Page 1

Series DPMX Extra Large Digital Panel Meter

Specifications - Installation and Operating Instructions

10-19/32

MINIMUM PANEL

CLAMP DIM.

(MAXIMUM PANEL

THICKNESS 1/2˝)

[12.70]

1-31/32

[50.04]

(2-43/64)

[67.87]

[261.11]

10-19/32

[269.24]

Bulletin G-62

The Series DPMX Extra Large LED Digital Panel Meter can

easily be viewed from across a room or in dark areas. The 2.3”

LED segments are available in red, green, or blue. These panel

meters come equipped with a universal power supply and user

selectable process inputs to fit most applications. The Series

DPMX includes a mounting bracket that can be adjusted up to

180°.

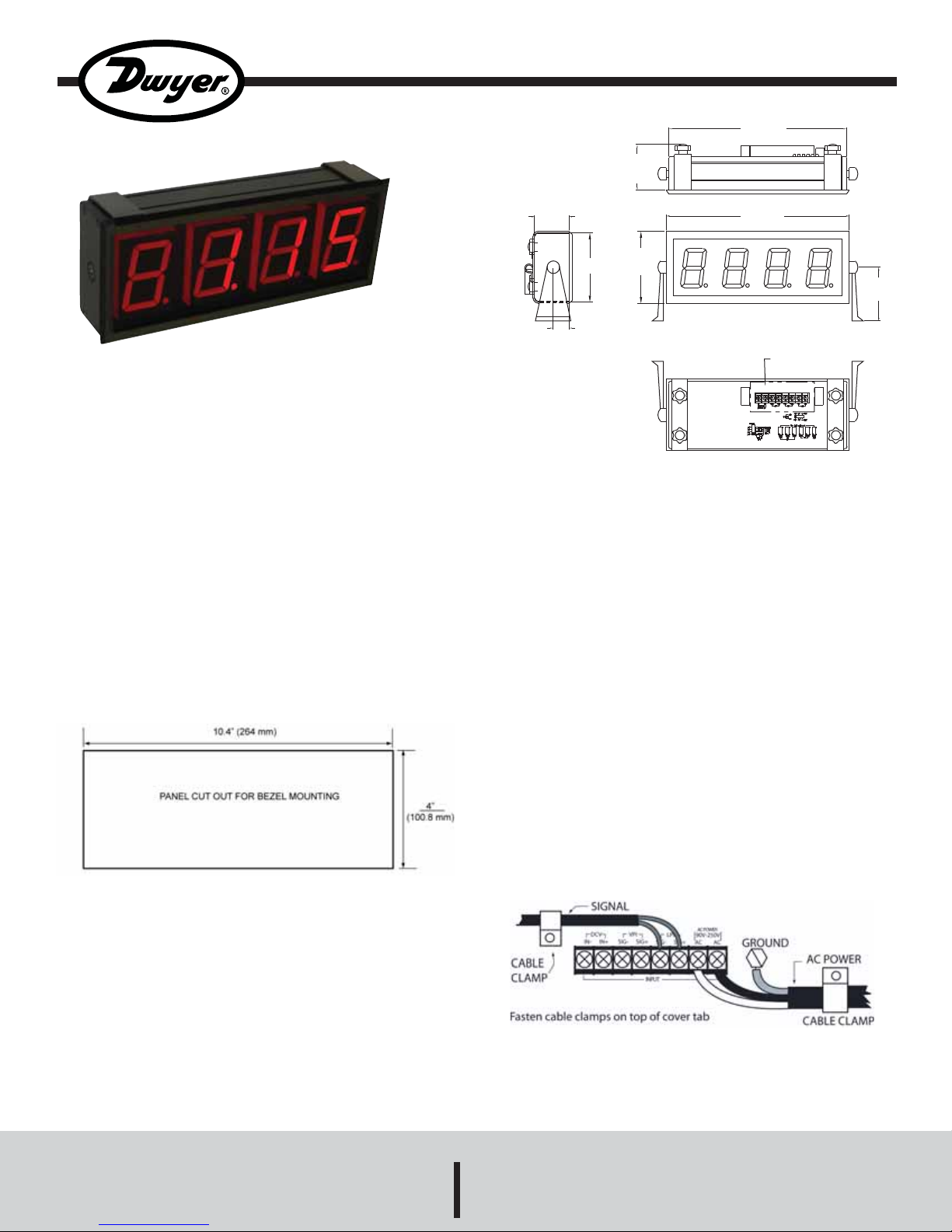

INSTALLATION

The Series DPMX is designed to be bezel mounted or gimbal

mounted. Mounting brackets are included in the box.

