Page 1

Bulletin IN-523

1/4 N.P.T.

6

-1/64

[

152.8]

D

IA.

7/8 [22.23]

A

DJUSTMENT SCREWS

2-1/4

[57.15]

1

-5/8

[

41.2 8]

1

/2 [12.7]

C

ONDUIT HOLE

5/8 [15.88]

MERCOID

C

ONTROL

Series DA/DS-7000 Bourdon Tube Pressure Switches

Specifications - Installation and Operating Instructions

eries DA/DS-7000 Bourdon Tube Pressure Switches are SPDT snap-action

S

witches that combine extremely high sensitivity and repeatability with easily

s

adjustable set and reset points through non-interactive external adjustments.

These switches have visible calibrated dials for set points and on-off indicators to

indicate switch actuation. DA models are equipped with two external adjustments.

One sets the high pressure operating point; the other sets the reset point.

Deadband or the difference between set and reset points is adjustable over the full

scale. DS models have a fixed deadband.

Note: The DS7300 has no status indicator.

INSTALLATION

The switch may be mounted in any position. Select a location recommended by

equipment manufacturer. Where excessive vibration occurs, mount the switch

remotely, using an appropriate remote connection and mounting bracket. See

accessories, below.

ACCESSORIES

Mounting Bracket

33-25

Remote Connection

49-62: 6 ft copper - 300 psig max

49-62HP: 6 ft copper - 2500 psig max

49-210: 12 ft 316 SS - 3000 psig

SPECIFICATIONS

Wetted Materials: Brass, 403 SS, or 316 SS.

Temperature Limit: 180°F (82°C).

Pressure Limit: Maximum pressure of the operating range.

nclosure Rating: General purpose, weatherproof or explosion-proof.

E

epeatability: ±1% of full operating range.

R

Switch Type: See circuit chart.

Electrical Rating: See electrical ratings chart.

Electrical Connections: Screw terminal.

Conduit Connection:

General purpose: 1/2˝ hole for conduit hub;

Weatherproof: 1/2˝ conduit hub;

Explosion-proof: 3/4˝ female NPT.

Process Connection:

General purpose and weatherproof: 1/4˝ male NPT, 1/2˝ male NPT on ranges

15S and 16S;

Explosion-proof: 1/2˝ male NPT and 1/4˝ female NPT.

Mounting Orientation: Vertical.

Set Point Adjustment: Thumbscrew.

Weight:

General purpose: 4 lb (1.8 kg);

Weatherproof: 6 lb (2.7kg);

Explosion-proof: 8 lb (3.5 kg).

Deadband: See Ranges and Differentials Chart.

CAUTIONS:

Control movement must not be oiled. Do not overload. Note electrical rating on

name plate and be sure that total current passing through the switch is within specified rating.

When testing a boiler or system, never exceed maximum pressure rating on control or it may be seriously damaged. Remove control if higher pressures are

required.

Do not fail to use a siphon on steam where range is 35 lbs (2413 mbar) or more.

