Page 1

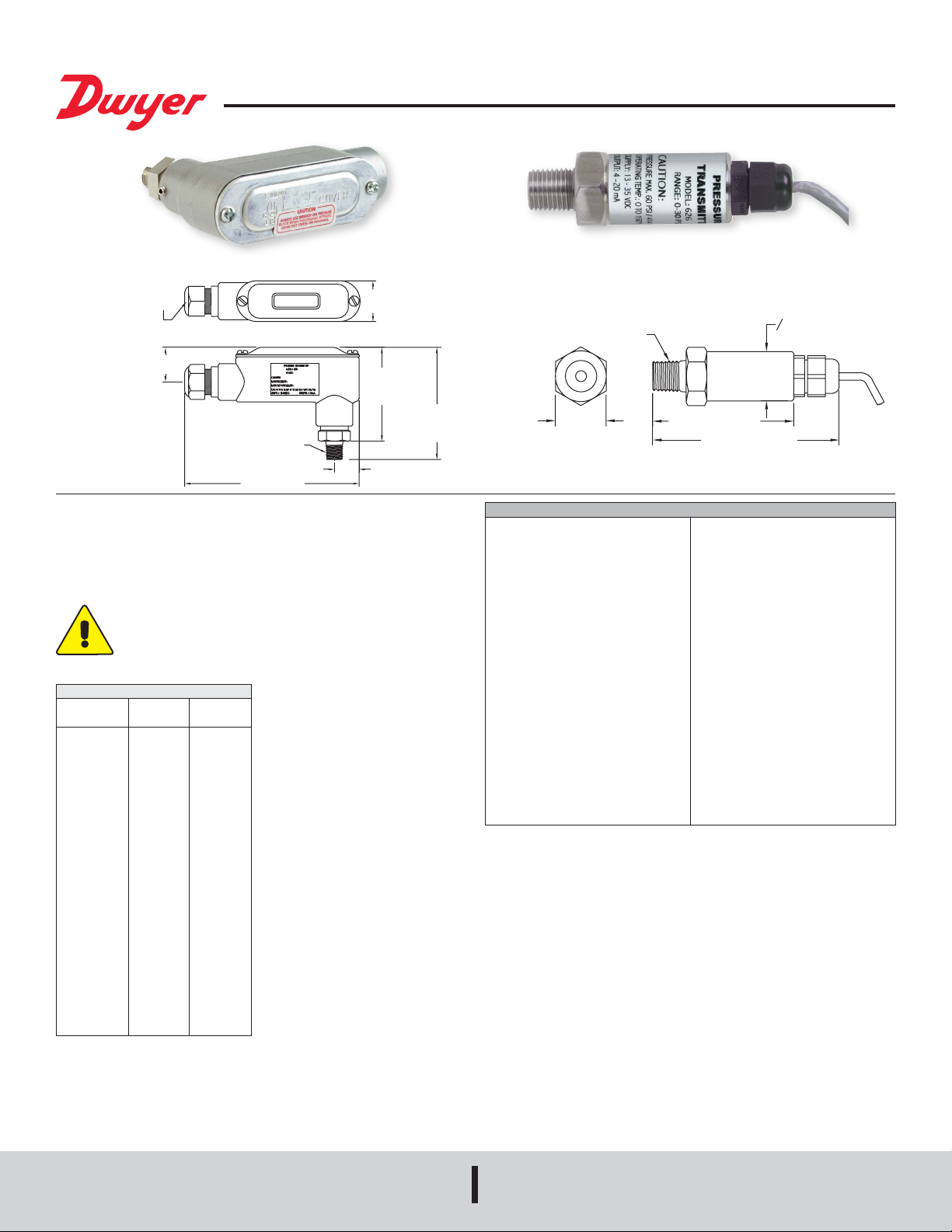

Series 626 & 628 Pressure Transmitters

LIQUID TIGHT FITTING

CORD DIAMETER RANGE

MALE FITTING

5-1/2 [139.70]

®

Specications - Installation and Operating Instructions

Bulletin E-111

.200 to .350 (5.08 to 8.89)

The Series 626 & 628 Pressure Transmitters converts a single positive pressure

into a standard 4 to 20 mA output signal. The Series 626 and 628 can be used to

accurately measure compatible gases and liquids; Series 626 full scale accuracy

is 0.25%; Series 628 full scale accuracy is 1.0% (see specications). Designed for

industrial environments with a NEMA 4X (IP66) housing, this transmitter resists most

effects of shock and vibration.

