Page 1

LIMITED WARRANTY AND LIMITATION OF LIABILITY

DWYER warrants its products to be free from defects in materials and workmanship, subject to

the following terms and conditions: Without charge, DWYER will repair or replace products

found to be defective in materials or workmanship within the warranty period; provided that:

a) the product has not been subjected to abuse, neglect, accident, incorrect wiring not our own,

improper installation or servicing, or use in violation of instructions furnished by DWYER;

b) the product has not been repaired or altered by anyone except DWYER or its authorized

service agencies;

c) the serial number or date code has not been removed, defaced, or otherwise changed; and

d) examination discloses, in the judgment of DWYER, the defect in materials or workmanship

developed under normal installation, use and service;

e) DWYER is notified in advance of and the product is returned to DWYER transportation

prepaid.

Unless otherwise specified in a manual or warranty card, or agreed to in a writing signed by a

DWYER officer, DWYER pressure and acceleration products shall be warranted for one year

from date of sale.

The foregoing warranty is in lieu of all warranties, express, implied or statutory, including but not

limited to, any implied warranty of merchantability for a particular purpose.

DWYER’s liability for breach of warranty is limited to repair or replacement, or if the goods

cannot be repaired or replaced, to a refund of the purchase price. DWYER’s liability for all other

breaches is limited to a refund of the purchase price. In no instance shall DWYER be liable for

incidental or consequential damages arising from a breach of warranty, or from the use or

installation of its products.

No representative or person is authorized to give any warranty other than as set out above or to

assume for DWYER any other liability in connection with the sale of its products.

OPERATING INSTRUCTIONS

Series 681

SANITARY PRESSURE TRANSMITTERS

GENERAL INFORMATION

Your Dwyer Series 681Sanitary Pressure Transmitter has been carefully tested and

calibratedbefore shipment and it should be handled with the same care given any

precision instrument. Detailed performance information is listed on the specification

bulletin for the transmitter.

The 681 is designed according to 3A Standard #37-01 for sanitary installations. It has

a rugged MICRO-TIG welded stainless steel housing and is exceptionally insensitive to

vibration, shock, EMI/RFI interference and other environmental extremes. The 681 is

insensitive to the thermal shocks typical of CIP and SIP installations.

INSTALLATION NOTES

Series 681 should not require adjustment at installation. If adjustments are made it

is important to replace and tighten the zero and span screws (with O-rings) to

prevent moisture from entering.

The 681 is vented through the cable. Connections to the cable should be made in a

dry junction box vented to atmosphere. Insure that moisture cannot enter the end of the

cable.

The 681 is shipped with a rubber boot over the stainless steel pressure sensing

diaphragm to protect the diaphragm during shipment, storage, and handling prior to

installation. This boot should not be removed until the transmitter is to be installed and

should be used whenever the unit is removed from its installation. Do not contact the

diaphragm with sharp objects, screwdrivers or other mechanical devices.

Dwyer Instruments, Inc.

102 Indiana Highway 212

Michigan City, Indiana 46360, U.S.A.

Phone: 800-872-9141/219-879-8868

Fax: 219/872-9057

Lit-By Fax: 888/891-4963

www.dwyer-inst.com

e-mail: info@dwyer-inst.com

SS2092 Rev A 11/11/02

Environment - The Series 681 Transmitter is designed to be used with any gas or liquid

compatible with 316L stainless steel (316 for ranges > 30 psig). It is designed to be

splash and drip proof for wash-down cleaning and can also be completely submerged

with the exception of the open end of the electrical cable.

Cleaning - The pressure sensing diaphragm will withstand normal high pressure

washing and partial vacuums created by fast cooling of steam sterilized tanks. However,

be sure not to exceed the proof pressure (listed on specification sheet). In high pressure

washing, care should be taken not to spray directly on diaphragm as it could result in

exceeding the proof pressure. The 681 can also be cleaned by dipping the diaphragm

in a container of cleaning solution or by wiping gently with a soft cloth.

