Page 1

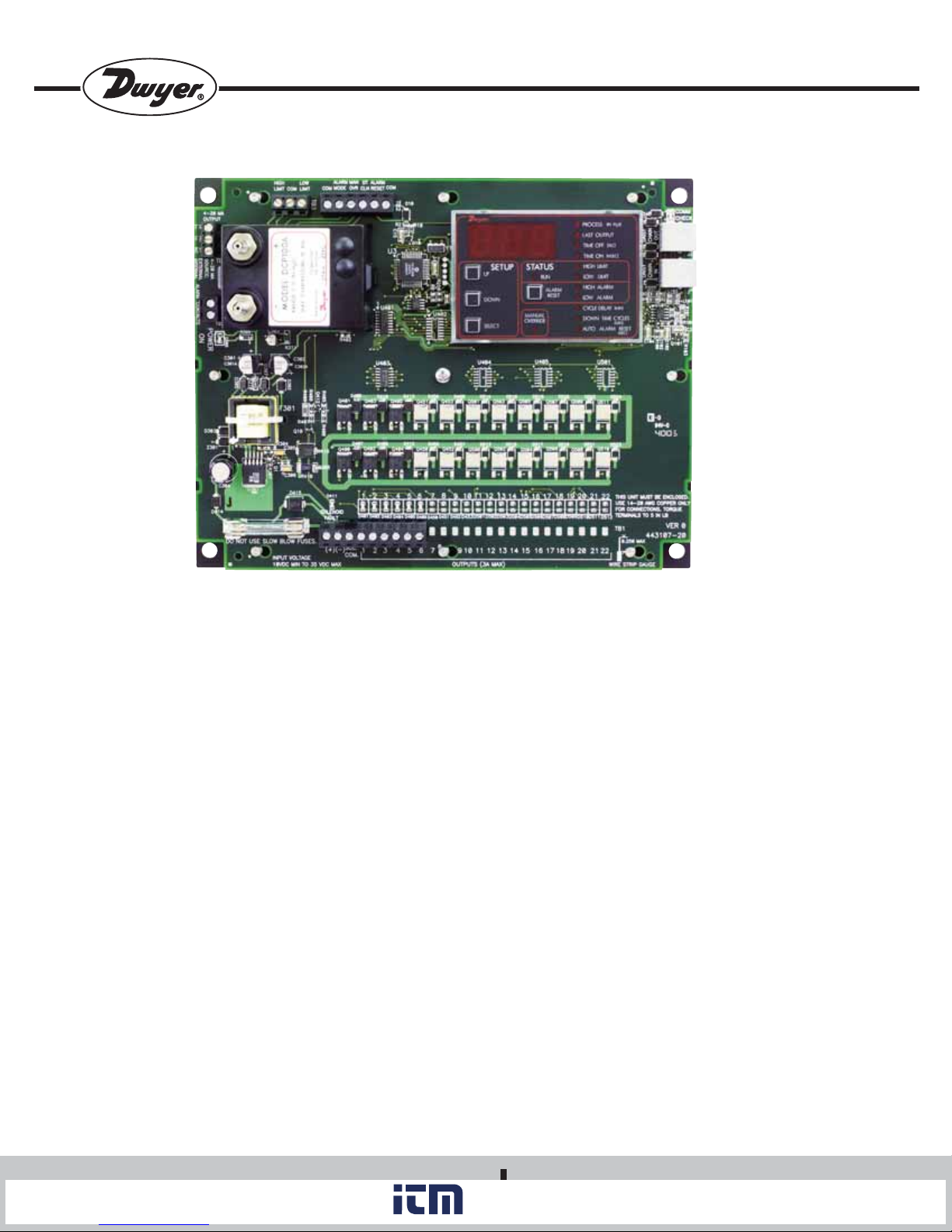

Series DCT1000DC Dust Collector Timer Controller

www. .com

information@itm.com1.800.561.8187

Specifications – Installation and Operating Instructions

Bulletin E-97DC

Thank you for purchasing the Dwyer®DCT1000DC Dust Collector Timer

Controller. You have selected a state of the art dust collector timer control

that will provide years of dependable operation and service.

The Dwyer®DCT1000DC Dust Collector Timer Controller was designed to

be used with pulse-jet type dust collectors for on-demand or continuous

cleaning applications.

Continuous cleaning applications do not require external inputs and can

be used for time based “on-demand” cleaning through use of the cycle

delay feature.

For on-demand applications, the plug-in pressure modules

(DCP100A/200A) can be used to take full advantage of all the features the

DCT1000DC offers, or an external pressure switch can be used for

High/Low limit control.

The Dwyer® DCT1000DC was designed so that it is easy to use, thus

allowing for a quick and easy start up for your dust control applications.

The contents inside this installation and operating manual will guide you

through the features of the DCT1000DC and how they can be applied to

get the most out of your dust control requirements.

SPECIFICATIONS

DCT1000DC Timer Controller:

Output Channels: 6, 10, & 22 channels.

Power Requirements: 10 - 30 VDC.

Solenoid Supply: 3A maximum per channel.

Fuse: 3A @ 250 VAC.

Temperature Limits: -40 to 140°F (-40 to 60°C).

Storage Temperature Limits: -40 to 176°F (-40 to 80°C).

On Time: 10 msec to 600 msec, 10 msec steps.

On Time Accuracy: ± 10 msec.

Off Time: 1 second to 255 seconds, 1 second steps.

Off Time Accuracy: ±1% of the value or ±50 msec, whichever is

greater.

Weight: 1 lb 3.0 oz (538.6 g).

