Page 1

Bulletin P-AVUL-M

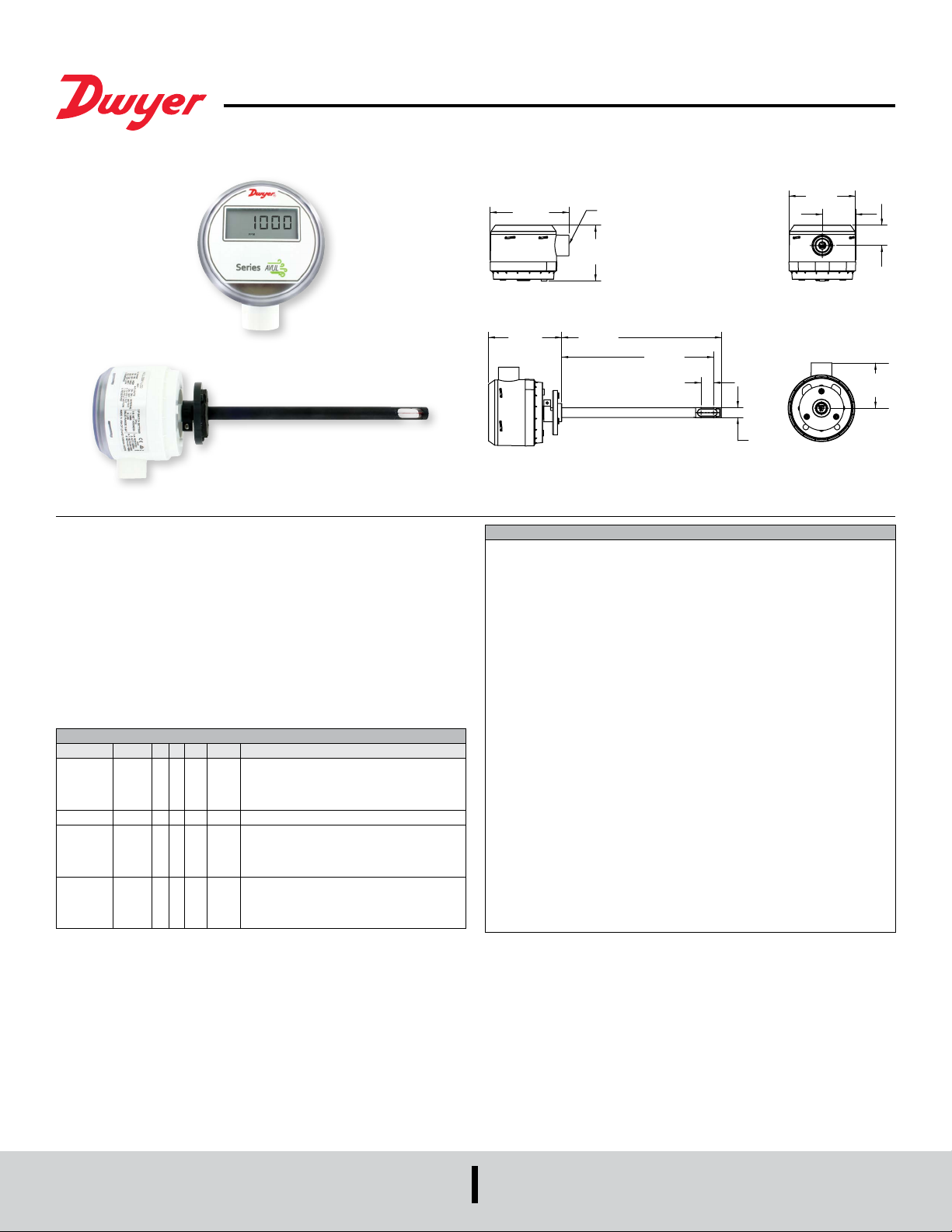

3-3/16

31/32

24.58

[11.84]

®

Series AVUL Air Velocity Transmitter with Modbus® Communication

Specications - Installation and Operating Instructions

The SERIES AVUL Air Velocity Transmitter quickly and accurately measures air

velocity or volumetric ow in imperial or metric units. Simultaneous current and

voltage outputs on all models provide universal inputs to monitoring equipment while

the output range, units, and 0 to 5/10 VDC output can be congured via local DIP

switches. The optional integral display, or the portable remote display tool, provide a

convenient way to locally monitor process values and congure the unit.

Models are available in 3% and 5% accuracy models to suit a variety of needs, and the

optional BACnet MS/TP or Modbus

to be daisy-chained while providing access to all of the velocity and ow data, as well

as additional information such as air temperature.

MODEL CHART

Model AVUL -3 D A1 -LCD AVUL-3DA1-LCD

Accuracy 5

3

Mounting D Duct mount

Output A1

Options LCD

®

RTU/ASCII communication protocol allows units

±(0.2 m/s + 5% of reading) @ standard

conditions

±(0.2 m/s + 3% of reading) @ standard

conditions

Analog universal (0 to 5 VDC, 0 to 10 VDC,

B1

M1

4 to 20 mA)

Analog + BACnet MS/TP

Analog + Modbus

LCD display

FC

Factory calibration certicate

NIST

NIST certicate

GLD

Electrical cable gland

®

RTU/ASCII

3-49/64

[95.71]

3-33/64

[89.13]

SPECIFICATIONS

Service: Clean air and non-combustible, compatible gases.

Wetted Materials: Consult Factory.

Range: 1000, 2000, 3000, 4000 FPM (5, 10, 15, 20 m/s); Field selectable.

Accuracy: ±(5% of reading + 0.2 m/s) or ±(3% of reading + 0.2 m/s) @ standard

conditions, depending on model.

Temperature Limits: 32 to 122°F (0 to 50°C).

Power Requirements: 24 VDC ±20% or 24 VAC ±20%.

Humidity Limits: 5 to 95% RH, non-condensing.

Output Signals: 4 to 20 mA, 0 to 5 VDC, 0 to 10 VDC .

Response Time (90%): 10 seconds, typical.

Zero & Span Adjustments: Digital push buttons.

Output Load Resistance: Current Output: 0 to 1100 Ω max.; Voltage Output:

Minimum load resistance 1 kΩ.

Current Consumption: 60 mA Max.

Display (optional): 5 Digit LCD.

Electrical Connections (Analog): Power and output: four wire removable

European style terminal block for 16 to 26 AWG.