Temperature Limits - The operating temperature limits of the 681, based on the limits

of the electronics, are -40

Mounting - The 681 will mount directly to a mating tri-clover flange along with a tri-clover

type clamp and gasket. (2 inch tri-clover for ranges up to 30 psig and 1.5 inch for higher

ranges.)

Note: The output signal is not appreciably affected by clamping forces so it is not necessary to orient the flange circle to any special position for best performance.

o

F to 260oF.

Thermal Effects 20

Zero Shift ± 2.00% F.S./100oF

Span Shift ± 2.00% F.S./100

o

F to 180oF range

Page 2

2 3

Venting - The 681 is vented to atmosphere through the cable to achieve best accuracy.

This is particularly important for models with pressure ranges below 30 psig. Connections

to the cable should be made in a junction box that is vented to atmosphere, with care taken

to insure that the end of the cable is not blocked or sealed.

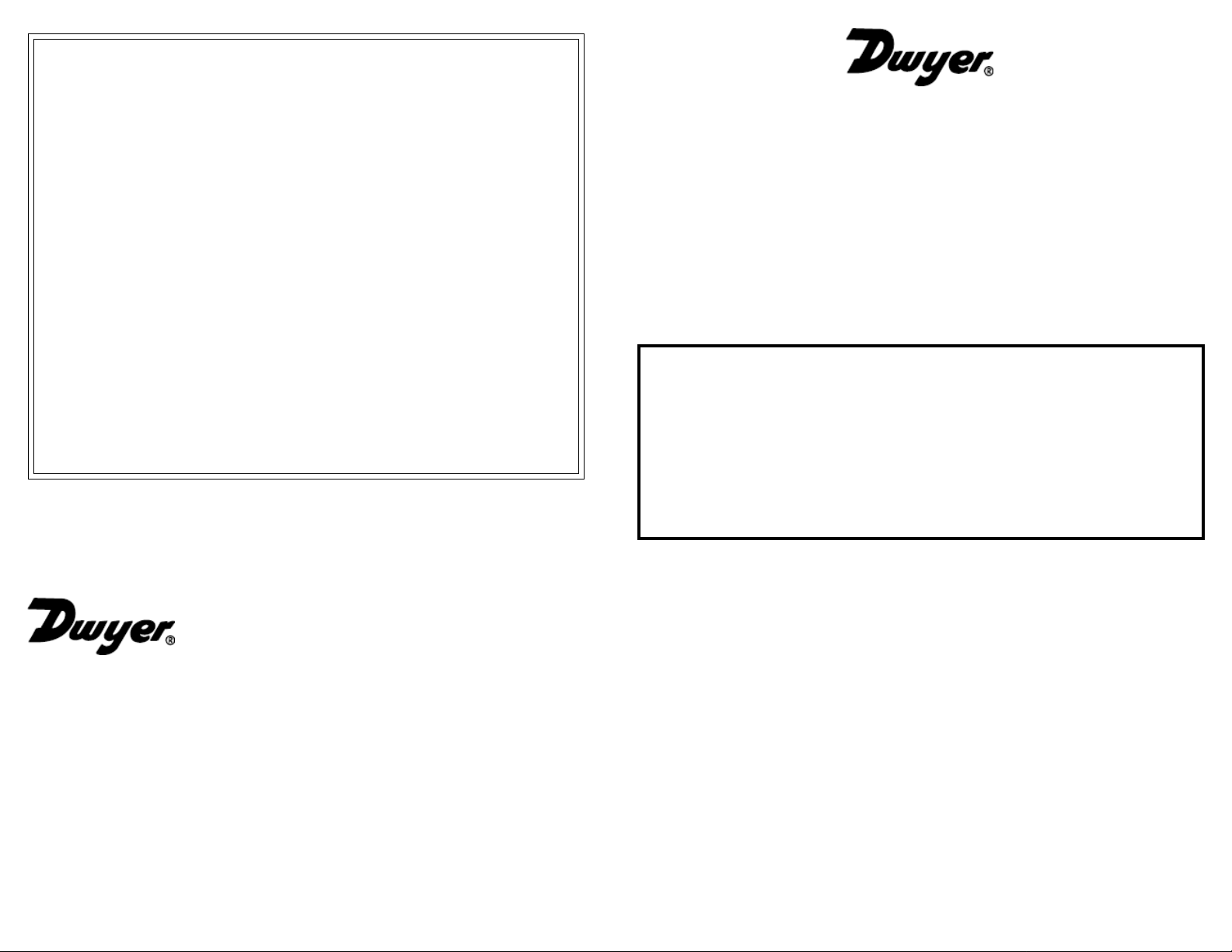

Junction Box Suggestion - The following junction box configuration is a recommended

method of terminating the 681’s signal cable in order to achieve a moisture resistant and

vented connection.

CALIBRATION

All Dwyer pressure transmitters are carefully calibrated to the specific input pressure range

vs. output current at the factory so little or no field calibrating is necessary. Series 681

transmitters (4-20 mA) are factory calibrated using a 250 ohm load at 24 VDC. External

zero and span adjustment capability is approximately ± 0.5 mA, individually. Zero and span

adjustments are made by removing the pan head screws and turning the potentiometer