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361 U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

SETUP

www. .com

information@itm.com1.800.561.8187

UP

DOWN

SELECT

STATUS

RUN

ALARM

MANUAL

OVERRIDE

RESET

PROCESS (IN H2O)

LAST OUTPUT

TIME OFF (SEC)

TIME ON (M SEC)

HIGH LIMIT

LOW LIMIT

HIGH ALARM

LOW ALARM

(MIN)

CYCLE DELAY

DOWN TIME CYCLES

(MIN)

AUTO ALARM RESET

(SEC)

6-1/4

[158.75]

6-7/8

[174.62]

2-3/4

[69.85]

8-1/4

[209.55]

8-3/4

[222.25]

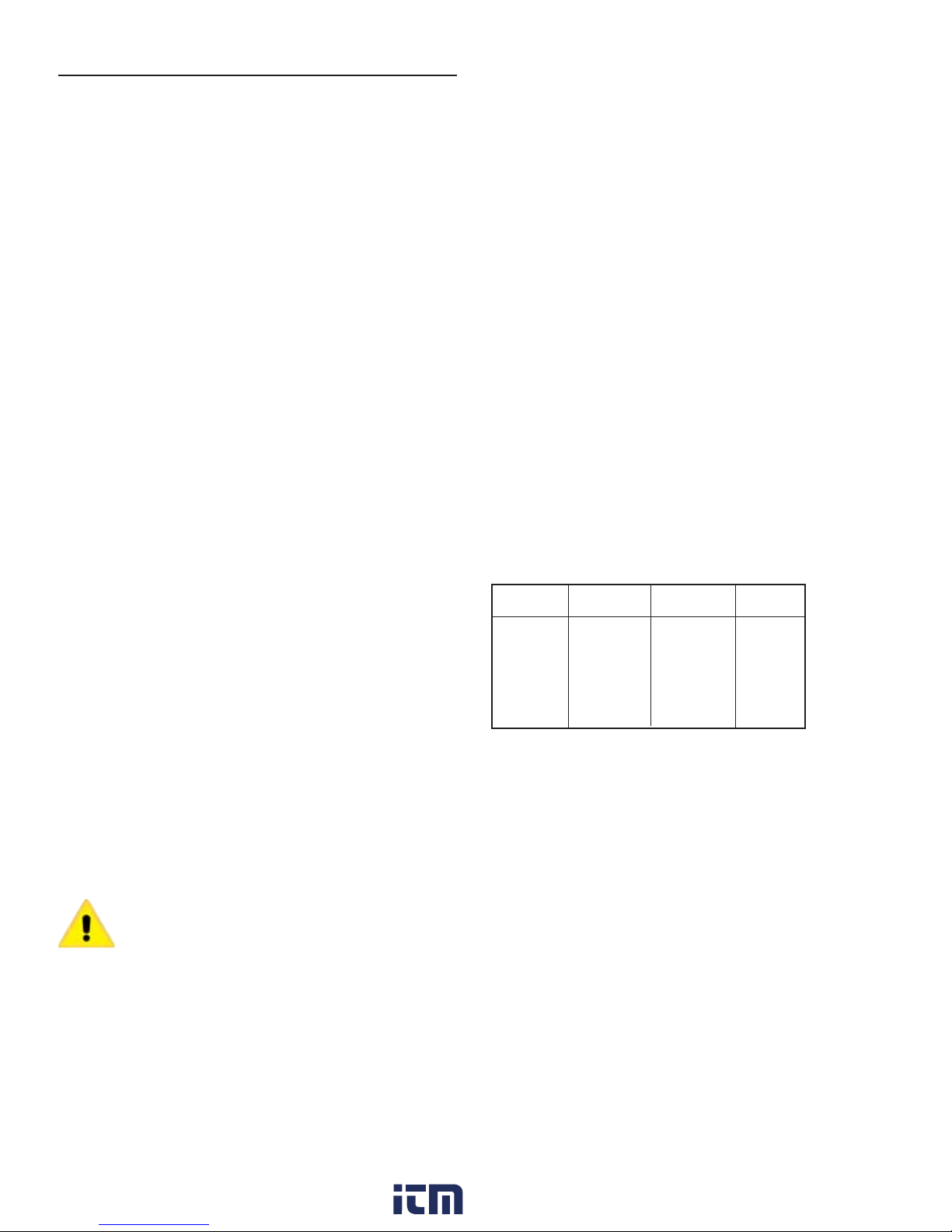

Figure 1 – Dimensional Specifications for the DCT1000DC

(shown with optional module DCP100A)

The Dwyer®DCP100A or DCP200A pressure modules are designed

exclusively for use with the DCT1000DC Dust Collector Timer Controller

boards for on-demand cleaning requirements. These series of modules

are available in 10˝ w.c. [2.49 kPa] or 20˝ w.c. [4.98 kPa] ranges, which

allow for differential process pressure measurement as indicated on the

display of the master controller. An isolated 4-20 mA readout channel is

provided for remote pressure display. The 4-20 mA output may be wired

either for use with an external power supply and indicator or using the

isolated on-board 24 volt power supply to power the loop.

1/16

[1.59]

1-13/16

[46.04]

1-11/16

[42.86]

1/2

[12.70]

1

[25.40]

2-7/16

[61.91]

SPECIFICATIONS

Pressure Ranges: 10 in w.c. or 20 in w.c.

Temperature Limits: -40 to 140°F (-40 to 60°C).

Pressure Limit: 10 psi (68.95 kPa).

Pressure Limit (differential): 10 psi (68.95 kPa).

Accuracy: ±1.5% F.S. @ 73°F (22.8°C).

Output Signal: 4-20 mA.

