Page 1

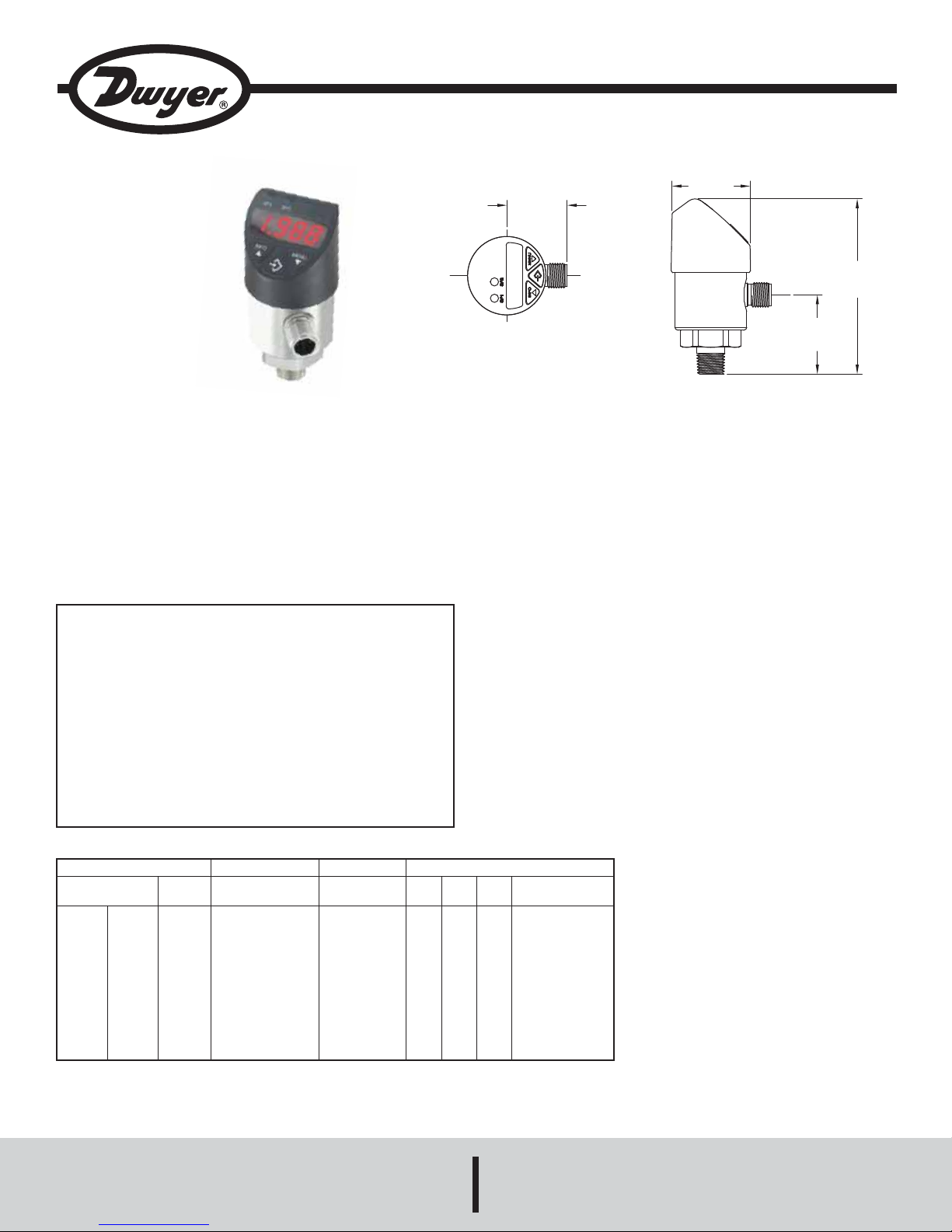

Bulletin P-DPT

1-5/32

[29.50]

1-1/2

[38.00]

1-33/64

[38.60]

3-23/64

[85.40]

Operating Modes

System start

- Display is fully activated for 2s

Display Mode

- Normal operation, displays system pressure

Programming Mode

- Setting Parameters

4-digit LED display - Display system pressure

- Display Menu Item

- Display Parameter

1. LED (red)

- Status Switch Output 1

2. LED (red)

- Status Switch Output 2 (Optional)

-When the pressure switch is powered up within

the range of the hysteresis, the output switch is

set to “not active” by default

Series DPT Digital Pressure Transmitter with Switches

Specifications - Installation and Operating Instructions

The Series DPT Digital Pressure Transmitter with Switches combines a large,

14-segment LED display with two programmable solid state switches into one

compact unit. A unique, 3-way rotating design allows the DPT to meet specific

installation requirements without any retrofitting. The display and electrical

connection can be rotated independently to maximize visibility while still orienting

the electrical connection in the best position for the cable connector. Large,

ergonomically designed push buttons allow for quick/easy programming and thinfilm piezoresitive sensor technology guarantees long-term reliability and stability.