screw inside. A jeweler’s screwdriver or a .015" x 3/32" flathead screwdriver with a 3" shaft

is easiest to use for making zero and span adjustments. It is important to replace the screws

after adjustments are made to avoid allowing moisture to enter the transmitter.

Junction Box

Strain Relief

Vent Screw

1/2" Conduit optionally

Z

S

C-290

1/2" Conduit Fitting

RETURNING PRODUCTS FOR REPAIR

Please contact Dwyer (800-872-9149 or 219-879-8868) to review information relative to your

application before returning unit for repair 2. Many times only minor field ajustments may

be necessary. When returning a product to Dwyer Instruments, the material should be

carefully packaged and shipped prepaid to:

Dwyer Instruments

Attn: Repair Department

Junction Box Cable Strain Relief

102 Indiana Highway 212

Michigan City, IN 46360

Part No. A-533PC1 3237 Heyco Flex Fitting

Dimensions: 4.92" x 2.95" x 2.95" 2.50" Long

Manufacturer: Hoffman Engineering Co. Heyco

900 Ehlen Drive Kenilworth, NJ 07033

Anoka, MN 55303 (201) 245-0033

(612) 421-2240 (800) 526-4182

1. Drill one 1/2" dia. hole at each end of junction box for cable strain reliefs. Note: if

conduit is to be installed, omit one 1/2" hole and drill appropriate hole for conduit.

2. Drill and tap one 1/2"–13 NC hole in bottom of junction box and install loosely one 1/2"13 NC plastic or stainless steel screw. The clearance between threads serves as a

vent for the box.

3. Install cable strain reliefs in 1/2" dia. holes. If using conduit at one end, be sure it is

sealed properly against moisture.