Communication (optional): Connections: BACnet MS/TP or Modbus

three wire removable European style terminal block for 16 to 26 AWG; Supported

Baud Rates: 9600, 19200, 38400, 57600, 76800, 115200.

Device Load: 1/8th unit load.

Electrical Entry: 1/2˝ NPS thread. Accessory (A-151): Cable gland for 5 to 10 mm

diameter cable.

Enclosure Rating: NEMA 4X (IP66).

Mounting Orientation: Flow direction must be parallel to the sensor tip;

See Installation section for details.

Weight: 6.0 oz (160 g).

Agency Approval: CE, RoHS.

1/2 NPS

2-43/64

[67.92]

7-41/64

[194.07]

7-17/64

[184.60]

39/64

[15.32]

Ø15/32

[80.81]

1-19/32

[40.59]

®

RTU/ASCII:

2-5/32

[54.82]

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Page 2

INSTALLATION

Duct Mount:

The transmitter should be mounted away from fans, corners, heating and cooling

coils, and other equipment that will effect the measurement of the air velocity. It

is recommended that the AVUL is mounted 10 duct diameters downstream of any

disturbances and 5 duct diameters upstream of any disturbances, if possible.

1. Mark and drill a 0.750-0.938˝ (20-24 mm) diameter hole into the duct.

2. Insert and center the duct mount ange in the previously drilled hole and mark

location of the three mounting screw holes.

3. Remove the mounting ange and drill or punch the mounting holes in the marked

locations.

4. Fasten the ange to the duct using three #8 x 1/2 pan head sheet metal screws. Do

not over tighten screws.

5. Insert the AVUL probe into the ducts mount ange and set the desired insertion

depth.

6. Note the ow direction and unit alignment as shown on sensor tip and product label,

tighten probe retention set screw on the duct mount ange screw to afx the probe in

place.

Electrical Connection:

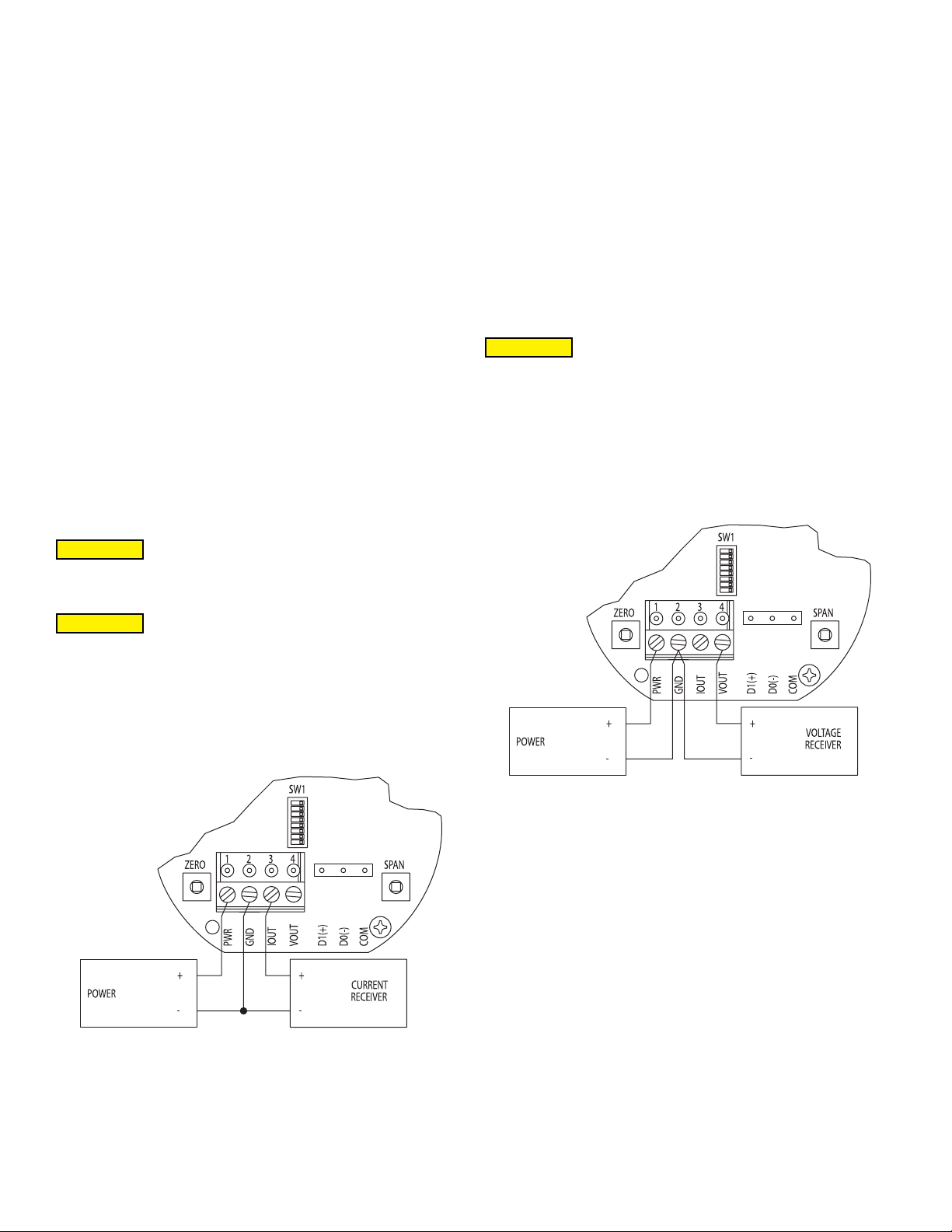

The Series AVUL is powered and simultaneously transmits a two-wire 4 to 20 mA

current output and a three-wire 0 to 5 VDC or 0 to 10 VDC voltage output via a

removable four conductor terminal block. The transmitter power supply common is

used to reference the current and voltage outputs so either current, voltage, or current

and voltage may be wired according to the application. The range of the voltage output

can be selected using the on board DIP switches as described in the Analog DIP

Switch Settings section of this manual.

Power Supply

Choose a power supply with a voltage and current rating sufcient to meet the power

specications under all operating conditions. If the power supply is unregulated, make

sure the output voltage remains within the required voltage range under all power line

conditions. Ripple on the supply should not exceed 100 mV.

Although low loop resistances are recommended, the absolute maximum current loop

load resistance, R

R

MAX = (VPS – 2.0) / 0.02 where VPS is the power supply voltage

For a 24 VDC nominal power supply, this evaluates to R

MAX , is dened by the following the equation:

MAX = 1100 ohms.

