

compromised.

7. Shielded cable for 4 to 20 mA loop is necessary to meet CE requirements or

when used in electrically noisy environments.

Wiring Diagram – Humidity and Temperature

Intrinsically Safe Installation Notes:

1. Remove power from the instrument before carrying out any servicing.

2. Use only FM approved Associated Apparatus. When installing the Associated

Apparatus, the manufacturer’s instructions must be followed.

3. The earth terminal on the housing must be wired to a local earth ground in the

hazardous area.

4. Refer to FM control drawing, Dwyer number 03-001467-00.

5. For Model HHT-IT, use ONLY Pepperl + Fuchs KFDØ-SCS-Ex1.55 Galvanically

Isolated Barriers.

SHOWN TRANSPARENT

FOR CLARITY

Entity Parameters:

Vmax = 28 VDC

Imax = 100 mA

Ci = 62 nF

Li = 7.7 µH

Pi = 651 mW

HHT-IT, RH AND TEMP.

Y SAFE WIRING

250 OHMS

CONVERSION RESISTOR

IF SHIELDED CABLE IS USED FOR

4-20 mA LOOP, GROUND THIS SIDE

OF CABLE ONLY

Figure 1 Figure 2

4-20 mA

LOOP

SUPPLY

SHOWN TRANSPARENT

FOR CLARITY

MODEL HHT-IT

Y SAFE WIRING

HAZARDOUS SIDE NON-HAZARDOUS SIDE

SHOWN TRANSPARENT

FOR CLARITY

+ FUCHS

BARRIER

NOTE! THE PEPPERL +

FUCH KFD0-SCS-Ex1.55

BARRIERS ARE

GALVANICALLY ISOLATED,

SO GROUNDING IS NOT

REQUIRED.

IF SHIELDED CABLE IS USED

KFD0-SCS-Ex1.55

KFD0-SCS-Ex1.55

I.S GROUND

4-20 mA

LOOP SUPPLY

RH

RECEIVER

TEMP.

RECEIVER

4-20 mA

LOOP SUPPLY

MODEL HHT-IU

MTL7787+

IF SHIELDED CABLE IS USED,

GROUND THIS SIDE OF CABLE ONLY

Figure 3

I.S GROUND

RH

RECEIVER

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

Power Supply Requirements:

The maximum DC Power Supply is 28 VDC. The minimum required DC Power Supply

required is based upon the following:

1. Minimum DC voltage requirement of the Model HHT.

2. Total load resistance.

3. Total leadwire resistance.

4. Zener barrier voltage drop ( Model HHT-IX only).

The formula for calculating the DC Power Supply is:

VDC = VHHT + VLOAD + VLEADWIRE + VBARRIER

Where VHHT = 9.5 V for Models HHT-IX and 16.5 V for Models HHT-EX.

VLOAD = Total load resistance X 20 mA

VLEADWIRE = Total leadwire resistance X 20 mA

VBARRIER = 8.1 V

(Typical zener barrier voltage drop for this application)

Example 1. Calculate minimum DC Power Supply for Model HHT-EX (Explosion

Proof)

Step 1. VHHT = Minimum voltage required by Model HHT-EX = 16.5 V

Step 2. Calculate VLOAD. Using the industry standard 250 OHM conversion resistor,

VLOAD = 250 X 20 mA = 5 V.

Step 3. Calculate VLEADWIRE. For this example assume a leadwire resistance of 10

OHMS. VLEADWIRE = 10 X 20 mA = 0.2 V

Step 4. VDC = VHHT + VLOAD + VLEADWIRE = 16.5 + 5 + 0.2 = 21.2 V

Example 2. Calculate minimum DC Power Supply for Model HHT-IU (Intrinsically

Safe)

Step 1. VHHT = Minimum voltage required by Model HHT-IX = 9.5 V

Step 2. Calculate VLOAD. Using the industry standard 250 OHM conversion resistor,

VLOAD = 250 X 20 mA = 5 V.

Step 3. Calculate VLEADWIRE. For this example assume a leadwire resistance of 10

OHMS. VLEADWIRE = 10 X 20 mA = 0.2 V

Step 4. VBARRIER = 8.1 V

Step 5. VDC = VHHT + VLOAD + VLEADWIRE + VBARRIER = 9.5 + 5 + 0.2 +8.1 =

22.8 V

For Model HHT-IT, follow instructions with Pepperl + Fuchs KFDØ-SCS-Ex1.55 Barrier.

INSTALLATION

Location: Select a location where the ambient temperature is between -40 to +140°F

(-40 to +60°C)

Position: The transmitter is not position sensitive. Units with the optional display

should be mounted for ease of viewing the display.