Pressure Ranges

Pressure

Range

0-15 psia

15-0 psia

0-30 psia

0-50 psia

0-100 psia

0-200 psia

0-300 psia

0-5 psig

0-15 psig

0-30 psig

0-50 psig

0-100 psig

0-150 psig

0-200 psig

0-300 psig

0-500 psig

0-1000 psig

0-1500 psig

0-2000 psig

0-3000 psig

0-5000 psig

0-8000 psig

-CH Conduit Housing

1-9/32

[32.54]

1-3/32

[27.76]

1/4 NPT

Caution: Do not exceed specied supply voltage ratings. Permanent

damage not covered by warranty will result. This device is not designed

for 120 or 240 volt AC operation. Use only on 13 to 30 VDC.

Maximum

Pressure

30 psia

30 psia

60 psia

100 psia

200 psia

400 psia

600 psia

10 psig

30 psig

60 psig

100 psig

200 psig

300 psig

400 psig

600 psig

1000 psig

2000 psig

3000 psig

4000 psig

6000 psig

7500 psig

10000 psig

Over

Pressure

45 psia

45 psia

90 psia

150 psia

300 psia

600 psia

900 psia

50 psig

150 psig

300 psig

300 psig

500 psig

750 psig

1000 psig

1500 psig

2500 psig

5000 psig

5000 psig

5000 psig

7500 psig

10000 psig

12000 psig

2-15/16 [74.61]

OPTIONAL 1/4 NPT

FEMALE FITTING

3/4

[19.05]

3-1/2 [88.90]

1/4 NPT

-GH General Purpose Housing

1/4 NPT

7/8 [22.23]

HEX

SPECIFICATIONS

Service: Compatible gases and liquids.

Wetted Materials: Type 316 SS.

Accuracy: 626: 0.25% FS, 0.20% RSS;

628: 1.0% FS, 0.5% RSS; 626 absolute

ranges: 0.5% FS, 0.35% RSS. (Includes

linearity, hysteresis, and repeatability).

Temperature Limit: 0 to 200°F (-18 to

93°C).

Compensation Temperature Range: 0

to 175° (-18 to 79°C).

Thermal Effect: 626: ±0.02% FS/°F.

628: ±0.04% FS/°F (includes zero and

span).

Pressure Limits: See table.

Power Requirements: 10-30 VDC (for

4 to 20 mA, 0-5, 1-5, 1-6 VDC outpus);

13-30 VDC (for 0-10, 2-10 VDC outputs);

5 VDC ±0.5 VDC (for 0.5-4.5 VDC ratiometric output).

Output Signal: 4 to 20 mA, 0-5 VDC,1-5

VDC, 0-10 VDC, or 0.5-4.5 VDC.

Response Time: 300 ms.

INSTALLATION

1. Location: Select a location where the temperature of the transmitter will be

between 0 and 175°F (-18 to 79°C). Distance from the receiver is limited only by

total loop resistance. The tubing or piping supplying pressure to the unit can be

practically any length required but long lengths will increase response time slightly.

2. Position: The transmitter is not position sensitive. However all standard models

are originally calibrated with the unit in a position with the pressure connection

downward. Although they can be used at other angles, for best accuracy it is

recommended that units be installed in the position calibrated at the factory.

3. Pressure Connection: Use a small amount of plumber’s tape or other suitable

sealants to prevent leaks. Be sure the pressure passage inside the port is not

blocked.

4. Electrical Connections

Wire Length - The maximum length of wire connecting the transmitter and receiver

is a function of wire size and receiver resistance. Wiring should not contribute more

than 10% of the receiver resistance to total loop resistance. For extremely long

runs (over 1000 feet), choose receivers with higher resistance to minimize the size

and cost of connecting leads. Where wiring length is under 100 feet, wire as small

as 22 AWG can be used.

2-27/64 [61.52]

3-13/64 [81.36]

Loop Resistance: 0-1000 Ohms max.

R max = 50 (Vps-10) Ohms (4 to 20 mA

output), 5K Ohms (0-5, 1-5, 1-6, 0-10,

2-10, 0.5-4.5 VDC output).

Current Consumption: 38 mA

maximum (for 4 to 20 mA output); 10 mA

maximum (for 0-5, 1-5, 1-6, 0-10, 2-10,

0.5-4.5 VDC output); 140 mA maxumum

(for all 626/628/629-CH with optional

LED).

Electrical Connections: Conduit

Housing (-CH): terminal block, 1/2˝

female NPT conduit; General Purpose

Housing (-GH): cable DIN EN 175801-

803-C.