INSTALLATION

When installing gage always use a hex at the base of the housing to tighten the

gage to a mating fitting. Do not apply wrench to housing.

POWER UP

UNITS CHART

Model

DPT-V00

DPT-V01

DPT-V02

DPT-V03

DPT-V04

DPT-V05

DPT-V06

DPT-V07

DPT-V08

DPT-V09

DPT-V10

*feet of seawater @ 4°C

DPT-A00

DPT-A01

DPT-A02

DPT-A03

DPT-A04

DPT-A05

DPT-A06

DPT-A07

DPT-A08

DPT-A09

DPT-A10

Range

(psig)

-14.5 to 0

0 to 15

0 to 25

0 to 30

0 to 50

0 to 100

0 to 160

0 to 200

0 to 300

0 to 500

0 to 1000

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Maximum Pressure

(psig)

30

30

60

60

100

200

290

400

600

1000

1740

Burst Pressure

(psig)

75

75

150

150

250

500

500

1500

1500

2500

7975

bar

1.034

1.034

1.724

2.068

3.447

6.895

11.03

13.79

20.68

34.47

68.95

MPa

.1034

.1034

.1724

.2068

.3447

.6895

1.103

1.378

2.068

3.447

6.895

SPECIFICATIONS

Service: Compatible gases, liquids or vapors.

Wetted Materials:

Pressure connection: 316 L SS;

Pressure sensor: 316 L SS (13-8 PH for ranges above 150 psi).

Housing: 316 L SS lower body, heat and chemical resistant fiberglass reinforced

plastic (PBT) plastic head, TPE-E keyboard, PC display window.

Accuracy: 1.0% F.S. (includes non-linearity, hysteresis, zero point).

Pressure Limit: See table.

Temperature Limits: 32 to 176°F (0 to 80°C).

Process Connections: 1/4˝ male NPT.

Display: Red LED 4-digit (0.35˝ H digits).

Weight: 7 oz (0.2 kg).

SWITCH SPECIFICATIONS

Switch Type: PNP.

Electrical Rating: 250 mA.

Electrical Connections: M 12x1, 5-pin.

Mounting Orientation: Mount in any position.

TRANSMITTER SPECIFICATIONS

Temperature Limits: 32 to 176°F (0 to 80°C).

Thermal Effect: 0.2% FS / 10k.

Power Requirements: 15 to 35 VDC.

Output Signal: DPT-A: 4 to 20 mA; DPT-V: 0 to 10 VDC.

Loop Resistance: DPT-A: ≤ 0.5k; DPT-V: > 10k.

Power Consumption: ≤ 100 mA.

Electrical Connections: M 12x1, 5-pin.

Enclosure Rating: IP65 and IP67.

Agency Approvals: CE.