4. Mount junction box and install cables.

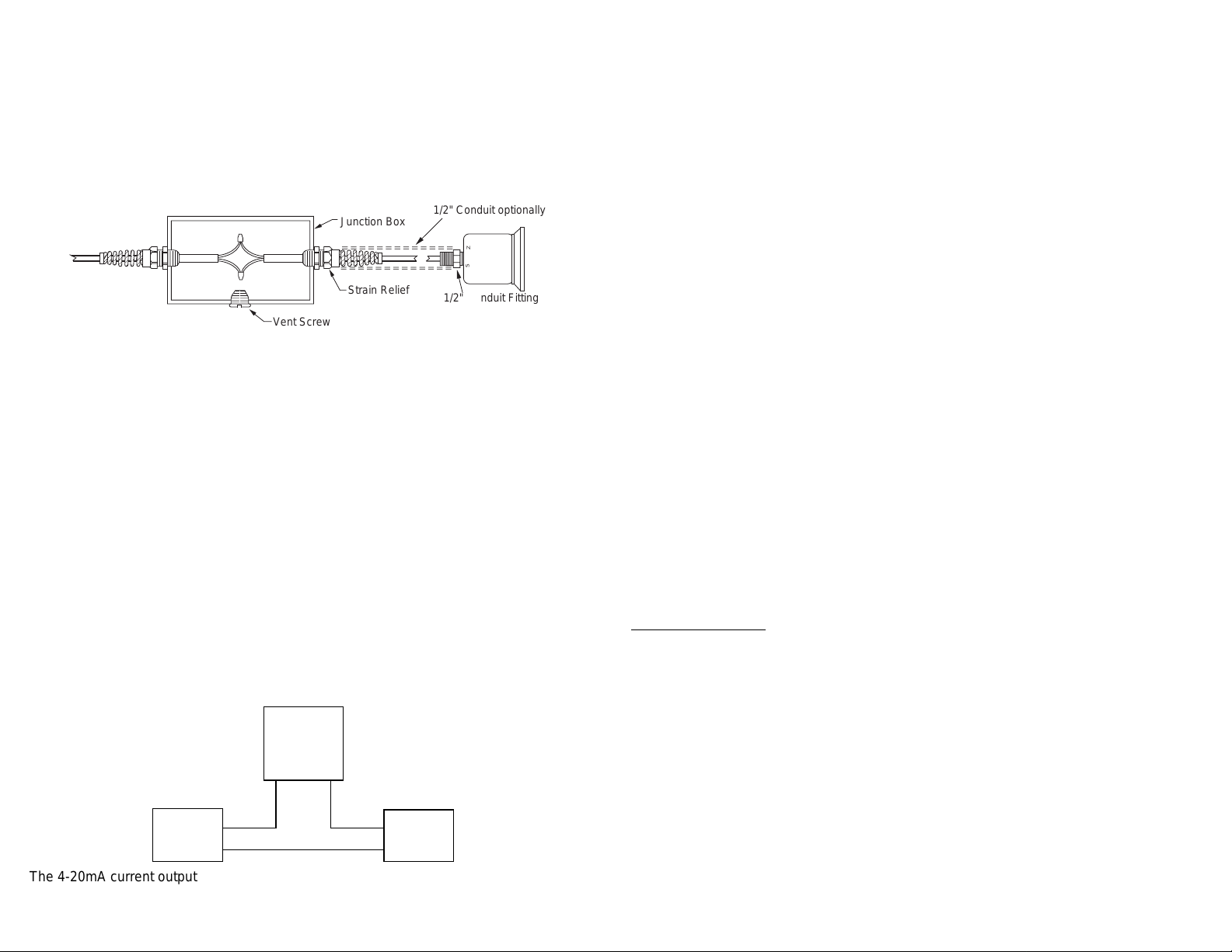

Electrical Connections - The Sereis 681 (current output) Sanitary Transmitter is a true 2wire, 4-20 mA current output device and delivers rated current to any external load of 0-800

ohms. The 681 has a two wire cable where red is positive and black is negative.

To assure prompt handling, please supply the following information and include it inside the

package of returned material:

1. Name and phone number of person to contact.

2. Shipping and billing instructions

3. Full description of the malfunction.

4. Identify any hazardous material used with product.

Notes: Please remove any pressure fittings and plumbing that you have installed and

enclose any required mating electrical connectors and wiring diagrams.

Allow approximately 3 weeks after receipt at Dwyer for the repair and return of the unit.

Non-warranty repairs will not be made without customer approval and a purchase order to

cover repair charges.

Calibration Services

Dwyer maintains a complete calibration facility that is traceable to the National Institute of

Standards & Technology (NIST). If you would like to recalibrate or recertify your Dwyer

pressure transducers or transmitters, please call our Repair Department at 1-800-872-9141

or 219-879-8868 for scheduling, cost and turn around estimates.

Setra

Transmitter

(4-20 mA)

+

-

++

Power Supply

Load

(Monitor)

--

The 4-20mA current output circuit is designed to have current flow in one direction only

please observe polarity. It is suggested that the cable shield be connected to the system

loop circuit ground to improve electrical noise rejection.

Loading...

Loading...