Dwyer Instruments HFPC Series, HFPS Series Specifications-installation And Operating Instructions

Page 1

Series HFPC & HFPS Plastic Flow Meters

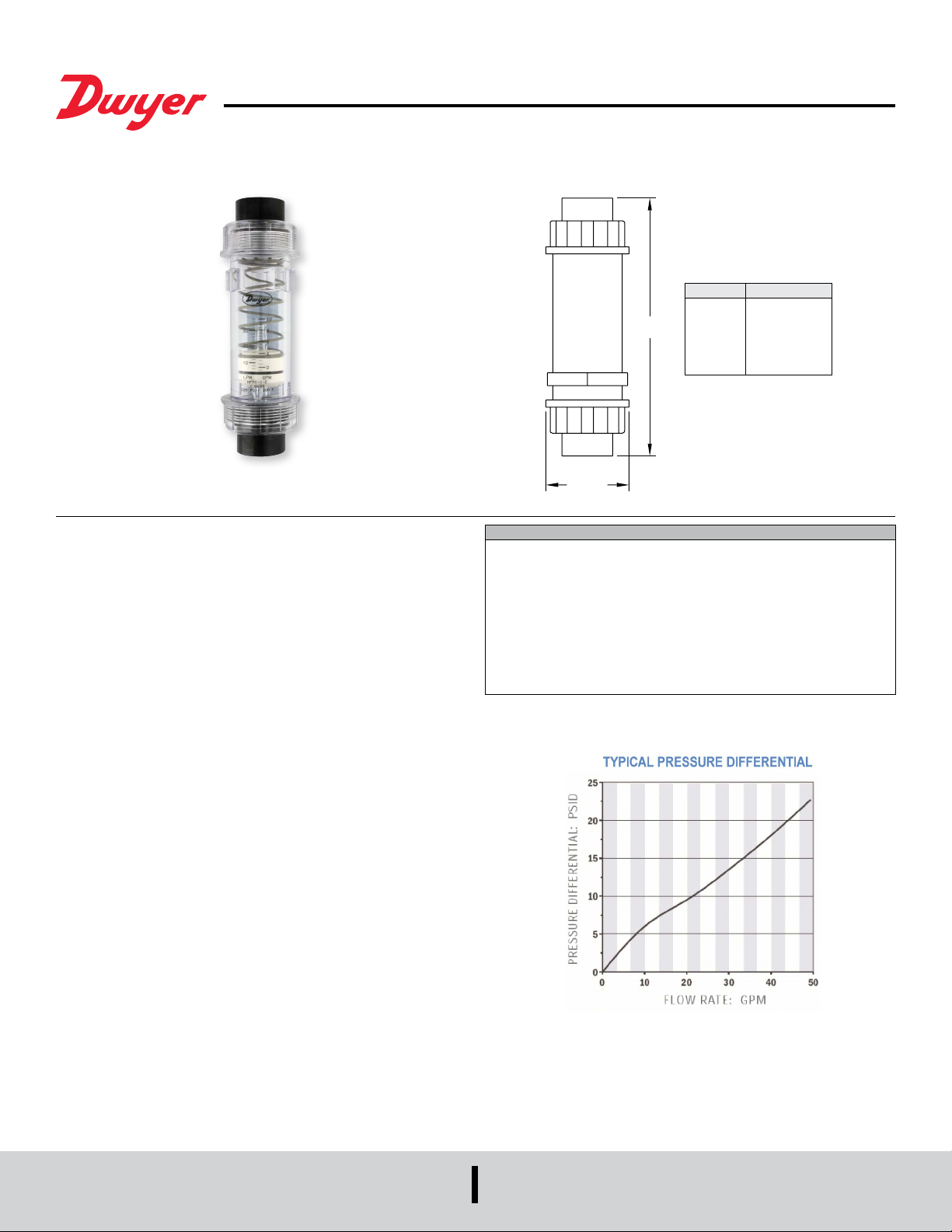

[61.91]

®

Specications - Installation and Operating Instructions

Meter Size Dim “L”

1/2 male

1/2 female

“L”

3/4 male

3/4 female

1 male

1 female

ø2-7/16

Bulletin F-71

7-11/16 [195.26]

7-5/32 [181.76]

8-1/32 [204.00]

7-9/16 [192.09]

8-3/32 [205.58]

7-9/16 [192.09]

The HFPC & HFPS SERIES Flowmeters are made of injection molded, polycarbonate

and polysulfone bodies. Series HFPC and HFPS owmeters have dual scales

measuring in both GPM and LPM with ±5% full scale accuracy. Models are available

with 1/2˝, 3/4˝ or 1˝ male or female NPT connections. Female 1/2˝, 3/4˝ and 1˝ BSPP

connections are also available. Rugged construction allows these meters to handle

maximum pressures of 325 psig and 200 F. Units can be mounted in any position, even

applications with downward ow.

