Dwyer Instruments DPG-100 Series, DPG-102, DPG-100, DPG-100C, DPG-103 Operating Instructions Manual

...Page 1

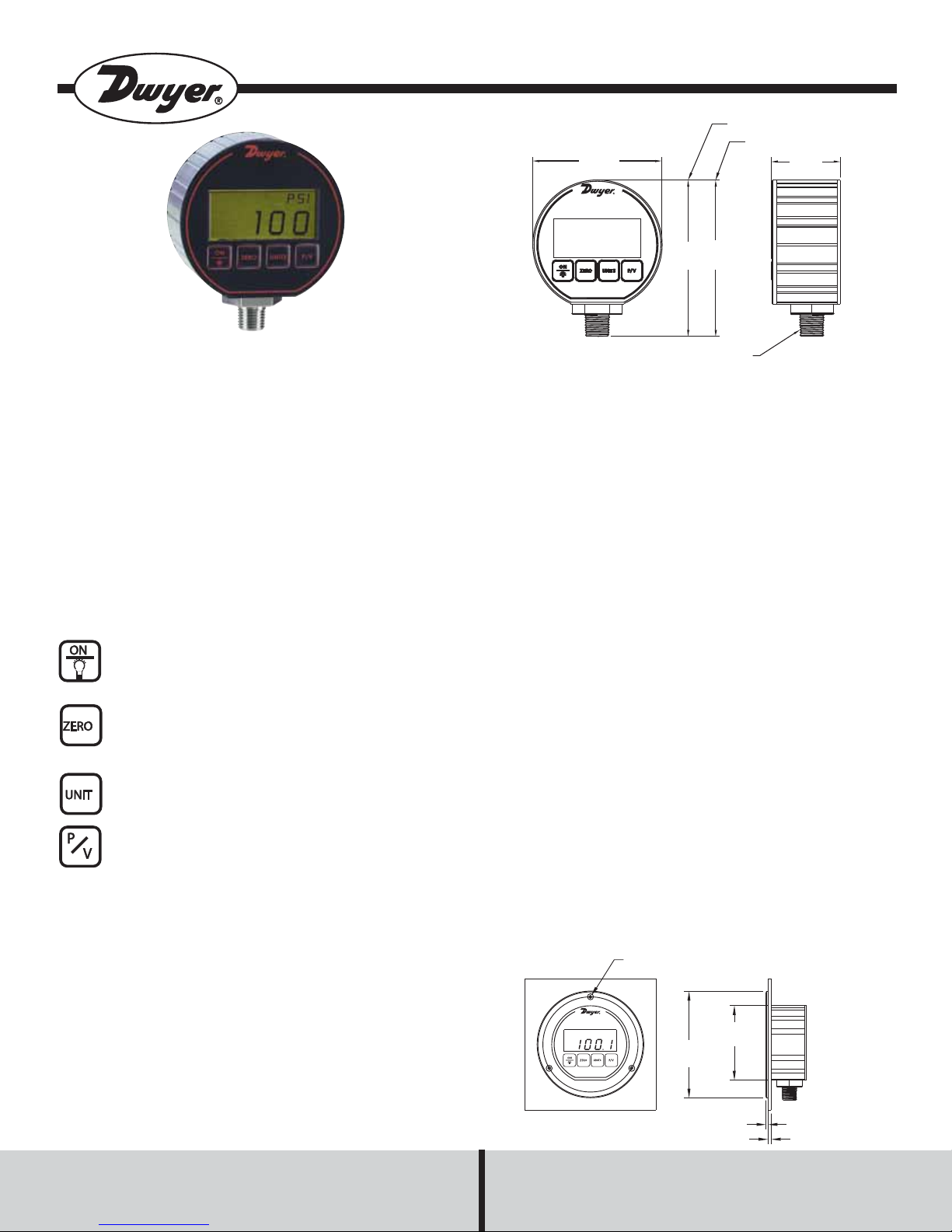

Series DPG-100 Digital Pressure Gage

Specifications - Installation and Operating Instructions

STANDARD RANGES

3

[76.20]

3-3/4

3-5/8

[95.25]

[91.39]

Bulletin A-34

CERAMIC RANGES

1-5/8

[40.39]

The Series DPG-100 Digital Pressure Gage has a precise +/- 0.25%

full scale accuracy. The 4 digit digital display will reduce the potential for

errors in readings by eliminating parallax error commonly produced with

analog gages.