Process Connection: 1/4˝ male or

female NPT and BSPT.

Enclosure Rating: NEMA 4X (IP66).

Mounting Orientation: Mount in any

position.

Weight: 10 oz (283 g).

Agency Approvals: CE.

055/64 [21.83]

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Page 2

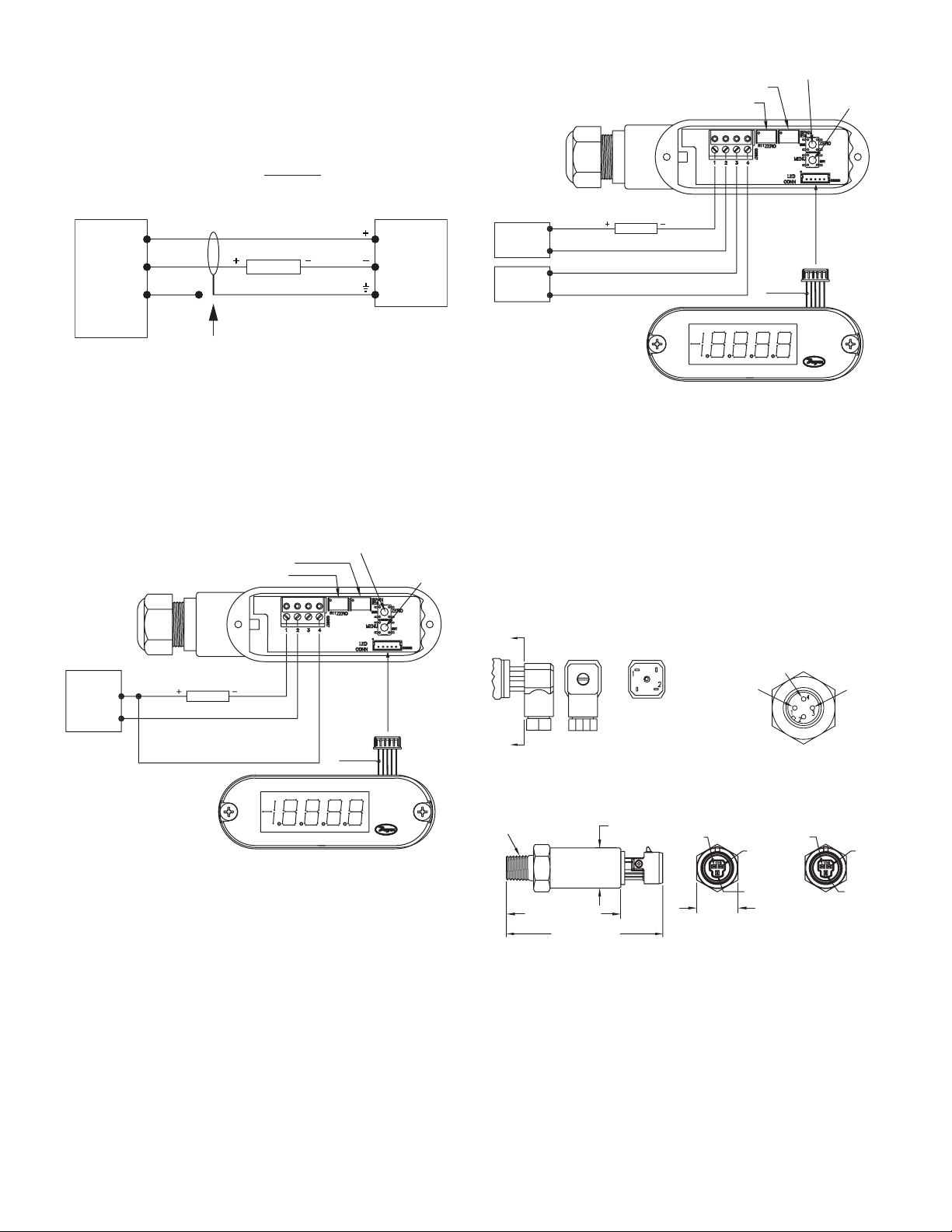

CURRENT (4 to 20 mA) OUTPUT OPERATION

PRESS AND HOLD TO

PRESS TO

- TURN ON POWER

SO CAN RESULT IN THE GAGE DAMAGE.