CAUTION: Series HFPC & HFPS Flowmeters are for indoor use only or areas

without direct sunlight. Polycarbonate & polysulfone are adversely affected by

ultraviolet light.

INSTALLATION

The casing and union retainers are made of either Polycarbonate or Polysulfone

materials permitting use with a variety of media. Use of mild detergent to clean the

meter body is encouraged to prevent damaging the label or associated components.

The meters are mounted in-line and are direct reading. The meters can be mounted

in a vertical or horizontal position as long as the uid is owing in the direction of

the arrow on the ow scale. No straight pipe is required before or after the meter. In

fact, 90° elbows can be installed on both ends without any noticeable ow variation.

When installing a meter, apply “Plumbers Tape” or “Liquid Plumber’s Sealant” on pipe

threads. If tape is used, be sure to leave 1/8˝ (3 mm) of pipe thread exposed on end

of pipe. Position lter in front of meter and in a location that allows easy access for

routine maintenance.

The meter should not be mounted in a manner such that piping misalignment or other

system components can exert force or produce a bending moment on the pressure

vessel.

To retain accuracy and repeatability internal moving parts are closely toleranced and

require ltration of at least 74 micron or a 200 mesh screen.

When installing meters onto threaded pipe caution should be taken not to over tighten

the pipe connections or introduce torque on the main body of the meter. The meter

main body may rupture if over-tightened.

SPECIFICATIONS

Service: Compatible liquids.

Wetted Materials: HFPC: Polycarbonate body, Buna-N seals, Stainless Steel

spring, Polysulfone connections. HFPS: Polysulfone body, Buna-N seals, Stainless

Steel spring, Polysulfone connections.

Maximum Pressure: 325 psig (22.4 bar).

Maximum Temperature: HFPC: 200° F (93° C) HFPS: 250° F (121° C).

Accuracy: ±2% FS.

Repeatability: ±1% FS.