Shielded two wire cable is recommended for current output loop wiring. Ground the

shield at the power supply end only.

The maximum length of connecting wire between the current transmitter and the

receiver is a function of wire size and receiver resistance. That portion of the total

current loop resistance represented by the resistance of the connecting wires

themselves should not exceed 10% of the receiver resistance. For extremely long

runs (over 1,000 ft.), it is desirable to select receivers with higher resistances in order

to keep the size and cost of the connecting leads as low as possible. In installations

where the connecting run is no more than 100 ft, connecting lead wire as small as No.

22 Ga. can be used.

Voltage Output Operation

CAUTION

DO NOT EXCEED SPECIFIED SUPPLY VOLTAGE RATINGS.

PERMANENT DAMAGE NOT COVERED BY WARRANTY WILL

RESULT.

The terminal block is removable, and each of the terminals are labeled underneath the

terminal block on the circuit board. The voltage output and the power supply must have

separate wire leads that are only joined at terminal 2 of the transmitter, as shown in

Figure 2. Additional error may occur for the voltage output if a single wire is used or if

the wires are joined at the power supply or receiver. The connections to the transmitter

are made to terminals 1, 2, and 4 (PWR, GND, and VOUT respectively) on the terminal

block as shown in Figure 4.

CAUTION

DO NOT EXCEED SPECIFIED SUPPLY VOLTAGE RATINGS.

PERMANENT DAMAGE NOT COVERED BY WARRANTY WILL

RESULT.

Current Output Operation

CAUTION

DO NOT EXCEED SPECIFIED SUPPLY VOLTAGE RATINGS.

PERMANENT DAMAGE NOT COVERED BY WARRANTY WILL

RESULT.

The terminal block is removable, and each of the terminals are labeled underneath

the terminal block on the circuit board. As the power supply and outputs share the

same common signal (GND), the outputs may have separate wires but must effectively

join at terminal 2 of the transmitter, as shown in Figure 1. The connections to the

transmitter are made to terminals 1, 2, and 3 (PWR, GND, and IOUT respectively) on

the terminal block as shown in Figure 4.

Figure 2

Voltage Output Wiring

The minimum receiver load is 1 kΩ. The resistance due to the wire should be low

compared to the receiver load resistance. While the voltage at the terminal block

remains unchanged with a 10 mA current ow, resistive losses in the wiring do cause

errors in the voltage delivered to the receiver. For a 1% accurate gauge, the resistance

of the wires should be less than 0.1% of the value of the receiver load resistance. This

will keep the error caused by the current ow below 0.1%.

The output across VOUT and COM will be either 0 to 5 VDC, 0 to 10 VDC, or the

inverse depending on the DIP switch setting. See the Analog DIP Switch Settings

section for more information.

Figure 1

Current Output Wiring

Page 3

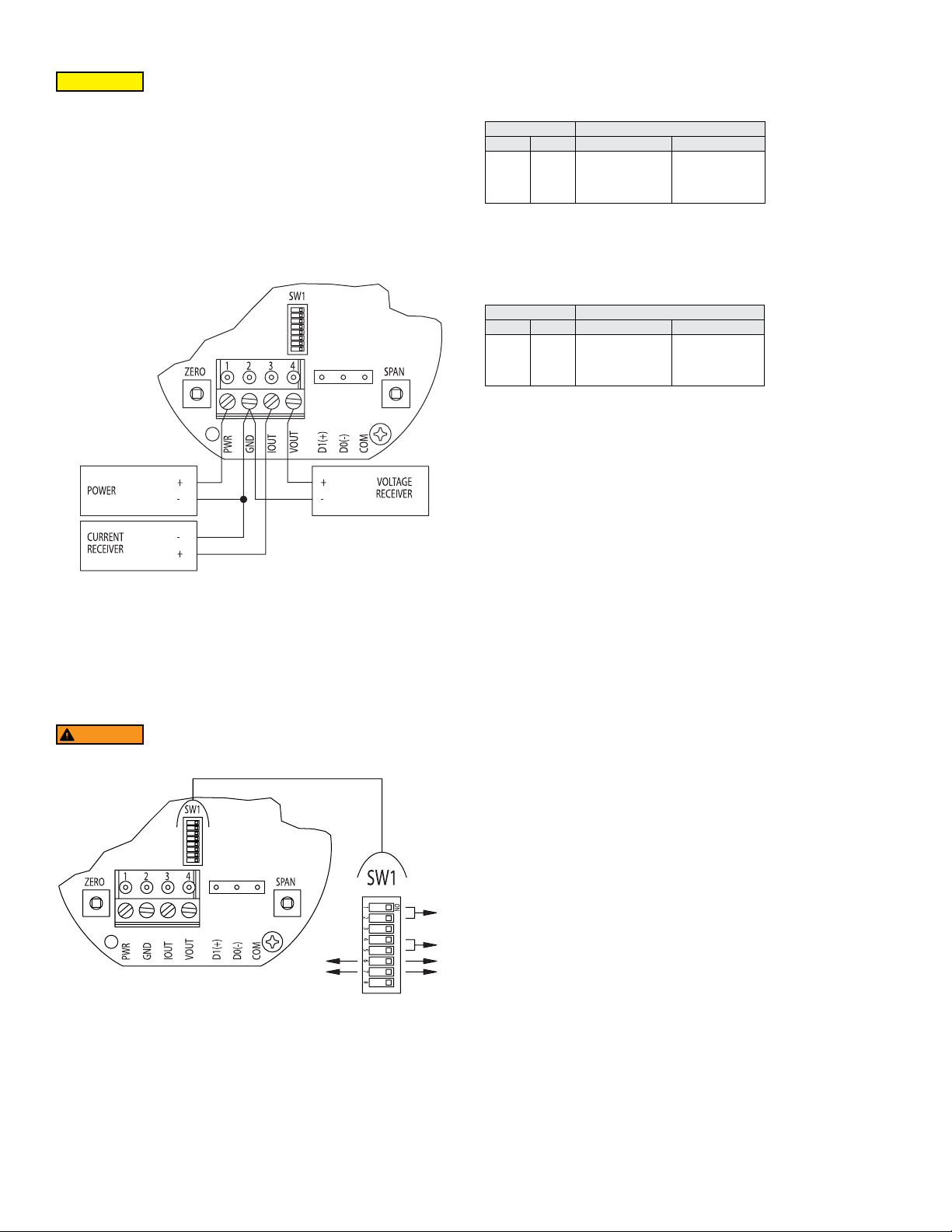

Simultaneous Current and Voltage Output Operation

RANGE

CAUTION

DO NOT EXCEED SPECIFIED SUPPLY VOLTAGE RATINGS.