Pigtail Siphon

42-52: 250 psig max

42-58: 2000 psig max

MERCOID DIVISION

DWYER INSTRUMENTS, INC. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

P.O. BOX 258 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

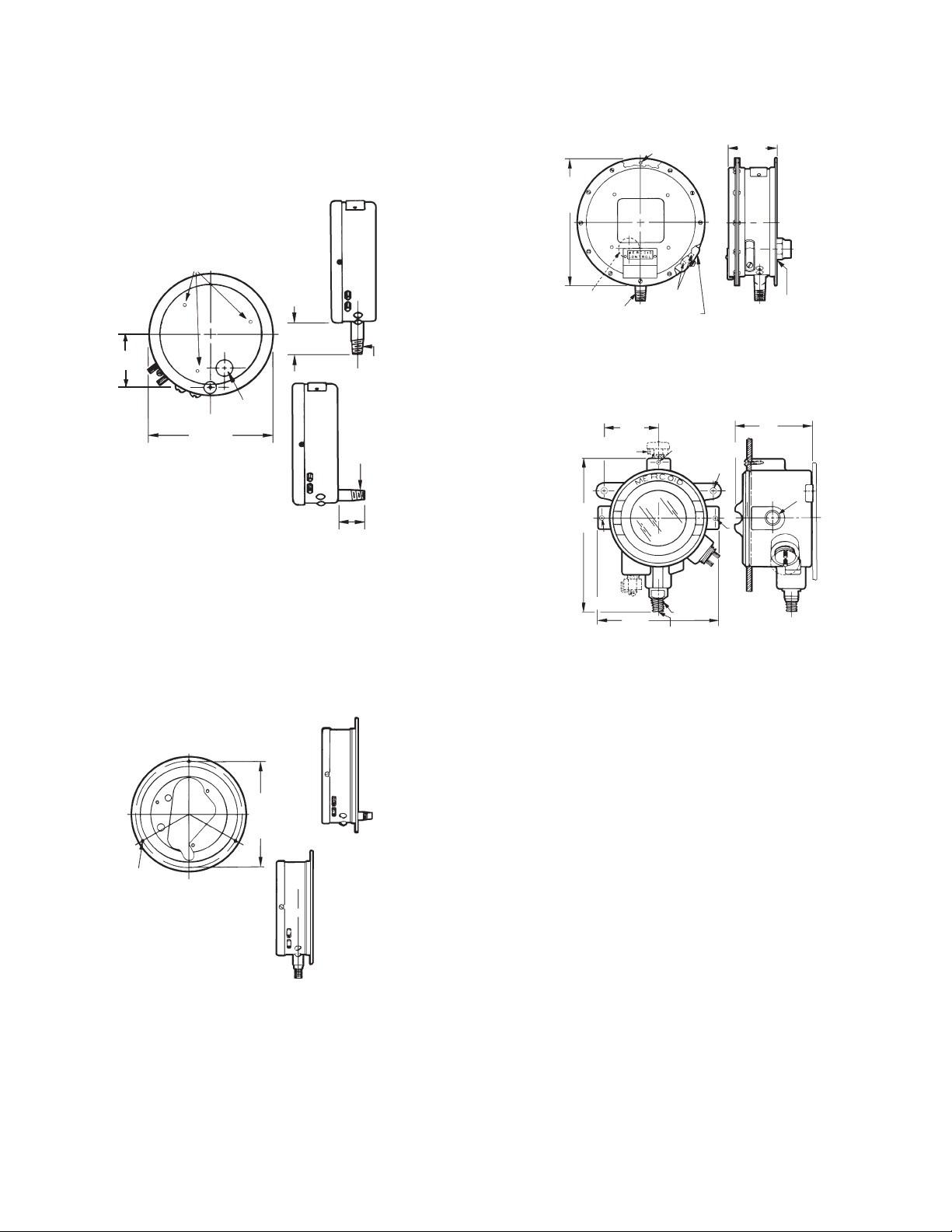

GENERAL PURPOSE CONTROLS, TYPES DA, DL, DR, DS

M

OUNTING

HOLES (OPTIONAL)

1/29 NPT

9-7/89

BREATHER

(OPTIONAL)

59

3

/49 CONDUIT

CONNECTION

13/329 DIA.

1/49 NPT

7-3/49

3-1/29

6-1/29 DIA.

13/649

DIA.

BACK

CONNECTION

BOTTOM CONNECTION

DA24

DA34

DA44

DA23

DA33

DA43

HOLES FOR

F

LANGE SCREWS

1/29 CONDUIT

CONNECTION

6-1/649 DIA.

1/49 NPT

1-1/29

1/49

NPT

1

-1 /8 9

[«\«1

DA21

DA31

DA41

DA22

DA32

DA42

3

REAR FLANGE MOUNTING HOLES (3)

2-13/169

1/49 NPT

[

\««1

79 DIA.

ADJUSTMENTS

1

/29

CONDUIT

HUB

G

ASKETED COVER

Mount control in any position. Do not twist the case when installing. Use a wrench

on the square part of the control connection. On controls with operating Range No.

5S (500 to 5000 psi (34.47 to 344.75 bar)) or Range No. 16S (800 to 8000 psi

1

55.16 to 551.6 bar)), be sure the special sealing nut (with PTFE insert) is turned

(

o the uppermost threaded section of the 1/2″ pressure connection. Apply a flat

t

pen-end wrench to the flat side of the bottom pressure connection when piping the

o

control. After properly connecting the control, tighten the sealing nut to assure a

leak-proof connection.

WATERTIGHT AND WEATHERPROOF

NEMA 2, 3, 4, 5, TYPES DAW, DRW, DSW

hese switches are supplied with flanged case, bottom connection, for surface

T

ounting only.

m

Weather-Proof Types DAW, DSW, DRW

EXPLOSION-PROOF TYPES DAH, DRH, DSH

ount with mounting lugs attached to control housing.

M

FLANGED CASE CONTROLS

Mount by means of the three holes in the flange. Note: Series D7030 when used

for steam with operating ranges of 35 psi (2.413 bar) or higher, must be siphoned

to prevent live steam entering the Bourdon tube. With high-pressure steam

exceeding 100 psi (6.895 bar), use a remote connection. (Note accessories on

Page 1.)

Series D-7020 incorporate an orifice as standard in the pressure connection to

dampen surges or pulsations.

General Purpose Types DA, DS, DR, DL

Flange for Surface Mounting

Explosion-Proof Types DAH, DRH, DSH

WIRING

Wire in accordance with the National Electrical Code and local regulations. For

general purpose controls, use a short piece of BX between the rigid conduit and the

control so the control will not be subjected to conduit expansion and contraction.