Alarm Contacts: 1.5A inductive load, 3A resistive load @ 30 VAC or 40

VDC.

Process Connections: Two barbed connections for use with 1/8˝ (3.18

mm) or 3/16˝ (4.76 mm) I.D. tubing.

Weight: 5.5 oz (155.9 g).

Page 3

Table of Contents Page No.

www. .com

information@itm.com1.800.561.8187

Figure 1 Dimensional Specifications . . . . . . . . . . . . . . . . . . . .2

1.0 Installing the DCT1000DC . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.1 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2 DCT1000DC Terminal Connections . . . . . . . . . . . . . . . . . . . . .3

1.2.1 External Pressure Connection . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2.2 Manual Override Switch Connection . . . . . . . . . . . . . . . . . . . .4

1.2.3 Down Time Clean Connection . . . . . . . . . . . . . . . . . . . . . . . . .4

1.2.4 Connecting Multiple Timer Boards . . . . . . . . . . . . . . . . . . . . . .4

1.2.5 Continuous Cycle Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

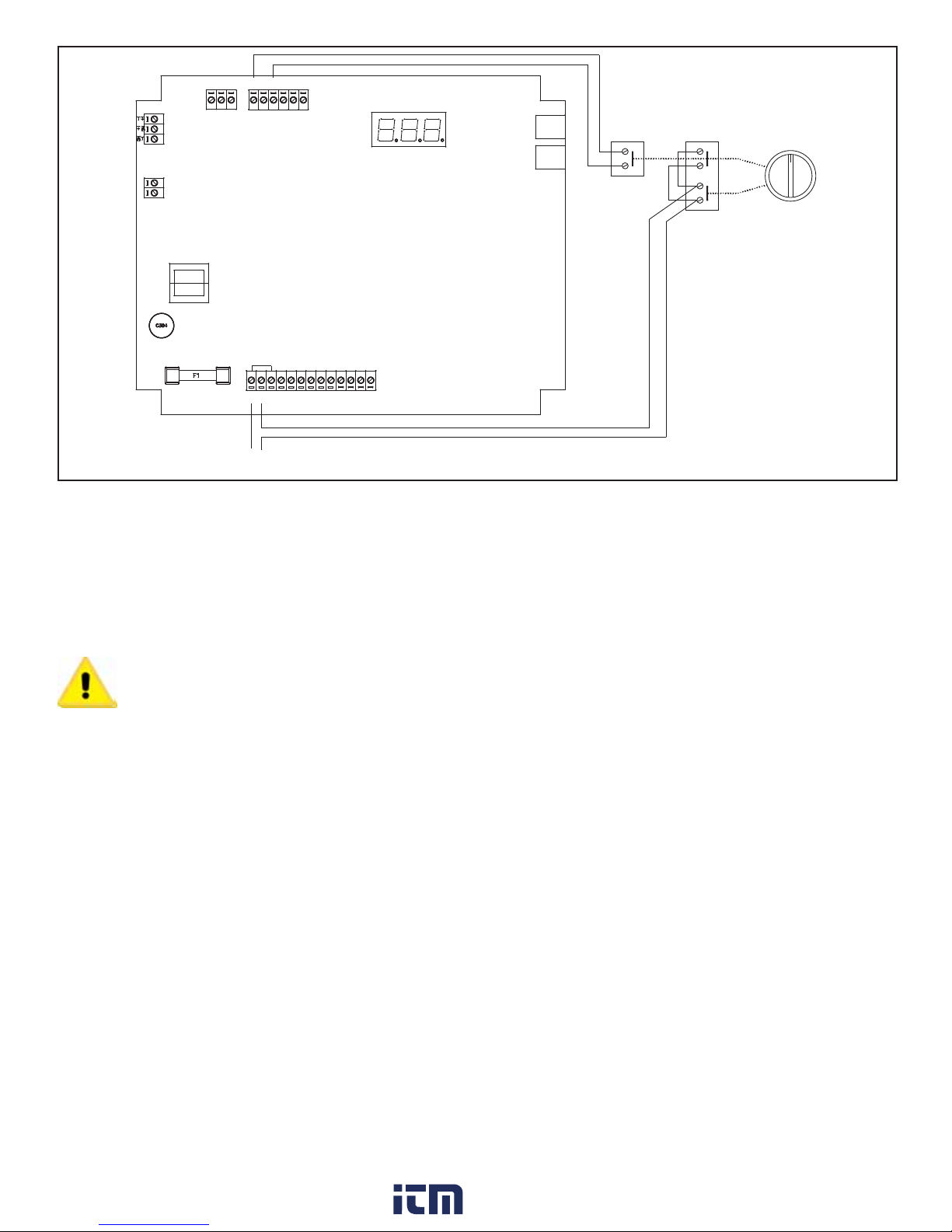

Figure 2 Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.3 DCP Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Figure 3 DCP Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3.1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3.2 Pressure Model Locking Pins . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3.3 Connecting DCP to Master Controller . . . . . . . . . . . . . . . . . . .5

1.3.4 DCP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3.5 DCP Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.4 Alarm Mode Switch Connection . . . . . . . . . . . . . . . . . . . . . . . .5

1.4.1 Alarm Reset Switch Connection . . . . . . . . . . . . . . . . . . . . . . .5

1.4.2 Connecting the 4-20 mA Loop . . . . . . . . . . . . . . . . . . . . . . . . .5

1.4.3 Connecting the Alarm Relay . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.5 Three Position Selection Switch Wiring . . . . . . . . . . . . . . . . . .6

2.0 Programming the DCT1000DC Master

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.1 Last Output Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.2 Time Off Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.3 Time On Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.4 High Limit Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.5 Low Limit Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.6 High Alarm Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.7 Low Alarm Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.8 Cycle Delay Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.9 Down Time Cycles Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.10 Auto Alarm Reset Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.0 Maintenance Support and Diagnostic s . . . . . . . . . . . . . . . .7

3.1 Restoring Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.2 Power Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.3 Active Channel Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.4 Comm Check Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.5 Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4.0 Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Customer Service Phone Number . . . . . . . . . . . . . . . . . . . .. . 8

1.0 Installing the DCT1000DC

The open frame design of the DCT1000DC will require an enclosure that

meets appropriate safety and local code requirements. For optimal

performance, the enclosure should also protect the controller from dirt,

water and direct sunlight. There are no special orientation requirements,

and the controller mounts easily using the mounting holes on the factory

installed base plate.

