Page 1

Series DS-300 Flow Sensors

Installation and Operating Instructions Flow Calculations

1-15/16 (49.21)

1-5/8 (41.27) TYP

Bulletin F-50

Series DS-300 Flow Sensors are averaging pitot tubes

that provide accurate, convenient flow rate sensing. When

purchased with a Dwyer Capsuhelic®for liquid flow or

Magnehelic®for air flow, differential pressure gage of

appropriate range, the result is a flow-indicating system

delivered off the shelf at an economical price. Series DS-300

Flow Sensors are designed to be inserted in the pipeline

through a compression fitting and are furnished with

instrument shut-off valves on both pressure connections.

Valves are fitted with 1/8˝ female NPT connections.

Accessories include adapters with 1/4˝ SAE 45° flared ends

compatible with hoses supplied with the Model A-471

Portable Capsuhelic®kit. Standard valves are rated at 200°F

(93.3°C). Where valves are not required, they can be

omitted at reduced cost. Series DS-300 Flow Sensors are

available for pipe sizes from 1˝ to 10˝.

LP

HP

1/4 MALE NPT

1-3/4 (44.45)

1-11/16 (42.86)

5/16 (7.94)

Location - The sensor should be installed in the flowing line

with as much straight run of pipe upstream as possible. A

rule of thumb is to allow 10 - 15 pipe diameters upstream

and 5 downstream. The table below lists recommended up

and down piping.

PRESSURE AND TEMPERATURE

Maximum: 200 psig (13.78 bar) at 200°F (93.3°C).

Upstream and Downstream Dimensions in

*

Downstream

5

Upstream Condition

One Elbow or Tee

Terms of Internal Diameter of Pipe

Minimum Diameter of Straight Pipe

Upstream

In-Plane Out of Plane

7

9

INSPECTION

Inspect sensor upon receipt of shipment to be certain it is

as ordered and not damaged. If damaged, contact carrier.

Two 90° Bends in

Same Plane

Two 90° Bends in

Different Plane

8

18

12

24

5

5

INSTALLATION

General - The sensing ports of the flow sensor must be

Reducers or Expanders

8

8

5

correctly positioned for measurement accuracy. The

instrument connections on the sensor indicate correct

All Valves**

24

24

5

positioning. The side connection is for total or high pressure

and should be pointed upstream. The top connection is for

static or low pressure.

DWYER INSTRUMENTS, INC.

* Values shown are recommended spacing, in terms of internal diameter for normal industrial

metering requirements. For laboratory or high accuracy work, add 25% to values.