Pressure Ranges

2

kPa

103.4

103.4

172.4

206.8

344.7

689.5

1103

1378

2068

3447

6895

kg/cm

1.055

1.055

1.758

2.109

3.515

7.031

11.25

14.06

21.09

35.15

70.31

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

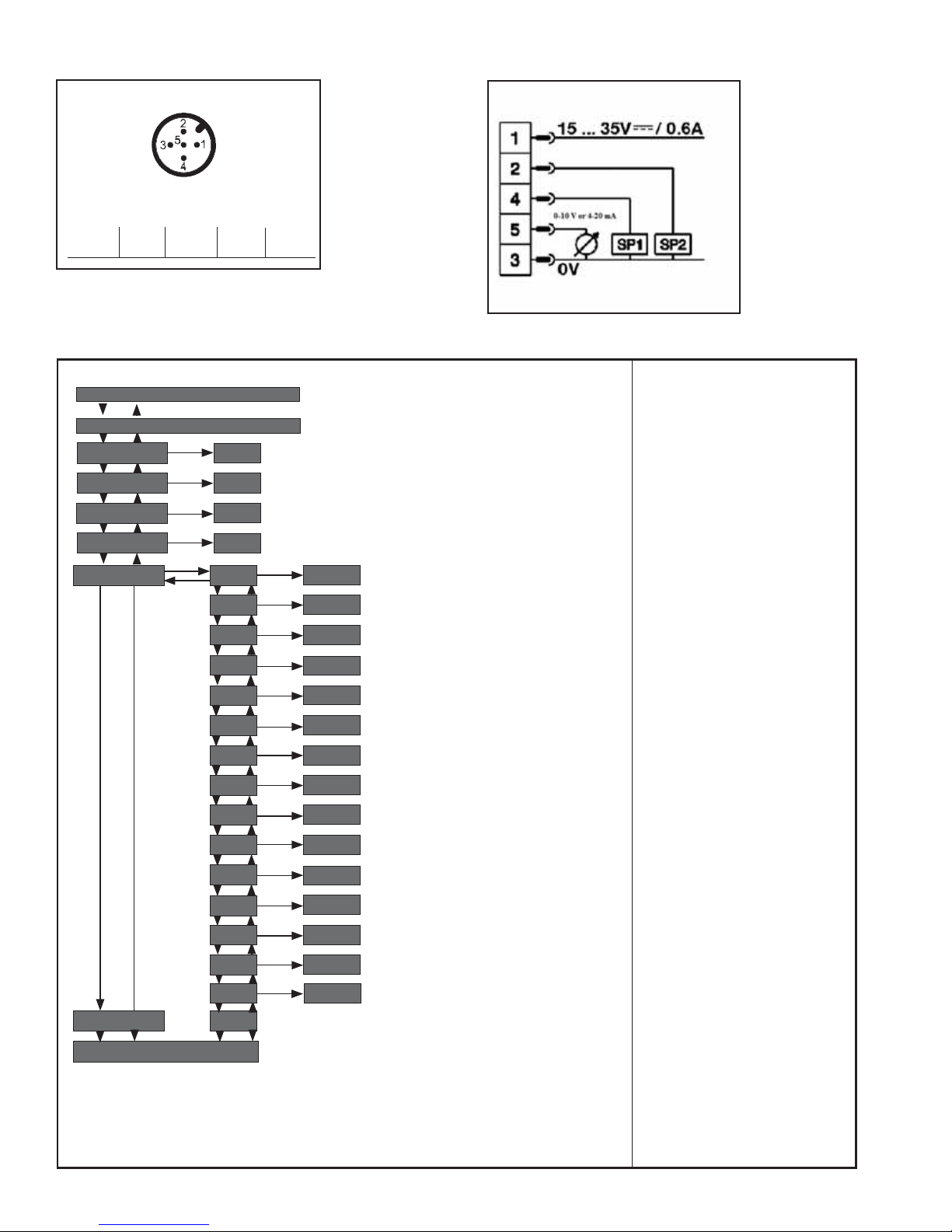

WIRING

Circular connector M12x1, 5-pin

2 switching outputs + 1 analogue output

+ = 1 - = 3

PROGRAMMING

SP1 = 4

0-10 V or 4-20 mA

SP2 = 2 = 5

Menu (Programming and Factory Setting)

Display-Mode

Long press on Menu Key

Programming-Mode

SP1 / FH1

RP1 / FL1

SP2 / FH2

RP2 / FL2

EF

value

value

value

value

RES

DS1

DR1

DS2

YES/NO

value

value

value

Factory Setting:

(Min: LLR + 0.5% Max: ULR) Instrument Nominal Pressure

(Min: LLR Max: SP1 - 0.5%) Instrument Nominal Pressure - 10%

(Min: LLR + 0.5% Max: ULR) Instrument Nominal Pressure

(Min: LLR Max: SP2 - 0.5%) Instrument Nominal Pressure-

(Return to Factory Settings)

(0 … 50 s) 0 s

(0 … 50 s) 0 s

(0 … 50 s) 0 s

10%

END

Display-Mode

Legend:

LLR = lower limit of range

ULR = upper limit of range

DR2

OU1

OU2

UNIT

0SET

DISM

DISU

DISR

RHL

PAS

TAG

END

value

PARA

PARA

unit

YES/NO

PARA

value

YES/NO

YES/NO

value

value

(0 … 50 s) 0 s

(HNO, HNC, FNO, FNC) HNO

(HNO, HNC, FNO, FNC) HNO

(BAR, MPA, KPA, PSI, KG/cm²) Order dependent

(Zero Point Offset adjustment max. 3 %)

(ACT, HIGH, LOW, OFF,

SP1/FH1, RP1/FL1, SP2/FH2, RP2/FL2) ACT

(1/2/5/10 Updates/Second)

5 / s

(Display rotate 180°)

(Reset HIGH, LOW)

(Password) without

(Measuring Point number) without

Page 3

BUTTON OPERATION

Hysteresis function

If the system pressure fluctuates around the nominal value,

the hysteresis keeps the switch status of the outputs stable.

When the system pressure is rising, the output switches when it

reaches the respective set point (SP); if the pressure falls again,

the output switches back only if the reset point (RP) is reached.

Application example: loading an accumulator.

The shut-off valve loads up to 8o bar and then shuts off. When

70 bar is reached again, it switches on once more.

Window function

The window function allows the monitoring of a defined range.

If the system pressure is between the window high (FH) and the

window low (FL), the output is activated (NO) respective

deactivated (NC).

Delay times (0.00 to 50 s):

By this means unwanted pressure peaks of short duration or high

frequency can be filtered out.