1.2 DCT1000DC Terminal Connections

The line and solenoid connections are located at the lower edge of the

board below the plastic guard. The terminal block is a “Euro” style

connector system that clamps the wire within the connector body. The

connector will accept wire sizes from 14 to 22 AWG. The wire should be

stripped to no more than 0.25 inches to avoid shorts. To assist you in

determining the proper strip length, a strip gauge is provided at the lower

right corner of the board. The connector system used on the DCT1000DC

is specified for single connection but you can piggyback to a single lug

provided that local codes allow for this and good workmanship practices

are followed. To power up the master controller and the channel expander,

connect line power to (+) and (-) (see Dimensional Specifications, Figure

1). Connect the solenoids between the selected output and the solenoid

common. Solenoid common and (+) are internally connected. Switches

connected to the control inputs at the top of the board must be isolated

contacts connected only to the relevant terminal and to the common

terminals. The following subparagraphs describe the external switch

connections. Refer to figure 2 for switch connection illustration.

1.2.1 External Pressure Connection

The controller may be used with an external pressure limit switch or

sensor to provide demand-cleaning operation. The high limit and low limit

inputs may be used for this purpose. A simple on-off system can be

established with a single pressure switch connected to the high limit input.

In this on-demand mode, time on, time off, and cycle delay may be

programmed to define the cleaning cycle. A three pin terminal block (TB3)

provides connection for external high and low limit switches (see Figure 2

on the next page). These switches must be isolated contacts. The

common line must not be connected to equipment ground or protective

ground, since these may introduce electrical noise and cause improper

operation or possible damage to the control board. The operation of these

inputs are summarized as follows (see next page):

Current

Operation

Hold

Hold or Run

Hold

Hold

Run

Hold

Run

Ø Transition from open to closed

≠Transition closed to open

X Either open or closed

Note: If a DCP100A or DCP200A pressure module is installed in the

master controller, the switching functions are ignored.

Low

Limit Switch

Open

X

Ø

Closed

Closed

Closed

≠

High

Limit Switch

Open

Closed

Open

Ø

≠

Ø

Open

Next

Operation

Hold

Run

Hold

Run

Run

Run

Hold

Caution: Do not run control wires, communication cables, or

other class 2 wiring in the same conduit as power leads. The

system may malfunction if class 2 wiring is run together with

power conductors.

1.1 Power Requirements

The DCT1000DC requires 10 to 30 VDC supply power. The solenoids

must be matched to supply voltage. DO NOT exceed 35V, because

transient suppression circuitry will begin to draw high current.

Page 4

4-20 mA CONNECTIONS

www. .com

information@itm.com1.800.561.8187

RECEIVER

USING DCT1000

24V SUPPLY

RECEIVER

OPTIONAL

CONNECTION

SUPPLY

USING EXTERNAL

POWER SUPPLY

SUPPLY

ALARM

LOAD

PRESSURE

LIMIT

SWITCHES

LOW

LIMIT

HIGH

LIMIT

4-20 MA

OUTPUT

4-20 MA

SOURCE

EXTERNAL

INTERNAL ALARM

CONTACTS

NORMALLY OPEN CONTRACTS

MAN

ALARM

D1

LOW

HIGH

LIMIT

COM

LIMIT

TB4

TB5

ALARM

OVR

MODE

CLN

RESET

COM

TB3

COM

TB2

DCT1000DC

MASTER CONTROLLER

OUT

DAISY

CHAIN

IN

DAISY

CHAIN

MASTER CONTROLLER

INPUT MUST NOT BE

CONNECTED

C3Ø4

TB1

L1

INPUT

(INTERNALLY CONNECTED)

SOL

L2

COM

+

-

LINE

12

F1

5

34

SOLENOIDS

(10 CHANNEL SHOWN)

8

6

7

10

9

TB1

Figure 2

Wiring Connections

1.2.2 Manual Override Switch Connection

The manual override function allows the system to be set to the run mode

regardless of other conditions. This mode is enabled when the manual

override terminal and common are connected. It is disabled when they are

disconnected. If the controller is to be run in continuous mode, a jumper

wire may be wired across these terminals. When manual override is

needed on a periodic basis, wire a SPST toggle switch between the

manual override terminal and the common terminal.

1.2.3 Down Time Clean Connection

The down time clean operation forces the system into a run cycle for a

programmed length of time between 0 – 255 minutes. The operation is

initiated by connecting the down time clean terminal to a common

terminal. This function is best accomplished through use of an external

normally open switch.

1.2.4 Connecting Multiple Timer Boards

The DCT1000DC is available with up to 22 channels on single unit. Where

the installation requires more than 22 channels, the system may be

expanded up to 255 channels by daisy chaining multiple controller boards.

The system will automatically detect the total number of channels and

operate as a singel system.