PERMANENT DAMAGE NOT COVERED BY WARRANTY WILL

RESULT.

The terminal block is removable, and each of the terminals are labeled underneath the

terminal block on the circuit board. The voltage output and the power supply must have

separate wire leads that are only joined at terminal 2 of the transmitter, as shown in

Figure 3. Additional error may occur for the voltage output if a single wire is used or if

the wires are joined at the power supply or receiver. The connections to the transmitter

are made to terminals 1, 2, 3 and 4 (PWR, GND, IOUT, and VOUT respectively) on

the terminal block as shown in Figure 4, which reects both the 4-20 mA and 0-5/10

VDC outputs in the same circuit. Details of each output are detailed in their electrical

connection sections.

Setting the Air Velocity Range

The range of the instrument is selected by using DIP switches 1 and 2 on SW1. Table

1 shows the maximum full scale value for the selected range and unit. Refer to Setting

the Engineering Units section for information on setting the unit.

DIP Switch SW1 Full Scale Range

1 2 Imperial (FPM) Metric (m/s)

ON

ON

ON

OFF

OFF

OFF

ON

OFF

4000

3000

2000

1000

20

15

10

5

Table 1: DIP Switch SW1 Settings for Full Scale Range

Setting the Engineering Units

The Series AVUL can be congured to indicate velocity in imperial (FPM, CFM) or

metric (m/s, m

3

/h) units using DIP switches 4 and 5 on SW1, and Table 2 shows the

values. The units will be displayed on the optional LCD display if connected.

DIP Switch SW1 Units

4 5 Velocity Mode Air Flow Mode

ON

ON

ON

OFF

OFF

OFF

ON

OFF

FPM

m/s

m/s

m/s

CFM

3

m

3

m

3

m

/h

/h

/h

Table 2: DIP Switch SW1 Settings for Units

The default operating mode is velocity, but changes can be made, such as ow

mode, via the menu system while an optional display or remote display accessory is

connected. Please refer to Appendix VI for a full menu ow chart.

Setting the Output Voltage Range

Voltage Output can be either 0 to 5 VDC or 0 to 10 VDC depending on the position of

DIP Switch 6 ON SW1.

Simultaneous Current and Voltage Output Wiring

Figure 3

ANALOG DIP SWITCH SETTINGS

The analog output DIP switches (SW1) are located above the terminal blocks on the

left are as shown in Figure 4. A small screw driver or pen can be used to change the

position of the switches as required.

WARNING

All power should be turned off to the transmitter before adjusting

the DIP switch settings to avoid electrical shock.

UNITS

5V

REV

10V

DIR

• When the switch is in the ON position, the output will be 0 to 10 VDC.

• When the switch is in the OFF position, the output will be 0 to 5 VDC.

Setting the Input / Output Action

The output will either follow the process directly (DIRECT) or inverted (REVERSED)

based on the position of DIP Switch 7 on SW1.

• When the switch is in the ON position, the output directly follows the input (i.e. output

increases as the input increases).

• When the switch is in the OFF position, the output acts in reverse of the input (i.e.

output decreases as the input increases).

Figure 4

Analog Dip Switches

Factory Default Settings (DIP SW1 – All Switches ON)

Range = Highest Range Setting (4000 FPM)

Units = Imperial (FPM)

Voltage Output Range = 0 to 10 VDC

Direct / Reverse Output Action = Direct

KEY

Page 4

CALIBRATION

NOTICE

takes place. This delay is used to reduce vibration or disturbances of the user related

to the button presses.

There is a 5 second delay from the time the zero or span calibration

buttons are released until the time that the change in calibration

NOTICE

adjusted by the user.

Zero Calibration

The zero calibration can be set by covering the sensor to ensure no air ow and

pressing the zero button for 3 seconds. If either the remote or local LCD is present, the

display will read ZEro and then sequence back to the home display.

SPAN Calibration

The span calibration can be adjusted only after setting the zero adjustment. It must

be completed within 5 minutes of the last zero calibration. The span calibration button

will be ignored until the zero calibration is completed. Place the sensor in airow that

matches the maximum selected range of the transmitter. Press and hold the span

button for 3 seconds. If either the remote or local LCD is present, the display will read

SPAn and then sequence back to the home display. If the span calibration is attempted

before adjusting the zero calibration, the FAiL error message will be displayed briey

before returning to the home display.

