Page 1

Series DM-2000 Differential Pressure Transmitter

(38.10)

®

Specications - Installation and Operating Instructions

HIGH PRESSURE PORT

1-1/4

[31.75]

LOW PRESSURE PORT

7/16

[11.11]

17/32

[13.50]

1-11/16

[42.86]

5/32

[3.97]

Bulletin E-43-DM

ø4-3/4

[120.65]

The Dwyer Series DM-2000 Differential Pressure Transmitter senses the pressure

of air and compatible gases and sends a standard 4-20 mA output signal. The DM-

2000 housing is specically designed to mount in the same diameter cutout as a

standard Magnehelic

calibrated to specic ranges.

Pressure connections are inherent to the glass lled plastic molded housing making

installation quick and easy. Digital push-button zero simplies calibration over typical

turn-potentiometers. Single push button allows eld selection of 5 engineering units

(LCD models only). An optional 3.5 digit LCD shows process and engineering.

Accessories

Mounting Lugs

6-20 x 2˝ Screws - 3

6-19 x 1/2˝ Screws - 3

INSTALLATION

1. Location

Select a clean, dry mounting location free from excess vibration where the

temperature will remain between 20 and 120˚F (-6.7 and 48.9˚C). Distance from the

receiver is limited only by total loop resistance. See Electrical Connections on next

page. The tubing supplying pressure to the instrument can be practically any length

required, but long lengths will increase response time slightly.

2. Position

A vertical position required. That is the position in which all standard models are

spanned and zeroed at the factory.

Pressure Connections

Two integral tubing connections are provided on the side of the gage. They are sized

to t 1/8˝ (3.12 mm) I.D. tubing. Be sure the pressure rating of the tubing exceeds that

of the operating ranges.

Note: The tubing connections on the back of the gage are not to be used as process

connections.

3. Mounting

Panel - Provide a 4-9/16˝ diameter opening in panel. Insert gage and secure in place

with provided screws and adapters.

Surface - Provide three 3/16˝ diameter holes in panel on a 4-1/8˝ diameter bolt circle.

Cut opening for terminal block as shown in diagram to right.

®

differential gage. A wide range of models are available factory

SPECIFICATIONS

Service: Air and non-combustible, compatible gases.

Wetted Materials: Consult Factory.

Accuracy: ±1% F.S. at 70°F.

Stability: ±1% F.S./yr.

Temperature Limits: 20 to 120°F (-6.67 to 48.9°C).

Pressure Limits: 10 psig (0.69 bar).

Thermal Effect: ±0.055% F.S./°F (0.099% F.S./°C).

Power Requirements: 10-35 VDC (2 wire).

Output Signal: 4 to 20 mA.

Zero and Span Adjustments: Digital push-button zero and span.

Loop Resistance: DC: 0-1250 ohms maximum.

Current Consumption: DC: 38 mA maximum.

Electrical Connections: Screw-type terminal block.

Process Connections: 1/8˝ I.D. tubing.

Mounting Orientation: Vertical.

Weight: 4.8 oz (136 g).

Panel

Surface

11/16

(17.46)

65.000°

1

(25.40)