To connect multiple boards together you will need one or more jumper

cables, Model DCA, available from Dwyer Instruments, Inc. in various

lengths. These are connected to the telephone-style connectors at the

upper right side of the controller boards. One board in the system is

designated as the master. Subsequent units become slave boards. The

master controller is the board at the head of the chain having no

connection to its daisy chain connector. Connect the cable from the daisy

chain out connector on connector on the master controller to the daisy

OUT

DAISY

CHAIN

IN

DAISY

CHAIN

TO ADDITIONAL

EXPANDER MODULES

DCT1000DC

SLAVE BOARD

(INTERNALLY CONNECTED)

SOL

L1

L2

COM

+

-

LINE

INPUT

12

5

34

SOLENOIDS

(10 CHANNEL SHOWN)

8

6

7

10

9

chain in connector of the first slave board. Subsequent slave boards are

connected from the daisy chain out connector on one board to the daisy

chain in on the next. The master controller must then be configured to the

system requirements. The display and status indicators of slave boards

are automatically disabled.

Caution: Do not use telephone jumper cables. These have

a “twist” in the connection and may damage the controllers.

Cables designed for use with the DCT1000DC are available

from Dwyer Instruments Inc.

1.2.5 Continuous Cycle Mode

The DCT1000DC has several operating modes available for different

applications. Starting with the most basic mode, it is capable of operating

in a continuous cleaning cycle. This can be initiated by either placing a

jumper between the high limit input and the common, or the manual

override input to the common connection. Controlling this cycle are three

setup parameters: time off, time on, and cycle delay. Time on and time off

specifically deal with the solenoid on time and the time interval between

the end of the on pulse and the start of the next. The cycle delay allows a

delay of up to 255 minutes to be programmed between the end of one

complete cleaning cycle and the beginning of the next. This allows

additional options for defining a cleaning profile.

1.4.3 Connecting the Alarm Relay

With the pressure module installed, a relay contact is provided for

controlling an external alarm. This relay is a single form-A contact. It is

activated when either the high alarm threshold is exceeded, or the

pressure drops below the low alarm threshold. The connection is made at

the two-pin connector TB5. See Figure 2 Wiring Connections

Page 5

1.3 DCP Installation

www. .com

information@itm.com1.800.561.8187

Caution: Prior to installing the DCP100A/200A please

review the operating specifications carefully.

Some operating systems, especially in pneumatic conveying

applications, may see static pressure or vacuum conditions

that exceed the capability of the DCP100A/200A pressure

module.

1.3.1 Location

The system should be located in an enclosure that meets relevant safety

standards and electrical codes. There are no other special orientation

requirements as the pressure module is not orientation sensitive. Care

should be observed when routing the air hoses to ensure that any

potential condensation or moisture will not drain into the sensor. Where

heavy condensation is present, a drip loop or an in-line filter should be

installed to ensure long term operation.