PRESS AND HOLD TO

Y

TERMINAL 4: (-)

out +]

3-5/16 [84.14]

1/4 NPT

Ø55/64

An external power supply delivering 10-30 VDC with minimum current capability of

40 mA DC (per transmitter) is required to power the control loop. See Figure A for

connection of the power supply, transmitter and receiver. The range of appropriate

receiver load resistance (RL) for the DC power supply voltage available is expressed

by the formula:

ZERO THE DISPLAY

SPAN

ZERO

PRESS TO

DISPLA

THE GAGE’S

PRESSURE

RANGE

1 RED

PRESSURE

TRANSMITTER

Conduit Housing with 4 to 20 mA Output (-CH) Electrical connections to the pressure

transmitters are made to the terminal block located inside the housing. Remove the

screws and lift off the cover. Wire as shown in Figure A, B or C. Use Figure A for

current output connection. Use Figure B for current output with optional LED display.

Use Figure C for current output with optional LED display using two power supplies.

If ordering optional pre-wired cable, black wire is negative (-) and red wire is positive

(+).

2 BLACK

3 (NC)

RL Max = Vps – 10

20 mA DC

RECEIVER

mA

4 SILVER

SHIELD WIRE (NOT CASE GROUNDED)

Figure A: Current output connection

ZERO THE DISPLAY

SPAN

ZERO

POWER

SUPPLY

13-30 VDC

DISPLAY

THE GAGE’S

PRESSURE

RANGE

POWER

SUPPLY

(40 ma)

+

-

-

+

10-30 VDC

10-30 VDC

(100 ma)

LED SUPPLY

POWER SUPPLY

TRANSMITTER CONNECTION:

- TURN OFF POWER

- CONNECT THE POWER SUPPLY

AND RECEIVER TO TERM 1 AND

TERM 2 OF THE GAGE AS SHOWN

- CONNECT LED POWER SUPPLY (-)

TO TERMINAL 3

- CONNECT LED POWER SUPPLY (+)

TO TERMINAL 4

- INSTALL THE DISPLAY’S CONNECTOR

- TURN ON POWER

Figure C: Current output with optional LED display using two power supplies

Hirschman DIN Connector with 4 to 20 mA When using cable version of -GH

General Purpose Housing, black wire is negative (-) and red wire is positive (+). When

using optional Hirschman DIN Plug, remove top-center screw and lift off the terminal

block assembly. Wire to terminals shown below in Figure D. For optional 4-pin M-12

connector, wire to pins as shown in Figure E.

RECEIVER

mA

LED DISPLAY

NEGATIVE SUPPLY

LED DISPLAY

POSITIVE SUPPLY

TERM 1 (+)

TERM 2 (-)

TERM 3 (-)

TERM 4 (+)

OPTIONAL LED DISPLAY

BE SURE TO TURN OFF POWER WHEN

CONNECTING OR REMOVING THE

DISPLAY’S CONNECTOR. FAILURE TO DO

SO CAN RESULT IN THE GAGE DAMAGE.

LED DISPLAY CONNECTOR

YELLOW

POWER

SUPPLY

10-30 VDC

(140 ma)

TRANSMITTER CONNECTION:

- TURN OFF POWER

- CONNECT THE POWER SUPPLY

AND RECEIVER TO TERM 1 AND

TERM 2 OF THE GAGE AS SHOWN

- CONNECT POWER SUPPLY (+) TO

TERMINAL 4 (REQUIRED FOR THE

OPTIONAL DISPLAY ONLY)

- INSTALL THE DISPLAY’S CONNECTOR

+

-

Figure B: Current output with optional LED display connection

RECEIVER

mA

LED DISPLAY

POSITIVE SUPPLY

TERM 1 (+)

TERM 2 (-)

LED DISPLAY CONNECTOR

TERM 4 (+)

OPTIONAL LED DISPLAY

BE SURE TO TURN OFF POWER WHEN

CONNECTING OR REMOVING THE

DISPLAY’S CONNECTOR. FAILURE TO DO

YELLOW

A

A

TERMINAL 1: (+)

SECTION A-A

TERMINAL 1: (+)

TERMINAL 2: (-)

Figure D Figure E

[21.83]

2-27/64 [61.52]

Figure F: Packard Connection

A; [-]

7/8

[22.23]

HEX

B; [+]

C; [GND]

A; [-]

TERMINAL 3:

(GROUND)

B; [+]

C; [V

Page 3

VOLTAGE (0-5, 1-5, 0-10, 1-6 or 2-10 VDC) OUTPUT OPERATION

(NOT CASE GROUNDED)

(NOT CASE GROUNDED)

PRESS AND HOLD TO

TO

E

GAGE’S

PRESSURE

RANGE

TERMINAL

TERMINAL 4: (-)

3:

(Vout)

TERMINAL

TERMINAL 4: (-)

3:

(Vout)

(Other outputs contact the factory) See Figure G for connection of the power supply,

transmitter and receiver.