BEZEL MOUNT

Remove the two U-brackets from the back of the panel meter.

Slide the unit through the panel from the front. Next, attach the Ubrackets to the rear and tighten the four retaining bolts.

See Figure 1 for dimensions of the cutout.

4-5/32

[105.66]

REMOVABLE

COVER

3-7/64

[78.99]

29/32

[22.86]

4[101.60]

SPECIFICA T IONS

Inputs Ranges: Set Voltage: ±200 mVDC, ±2 VDC, ±20 VDC.

Adjustable Voltage: 200 mVDC, 5 VDC, 10 VDC.

Adjustable Current: 0(4) to 20 mA DC.

Inputs Impedance: Set Voltage: >1 MΩ (>10 MΩ on 200 mV range).

Adjustable Voltage: 392 kΩ.

Adjustable Current: 300Ω nominal.

Accuracy: ±(1% F.S. + 1 count).

Power Supply: 90 to 250 VAC @12 VA or 10.5 to 30 VAC/DC @

6VA (depending on model).

Display: 3-1/2 digits, 2.3” height, 7 segment LED.

Sampling Rate: 3 readings per second.

Operating Temperature: -10 to 50ºC.

Storage Range: -40 to 75ºC.

Warm Up: 10 minutes.

Mounting: 180º gimbal mounting with 30º stops or bezel mount.

WIRING

The unit accepts signal inputs of 200 mVDC, 2 VDC, 5 VDC, 20

VDC, 10 VDC, and a 4 to 20 mA DC loop. The screw terminals for

wiring are located on the back of the adder board beneath the

cover. The cable clamps must be unfastened to access the screw

terminals. In order to reduce electrical noise, install the line voltage

and the process signal through separate cable clamps as shown

Figure 1

in Figure 2.

GIMBAL MOUNT

If the panel meter is to be gimbal mounted, remove and discard

the two U-brackets from the back of the panel meter. Fasten the

gimbal brackets to the mounting surface using appropriate

hardware. Lastly, fasten the panel meter loosely to the gimbals

using the thumbscrews. Note that detents are provided on both

sides of the case. Adjust the meter to the desired viewing angle

and securely tighten the thumb screws.

Figure 2

On the terminal cover, remove two thin break out sections that

best match the diameter of the wiring cables being used.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