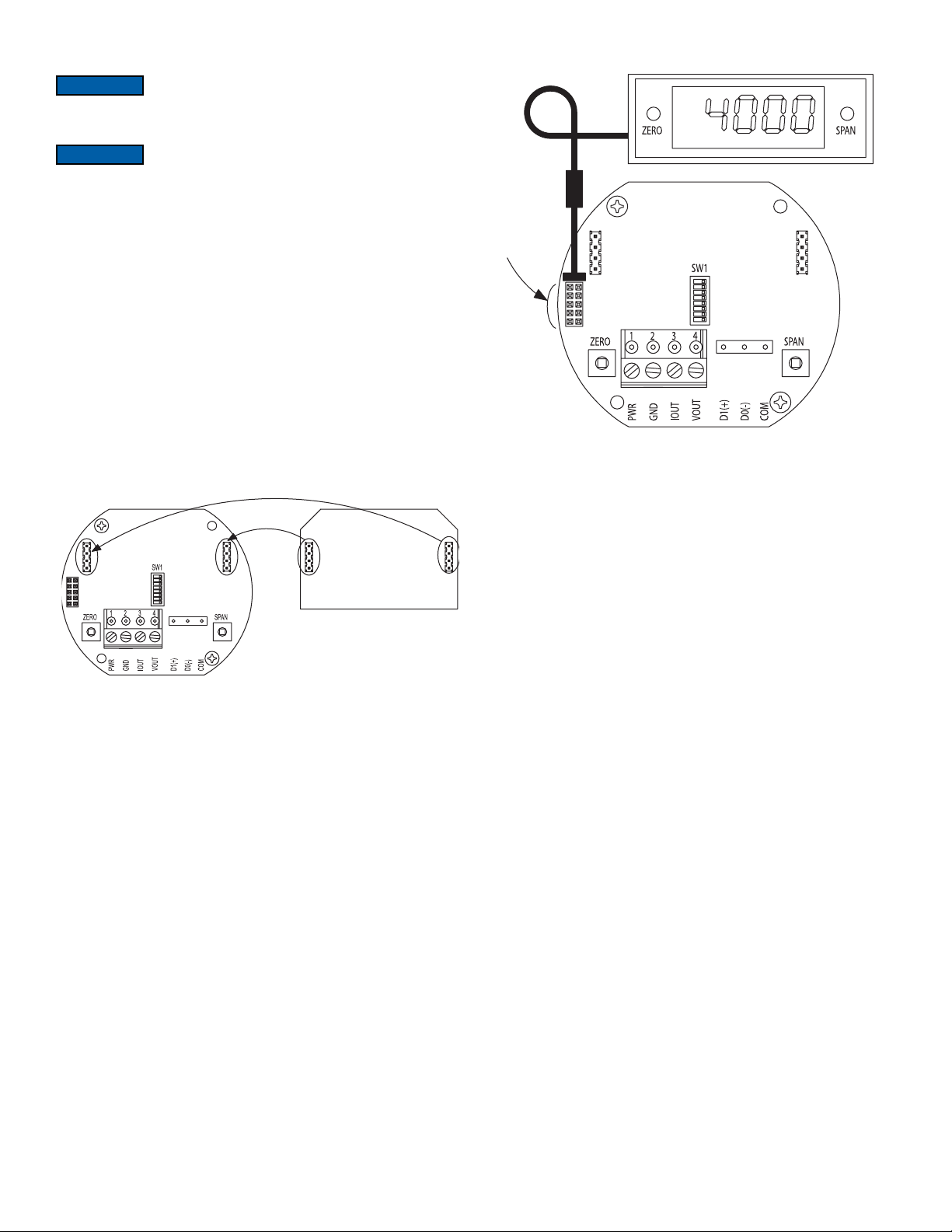

LCD Display

The Series AVUL can be ordered with an optional, integral LCD. It comes with a

housing cover and overlay to protect the display. The display will plug into the pins as

shown in Figure 5. If the display is not needed for normal operation, the transmitter can

be ordered without the LCD.

The security level that is set in the Programming Menu section

of the manual will determine which calibrations, if any, may be

Figure 6

Remote Display Diagram

Display Error Messages

ovEr = The air velocity is greater than the maximum span value causing an Over

Range Error

UndEr = The air velocity is less than the minimum span value causing an Under Range

Error

FAiL = When the span or zero buttons are pressed, the air velocity value is out of the

range to allow a correct setting. This may be due to a sensor failure.

Err1 = The sensor is damaged.

Pluggable Display Diagram

Figure 5

Another option for models that do not have a display would be to use a Model A-435-A

remote display tool which can plug into the connector shown in Figure 6. The remote

display tool has two buttons that function identically to the buttons on the PCB.

PROGRAMMING MENUS

Home Menu

During normal operation, the display will be in the Home Menu and will display the

current measured pressure and the engineering units.

Menu Access Security

While in the Home Menu, press and hold the Zero and Span buttons simultaneously

until SECUr appears on the display in order to access the other programming menus.

Upon releasing the buttons, the display will indicate the current security level.

If the current security level is the security level desired (i.e. Security Level 0), press

and hold the span button for 3 seconds to enter the Velocity or Air Flow Menu.

If the security level is not the desired level, the security level can be changed

temporarily to a lower security level or permanently to a higher level of security by

pressing the zero button. A security code will appear on the display, and it can be

changed to one of the codes listed in Table 3. The span button chooses which digit

and the zero button increments the value of that digit. Pressing and holding the span

button will store the value.

The level of access to the programming menus and the calibration is limited based on

the security level. Table 3 details the level of access for each security level.

Page 5

Security

Level Setting

0

1

2

3

Access

View Menu Edit Menu Span Zero

000

111

222

333

Yes

Yes

No

No

Yes

No

No

No

Yes

No

No

No

Yes

Yes

No

No

Table 3: Security Settings

Mode Selection / Digital Dampening Menu

From the home display, pressing the span and zero button simultaneously for 3

seconds will access the Menu Security Level. If the level is set to 0 or 1, pressing and

holding the span button for 3 seconds, a second time, will access the Mode Selection

Menu. The display will default to air velocity when rst powered up. Pressing the zero

button will cycle to air ow.

Once the desired mode is displayed, pressing and holding the span button for 3

seconds will save the selected mode and display the digital dampening or averaging

parameter. This parameter stabilizes the output and the display by averaging the

readings. There are 2.5 readings taken each second and the user can select the

number of seconds that they would like to average, up to 240 seconds. The display

and the output will continue to update at a rate of 2.5 updates per second, but the

moving average is used for these updates.

Velocity Mode

K-Factor Adjustment

If the Velocity Mode was selected, pressing and holding the span after adjusting the

digital dampening will enter the Velocity Mode and the transmitter will display the

engineering unit that has been selected by the DIP switch. Pressing and holding the

span button for 3 seconds will enter the K – Factor adjustment. The K – Factor can

be adjusted between 0.001 to 9.999. The K-Factor can be adjusted by pressing the

span button to select the digit and pressing the zero button to increment the value of

the digit. Pressing and holding the span button for 3 seconds will enter the Maximum

Output Adjustment parameter.

Flow Mode

K-Factor Adjustment

If the Flow Mode was selected, pressing and holding the span after adjusting the digital

dampening will enter the Flow Mode and the transmitter will display the engineering

unit that has been selected by the DIP switch. Pressing and holding the span button for

3 seconds will enter the K–Factor adjustment. The K–Factor can be adjusted between

0.001 to 9.999. The K-Factor can be adjusted by pressing the span button to select

the digit and pressing the zero button to increment the value of the digit. Pressing and

holding the span button for 3 seconds will enter the Area Adjustment parameter.

Area Adjustment

For ow applications, the area is multiplied by the velocity to determine the volumetric

air ow. The area will be listed in either CFM or m

3

/h depending on the DIP switch

settings. The units will appear on the display at the time of adjustment. The area can

be adjusted by pressing the span button to select the digit and pressing the zero button

to increment the value of the digit. Pressing and holding the span button for 3 seconds

will enter the Maximum Output Adjustment parameter.