Where the control is directly connected into the load circuit, it should be connected

into the hot side of the line. Do not exceed electrical rating as stamped on the control nameplate. DS-7300 controls are equipped with a terminal block. Field connection should be made to terminal block pole in common with required pole of the

control’s switch. The color code is:

Black - Common

Blue - ON Hi

Red - ON Lo

Page 3

ADJUSTMENTS: HOW TO SET OPERATING POINT

PIVOT POINT

BEARINGS,

TOP & BOTTOM,

BUSHED WITH ACETAL

SWITCH CARRIER

STOP POST SLEEVED

WITH ACETAL

ACETAL PIN

ACETAL PIN

BAR LINK

ACETAL BRUSHED

PIVOTAL END

BEARING &

CONNECTION

BAR PIN OF

ACETAL

ouble Adjustment Types - Fully Automatic:

D

ith double-adjustment switches (prefixed DA, DAH or DAW), adjust the upper

W

ointer ˝U˝ to set HIGH PRESSURE POINT for switch operation and adjust the

p

ower pointer ˝L˝ to set LOW PRESSURE OPERATING POINT. The difference

l

between the ˝U˝ and ˝L˝ pointers is the operating differential between ˝on-off˝

switch operation.

witch Indicator

S

range indicates

O

n high

o

U - Upper Pointer

- Lower Pointer

L

Double-Adjustment Types Fully Automatic

Semi-Automatic Control with Manual Reset:

Models prefixed DR, DRH, DRW and with suffix L or U (example: DR-7021-153U)

ave a single adjustment that sets the operating point for automatic operation. A

h

ush-button reset must be operated manually to restore the circuit to the original

p

position after automatic operation. Example: Type DR-7021-153L has a circuit that

opens automatically on a pressure rise to the pressure indicated by the pointer on

the scale; no matter how much the pressure drops, the circuit will not re-close until

the reset button is operated. Suffix L denotes control will operate automatically on

an increase. Suffix U denotes control will operate automatically on an decrease.

SINGLE ADJUSTMENT TYPES—FULLY AUTOMATIC:

odels prefixed DS, DSH, DSW, N3DSW are equipped with a single adjustment.

M

ifferential is fixed (not adjustable). The single pointer on the scale sets the pres-

D

ure at which switch operation occurs. Differential is listed in chart indicates

s

pproximate fixed differential.

a

witch Operating

S

ndicator

I

Single Adjustment

ingle Adjustment Types Fully Automatic

S

LOCKING DEVICE

When the control has been adjusted to desired range, the locking bar may be

nserted between the adjustment screws with the slot passing over the projecting

i

lugs. By placing a sealing wire between the locking bar and the hole in the lug protruding from the adjustment assembly, adjustments cannot be tampered with.

For DRF, DAW, DRW, adjusting knob cover may be sealed in place with sealing

ire through cover bolt hole. For DAH, sealing wire may pass through locking bar

w

nd hole in hub above adjusting knobs.

a

ACETAL BUSHED MOVEMENT ˝B˝

Acetal bushed movements prolong control life by alleviating wear of metal surfaces

due to excessive vibration and/or pulsation. They also prolong switch life in environments where corrosion may be a factor. Models with Acetal movements are

identified by the letter ˝B after the suffix number. Examples: -153B, -153UB, etc.

Semi-Automatic Types with Manual Reset

Adjustment

Reset

CONTROL NUMBER

Part of the control number (the fourth number in the sequence) identifies the type

of control case. Digit 1 of 7021, 7031, 7041, denotes a plain case with bottom connection. Digit 2 of 7022, 7032, etc., denotes a plain case with back connection.

Digit 3 of 7023, 7033, 7043, etc., denotes a flanged case with bottom connection.

Digit 4 of 7024, 7034, etc., denotes a flanged case with back connection. (Digit 3

of 7321, 7331, 7341, etc., denotes hermetically sealed snap switch.)

Acetal Bushed Movement ˝B˝

CIRCUITS (SWITCH OPERATION)

Suffix number after control number denotes switch action:

Suffix -153 designates SPDT; one circuit closes as other circuit opens.

Suffix - 804 designates two SPDT switches; two close, two open.