The DPG-100 is packaged in a durable extruded aluminum case

designed to meet NEMA 4/4X. The unit is battery powered and has an

auto-shut off to conserve battery life. A four button key pad allows easy

access to features without the need to work through complex menus or

difficult key combinations. These features include backlight, peak and

valley, auto zero and conversion of the pressure units. Readings may be

converted to various engineering units. See reverse page for available

units.

DPG Quick Start Button Operation

For complete detailed instructions on the four button operation see the

Operation Chart provided on back.

On/Backlight: Push to turn on; Press again for backlight.

Press and hold for 5 seconds to turn unit off.

Zero: Zeros the display - Push & hold for 2 seconds to zero

the display. If after pressing zero the display does not re-zero,

the unit is no longer meeting specified accuracy and should be

sent back to the factory for calibration. Do not use the zero

button when pressure is applied.

Units: Scroll (see next page for Model/Range Chart).

P/V: Peak recorded reading retrieved by initial push of button;

push again retrieves the valley or lowest value recorded.

INSTALLATION

When installing gage always use 1˝ hex at the base of the housing to

tighten the gage to a mating fitting. Do not apply wrench to housing.

1/4 NPT

Service: Liquids and combustible

compatible gases (for FM listings

see agency approvals below).

Wetted Materials: Type 316L SS;

Ceramic Ranges: Type 316L SS,

ceramic, fluoroelastomer.

Housing Materials: Black polycarbonate front & back cover, anodized

aluminum extruded housing with

recessed grooves, polycarbonate

overlay,Buna-N O-Rings, 316L SS

sensor construction.

Accuracy: 0.25% full scale;

Ceramic Ranges: 0.5% full scale; ±

1 least significant digit @ 70°F

(21°C) . (Includes linearity, hysteresis, repeatability).

Pressure Limit: 2x pressure range

for models ≤1000 psi;5000 psi for

3000 psi range;7500 psi for 5000

psi range.

Enclosure Rating: Designed to

meet NEMA 4/4X (IP65).

Temperature Limits: 0 to130°F

(-18 to 55°C).

Thermal Effect: Between 70 to

130°F is 0.016%/F; Between 32 to

70°F is0.026%/F; Between 10 to

32°Fis 0.09%/F; Between 0 to

10°Fis 0.50%/F.

*Note: Gages with ceramic sensor are not CE and FM approved.

Size: 3.00˝ OD x 1.90 deep (max).

Process Connection: 1/4˝ male

NPT.

Weight: 8.84 oz (275 g).

Display: 4 digit (.425 H x .234W

digits).

Sample Rate: 2 sec.

Power Requirements: Two AAA

batteries.

Battery Life: 2000 hours typi-cal;

low battery indicator.

Auto Shut-Off: Gage: 60 minute

auto shut-off. Auto shut-off may be

disengaged; Backlight: 2 minute

auto shut-off.

Agency Approvals: FM approved

to be intrinsically safe for Class I,

Division I, Groups A,B, C and D, for

ranges 0-15 to0-3000 psi. CE EMC

Directive:

EN 61000-4-2

EN 61000-4-3 & ENV50204

EN 61000-6-2

EN 61000-6-4

EN 55011.

WARNING: DO NOT pressurize DPG over maximum allowable pressure

limits. Extreme damage can occur if limits are exceeded (see Pressure

Limit under Specifications). An overflow “OFL” designator will flash to

acknowledge that the gage’s pressure range has been exceeded.

PANEL MOUNT OPTION

Drill a 3-1/4˝ (82.55) diameter hole in a panel, locate three mounting

holes for a #6 screw 120° apart on a 3-58˝ (92.08) bolt circle.