Maximum Output Adjustment

The maximum output can be equivalent to air velocity or air ow. After adjusting

the K-Factor, the display will indicate if the adjustment is set for velocity or air ow.

Pressing the zero button will toggle between the selections. Pressing and holding the

span button for 3 seconds will enter the maximum output adjustment. The maximum

output can be adjusted by pressing the span button to select the digit and pressing the

zero button to increment the value of the digit. Pressing and holding the span button

for 3 seconds will save this value and go to the Security Update Menu.

Security Update / Save Changes Menu

The Security Update Menu allows the security level to be set either higher or lower

than the current security level setting. This security level will be displayed the next

time the Menus are accessed from the home screen. Pressing the zero button cycles

through the security levels. Pressing and holding the span button for 3 seconds

accepts the new security level and gives the option to save all the menu changes.

Pressing the zero button will toggle between yes and no. Yes will save the changes

made to all menu items and no will discard all the changes made to all menu items. If

the display is set to yes, pressing and holding the span will save the menu items and

return the display to the home position.

FACTORY DEFAULT PROCEDURE

In order to reset all of the menu settings back to their factory programmed values,

press and hold both the span and zero buttons simultaneously for 10 seconds until

FACt is displayed on the LCD. Upon releasing the buttons, the unit will be factory

defaulted. Since resetting the transmitter will wipe out all changes, it is necessary to

zero (and possibly span) the transmitter before taking measurements.

MAINTENANCE/REPAIR

Upon nal installation of the Series AVUL Air Velocity Transmitter, no routine

maintenance is required besides zeroing the transmitter occasionally. Besides routine

calibration and installation of the LCD, the Series AVUL is not eld serviceable, and

it is not possible to repair the unit. Field repair should not be attempted and may void

warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping the

product back for repair. Be sure to include a brief description of the problem plus any

additional application notes.

APPENDIX I: Air Velocity / Air Flow Calculations

Velocity in m/s is then calculated from the equation:

Velocity (m/s) = Velocity (FPM) x 0.00508

3

Flow in m

Flow (CFM) = Area (ft

Flow (m

/h is then calculated using the below equation:

3

/h) = Flow (CFM) x 1.6992

2

) x K-Factor x Velocity (FPM)

APPENDIX II: Maximum Flow

Max Flow Max K Factor x Area

CFM m

3

/h CFM Range m3/h Range

5885000 9999000 1471.25 138.875

Table 4: Maximum Flow Values

APPENDIX III: Modbus

NOTICE

®

Communication Protocol Operation

Wiring should comply with Electrical Characteristics of

Generators and Receivers for Use in Balanced Digital Multipoint

Systems, TIA/EIA-485-A-1998, Telecommunications Industry Association, 1998.

NOTICE

Wiring should comply with Modbus® Communication Protocol

over Serial Line Specication and Implementation Guide V1.02,

Modbus Organization, Inc., 2006

NOTICE

Communications wiring must be in a daisy-chain fashion. Star

connections are not permitted.

NOTICE

Cable shield must be connected to earth ground at one location

only.

Figure 7 shows how to connect the AVUL in a network containing a common power

supply. Use a cable containing two twisted pairs. One pair is to be used for D1(+)

and D0(-). The other pair is to be used for power and common. This conguration is

not suitable for AC supplies. Use a DC supply only. Care should be taken that there

are not too many devices powered from the same supply as voltage drops will occur

in the wiring. If you have many devices, or have long cable runs, the local supply

conguration may be a better choice.

Figure 8 shows how to connect the AVUL in a network containing individual local

supplies. Use a cable containing a twisted pair and a single conductor. The pair is to

be used for D1(+) and D0(-). The single conductor is to be used for common. Both AC

and DC supplies are suitable for this conguration.

In either conguration you must use shielded cable. The AVUL has a shield terminal

for a convenient location to make connections. It is not electrically connected to the

AVUL. Connect the shield to earth ground at one location only to prevent ground loops.

All devices in the network should be daisy chained. Star connections and T

connections are not permitted.

The D1(+) and D0(-) lines must be terminated at both ends with a 120 ohm resistor. If

the AVUL is an end device it has an on-board resistor that may be used. See Modbus®

Communication Protocol DIP Switch Settings to enable it.

The network must be biased properly. If needed, there are bias resistors on-board the

AVUL. No more than two sets of bias resistors should be enabled in the network. See

®

Communication Protocol DIP Switch Settings to enable them.

Modbus

Page 6

PWR GND IOUT VOUT

NEXT

TO

PREVIOUS

D1(+) D0(-)COM

D1(+)

D1(+)

D0(-)

COM

SUPPLY

PWR GND IOUT VOUT D1(+) D0(-) COM

KEY:

DEVICE

D1(+)

D0(-)

PWR

COM

TO

DEVICE

D1(+)

D0(-)

PWR

COM

®

APPENDIX IV: Programming Via Modbus

Communication Protocol

Modbus® Mode Supported Baud Rates Data Size Parity Stop Bits

RTU 9600

19200

8 Even

38400

57600

ASCII 7 Even

76800

115200

Odd

1

None

None 2

Odd

1

1

None 2

Table 6: Supported Modbus

®

Communication Protocol Congurations

Figure 7

Common Power Supply

D0(-)

COM

+ -

POWER

Figure 8

Local Power Supply

Modbus® Communication Protocol DIP Switch Settings

Use the middle DIP Switch SW2 to congure the Modbus

®

Communication Protocol

address of the device. The LCD will show the address when the transmitter is powered

on. Valid addresses range from 1 to 247. By default, the device is shipped with the

address 127 (as shown in Figure 10). A valid and unused address should be set before

connecting to an existing network. However, the address can be changed while the

device is operational. If the address is changed, the device will stop responding to the

currently congured address immediately. The device waits 15 seconds after the last

switch change before applying the new address. The device will not function properly

if an invalid address is set. The red LED will periodically blink once indicating an invalid

address. The LCD will display A Err when the transmitter is powered on if the address

is invalid. See Appendix V for setting the Modbus

®

Communication Protocol address

of the device. Use the right DIP Switch SW3 to congure other hardware and software

options.

SW2

BIAS

RESISTOR

128 - MSB

32

AUTO SERIAL

CONFIGURATION

TERMINATING

RESISTOR

64

16

8

2

4

1 - LSB

Figure 9

Intelligent Serial Conguration

Intelligent serial conguration enables the device to determine the baud rate, data

size, party, stop bits and even the Modbus

from the serial trafc. This allows the Series AVUL to be quickly and easily deployed

after a valid Modbus

®

Communication Protocol address is chosen.