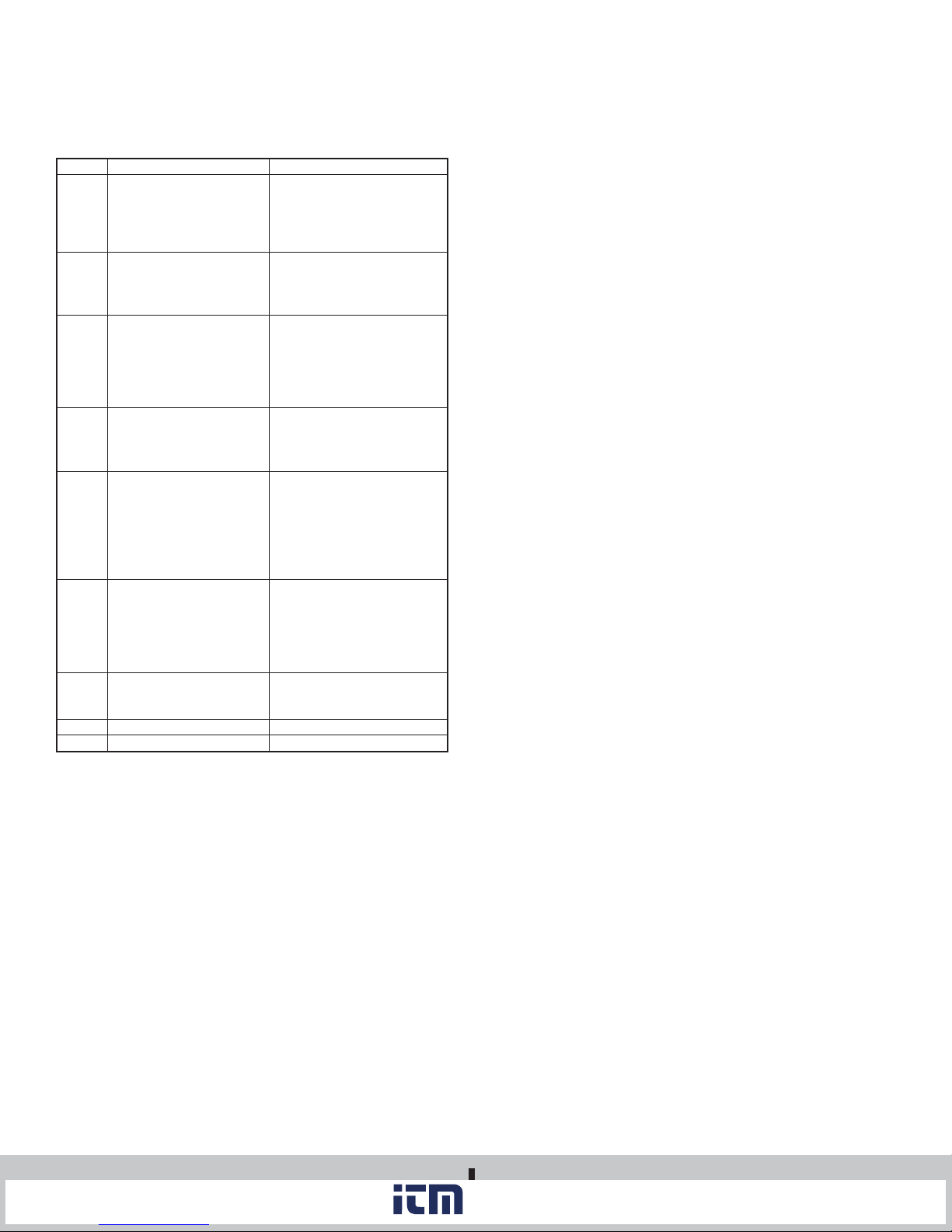

PRESSURE

ALIGNMENT

PINS

MODULE

LOCKING PINS

INSERTED FROM

UNDERNEATH

MODULE ONLY

CIRCUIT

BOARD

INSERT LOCKING PINS UNTIL THEY SNAP FIRMLY IN PLACE

DCP Installation

Figure 3

LOCKING PINS INSERTED

ALL THE WAY INTO THE

CHANNEL

1.3.2 Pressure Module Locking Pins

The DCP100A and DCP200A are supplied with locking pins to secure the

module. In normal operation these are not required since the latching

tabs are sufficient to secure the module even in a high vibration

environment. However if the unit is to be shipped or used where severe

mechanical shock could be encountered the locking pins ensure the

module will not snap out of the board.

To install the locking pins, from underneath the module insert one locking

pin behind each of the two latching tabs. Press these all the way into the

channel. The ends of the tabs will extend through the slots at the top of

these channels. Next insert the module in the board as described above,

making sure it is properly aligned and snaps firmly in place. Press the

exposed locking tabs down until the tab is seated behind the latch in the

board. To remove the module, slide the locking tabs up using a small

screw driver then remove the module as described above. See Figure 3.

1.3.3 Connecting DCP to Master Controller

The pressure module is attached to the Master Controller using integral

connectors on both units. The insertion ports for the pressure module are

located in the upper left quadrant of the DCT1000DC. The pressure

module can be removed by compressing the retaining clips on each end

of the module, then gently pulling the module out of the controller board.

When inserting the module, the following procedure should be adhered to

insure proper installation:

• Examine the bottom of the pressure module and note the orientation of

the connectors.

• Align the module so that these connectors match the connector

receptacles on the controller board.

• Orient the module with the four alignment pins over their respective

mounting holes.

• Gently press the module into the connectors and snap the retaining clips

on either end of the module into their slots.

• Always install and service this device with the power off and a lockout

installed if required. “Hot” plugging the pressure module into an operating

system may damage the system or cause the calibration parameters to

be erased.

When installing or removing the module make sure to orient the module

straight with board. Installing or removing the module at any angle may

break the alignment pins.

Caution: Do not force the module into the connectors. Forcing

the insertion may damage the connectors. Properly aligned,

the module should snap into place.

1.3.4 DCP Connections

When a pressure module is installed, the 4-20 mA process signal and the

alarm relay contacts are available. The 4-20 mA circuit is isolated from

ground and other signals. The alarm relay contacts are isolated, normally

open contacts. Pressure connections may be made to the stepped hose

barbs with either 1/8˝ (3.18 mm) or 3/16˝ (4.76 mm) I.D. tubing.

1.3.5 DCP Maintenance

The pressure module should require very little maintenance under normal

operational conditions. However, periodic calibration may be desirable to

assure accuracy of the readings. The module may be removed and

returned to the factory for calibration.

1.4 Alarm Mode Switch Connection

The auto alarm reset is controlled by the alarm mode switch connection.

To enable the auto alarm reset the alarm mode input must be connected

to a common connection. A jumper may be used when auto alarm reset

is always active. A switch may be used if there are times that the auto

alarm reset must be disabled. The switch must be an isolated contact and

wired such that no connection is made between either of the wires and

ground. See Figure 2 Wiring Connections.

1.4.1 Alarm Reset Switch Connection

The alarm may be reset either by pressing the Alarm Reset button on the

control panel or by an external switch connected between the alarm-reset

terminal and one of the common terminals. The alarm reset will only

operate if the pressure module is installed and the pressure has returned

to a normal condition. See Figure 2 Wiring Connections.

1.4.2 Connecting the 4-20 mA Loop

The pressure module provides an isolated 4-20 mA output, which may be

used to remotely monitor the differential pressure across the dust bags or

cartridges. The connection is made on the master control module at the

terminal block designated for this signal. The connection is a 2-wire

configuration with the option of using either an external 15 to 35 VDC

power source or using the internal 24 VDC source. See Figure 2 Wiring

Connections.

Page 6

4-20 MA

www. .com

information@itm.com1.800.561.8187

OUTPUT

4-20 MA

SOURCE

EXTERNAL

INTERNAL ALARM

CONTACTS

ALARM

MAN

ALARM

HIGH

LOW

COM

LIMIT

LIMIT

TB4

TB5

DT

COM

TB3

MODE

OVR

RESET

CLN

COM

TB2

DCT1000DC

MASTER CONTROLLER

DAISY

DAISY

CHAIN

CHAIN

MODE SELECTION SWITCH

OUT

IN

REAR

SECTION

FRONT

SECTION

CONTINUOUS

OFF

ON DEMAND

TB1

(INTERNALLY CONNECTED)

L2

L1

-

+

(10 CHANNEL SHOWN)

12

34

5

8

6

7

10

9

SOL

COM

OUTPUTS (3A MAX)

(+)

(-)

L1

L2

LINE

INPUT

1.5 Three Position Selection Switch Wiring

An optional mode selection switch is available with the weatherproof

enclosure. With this switch the user may select either continuous

cleaning, on-demand cleaning, or off. This switch is supplied factory wired

as shown in Figure 4. The switch has a front and rear section. The front

section, consisting of two independant contacts, controls the power to the

board. These contacts must be wired in parallel as shown in the diagram.