Page 4

ourdon Tube

B

aterial

M

rass

B

Bourdon Tube

03SS

4

Bourdon Tube

316SS

Bourdon Tube

316SS

Bourdon Tube

Carbon Steel

Bottom

Connection

Code

D

E

F

G

K

ANGES:

R

ange

R

Number

2

3

1

A

3

4

7

2

5

6

7

8

9

Range

umber

N

25S

26S

S

5

6S

S

8

9S

AS

9

10S

11S

12S

3S

1

15S

6S

1

Range

Number

26E

23E

6E

24E

9E

21E

22E

11E

13E

Range

Number

23K

24K

9K

Electrical Ratings

120V

10A

15A

12A

djustable

A

Operating Range

psig)

(

0-30˝ Hg Vac

.0˝ Hg Vac-12

1

1/8-15

/8-20

1

-35

1

25˝ Hg Vac-50

-60

2

5-100

-150

5

10-200

0-300

1

Adjustable

perating Range

O

(psig)

0˝ Hg Vac-60

3

30˝ Hg Vac-75

2-60

-100

5

10-200

0-300

1

40-350

5-600

2

50-1000

00-1500

1

300-2500

00-5000

5

800-8000

Adjustable

Operating Range

(psig)

30˝ Hg Vac- 75

5-75

10-100

10-150

10-300

30-400

75-800

100-100

200-2500

Adjustable

Operating Range

(psig)

5-75

10-150

10-300

AC Capacity

240V

10A

15A

10A

5A @ 250 AC. Resistive & Inductive; 30V DC Resistive

YPE DA Double

T

Adjustment Minimum

ifferential (psig)

D

SPDT

A-7031-153

D

AW-7033-153

D

DAH-7031-153

3.5˝ Hg

1

6

6

6

7

2

1

9

3.5

1

24

4

2

37.5

PDT

S

A-7021-153

D

DAW-7023-153

AH-7021-153

D

18

2.5

2

13.5

19.5

2.5

2

28.5

0

3

67.5

142.5

195

90

3

1350

250

2

SPDT

A-7041-153

D

DAW-7043-153

DAH-7041-153

15

12

15

16.5

42

78

180

285

600

SPDT

DA-7041-153

DAW-7043-153

DAH-7041-153

12

16.5

42

See Code F*

See Code D

Electrical Ratings

480V

NA

15A

5A

5A @ 125/250 AC, Resistive; 30V DC Resistive

S

DS-7231-153

D

DSH-7231-153

3

1

1.5

1

1.5

2

2

2

3

4.75

6

SPDT

D

DSW-7223-153

DSH-7221-153

3

3.5

3

3.5

4

7

7

1

22

3

60

2

500

SPDT

D

DSW-7243-153

DSH-7241-153

3.5

4

3.5

4.5

8

12

25

35

75

SPDT

DS-7241-153

DSW-7243-153

DSH-7241-153

4

4

8

See Code E

DC Capacity

120V

.5A

NA

.5A

PDT

SW-7233-153

˝ Hg

.5

.5

.5

.5

.5

S-7221-153

.5

.75

2

5

00

S-7241-153

ingle Adjustment

S

ixed Differential (psig)

F

2) SPDT

(

D

DSW-7233-804

D

2.5˝ Hg

1

1.25

1

1

2

1

2

3

4

6

2) SPDT

(

D

D

DSH-7221-804

3

3

2.5

3

4

6

6

1

20

3

50

1

180

2) SPDT

(

DS-7241-804

DSW-7243-804

DSH-7241-804

4

2.5

4

3

6

10

17

30

95

(2) SPDT

DS-7241-804

DSW-7243-804

DSH-7241-804

2.5

3

6

See Code D

240V

.25A

NA

.25A

TYPE DS

S-7231-804

SH-7231-804

.25˝

.25

.5

.5

.5

S-7221-804

SW-7223-804

0

0

10

AC Horsepower

120V

1/8

1/4

1/4

SPDT

S-7331-153

D

DSW-7333-153

SH-7331-153

D

5˝ Hg

˝

3

3

3

3

3.75

3

3.75

.25

5

.75

6

9

PDT

S

DS-7321-153

SW-7323-153

D

DSH-7321-153

5.25

.25

5

4.5

.25

5

7.125

0.5

1

10.5

18

33

2.5

5

90

00

3

750

SPDT

S-7341-153

D

DSW-7343-153

DSH-7341-153

5.25

6

5.25

6.75

12

18

37.5

52.5

112.5

SPDT

DS-7341-153

DSW-7343-153

DSH-7341-153

6

6

12

See Code K

240V

1/4

1/2

1/2

Circuit

Suffix No.

-153

-804

*Note: Minimum differentials increase when using multiple circuits. Controls using #804 circuits in ranges

over 35 psig have 30% higher minimum differentials; ranges under 35 psig are not available in Code F.

©Copyright 2013 Dwyer Instruments, Inc. Printed in U.S.A. 1/13 FR# 76-441853-00 Rev. 3

Switch Action on Pressure Increase

SPDT: one OPENS as one CLOSES

(2) SPDT: two OPEN as two CLOSE

MERCOID DIVISION

Electrical Rating Code

D-7000 D-7200 D-7300

D E K

F* G

Phone: 219/879-8000 www.dwyer-inst.com

DWYER INSTRUMENTS, INC. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

P.O. BOX 258 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Loading...

Loading...