To activate intelligent serial conguration, set a valid Modbus

®

Communication Protocol mode directly

®

Communication Protocol

address using the left DIP switch SW2, connect the serial bus and power wires, and

then apply power. The device will power up and begin examining the serial bus for

communication. The Red LED will repeatedly ash twice, indicating that intelligent

serial conguration is in progress.

If the device is setup ofine or away from the main network, it is necessary to

generate Modbus

communication. Attempting to read input registers is a good method to generate

®

Modbus

®

Communication Protocol trafc in order to congure the serial

Communication Protocol trafc. Note that while serial conguration is in

progress, the device may not respond to requests. The device may require multiple

read requests to complete the serial conguration process.

The intelligent serial conguration process will complete once a message addressed

to the device is received and processed successfully. The serial conguration

parameters are then saved to non-volatile storage and loaded by default each time the

device starts. If the serial conguration of the bus changes, a power cycle of the device

is required to restart the Intelligent Serial Conguration process.

Function Name Function Code

Read Coils

Read Holding Registers

Read Input Registers

Write Single Coil

Write Single Register

Write Multiple Registers

Table 7: Supported Modbus

01

03

04

05

06

16

®

Communication Protocol Functions

The String data type is read as a stream of ASCII characters, with the rst character

sent in the MSB of the rst register, and the second character sent in the LSB of the

rst register and so on. If the string is shorter than the allotted size, the remaining bytes

will be zero padded.

Multi-

Address

Register Description Data Type Value Range

0001 –

0002

0003 –

0004

Register

Velocity

Flow Area

(ft2)

Velocity

Flow Area

(m2)

Description

Float

Float

Data Type

0.01…999.99

0.00093…92.9

Value

0.01…999.99

0.00093…92.9

Range

Supported

Yes

Yes

Multi-

Address

Supported

Table 8: Holding Registers

Switch On Off

1-2 – Display Units Selection

3-4 – Reserved

5 - Intelligent Serial

Conguration

6 – D1(+) Network resistor

7 – D0(-) Network resistor

8 – Terminating resistor

Enabled

511Ω Pull-up to 5V

511Ω Pull-down to GND

120Ω between D0(-) and

D1(+)

Disabled

Pull-up not connected

Pull-down not

connected

Open

Table 5: DIP Switch SW3 Functions

1 - The serial conguration, no parity with one stop bit is not ofcially supported by the

®

Communication Protocol standard. However, if this conguration is desired,

Modbus

set switch 5 on DIP switch SW3 to off. The device will congure itself in Modbus

®

RTU

Communication Protocol mode with a data size of 8, no parity, and 1 stop bit. The baud

rate will still be determined automatically.

Page 7

Coils

The coil registers represent functions of the device. The value returned when reading

a coil register indicates the status of the last function execution. If the value is 1, then

the last time the function executed was a success. If the value is 0, then the function

has either not been executed since power on or failed during the last execution. To

execute a function, write 1 to the corresponding register. A response will be returned

immediately and the value of the coil will be set to 0. Once the function completes,

the value of the coil will be set to 1 if the operation was a success. An application

should poll the value of the coil periodically during this time to determine if the function

succeeded. If the coil value does not transition to 1 after at most 10 seconds, then the

operation failed.

Multi-

Address

Register Description Data Type Value Range

0001

0002

0003

0004

Perform Zero Function

Perform Span Function

Reset Factory Defaults

Reset Device

Boolean

Boolean

Boolean

Boolean

0…1

0…1

0…1

0…1

False – True

False – True

False – True

False – True

Supported

No

No

No

No

Table 9: Coils

Coil 1 – Zero Function

The zero function will attempt to recalibrate the zero point. This may be needed if the

sensor has drifted over time. Note that the zero function will only re-zero the sensor

if the current air velocity is within ±2% of span air velocity of the previous zero. If the

current air velocity is outside the valid band, the zero function will fail and the coil value

will remain 0. If the sensor has drifted far enough that the zero function fails, then the

unit will have to be placed in ow to bring the current air velocity closer to the current

zero, and the zero function will have to be executed multiple times until the actual zero

is reached.

Coil 2 – Span Function

The span function will attempt to recalibrate the maximum air velocity. Note that

accurate span air velocity depends on an accurate zero air velocity. The span function

will fail if the zero function has not been executed within the last 5 minutes.

Coil 3 – Reset factory Defaults Function

The reset factory defaults function resets the zero, span, Velocity K value, Area, and

Use Default K Value variables back to their factory default values.

Coil 4 – Reset Device Function

The reset device function allows this device to be reset remotely from the Modbus

Communication Protocol. When the reset device function coil is written with a value

of 1, the device will immediately respond with success. The reset will take place

approximately 5 seconds after the command was received. Writing the value 0 to this

coil has no effect.

Multi-address Support

Multi-Address support allows a register to be read or written to using different byte

orientations specied by the address range. For example, input register 0003 can also

be read at 2003, 4003 and 6003 with different byte orientations as listed in Table 10.

Registers that do not have multi-address support are only available in Big-Endian byte

orientation (Modbus

®

Communication Protocol standard).

Float/32 Bit Values 16 Bit Values

Register 1 Register 2 Register 1

Byte Order Address Range MSB LSB MSB LSB

Big-Endian

Byte Swap

Word Sway

Little-Endian

1 – 2000

2001 – 4000

4001 – 6000

6001 - 8000

A

B

C

D

A

B

A

D

C

D

D

C

C

A

B

B

A

B

B

A

A

B

B

A

Table 10: Multi-Address Support

®

APPENDIX V: Setting Modbus

Communication Protocol MAC Address of Unit

Switch Position 1 2 3 4 5 6 7 8

Address Value 128 64 32 16 8 4 2 1

Table 11: Device Objects

The address assignment is determined by adding the values for each of the switches

that are in the ON position. The transmitter comes from the factory with all of the DIP

switches, except position 1, in the ON position as shown in Figure 10. The address

of the transmitter would be 127 as it would be 64+32+16+8+4+2+1 = 127. Another

example would be if the address desired was 008, the only DIP switch position in the

ON position would be position 5 as shown in Figure 11

.