The pressure must remain for at least this time to enable the

switch to operate. The switching output does not immediately

change its status when it reaches the switching event, but only

after the delay time has elapsed. If the switching event no longer

pertains when the delay time has elapsed, the switching output

does not change.

Error Display Description

ATT1 On changing the Switch Point the system automatically reduces the Reset Point

ATT2 Zero Point adjustment error, current pressure is outside the limits

ATT3 Password entered for Menu access is incorrect

ERR Internal error

OL Overpressure, measuring range exceeded > approx. 5% (Display blinks)

UL Underpressure, under measuring range < approx. 5% (Display blinks)

Acknowledgement of an Error Display by pressing the ˝Enter˝ key.

Display-Mode Programming-Mode

short press:

INFO

Display units

long press:

Run-through Parameter Info

1. UNIT + unit

2. SP1 / FH1 + value

3. RP1 / FL1 + value

4. SP2 / FH2 + value (optional)

5. RP2 / FL2 + value (optional)

6. LOW + value

7. HIGH + value

8. TAG + value (Only display when value set)

short press:

Display units

MENU

long press:

Switch to Programming Mode

If the password is set to <> 0000, a pass

word will be requested. If authentication is

successful, then it enters the Program Mode,

otherwise it reverts to Display Mode.

short press:

Display units

INFO

short press:

- Menu up

- Increase parameter value

long press:

- Menu up

- Increase parameter value

short press:

- Menu down

- Decrease parameter value

long press:

- Menu down

- Decrease parameter value (Increment rate is time dependent)

long press (during Restart, keep pressed)

short press:

- Select Menu Item

- Confirmation of the entry (Parameter value)

+

MENU

short press (both keys at the same time):

Return to Display Mode

SWITCH FUNCTION

ERROR

Page 4

PARAMETERS

Parameter Description

SP1 / SP2 Hysteresis function: Switch point switch output (1 or 2)

FH1 / FH2 Window function: Window high switch output (1 or 2)

RP1 / RP2 Hysteresis function: Reset point switch output (1 or 2)

FL1 / FL2 Window function: Window low switch output (1 or 2)

EF Enhanced Programming Functions

RES Return the set parameter to the Factory Settings

DS1

DS2

DR1

DR2

OU1 Switching Function Switching Output (1 or 2)

OU2 HNO = Hysteresis Function, normally open

UNIT Changing Units

0SET Zero Point adjustment (+ 3% of Nominal Pressure)

DISM Display value in Display Mode

DISU Display-Update 1, 2, 5, 10 Updates/Second

DISR Display rotate 180°

RHL Clear the Min- and Max-value memory

PAS Password input, 0000 = no password

TAG Input of a 16-digit alphanumeric Measuring Point number

Switch Delay Time, which must occur without interruption before any electrical signal change occurs

(SP1 or SP2)

Switch Delay Time, which must occur without interruption before any electrical signal change occurs

(RP1 or RP2)

HNC = Hysteresis Function, normally closed

FNO = Window Function, normally open

FNC = Window Function, normally closed

(If the pressure range is higher than the display range, no change of the unit is posssible

and the parameter UNIT is not shown)

ACT = Current System Pressure, LOW, HIGH = Minimum, Maximum System Pressure, OFF = Display off;

SP1/FH1 = Function switch point 1, RP1/FL1 = Function reset point1,

SP2/FH2 = Function switch point 2, RP2/FL2 = Function reset point 2

Password input Digit by Digit

TROUBLESHOOTING

Failure Possible cause Procedure

No output signal Cable break Check connections and cable

No output signal No/incorrect voltage supply

No/False output signal Incorrectly wired

Output signal unchanged after change

Abnormal zero point signal Overload limits exceeded

Signal span too small

Signal span too small Power supply too high/too low

WARRANTY

Upon final installation, no routine maintenance is required. A periodic check of the

calibration is recommended. The series DPT is not field serviceable and should be

returned if repair is needed (field repair should not be attempted and may void

warranty). Be sure to include a brief description of the problem plus any relevant

application notes. Contact customer service to receive a returns goods authorization

number before shipping.

in pressure

Mechanical overload through over pressure

Mechanical overload through over pressure

Adjust the voltage supply to correspond

with the Operating Instructions

Follow pin assignment (see Instrument

Label / Operating Instructions)

Replace instrument; if failure reoccurs,

consult the manufacturer

Ensure permissible overload limits are

observed (see Operating Instructions)

Replace instrument; if failure reoccurs,

consult the manufacturer

Correct the power supply in line with

the Operating Instructions

11609185.01

10/2010

©Copyright 2010 Dwyer Instruments, Inc. Printed in U.S.A. 10/10 FR# RA-443873-00 Rev. 1

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...