Page 1

Series 668B/D Compact Differential Pressure Transmitter

3-15/32 [88.00]

[32.60]

[92.94]

040

1500

*Loop Resistance = Wire Res. + Receiver Res.

LOOP RESISTANCE (OHMS)*

®

Specications - Installation and Operating Instructions

Bulletin P-668BD

3-5/32 [80.00]

668B

3-15/32 [88.00]

668B

1-9/32

668D

Our low cost Series 668B/D Compact Differential Pressure Transmitter is capable of

sensing differential gage pressure with ±0.8% FS accuracy, and converts this pressure

difference to a proportional high level analog output for both unidirectional and bidirectional pressure ranges. Transmitters can withstand up to 15 psig overpressure

with no damage to the unit. The compact, lightweight design makes installation

simple and easy. Units are protected against incorrect wiring, and include a protective

terminal cover.

INSTALLATION

Work on electrical installations must only be carried out by electricians who are

specically trained for this purpose.

CAUTION

can cause electrical shock and equipment may be damaged.

Risk of Shock: Disconnect power supply before making electrical

connections. Contact with components carrying hazardous voltage

3-5/32 [80.00]

668D

2X 3/16

[ø4.80]

1-3/16

[30.20]

1-45/64

[43.25]

1-7/32

[30.80]

1-57/64

1-45/64

[48.20]

[43.25]

2X 3/16

[ø4.80]

SPECIFICATIONS

Service: Air and non-conductive gases.

Accuracy: ±0.8% FS.

Temperature Limits: Operating: 0 to 170°F (-18 to 77°C); Storage: -40 to 185°F

(-40 to 85°C).

Pressure Limits: 15 psig (1.0 bar).

Thermal Effects: ±0.03% FS/°F (±0.054% FS/°C).

Compensated Range: From 40 to 170°F (4.4 to 77°C).

Power Requirements: 12 to 32 VDC.

Output Signals: 4 to 20 mA (2-wire), 0 to 10 VDC (3-wire), or 0 to 5 VDC (3-wire).

Zero Adjustment: Accessible under the small terminal cover.

Electrical Connection: Terminal strip.

Process Connection: 3/16˝ OD barbed brass for 1/8˝ ID push-on tubing.

Enclosure: Stainless steel and PC+ABS alloy, UL 94 V-0 rated.

Weight: 4.0 oz (113 g).

Agency Approvals: CE.

3-21/32

1-13/32

[35.60]

1-57/64

[48.20]

The Series 668B/D is designed to be used with 3/16˝ I.D. push-on tubing. The high

pressure port and the low pressure port are labeled “+” and “-” respectively. For best

results (shortest response times), 3/16˝ I.D. tubing is suggested for tubing lengths up

to 80 feet (25 meters), 1/4˝ I.D. for tubing lengths up to 250 feet (75 meters) and 3/8˝

I.D. for tubing up to 720 feet (220 meters).