(3) HOLES FOR #6 SCREW

EQUALLY SPACED ON

1-1/2

4-1/8 (104.78) B.C.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Page 2

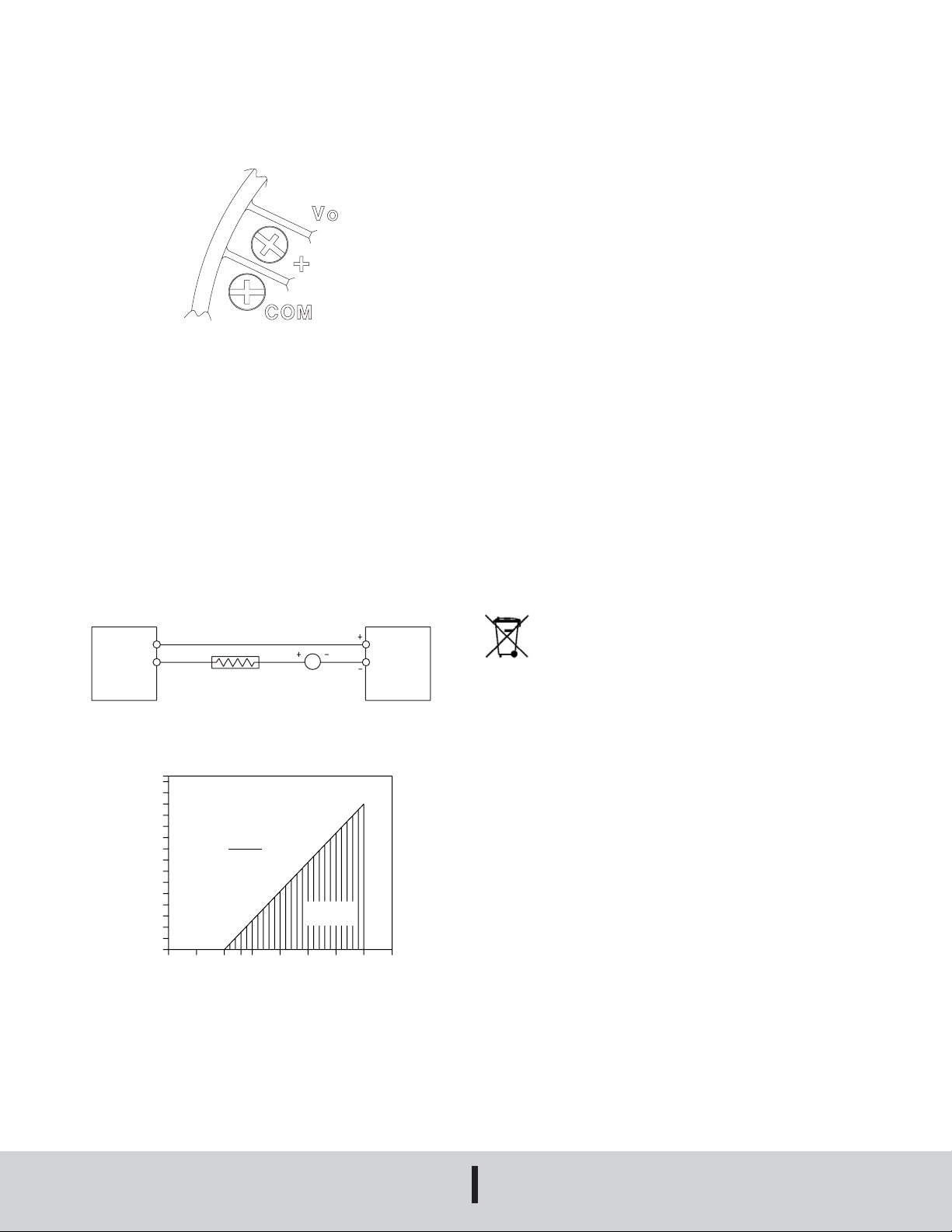

ELECTRICAL CONNECTIONS

1500

Total Receiver Resistance ()

0 5 10 13 15 20 25 30 35 40

CAUTION: Do not exceed specied supply voltage ratings. Permanent damage not

covered by warranty will result. This unit is not designed for 120 or 240 volts AC line

operation.

Electrical connections are made to the terminal block located in back of the transmitter.

Terminals are marked + and - (see Fig. B below).

Figure B

Wire Length

The maximum length of wire connecting transmitter and receiver is a function of wire

size and receiver resistance. Wiring should not contribute more than 10% of the

receiver resistance to total loop resistance. For extremely long runs (over 1000 feet),

choose receivers with higher resistance to minimize size and cost of connecting leads.

Where wiring length is under 100 feet, hook-up wire as small as 22 AWG can be used.

2-Wire Operation

An external power supply delivering 10-35 VDC with minimum current capability of

40 mA DC (per transmitter) must be used to power the control loop. See Fig. C for

connection of the power supply, transmitter and receiver. The range of appropriate

receiver load resistance (RL) for the DC power supply voltage available is expressed

by the formula and graph in Fig. D. Shielded two wire cable is recommended for

control loop wiring. If grounding is required, use the negative side of the control loop

after the receiver.

2-Wire Connections

SERIES

DM-2000

PRESSURE

TRANSMITTER

1

2

RECEIVER

Figure C

mA

POWER

SUPPLY

10-35 VDC

USER CALIBRATION

The transmitter may be user calibrated with two buttons on the front. The standard

models have buttons labeled “ZERO” and “SPAN”. LCD models have buttons labeled

“ZERO” and “UNITS”. The “UNITS” button on the LCD models has 2 functions. If

pushed for less than 2 seconds and released the pressure units that are displayed on

the LCD will change when the button is released. If pushed and held for 4 - 5 seconds

the “UNITS” button serves the same function as the “SPAN” button on the standard

models.

To calibrate the transmitter you will need three pieces of equipment. You will need

a calibrated pressure source capable of generating a stable pressure value for

the maximum range of the unit under test, an instrument capable of validating the

calibration pressure, and an ampmeter, capable of measuring mA, to measure the

current output from the unit under test. The transmitter is calibrated using the following

procedure.

Preparation – Connect the ampmeter and power supply, being careful to observe

polarities. The transmitter must be calibrated in a vertical position.

Performing ZERO Calibration, SPAN Calibration or Restore Factory

Calibration Coefcients:

1. Press both the ZERO and UNITS/SPAN buttons simultaneously for 6 or more

seconds. Release both buttons. The units indicator on the LCD should blink on

and off. This indicates the gage is ready for calibration or restoration of

coefcients. The units indicator blinks for approximately 10 minutes, then stops

blinking.

2. a) ZERO calibrate the gage by applying no pressure to the gage and

then pressing the ZERO button for 3 seconds.

b) SPAN calibrate the gage by applying full-scale pressure to the gage and

then pressing the UNITS/SPAN button for 3 seconds.

c.) Restore the gage’s factory calibration coefcient by pressing both the ZERO

and UNITS/SPAN buttons simultaneously for 3 seconds.

MAINTENANCE

Upon nal installation of the Series DM2000 Differential Pressure Transmitter and

the companion receiver no routine maintenance is required. The Series DM2000

Transmitter is not eld serviceable and should be returned, freight prepaid, to the

factory if repair is required. Please enclose a description of the problems encountered

plus any available application information.

This symbol indicates waste electrical products should not be disposed

of with household waste. Please recycle where facilities exist. Check with

your Local Authority or retailer for recycling advice.

Power Supply Voltage – VDC (2-wire)

1400

1300

1200

1100

1000

900

R Max. =

L

800

700

600

500

400

300

200

100

50

©Copyright 2019 Dwyer Instruments, Inc. Printed in U.S.A. 2/19 FR# 443402-00 Rev. 5

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Vps–10.0

20mA DC

Figure D

Maximum Value (1250 )

Operating

Region

Phone: 219/879-8000

Fax: 219/872-9057

dwyer-inst.com

e-mail: info@dwyermail.com

Loading...

Loading...