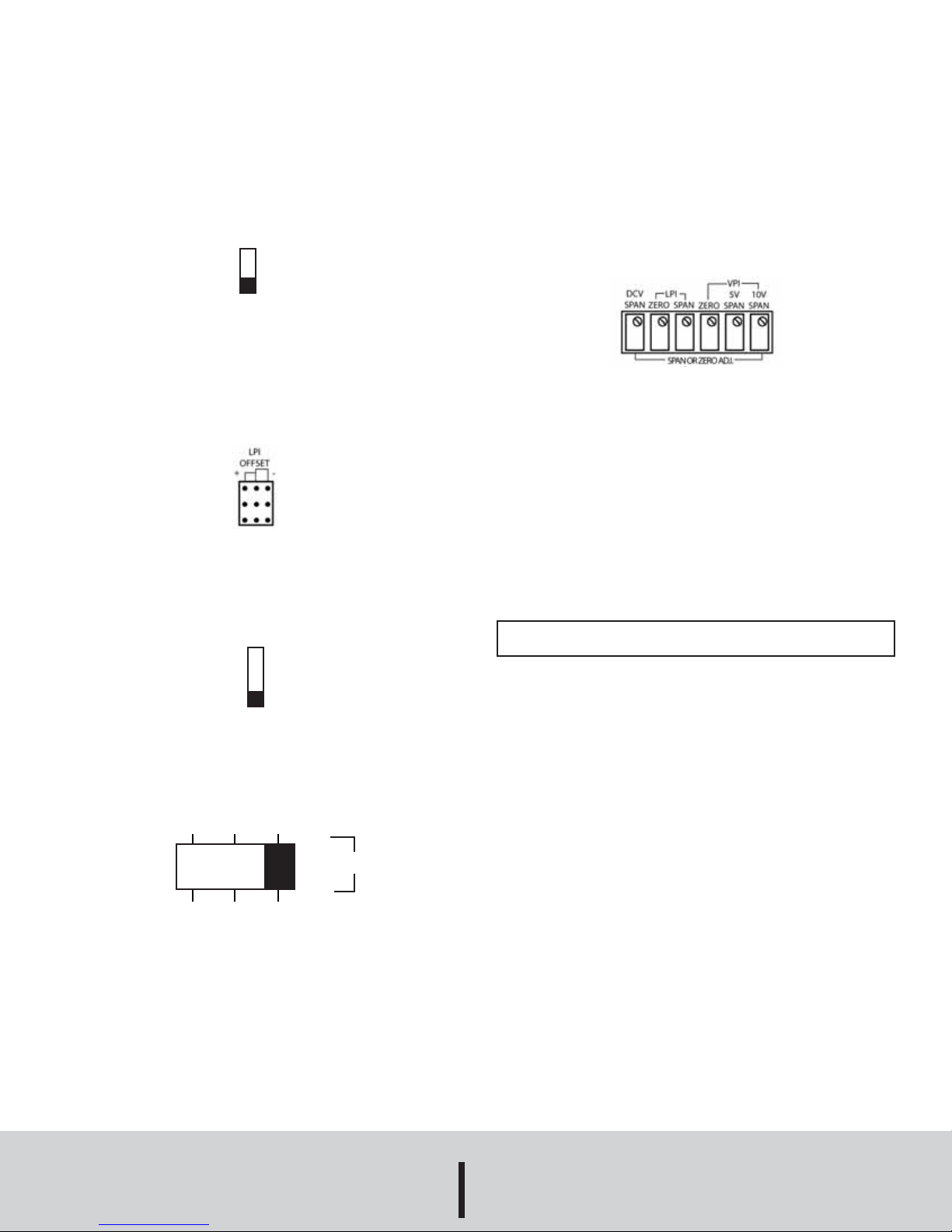

OPERA TION

FUNCTION

The Series DPMX panel meter can be used with voltage or current

signal inputs. It is important that the signal wires be connected to

the proper terminals as labeled in Figure 2. Along with wiring to the

proper terminals, the proper input should be selected using the

function selection switch shown in Figure 3. For current inputs, the

function switch should be set to LPI. For adjustable voltage inputs,

the function switch should be set to VPI. For fixed voltage inputs,

the function switch should be set to DCV.

LPI

VPI

DCV

FUNCTION

Figure 3

ZERO SUPPRESSION FOR CURRENT INPUT

The Series DPMX can be used with either 0 to 20 mA or 4 to 20

mA current inputs. In order to maximize the rangeability of the

meter, the LPI offset jumper should be set to “+” for 4 to 20 mA

signal inputs or to “-” for 0 to 20 mA inputs.

See Figure 4.

Figure 4

SELECTING DECIMAL POINT POSITION

Four decimal point positions are available on the digital panel

meter, DP1-OFF. Move the switch to the corresponding decimal

point location. See Figure 5.

DP1

DP2

DP3

OFF

DECIMAL

Figure 5

SPAN & ZERO ADJUSTMENT

The unit is equipped with a span adjustment for DCV inputs, and

both span and zero adjustments for LPI and VPI inputs. To use

either function, a flathead screwdriver is required to set the

appropriate values. First, choose the span and/or zero adjustment

that corresponds with the input that is being supplied. For

example, if a VPI inputs is being supplied to the meter, you will

need to adjust the VPI span. Next, apply the lowest input into the

meter and adjust the zero position for the required reading. After

adjusting the zero position, apply the highest input into the meter

and adjust the span position for the meter. Recheck the zero input

and readjust as needed. See Figure 6.

Figure 6

MAINTENANCE

Upon final installation of the Series DPMX LED Digital Panel Meter,

no routine maintenance is required. A periodic check of the system

calibration is recommended. The Series DPMX is not field

serviceable and should be returned if repair is needed (field repair

should not be attempted and may void warranty). Be sure to

include a brief description of the problem plus any relevant

application notes. Contact customer service to receive a return

goods authorization number before shipping.

CAUTION! Do not mount the panel meter outdoors or in damp

environments, or other extreme environments. It is not a sealed unit.

SELECTING VOLTAGE INPUT RANGE

Three input positions are available for either VPI or DCV (see Figure

3 above). Move the switch to desired input range (see Figure 7).

200 mV 5V 10V

200 mV 2V 20V

VPI

RANGES

DCV

Figure 7

©Copyright 2008 Dwyer Instruments, Inc. Printed in U.S.A. 11/08 FR# R5-443568-00 Rev. 2

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...