Caution: Use electrostatic discharge precautions (e.g. use of wrist straps) during

installation and wiring to prevent equipment damage.

Avoid locations where severe shock or vibration, excessive moisture or corrosive

fumes are present.

Do not exceed ratings of this device. Permanent damage not covered by the warranty

may result.

Display: The temperature indicated on the display, if equipped with the LCD option,

is eld selectable via a jumper located on the circuit board just above the display. To

change the jumper position, remove the housing cover and position the jumper for °F

or °C according to Figure 4.

Figure 4

MAINTENANCE

Upon nal installation of the Series HHT Hazardous Area Humidity / Temperature

Transmitter, a periodic check of system calibration is recommended. The Series HHT

is not eld serviceable and should be returned if repair is needed (eld repair should

not be attempted and may void warranty). Be sure to include a brief description of the

problem plus any relevant application notes. Contact customer service to receive a

return goods authorization number before shipping.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

03-001467-00

03-001467-00

1

FM APPROVED

ASSOCIATED APPARATUS

2

NON-HAZARDOUS LOCATION

GROUND CONNECTION

G

2

1

GROUND CONNECTION

G

I.S. SAFETY GROUND

3

+

COM

HHT SERIES

TRANSMITTER

CATALOG NUMBERS:

HHT-IU AND HHT-IT

4

-

RH

m

Vmax=28VDC

Imax=100mA

Ci = 62nF

Li = 7.7 H

Pi = 651mW

-

TEMPERATURE

3

HAZARDOUS (CLASSIFIED) LOCATION

INTRINSICALLY SAFE FOR:

CLASS I DIV. 1 GROUPS A, B, C, D

4

OPTIONAL SHIELD

VI

IV

IV

CLASS II DIV. 1 GROUPS E, F, G

CLASS III DIV. 1

T4 Ta = -40°C TO 60°C TYPE 4X, IP 66

OR

T4 Ta = -40°C TO 60°C TYPE 4X, IP 66

CLASS I, ZONE 0, GROUPS IIC

VI

VI

FM CONTROL DRAWING

THIS LINE IS

NEMA 4X IP66

HOUSING ABOVE

UP TO LINE

PROBE TUBE

IS NOT

Voc OR Uo OR Vt Vmax, Isc OR Io OR It Imax, Ca OR Co Ci + Ccable, La OR Lo Li + Lcable, Po Pi

DEVICES WITH ENTITY PARAMETERS NOT SPECIFICALLY EXAMINED IN COMBINATION AS A SYSTEM WHEN:

NEMA 4X

IP66

1. THE INTRINSIC SAFETY ENTITY CONCEPT ALLOWS THE INTERCONNECTION OF TWO FM APPROVED INTRINSICALLY SAFE

ZONE 0 HAZARDOUS LOCATIONS MUST BE IN ACCORDANCE WITH THE NATIONAL ELECTRICAL CODE NFPA 70, ARTICLE 505. ALL INSTALLATIONS MUST BE

IN ACCORDANCE WITH ISA RP-12.6.

3. DIVISION 1 HAZARDOUS (CLASSIFIED) LOCATIONS INSTALLATIONS MUST BE IN ACCORDANCE WITH THE NATIONAL ELECTRICAL CODE NFPA 70, ARTICLE 504;

2. EQUIPMENT CONNECTED TO THE ASSOCIATED APPARATUS MUST NOT USE OR GENERATE MORE THAN 250 Vrms OR VDC

IRON/STEEL TO PREVENT IGNITION CAPABLE SPARKS.

6. DUST TIGHT CONDUIT SEAL MUST BE USED IN CLASS II AND CLASS III ENVIRONMENTS.

4. NO REVISIONS WITHOUT PRIOR APPROVAL FROM FM RESEARCH.

5. THE ASSOCIATED APPARATUS MANUFACTURERS INSTALLATION INSTRUCTIONS MUST BE FOLLOWED WHEN INSTALLING THIS EQUIPMENT.

7. WARNING - ENCLOSURE PARTS ARE CONSTRUCTED OF ALUMINUM. ENCLOSURE MUST BE PROTECTED FROM MECHANICAL FRICTION AND IMPACT WITH

9. ADDITIONAL SUFFIX LCD (LCD DISPLAY) DOES NOT IMPAIR INTRINSIC SAFETY.

8. SUBSTITUTION OF PARTS MAY IMPAIR INTRINSIC SAFETY. RETURN TO MANUFACTURER FOR ANY REPAIRS.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...