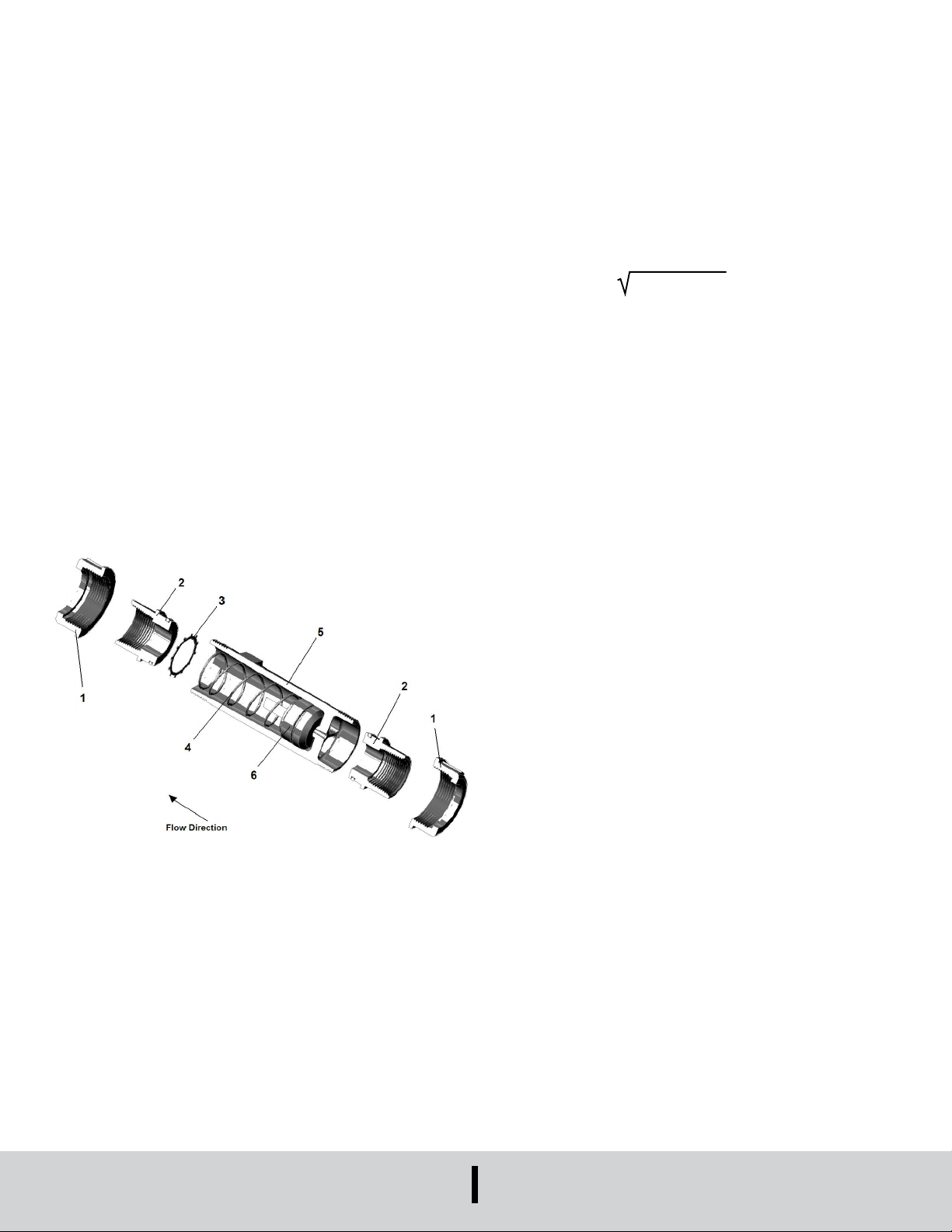

Pressure Loss: See chart.

Weight: Standard models 1 lb (453.6 g). Models with optional brass connections 2

lb (907 g).

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Page 2

INSTALLATION DOS AND DON’TS

To obtain satisfactory operation from a HFPC & HFPS meters, the following points

should be considered:

DO:

• Install a pressure gauge near the inlet of the meter

• Place throttling valves at the outlet of the meter

• Use pipe sealer on the connections

• Install solenoid valves at meter outlet (as far downstream as possible)

• Mount in any orientation: vertical, horizontal or upside down

DO NOT:

• Place restrictions between the meter’s pressure gauge meter inlet

• Use in systems where reverse ow is possible

• Place meter in non-aligned piping

• Over-ow the meter by more than 150% of maximum reading

• Operate at pressures and temperatures greater than specied

• Be mounted near hot pipes or equipment which can cause damage to the pressure

vessel

• Use in systems where the assembled piping is not supported. Externally applied

piping forces may cause the meter to rupture or malfunction.

OPERATION

The meters are tubular, with all internal wetted parts sealed within the body casing

(5). Running through the center of the body casing is a tapered center shaft which is

centered in the bore. Encircling the shaft is a sharp-edged, oating metering poppet

(6). The metering poppet is held in the “no ow” position by the biased return spring

(4). As the ow moves through the meter it creates a pressure differential across the

oating orice disk, forcing the disk and transfer magnet against the return spring. As

ow increases, the pressure differential across the metering poppet increases, forcing

poppet to move along the tapered center shaft. As ow decreases, the biased return

spring forces the poppet down the tapered center shaft, returning to the “no ow”

position.

Reading the Meter

Notice the black reference line which runs 360° around the metering poppet. This

reference line moves under the scale in direct relation to the movement of the poppet.

When uid is owing, the ow rate through the meter is read by lining up the black

reference line with the closest rate line on the ow scale.

Specic Gravity or Density Effect

Standard meters are calibrated for WATER with a specic gravity of 1.0. The oating

disk meter is affected by uid density as are most other similar type meters. HFPC &

HFPS meters have less of this effect because of the sharpness of the oating orice

disks being used. The indicated ow reading will read high for heavier uids and low

for lighter uids. A corrective factor can be applied to the standard scale or a special

scale can be added at additional costs. When measuring uids with other specic

gravities, the basic equation below can be used to develop corrected readings.

For WATER Meters use: 1.0/Specic Gravity x scale reading

CONTAMINATION AND FILTRATION

Recommended Filtration

System ltration of at least a 74 micron lter or a 200 mesh screen is recommended. It

has been found that if inadequate ltration has caused meter failure, it will normally fail

in the open position. Some systems may require a magnetic lter. IMPORTANT: Meter

damage caused by excessive contamination is not covered under warranty.

Stabilized Contamination

The goal of ltration is to create effective protection from system contamination.

Proper ltration stabilizes contamination to allow uid components to function properly.

A uid system is considered stabilized when, “contamination in” equals “contamination

out”. Proper ltration must reduce initial contamination to a stabilized level within an

acceptable time period. The system should be stabilized in time to prevent premature

wear or damage to meter components.

Figure 1 (Flow Meter Cross Section)

MAINTENANCE

Upon nal installation of the Series HFPC and HFPS Plastic Flow Meters, no routine

maintenance is required. A periodic check of the system calibration is recommended.

The Series HFPC and HFPS is not eld serviceable and should be returned if repair

is needed (eld repair should not be attempted and may void warranty). Be sure to

include a brief description of the problem plus any relevant application notes. Contact

customer service to receive a return goods authorization number before shipping.

©Copyright 2016 Dwyer Instruments, Inc. Printed in U.S.A. 8/16 FR# 443560-00 Rev. 1

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Loading...

Loading...