MAINTENANCE

A “LOW BAT” descriptor indication will appear on the display when batteries need to be replaced.

(3) MOUNTING HOLES FOR #6 FLAT HEAD SCREW

EQUALLY SPACED ON A 3-5/8 (92.08) B.C.

Battery Replacement: Remove the three screws on backplate. Lift back-

4-1/16

(103.19)

3-1/4 (82.55)

HOLE IN PANEL

plate off by hand. Replace batteries per polarity indicators. To reassemble, ensure O-Ring seats into housing evenly and press until seated

completely. Replace screws.

WARNING: Substitution of components may impair intrinsic safety.

Batteries must be changed in a non-hazardous location only. DO NOT

mix batteries from different manufacturers. DO NOT mix old batteries

with new batteries.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

5/64

(1.98)

P.O. Box 373 • Michigan City, IN 46361-0373, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

9/32 (7.14) MAX

PANEL THICKNESS

Page 2

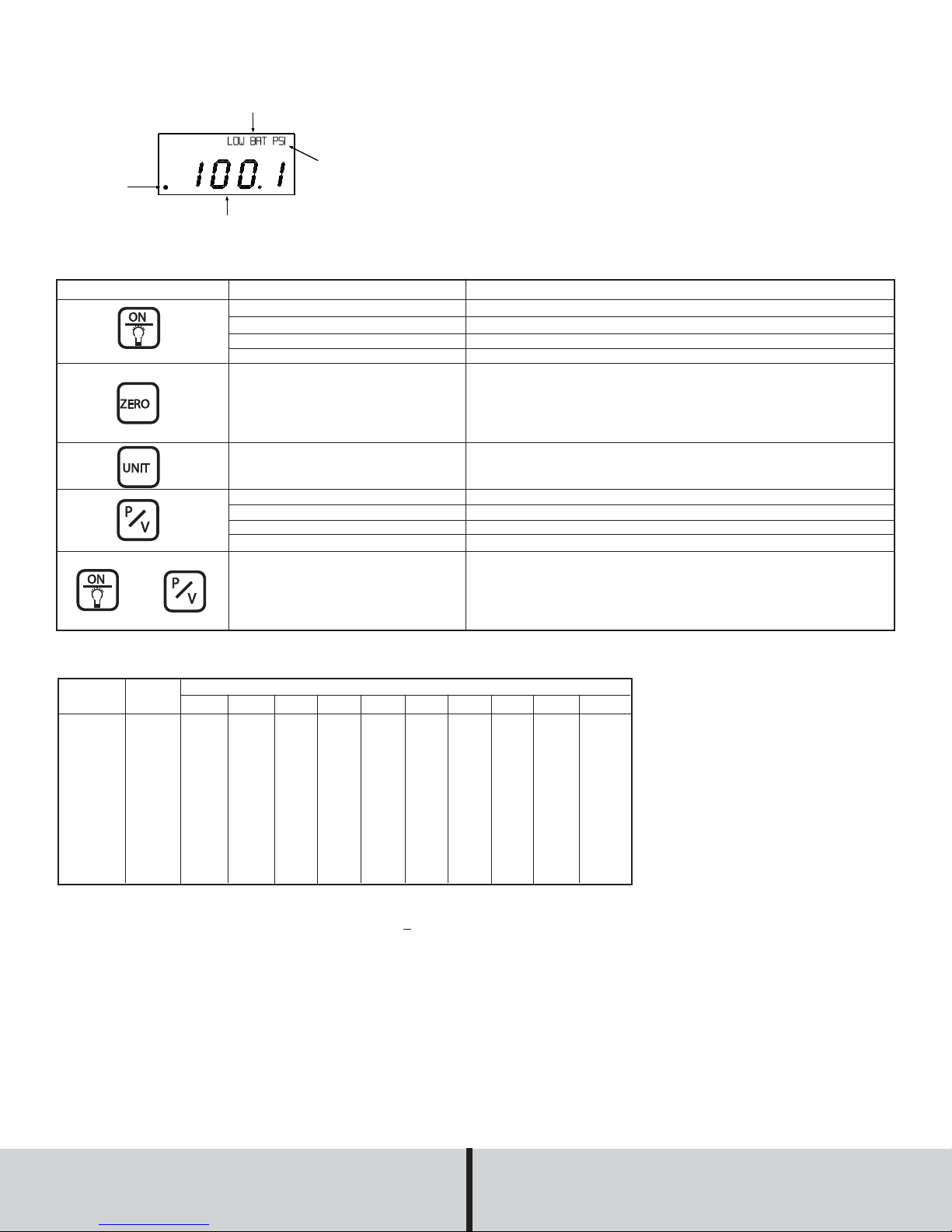

LOW BATTERY INDICATION

UNITS

PRESSURE READING

AUTO SHUT-OFF

INDICATOR

DPG-100 DISPLAY

DPG Button Operation

Button Operation Action

Press and hold ON button

While gage is on press ON button

While backlight is on press ON button

While gage is on, press and hold ON button 5 seconds for unit to turn off.

With no pressure applied to the gage, press and hold ZERO button until

display flashes

If gage will not zero, then gage is no longer meeting specified accuracy

and should be sent back to the factory for recalibration

NOTE: Gage is not to be zeroed while pressure is applied

Press UNIT button to change units on gage (Not all units are available for

each range, please refer to model/range chart located below for available

units)

Press P/V button to read peak (highest pressure) measurement

Press P/V button again to read valley (lowest pressure) measurement

Press and hold P/V button to reset peak and valley

