Page 1

Series H2 Dual-Action Explosion-Proof Pressure Switches

[127.00]

3-3/8

Ø2-5/8

L

1/4 NPT PRESSURE CONNECTION

®

Specications - Installation and Operating Instructions

Bulletin F-64

Accurate, dependable long-lived operation results from the built-in quality of Duotect®

pressure switches. They are designed for sequencing work where two different actions

are to be triggered, as pressure of a liquid or gas increases or decreases. This permits

control and protection of many types of equipment and systems subject to pressure

variations. The patented design consists of two pistons in a concentric arrangement,

operated by a single diaphragm with one pressure chamber. Each piston actuates a

separate switch independent of the other. The switches may be adjusted to operate

together, or at opposite ends of the range, or at any two intermediate setpoints. They

can be easily eld adjusted. For quick maintenance, the threaded top is removed to

adjust or service switches without disturbing electrical or pressure connections. The

controls are UL and CSA Listed as Explosion Proof, Class I, Groups B, C, D. Class II

groups E, F & G, and weatherproof NEMA-4.

Expanded Listings. Consult factory for models that are UL Listed (not CSA) Explosion-

proof Class I, Groups A, B, C, & D; Class II, Groups E, F, & G; Weatherproof, NEMA4X. Contacts rated 10 amp @ 125/250 VAC, 5 amps @ 30 VDC.

[66.68]

5

SPECIFICATIONS

Wetted Materials: See model chart on next page.

Temperature Limit: 275°F (135°C). CSA approved -20 to 90°C (-4 to 184°F).

Pressure Limit: 1500 psig (103 bar).

Enclosure Rating: UL listed explosion-proof, Class I, Groups B, C, and D. Class

II Groups E, F, and G. Meets NEMA 4X (IP65). CSA optional. Class I, Groups B, C

& D. Class II, Groups E, F, & G -20°C ≤ Tamb ≤ 75°C T6 [optional -20°C ≤ Tamb ≤

40°C T5] Type 4.

Switch Type: One or two SPDT snap switches.

Electrical Rating: 5A @ 125/250 VAC. 5A res., 3A ind. @ 30 VDC. MV option: 1A

@ 125 VAC, 1A res. or .5A ind. @ 30 VDC.

Electrical Connections: 18 AWG, 18˝ (460 mm) long.

Conduit Connection: 3/4˝ female NPT.

Process Connection: 1/4˝ female NPT.

Mounting Orientation: Any position.

Set Point Adjustment: Internal nut.

Weight: 2 lb (0.9 kg).

Deadband: Approximately 10% of range.

[85.73]

3/4 NPT ELECTRICA

CONNECTION

2-15/16

[74.63]

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Page 2

MODEL CHART

Example H2 S 2 MV H2S-2-MV weatherproof and explosion-proof

Construction H2 Series designator, weatherproof and

Wetted

Material

Options

Adjustable

Operating

Range

Options CSA

INSTALLATION

1. Connect pressure switch to supply pressure. (1/4˝ female NPT connection.)

2. Run connecting wires through external conduit and connect. (3/4˝ NPT

connection).

3. Color coding legend is as follows:

Black: Common

Red: Normally Closed with no pressure in the system.

Blue: Normally Open with no pressure in the system.

4. The individual wires are tagged as follows:

CO1 - Common for #1 Pressure Adjustment.

(High Range).

NC1 - Normally Closed for #1 Pressure Adjustment.

(High Range).

NO1 - Normally Open for #1 Pressure Adjustment.

(High Range).

CO2 - Common for #2 Pressure Adjustment.

(Low Range).

NC2 - Normally Closed for #2 Pressure Adjustment.

(Low Range).

NO2 - Normally Open for #2 Pressure Adjustment.

(Low Range).

A

S

1

1S

2

2S

3

3S

pressure control; 316SS chamber with FEB

diaphragm and Buna-N O-rings, dual switch,

adjustable range; low: 25-250 psig (1.72-17.2

bar), high: 30-400 psig (2.07-27.6 bar), gold

contact snap switch for dry circuits.

explosion-proof

Aluminum chamber with Mylar diaphragm and

Buna-N O-rings

316SS chamber with FEB diaphragm and BunaNO-rings

Dual switch, adjustable range; low: 3-40 psig

(0.21-2.76 bar), high: 5-75 psig (0.35-5.17 bar)

Single switch, adjustable range 3-75 psig

(0.21-5.17 bar)

Dual switch, adjustable range; low: 25-250 psig

(1.72-17.2 bar), high: 30-400 psig (2.07-27.6 bar)

Single switch, adjustable range 25-400 psig

(1.72-27.6 bar)

Dual switch, adjustable range; low: 100-1000

psig (6.89-68.9 bar), high: 150-1500 psig (10.3103 bar)

Single switch, adjustable range 100-1500 psig

(6.89-103 bar)