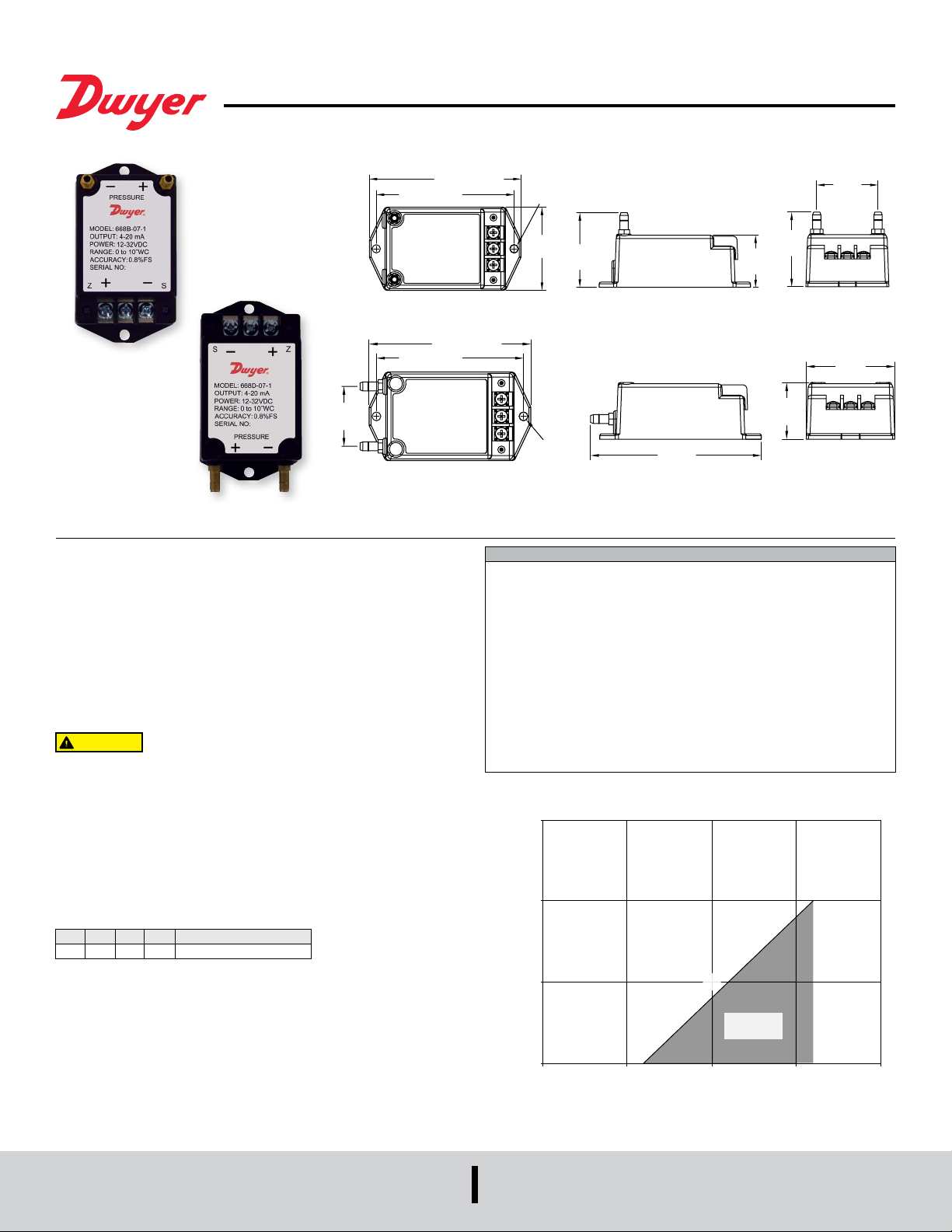

The table below shows the maximum wire and receiver resistances as a function of

supply voltage (See Figure 1).

Vmin Vmax Rmin Rmax RL at Supply Voltage (Vs)

12 32 0 1000 RL≤50(Vs-12)

Example: If the Supply Voltage is 24 VDC, RL≤50(24-12)=600 Ω, the load resistance