RATIOMETRIC (0.5-4.5 VDC) OUTPUT OPERATION

(Other outputs contact the factory) See Figure K for connection of the power supply,

transmitter and receiver.

1 RED

PRESSURE

TRANSMITTER

Conduit Housing (-CH) Electrical connections to the pressure transmitters are

made to the terminal block located inside the housing. Remove the screws and lift

off the cover. Wire as shown in Figure G or Figure H. Use Figure G for voltage output

connection. Use Figure H for voltage output with optional LED display connection. If

ordering optional pre-wired cable, black wire is negative (-), red wire is positive (+) and

white wire is +Vout.

POWER

SUPPLY

RECEIVER

TRANSMITTER CONNECTION:

- TURN OFF POWER

- CONNECT POWER SUPPLY

(+) TO TERMINAL 1

- CONNECT POWER SUPPLY

(-) TO TERMINAL 2 AND TO

THE RECEIVER (-)

- CONNECT THE RECEIVER

(+) TO TERMINAL 3

- CONNECT LED POWER SUPPLY

(+) TO TERMINAL 4

- INSTALL THE DISPLAY’S

CONNECTOR

- TURN ON POWER

Figure H: Voltage output with optional LED display connection

2 BLACK (COMMON) POWER

3 WHITE (+V OUT)

4 SILVER

RECEIVER

Figure G: Voltage output connection

LED DISPLAY POSITIVE SUPPLY

+

-

-

+

TERM 4 (+)

+ V OUT

V IN

ZERO THE DISPLAY

ZERO

TERM 1 (+)

TERM 2 (-)

TERM 3 (-)

OPTIONAL LED DISPLAY

BE SURE TO TURN OFF POWER WHEN

CONNECTING OR REMOVING THE

DISPLAY’S CONNECTOR. FAILURE TO DO

SO CAN RESULT IN THE GAGE DAMAGE.

SHIELD WIRE

SPAN

LED DISPLAY CONNECTOR

YELLOW

SUPPLY

PRESS

DISPLAY TH

1 RED

POWER

PRESSURE

TRANSMITTER

General Purpose Housing with Ratiometric Output When using cable version of

-GH General Purpose Housing, black wire is negative (-), red wire is positive (+) and

white wire is output. When using optional Hirschman DIN Plug, remove top-center

screw and lift off the terminal block assembly. Wire to terminals shown below in Figure

L. For optional 4-pin M-12 connector, wire to pins as shown in Figure M. If utilizing

optional A-164 cable for M-12 connection, brown wire corresponds to pin #1, white #2,

blue #3, and black #4.

2 BLACK (COMMON)

3 WHITE (+V OUT)

V IN

RECEIVER

Figure K: Voltage output connection

4 SILVER

SHIELD WIRE

SUPPLY

5 VDC

±10%

A

1: (+)

SECTION A-A

TERMINAL 1: (+)

A

MAINTENANCE

After nal installation of the pressure transmitter and its companion receiver, no routine

maintenance is required. A periodic check of system calibration is suggested. The

Series 626 and 628 transmitters are not eld repairable and should be returned if

repair is needed (eld repair should not be attempted and may void warranty). Be

sure to include a brief description of the problem plus any relevant application notes.

Contact customer service to receive a return goods authorization number before

shipping.

TERMINAL 2: (-)

TERMINAL 3: [OUTPUT]

Figure L Figure M

TERMINAL

(GROUND)

TERMINAL 2:

Hirschman DIN Connector with Voltage Output When using cable version of

-GH General Purpose Housing, black wire is negative (-), red wire is positive (+) and

white wire is output. When using optional Hirschman DIN Plug, remove top-center

screw and lift off the terminal block assembly. Wire to terminals shown below in Figure

I. For optional 4-pin M-12 connector, wire to pins as shown in Figure J. If utilizing

optional A-164 cable for M-12 connection, brown wire corresponds to pin #1, white #2,

blue #3, and black #4.

A

1: (+)

SECTION A-A

TERMINAL 1: (+)

A

TERMINAL 2: (-)

TERMINAL 3: [OUTPUT]

Figure I Figure J

TERMINAL

(GROUND)

TERMINAL 2:

Note: Please do not cover or insert objects into vent hole.

Page 4

NOTES

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________________________

Printed in U.S.A. 2/18 FR# 443271-00 Rev.21©Copyright 2018 Dwyer Instruments, Inc.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com

Loading...

Loading...