** Includes gate, globe, plug and other throttling valves that are only partially opened. If valve is to

be fully open, use values for pipe size change. CONTROL VALVES SHOULD BE LOCATED

AFTER THE FLOW SENSOR.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

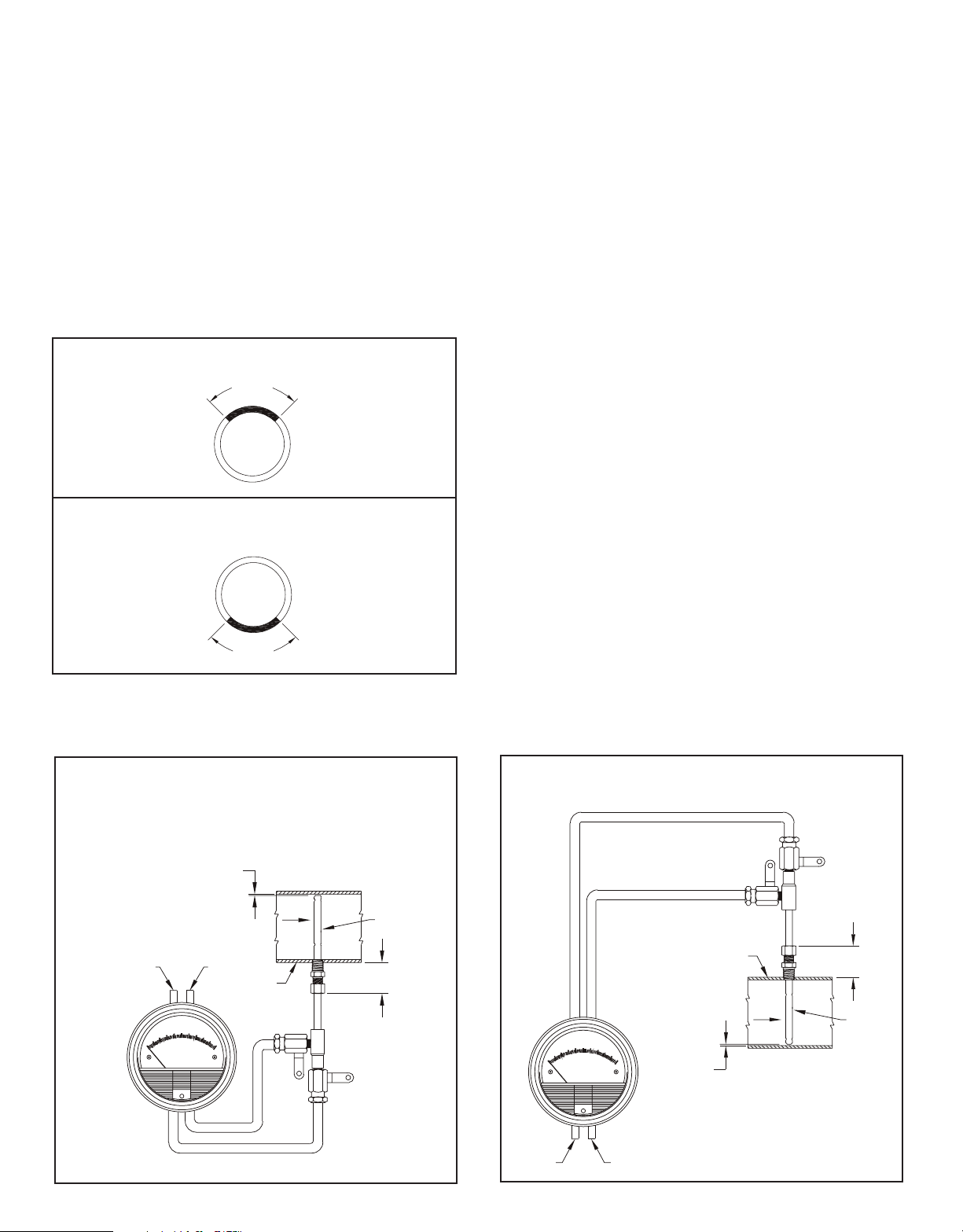

POSITION

Be certain there is sufficient clearance between the

mounting position and other pipes, walls, structures, etc, so

that the sensor can be inserted through the mounting unit

once the mounting unit has been installed onto the pipe.

Flow sensors should be positioned to keep air out of the

instrument connecting lines on liquid flows and condensate

out of the lines on gas flows. The easiest way to assure this

is to install the sensor into the pipe so that air will bleed into,

or condensate will drain back to, the pipe.

For Air or Gas Flow

UPPER PIPE

Install in upper

quadrant of pipe

QUADRANT

Condensate drains

back to pipe

For Liquid or Steam Flow

Install in lower

quadrant of pipe

Air bleeds

back to pipe

INSTALLATION

1. When using an A-160 thred-o-let, weld it to the pipe wall.

If replacing a DS-200 unit, an A-161 bushing (1/4˝ x 3/8˝) will

be needed.

2. Drill through center of the thred-o-let into the pipe with a

drill that is slightly larger than the flow sensor diameter.

3. Install the packing gland using proper pipe sealant. If the

packing gland is disassembled, note that the tapered end of

the ferrule goes into the fitting body.

4. Insert sensor until it bottoms against opposite wall of the

pipe, then withdraw 1/16˝ to allow for thermal expansion.

5. Tighten packing gland nut finger tight. Then tighten

nut with a wrench an additional 1-1/4 turns. Be sure to hold

the sensor body with a second wrench to prevent the

sensor from turning.

INSTRUMENT CONNECTION

Connect the slide pressure tap to the high pressure port of

the Magnehelic®(air only) or Capsuhelic®gage or

transmitting instrument and the top connection to the low

pressure port.

See the connection schematics below.

Bleed air from instrument piping on liquid flows. Drain any

condensate from the instrument piping on air and gas flows.

Water Flow

LP BLEED

INCHES OF WATER

.40

.20

0

CAPSUHELIC®

MAX. OPERATING PRESS. 500 PSIG

DWYER INSTRUMENTS, INC MICHIGAN CITY, INDIANA 46360 U.S.A.

ZERO SET

LP

LOWER PIPE

QUADRANT

1/16 (1.59)

CLEARANCE

HP BLEED

.60

.80

1.0

HP

PIPE

FLOW

HP

SENSOR

1-7/16 (36.53)

LP

Open valves to instrument to place flow meter into service.

For permanent installations, a 3-valve manifold is

recommended to allow the gage to be zero checked

without interrupting the flow. The Dwyer A-471 Portable

Te st Kit includes such a device.

Air or Gas Flow

LP

HP

LP

INCHES OF WATER

.40

.20

0

CAPSUHELIC®

MAX. OPERATING PRESS. 500 PSIG

DWYER INSTRUMENTS, INC. MICHIGAN CITY, INDIANA 46360 U.S.A.

ZERO SET

PIPE

HP

.60

.80

1.0

1/16 (1.59)

FLOW

CLEARANCE

1-7/16 (36.53)

SENSOR

LP DRAIN

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

HP DRAIN

Page 3

1/4 MALE NPT

1-15/16 (49.21)

LP

HP

5/16 (7.94)

1-5/8 (41.27) TYP

1-3/4 (44.45)

1-11/16 (42.86)

Flow Calculations and Charts

The following information contains tables and equations for

determining the differential pressure developed by the DS300 Flow Sensor for various flow rates of water, steam, air

or other gases in different pipe sizes.