The rear section controls the manual override, which when closed will

force the system into a continuousmuct be reconneccted, follow the wiring

diagram.

Caution: Do not interconnect the low voltage manual override

leads with the power leads. This will destroy the control board

as well as pose a serious shock hazard

2.0 Programming the DCT1000DC Master Controller

We’ve made it easy to navigate the DCT1000DC. Menu items can be

accessed simply by pressing the “SELECT” button. The menu item that

you are currently accessing is indicated by the illumination of an LED. To

change menu items, all you have to do is push “UP” to increase a value

or push “DOWN” to decrease a value. There are no keystrokes that you

need to memorize, special combinations, or passwords that are required.

Three Position Selection Switch Wiring

Figure 4

2.1 • Last Output

The Last Output setup selects the last channel to be activated. When first

selected, the display will flash the last output available in the system. With

single board installations, this will be the number of channels installed,

typically 6, 10 or 22. This value becomes more important when multiple

modules are installed. The last output value flashed will be the sum of all

channels available in the system.

After the last available channel indication has completed, the currently

programmed last channel value is displayed. This value may be changed

using the “UP” and “DOWN” buttons. The minimum value is one while the

maximum value is the maximum number of installed channels, including

all expansion modules.

The default value is the maximum number of channels. Pressing

“SELECT” will change the setup mode to Time Off Setup.

2.2 • Time Off (Sec.)

Time off defines the period of time between solenoid activations when no

channels are enabled. This may be set between one second and 255

seconds. The factory default is 10 seconds. The display will show the

current time off setting when the time off setup mode is entered. The value

may be changed using the Up and Down buttons. Pressing both “UP” and

“DOWN” simultaneously and holding for approximately four seconds will

restore the default value of 10.

The master controller is equipped with an on board display and

programming information center. The controller will power-up with the

process indicator illuminated. If a pressure module is installed, the display

will indicate the measured pressure in inches of water (w.c.); otherwise it

will normally be blank.

2.3 • Time On (msec)

Time On Setup sets the solenoid on time. The display will indicate the

currently programmed time on setting. This is measured in milliseconds.

Using the “UP” and “DOWN” buttons, the value may be changed. The

value may be set between 10 msec and 600 msec in 10 msec increments.

Pressing the “UP” and “DOWN” buttons simultaneously for approximately

four seconds will restore the factory default value of 100 msec. Pressing

the “SELECT’ button will advance the setup mode to the High Limit setup

if the pressure module is installed. With no pressure module, it will step to

Cycle Delay Setup.

2.4 • High Limit [Only available when DCP connected]

The High Limit Setup, available only with a pressure module installed,

sets the pressure at which the cleaning cycle will begin. This value may

be between zero and the pressure module full scale pressure. Normally,

the High Limit should be above the Low Limit. If, however, the High Limit

pressure is set below the Low Limit, the cleaning cycle will begin when the

High Limit is exceeded and stop when the pressure falls below the High

Limit. The Low Limit in this case will have no effect. Pressing “SELECT”

will change the system to the Low Limit Setup mode.

Page 7

2.5 • Low Limit [Only available when DCP installed]

www. .com

information@itm.com1.800.561.8187

The operation of the Low Limit, available only with a pressure module

installed, is identical to the High Limit except this value sets the pressure

where the cleaning cycle will end. The upper settable value is the

calibration pressure of the pressure module and the lower limit is zero.

Pressing “SELECT” will change the system to the High Alarm Setup

mode.

2.6 • High Alarm [Only available when DCP installed]

The operation of the High Alarm Setup is identical to the High and Low

Limit Setup and is only available when a pressure module is installed. The

High Alarm default is 0. The upper settable value is the full scale pressure

of the pressure module and the lower limit is zero. Pressing “SELECT” will

change the system to the Low Alarm Setup mode.

2.7 • Low Alarm [Only available when DCP installed]

The operation of the Low Alarm Setup is identical to the High and Low

Limit Setup. The Low Alarm default is 0. The upper settable value is the

full scale pressure of the pressure module and the lower limit is zero.

Pressing “SELECT” will change the system to the Cycle Delay Setup

mode.

2.8 • Cycle Delay (min)

The cycle delay inserts a delay time between the end of the last channel

and the beginning of the first channel. This may be set to between zero

and 255 minutes. The factory default is zero. Setting the value to zero will

disable the delay. Pressing “SELECT” will change the system to the Down

Time Cycles Setup mode.

2.9 • Down Time Cycles (min)

The Down Time Cycles setup will select a value between zero and 255

minutes. The factory default is one minute. Selecting zero will disable the

operation. When the down time cycles is activated by shorting the down

time cycles input to the common terminal, (see figure 2) the system will

enter a forced cleaning mode for the programmed duration. Note: The

cycle delay, if one is programmed, will not be inserted in the timing cycle.

Pressing “SELECT” will change the system to the Auto Alarm Reset Setup

mode, if a pressure module is installed, or to Process when no pressure

module is available.