ON

12345678

Figure 10

Figure 11

NOTICE

possible address would be address 255 when all of the DIP switches were set to ON,

but the transmitter only has valid address from 1 to 247. Any address outside of this

range will give an error code.

APPENDIX VI: Modbus

Register Description Data Type Value Range

0001

0002

0003

®

0004

0005

0006

0007 –

0008

0009 –

0010

0011 –

0012

0013 –

0014

0015 –

0016

0017 –

0018

0019

0020 –

0021

8001 –

8006

8007 –

8012

8013 –

8018

8019 –

8024

Though the minimum possible address would be address 0 when

all the DIP switch positions were set to OFF, and the maximum

®

Communication Protocol Registers

Velocity (FPM)

Velocity (0.001 MPS)

Flow (CFM)

Flow (CMH)

Temperature (0.1 °F)

Temperature (0.1 °C)

Velocity (FPM)

Velocity (MPS)

Flow (CFM)

Flow (CMH)

Temperature (°F)

Temperature (°C)

Sensor Operational

Sensor

Communication

Errors

®

Application

Modbus

Firmware Version

Sensor Application

Firmware Version

®

Application

Modbus

Serial Number

Sensor Application

Serial Number

Table 12: Modbus

Signed 16bit

integer

Signed 16bit

integer

Signed 16bit

integer

Signed 16bit

integer

Signed 16bit

integer

Signed 16bit

integer

Float

Float

Float

Float

Float

Float

Unsigned 16bit

integer

Unsigned 32bit

integer

0…1

0…2

String

String

String

String

®

Communication Protocol Registers

False –

True

32

-1

0…2321

Multi-

Address

Supported

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

Page 8

APPENDIX III: Menu Flow Chart

BUTTON PRESS LEGEND

MENU CONVENTIONS

ZERO

SPAN

ZERO

SPAN

ZERO

SPAN

Averaging Menu

= PRESS ZERO BUTTON

= PRESS SPAN BUTTON

= PRESS AND HOLD ZERO BUTTON

= PRESS AND HOLD SPAN BUTTON

= PRESS AND HOLD ZERO AND SPAN BUTTONS

SECURITY LEVEL

SELECTION

IN HOME POSITION:

CALIBRATE UNIT TO ZERO PRESSURE.

ZERO

CALIBRATE UNIT TO SPAN PRESSURE.

SPAN

ZERO

ENTER MENU DISPLAY

SPAN

IN MENU DISPLAY:

SEQUENCES TO NEXT MAIN MENU ITEM, AND IF A MENU ITEM IS CHANGED TEMPORARILY SAVES THE SELECTION

SPAN

SEQUENCES THROUGH SUB MENU SELECTIONS OR INCREMENTS DIGITS

ZERO

SEQUENCE TO NEXT DIGIT. ACTIVE DIGIT WILL BLINK.

SPAN

HOME POSITION

ZERO

SPAN

WHILE BUTTONS ARE

PRESSED

WHEN BUTTONS ARE

RELEASED DISPLAYS CURRENT

SECURITY LEVEL

ZERO

TO CHANGE

SECURITY LEVEL

SPAN SPAN

IF SECURITY IS SET TO

0, 1, OR 2

ZERO

SPAN

IF SECURITY IS SET TO 3

DISPLAY IS NOT NECESSARY

FACTORY SETTINGS

HOLD 7

SECONDSTO HOME POSITION

RESTORED, THEN RE TURNS

ZERO

SPAN

INCREMENT

DIGIT

SELECT

DIGIT

SECURITY LEVEL SETTING

0000

1111

2222

3333

HOME POSITION

= BLINKING DIGIT

USE DEFAULT DIP

SWITCH SETTINGS

MODE SELECTION

VELOCITY OR FLOW

ADJUST AVERAGING

TO "VELOCITY OR FLOW" MENUS

PRESS ANY KEY

OR WAIT 5 SECONDS

ZERO SPAN

ZEROSPAN

ZERO

BLINKING UNITS AS

ZEROSPAN

SELECTED BY DIP

SWITCHES

SPAN

INCREMENT

ZERO

DIGIT

SELECT

AVG

SPAN

DIGIT

SPAN

Page 9

FROM AVERAGING MENU

T

T

Velocity Mode Menu

SPAN

ADJUST DISPLAY

K FACTOR

SELECT MAXIMUM OUTPUT

SET BY PRESSURE OR

VELOCITY

ADJUST VELOCITY

OUTPUT HIGH

TO "UPDATE SECURITY

AND SAVE" MENU

UPON RELEASE

SPAN

SPAN UPON RELEASE

SPAN UPON RELEASE

K

SPAN

SPAN

FPM

FPM OR M/S BASED

ON DIP SWITCH SETTING

M/S

SPAN

ZERO

SPAN

ZERO

SPAN

INCREMEN

DIGIT

SELECT

DIGIT

INCREMEN

DIGIT

SELECT

DIGIT

Page 10

FROM AVERAGING MENU

SPAN

ADJUST DISPLAY

K FACTOR

SPAN

SPAN

UPON RELEASE

SPAN UPON RELEASE

SPAN

SPAN UPON RELEASE

SPAN

TO "UPDATE SECURITY

AND SAVE" MENU

INCREMEN

T

SELECT

ZERO

SPAN

DIGIT

DIGIT

INCREMEN

T

SELECT

ZERO

SPAN

DIGIT

DIGIT

ON DIP SWITCH SETTING

FPM OR M/S BASED

ADJUST FLOW

OUTPUT HIGH

K

CFM

M /H

INCREMEN

T

SELECT

ZERO

SPAN

DIGIT

DIGIT

FAREA

SQ. FEET OR SQ. METERS BASED

ON DIP SWITCH SETTING

MAREA

SPAN UPON RELEASE

SPAN

SELECT MAXIMUM OUTPUT

SET BY PRESSURE OR

FLOW

3

Flow Mode Menu

Page 11

FROM "UPDATE SECURITY

Security Menu

UPDATE SECURITY

LEVEL

AND SAVE" MENU

ZERO ZERO ZERO

ZERO

SPAN SPAN SPAN SPAN

SAVE CHANGES

SPAN UPON RELEASE ZERO

ZERO

SPANSPAN

HOME POSITION

Page 12

NOTES

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

©Copyright 2017 Dwyer Instruments, Inc. Printed in U.S.A. 2/17 FR# 444387-00 Rev. 1

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

dwyer-inst.com

e-mail: info@dwyermail.com

Loading...

Loading...