CSA approved construction

MV

Gold contact snap switch for dry circuits

VIT

Fluorocarbon O-rings

EPDM

EPDM O-rings

FEB

FEB diaphragm option where not standard

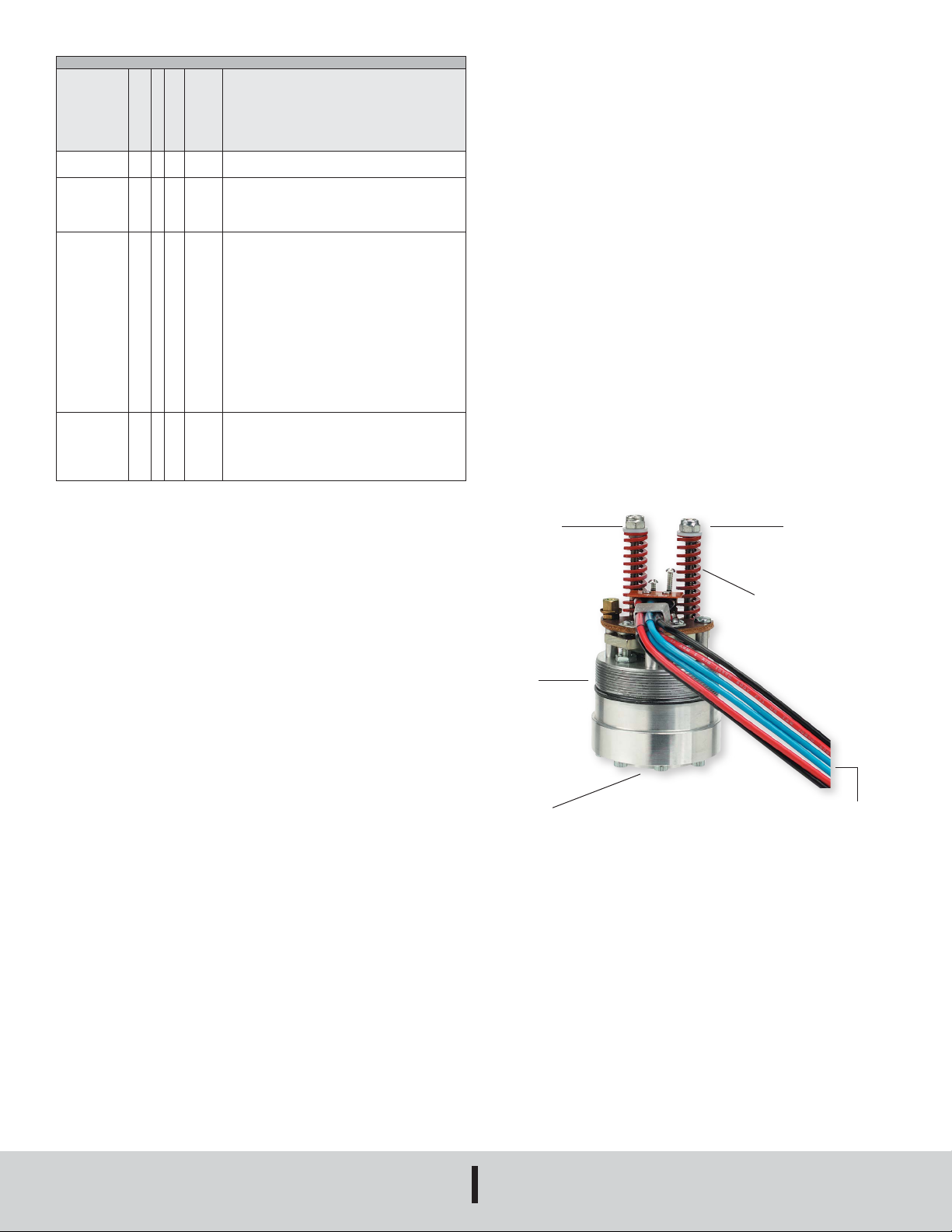

PRESSURE ADJUSTMENT PROCEDURE

The #1 pressure adjustment (see Figure 1) is for the high range of the switch. The #2

adjustment is for the low range. Due to the conguration of the concentric pistons, the

#1 setting must always be the higher of the two.

To adjust the switch, connect it to a source of controlled pressure such as a hand pump

or a regulated uid supply.

1. Set the high range switch #1 by screwing the elastic stop nut up or down as

required to obtain switch actuation at the desired pressure. Be sure to set the

switch with the pressure moving in the proper direction: that is, switch actuation

on an increasing pressure or on a decreasing pressure as required by the

application.

2. Set the low range switch #2 in the same manner.

Note: The 4-40 micro switch adjustment screws are factory set and should not be

changed.

WARRANTY

We guarantee our products to be free from defects in workmanship or material, and

will, without charge, at our option, replace or repair within one year from date of

shipment from our factory any product that may be found defective upon inspection

at our factory. Product to be returned transportation charges prepaid. This guarantee

does not obligate us where product has been subject to careless handling, improper

application or faulty installation, and we expressly disclaim any obligation, guaranty or

liability whatsoever except as above stated.

Set Point Adjustment

NO. 2

PRESSURE

ADJUSTMENT

EXPLOSIONPROOF

ALUMINUM

HOUSING

1/4˝ FEMALE

NPT PIPE

CONNECTION

(UNDERSIDE)

Figure 1

NO. 1

PRESSURE

ADJUSTMENT

EXTRA LONGLIFE CHROME

VANADIUM

SPRINGS

PRE-WIRED

18 GAUGE

LEADS

18˝ (460 MM)

LONG

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Printed in U.S.A. 12/17 FR# 440827-00 Rev. 5©Copyright 2017 Dwyer Instruments, Inc.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Loading...

Loading...