This information can be used to prepare conversion charts

to translate the differential pressure readings being sensed

into the equivalent flow rate. When direct readout of flow is

required, use this information to calculate the full flow

differential pressure in order to specify the exact range of

Dwyer Magnehelic®or Capsuhelic®gage required. Special

ranges and calculations are available for these gages at

minimal extra cost. See bulletins A-30 and F-41 for

additional information on Magnehelic®and Capsuhelic

gages and DS-300 flow sensors.

For additional useful information on making flow

calculations, the following service is recommended: Crane

Valve Co. Technical Paper No. 410 “Flow of Fluids Through

Valves, Fittings and Pipe.” It is available from Crane Valve

Company, www.cranevalve.com.

®

Using the appropriate differential pressure equation from Page 4 of this bulletin,calculate the differential pressure generated by

the sensor under normal operating conditions of the system. Check the chart below to determine if this value is within the

recommended operating range for the sensor. Note that the data in this chart is limited to standard conditions of air at 60°F

(15.6°C) and 14.7 psia static line pressure or water at 70°F (21.1°C). To determine recommended operating ranges of other

gases, liquids an/or operating conditions, consult factory.

Note: the column on the right side of the chart which defines velocity ranges to avoid. Continuous operation within these

ranges can result in damage to the flow sensor caused by excess vibration.

Pipe Size

(Schedule 40)

1

1-1/4

1-1/2

2

2-1/2

3

4

6

Flow

Coefficient

“K”

0.52

0.58

0.58

0.64

0.62

0.67

0.67

0.71

Operating Ranges

Air @ 60°F & 14.7 psia

(D/P in. W.C.)

1.10 to 186

1.15 to 157

0.38 to 115

0.75 to 75

1.72 to 53

0.39 to 35

0.28 to 34

0.64 to 11

Operating Ranges

Water @ 70°F

(D/P in. W.C.)

4.00 to 675

4.18 to 568

1.36 to 417

2.72 to 271

6.22 to 193

1.43 to 127

1.02 to 123

2.31 to 40

Velocity Ranges

Not Recommended

(Feet per Second)

146 to 220

113 to 170

96 to 144

71 to 108

56 to 85

42 to 64

28 to 43

15 to 23

8

10

0.67

0.70

Find Quality Products Online at: sales@GlobalTestSupply.com

0.10 to 10

0.17 to 22

www.GlobalTestSupply.com

0.37 to 37

0.60 to 79

9.5 to 15

6.4 to 10

Page 4

FLOW EQUATIONS

DIFFERENTIAL PRESSURE EQUATIONS

1. Any Liquid

Q (GPM) = 5.668 x K x D2x ∆P/S

2. Steam or Any Gas

Q (lb/Hr) = 359.1 x K x D2x p x ∆P

3. Any Gas

Q (SCFM) = 128.8 x K x D2x P x ∆P

f

(T + 460) X S

S

Technical Notations

The following notations apply:

∆P = Differential pressure expressed in inches of water column

Q = Flow expressed in GPM, SCFM, or PPH as shown in equation

K = Flow coefficient— See values tabulated on Pg. 3.

D = Inside diameter of line size expressed in inches.

For square or rectangular ducts, use:

D = 4 x Height x Width

1. Any Liquid

P (in. WC) = Q

∆

2. Steam or Any Gas

∆P (in. WC) = Q

3. Any Gas

∆P (in. WC) = Q

π

2

x S

f

K2x D4x 32.14

2

K2x D4x p x 128,900

2

x SSx (T + 460)

K2x D4x P x 16,590

P = Static Line pressure (psia)

T = Temperature in degrees Fahrenheit (plus 460 = °Rankine)

p = Density of medium in pounds per square foot

Sf= Sp Gr at flowing conditions

SS= Sp Gr at 60°F (15.6°C)

SCFM TO ACFM EQUATION

SCFM = ACFM X

ACFM = SCFM X

POUNDS PER

CUBIC FOOT CUBIC FOOT

POUNDS PER

CUBIC FOOT CUBIC FOOT

1 Cubic foot of air = 0.076 pounds per cubic foot at 60° F (15.6°C) and 14.7 psia.

* (520°= 460 + 60°) Std. Temp. Rankine

STD. =

ACT. =

14.7 + PSIG

(

14.7 460 + °F

14.7

(

14.7+ PSIG 520

POUNDS PER

POUNDS PER

)(

)(

ACT. X

STD. X

520*

)

460 + °F

)

14.7

(

14.7 + PSIG 520*

14.7 + PSIG

(

14.7 460 + °F

)(

)(

460 + °F

520*

)

)

©Copyright 2004 Dwyer Instruments, Inc. Printed in U.S.A. 7/04 FR# 72-440451-01 Rev. 2

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...