2.10 • Auto Alarm Reset (sec) [Only available when DCP installed]

The Auto Alarm Reset Setup, available only when a pressure module is

installed, allows the auto alarm reset time to be selected. This value may

be set between zero and 255 seconds. The factory default value is five

seconds. When the auto alarm reset is enabled by shorting the auto alarm

reset terminal to a common terminal, (See Figure 1) the alarm will be reset

after the pressure returns to the normal range and the timeout has

expired. Pressing “SELECT” will change the system to Process mode.

3.0 Maintenance Support and Diagnostics

We have also included a number of features that will aid maintenance

personnel in diagnosing problems or verifying that the system is operating.

3.1 Restoring Factory Defaults

The DCT1000DC has been programmed with factory default values that

meet most industry operating conditions. In the event that you want to

restore all of the parameters to the original factory default values:

(1) Return the master controller to the process mode.

(2) Press and hold both “UP” and “DOWN” buttons.

The display will indicate a 10-second countdown, at the end of which all

parameters will be restored to factory defaults. Releasing the switches

prior to the end of the count will stop the process and no modification will

be made. Likewise, in each of the parameter setup modes, pressing and

holding the “UP” and “DOWN” buttons simultaneously will reset the

individual default value, leaving other settings unchanged.

3.2 Power Indicator

A power on LED indicator is provided at the center left edge of the board.

This will be illuminated when the power supply is operating properly. If the

power LED is not illuminated, the primary power may be off or there is a

fault in the power circuit.

3.3 Active Channel Indicator

Located just above the solenoid terminations, you will find that each

channel is provided with an LED that is illuminated when the triac switch

is on. This allows a visual correlation between the channel being pulsed

and the operation of the solenoid.

3.4 Comm Check Indicator

The comm check indicator can be found in the upper right hand corner of

the slave and master controller board (just above the “out” terminal, a

telephone style connector). This indicator is used for two purposes. First,

on a master controller a brief flash once per second is produced to

indicate that the system is operating. Second, this indicator is used to

show when the communication check operation is performed on slave

boards. The master controller will check each of the slave boards at a rate

of about one inquiry per second, starting with the slave board connected

directly to the master controller and ending with the last slave board in the

chain. The master controller will flash its Comm Check LED for about 250

msec each time it makes a communication check. The external module

selected for test will also flash its Comm Check LED for about the same

time each time it is interrogated. Observing this test sequence will indicate

that the communication between boards is operational. When a slave

board powers up, the Comm Check LED will be illuminated continuously.

It will be extinguished when the master controller has initialized its

communication channel. This indicator then shows that a master

controller is operating and that each slave board is responding properly on

the daisy chain.

Page 8

3.5 Error Codes

www. .com

information@itm.com1.800.561.8187

Error codes will be displayed on the three-digit display when certain faults

occur. Most of these indicators are associated with the daisy chain

communication, but certain error codes pertain to single board operation

also. These codes are:

Display

Err 1

Err 2

Err 3

Err 4

Err 5

Err 6

Err 7

Err 8

Err 9

Meaning

This is a “watchdog” reset

that is enabled when the

master controller isn’t able

to cycle through its

operation.

The pressure module has

failed to respond to the

request of the master

controller.

Communication error in the

daisy chain interface. This

will only appear when the

master controller is used in

conjunction with a slave

board.

The master controller has

detected a change in

module configuration or a

fault in one of the modules.

If the fault described in “Err

4” is not corrected, the

master controller will

reconfigure the modules

that are responding

properly and operate at a

degraded condition.

A message error affecting

the software of the master

controller or one of its

modules.

Indicates that one of the

triac drivers are not

functioning.

Internal Error.

Unassigned message code.

Action Required

Make sure all electrical

connections are appropriately

shielded so the master

controller is not disrupted by

noise.

The master controller will try

to recover from the fault. If

unsuccessful, replace the

pressure module.

Make sure the control cable

used in the daisy chain

interface is properly shielded

from noise.

Reinstall all modules in

accordance with the

instructions in the factory IOM.

Reinstall all modules. Contact

factory if the problem persists.

Check the integrity of all

connecting cables used to

drive slave boards for

additional solenoids. Also

check the electrical grounding

of the system installation.

Return to factory for

evaluation and repair.

Contact the factory.

Contact the factory.

4.0 Glossary of Terms

• Run Mode: The term used when the timer board is firing the

solenoids.

• Pressure Module: The pressure measurement subsystem that

includes the software and hardware for on-demand cleaning, alarms

and signal retransmission of the process variable (i.e., the differential

pressure across the dust bags).

• Master Controller: The primary timer board that contains all of the

major features, connections for external inputs and power to drive the

DCT1000DC Dust Collector Timer Controller system.

• Power DC Guard: A plastic shield that covers the output triacs and

other line voltage circuitry.

• Demand Cycle Mode: A process in which the run mode is enabled

through the on-board pressure module or an external switch.

• Euro Connector: A “caged” connection used to terminate solenoids,

incoming power, or external switches on the DCT1000DC.

• Continuous Cycle Mode: A time based cycling mode dependent on

solenoid time on/off settings and time set between complete cycles.

• Manual Override: Allows the user to override the DCT1000DC

remotely or from the master controller panel through use of a switch or

a wire jumper.

• Slave Board: A channel expander that is used in conjunction with the

master controller to accommodate additional solenoids on larger dust

collection systems. It can be recognized easily as it does not have the

on-board display panel or the power supply present. A master

controller may also be used as a slave board.

Still need help? Please feel free to contact one of our customer service representatives or visit us on the web at www.dwyer-inst.com. Thank

you for choosing Dwyer Instruments, Inc.

©Copyright 2010 Dwyer Instruments, Inc.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361 U.S.A.

Printed U.S.A. 10/10

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

FR# 443123-05 Rev. 3

Loading...

Loading...