Press ON button to exit peak/valley

Auto shut-off will turn off an idle gage after 60 minutes. To disengage

auto shut-off, press and hold ON button, then press and hold P/V button.

A decimal will blink in the lower left hand corner of the display to indicate

the auto-shut off is turned off. To turn on auto shut-off, repeat above procedure until decimal point stops blinking

plus

Turn Unit On

Turn Backlight On (Auto Shut-Off: 2 Min)

Turn Backlight Off

Turn Unit Off

Zero Gage

Unit Selection

View Peak

View Valley

Reset Peak & Valley

Exit Peak & Valley

Disengage Auto Shut-Off

Model/Range Chart

Model

Number

DPG-100*

DPG-102

DPG-103

DPG-104

DPG-105

DPG-106

DPG-107

DPG-108

DPG-109

DPG-110

DPG-111*

Compound Ranges available: DPG-120* Range: 30˝ Hg-0-15 psi; DPG-121* Range: 30˝ Hg-0-30 psi; DPG-122* Range: 30˝ Hg-0-45 psi; DPG-123*:

Range 30˝ Hg-0-60 psi; DPG-124*: 30˝ Hg-0-100 psi.

*Optional ceramic sensor available. Add “C” to the range (Ex. DPG-100C).

Range

psi

-14.70-0

15.00

30.00

50.00

100.0

200.0

300.0

500.0

1000

3000

5000

kg/cm

-1.033

1.055

2.109

3.515

7.03

14.06

21.09

35.15

70.3

210.9

351.5

2

bar

-1.013

1.034

2.069

3.448

6.895

13.79

20.69

34.48

68.98

206.9

344.8

in Hg

-29.93

30.54

61.08

101.8

203.6

407.2

610.8

1018

2036

6108

Pressure Ranges

ft wc

-33.94

34.61

69.21

115.4

230.7

461.4

692.1

1154

2307

6921

kPa

-101.4

103.4

206.9

344.8

689.5

1379

2069

3448

6895

oz/in

-235.2

240

480

800

1600

3200

4800

8000

2

in wc

-407.3

415.2

830.4

1384

2768

5536

8304

mbar

-1013

1034

2069

3448

6895

cm wc

-1034

1055

2109

3515

7031

mm Hg

-760.7

775.7

1551

2586

5172

©Copyright 2009 Dwyer Instruments, Inc. Printed in U.S.A. 8/09 FR# 18-443202-04 Rev. 9

DWYER INSTRUMENTS, INC.

P.O. Box 373 • Michigan City, IN 46361-0373, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...