should not exceed 600 Ω.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

1000

500

MAXIMUM RESISTANCE

0

010203

POWER SUPPLY VOLTAGE

Figure 1

Phone: 219/879-8000

Fax: 219/872-9057

OPERATING

REGION

www.dwyer-inst.com

e-mail: info@dwyermail.com

Page 2

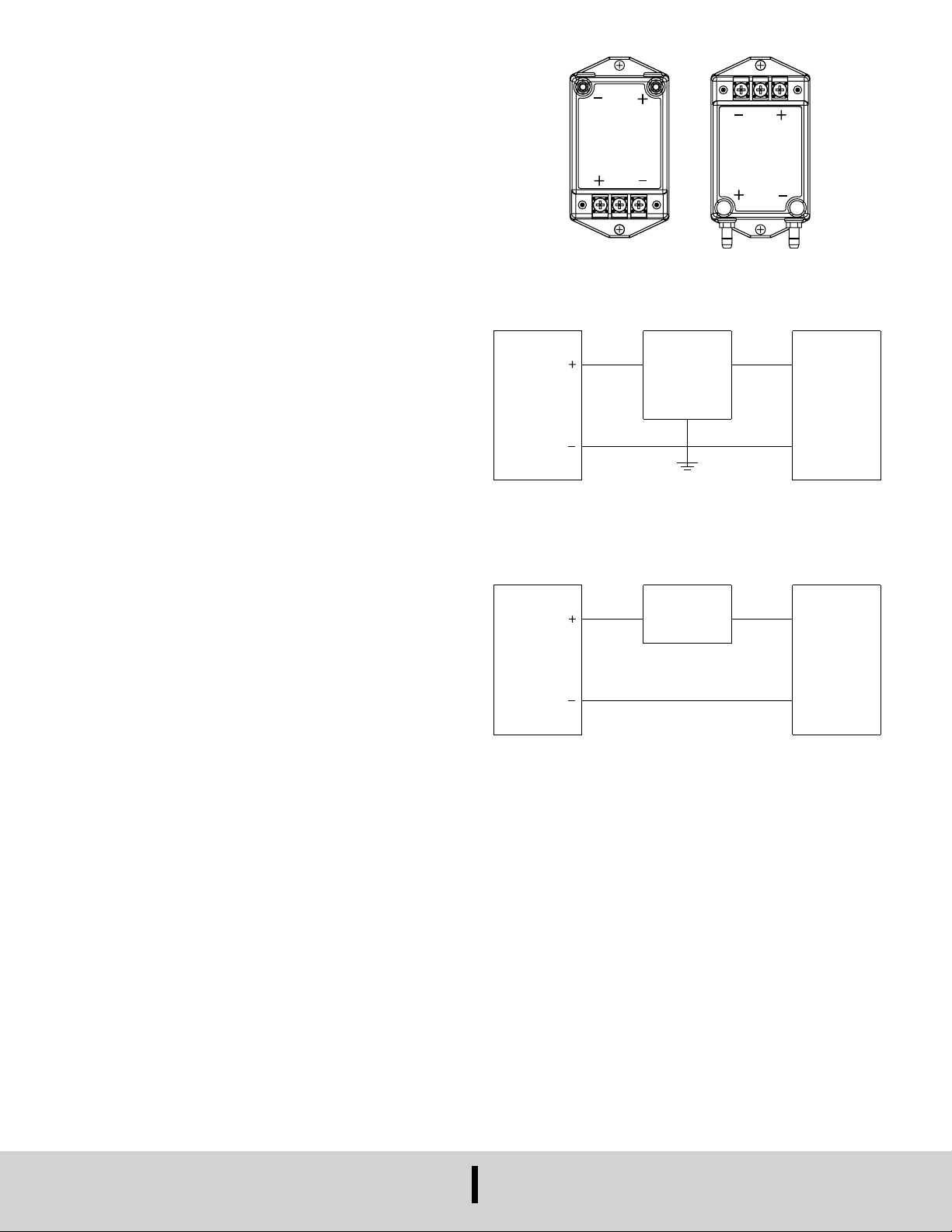

VOLTAGE OUTPUT

ZS

SZ

The 668B/D has a 0 to 5 or 0 to 10 VDC output in a 3-wire conguration, with three

terminals available for wiring. These terminals have the designation “+”, “O”, and

“-” (See Figure 2). The power supply and signal references are commoned on the

circuit (See Figure 3), and the 668B/D voltage output can operate from 12 to 32 VDC

power supply. The unit is calibrated at the factory with a 24 VDC power supply, 50 KΩ

load resistor.

O

Connect the “+” terminal to the positive terminal of the DC power supply.

Connect the “O” terminal to the positive terminal of the control or pressure monitor.

Connect the “-” terminal as the reference for the power supply and output signal.

CURRENT OUTPUT

The 668B/D current output is a 2-wire loop-powered 4 to 20 mA current output unit and

delivers rated current into any external load to 0 to 1000 Ω. These terminals have the

designation of “+” and “-” (See Figure 2). The current ows into the “+” terminal and

returns back to the power supply through the “-” terminal (See Figure 4). The 668B/D

current output can operate from 12 to 32 VDC power supply. The unit is calibrated at

the factory with a 24 VDC loop supply voltage and a 250 Ω load resistor.

CALIBRATION

The 668B/D transmitter is calibrated in the vertical mounting position at the factory.

The zero adjustment is accessible under the terminal cover of the unit in case there is

a zero shift when using other positions.

Zero Adjustment

While monitoring the output of the unit with both pressure ports open to atmosphere,

the zero may be adjusted by turning the zero adjustment screw.

Voltage Output:

Unidirectional Pressure Ranges: 0 VDC

Bi-directional Pressure Ranges: 2.5 VDC or 5.0 VDC

Current Output:

Unidirectional Pressure Ranges: 4 mA

Bi-directional Pressure Ranges: 12 mA

MAINTENANCE/REPAIR

Upon nal installation of the Series 668B/D transmitter no routine maintenance is

required. The Series 668B/D transmitter is not eld serviceable and should be returned

if repair is needed. Field repair should not be attempted and may void warranty.

POWER

SUPPLY

O

Figure 2

+ EXC + OUT

+ EXC – EXC

668B/D

– EXC

Figure 3

668B/D

READOUT

OR

DAS

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping the

product back for repair. Be sure to include a brief description of the problem plus any

additional application notes.

POWER

SUPPLY

Figure 4

CURRENT

MONITORING

DEVICE

©Copyright 2015 Dwyer Instruments, Inc. Printed in U.S.A. 11/15 FR# 444276-00

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Loading...

Loading...