Dwyer Instruments 604D-0, 604D Series, 604D-2, 604D-1, 604D-5 Specifications-installation And Operating Instructions

...Page 1

Series 604D Indicating Pressure Transmitter

Specifications - Installation and Operating Instructions

Bulletin E-34

The Dwyer Series 604D Indicating Transmitter simulta-

neously provides local indication on a compact, easy to

read analog scale while also converting that pressure into a

standard 2, 3 or 4 wire, 4-20 mA signal for ranges as low

as 0-0.5 in. w.c. Positive, negative or differential pressures

can be measured within ±5% of full scale (gage reading) or

±2% of full span output (transmitter signal). The basic

mechanical components of the Series 604D units are simi-

®

lar to those used in the popular, time-proven Minihelic

differential pressure gage. However, the Series 604D models

add electrical conditioning and amplification of a resistance

change produced by a silicon strain gage cemented to the

range spring. This resistance change is the result of a slight

flexing which results from spring deflection as pressure is

applied to the diaphragm which is mechanically linked to

the spring.

Series 604D Indicating Transmitter Model & Ranges

Model

Number

604D-0

604D-1

604D-2

604D-3

604D-5

604D-10

604D-20

604D-40

604D-60

604D-100

Ranges, Inches W.C.

0-0.5

0-1.0

0-2.0

0-3.0

0-5.0

0-10

0-20

0-40

0-60

0-100

Minor Divisions

.02

.05

.10

.10

.20

.50

1.0

2.0

2.0

5.0

PHYSICAL DATA

GENERAL

Maximum Pressure: 30 psig (207 kPa) continuous

50 psig (344 kPa) momentary surge.

Media Compatibility: Air and non-combustible, non-corrosive gases.

Materials: Mineral and glass filled nylon housing, high

impact acrylic cover, silicone rubber diaphragm.

ELECTRICAL

Power Supply: 10-35 VDC-2,3 or 4 wire

16-26 VAC-4 wire.

Connections: 4 screw terminal block

Cable Gland: Fits .10 - .25 in (2.5 - 6 mm) O.D. cable.

Output Signal: 4-20 mA DC (limited at 38 mA DC).

Loop Resistance: DC; 0-1300 ohms

AC; 0-1200 ohms.

Current Consumption: DC; 38 mA max. AC; 76 mA

max.

Warm-Up: 10 minutes.

PERFORMANCE AT 70°F (21.1°C)

Zero Output: 4 mA DC.

Full Span Output: 20 mA DC.

Accuracy, Gage: ±5% of full scale.

Accuracy, Transmitter: ±2% of full span output

(Includes linearity, hysteresis and repeatability).

Stability: 1% F.S./year.

ENVIRONMENTAL

Operating Temperature: 20-120°F (-6.7° to 49°C)

Thermal Errors: ±1%/50°F

MECHANICAL

Weight: 8 oz. (227 grams)

Span and Zero: Internally accessible potentiometers

Pressure Connections: Barbed, for 3/16″ (4-5 mm) I.D.

tubing.

STANDARD ACCESSORIES

(2) #10 x 1″ pan head sheet metal screws, (1) .050″ hex

allen wrench.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Lit-By Fax: 888/891-4963

Page 2

Series 604D Indicating Pressure Transmitter

Specifications - Installation and Operating Instructions

Bulletin E-34

Page 2

INSTALLATION

LOCATION: Select a location where temperature of the unit will be

between 20°F and 120°F (7°C and 49°C). Distance from the

receiver is limited only by total loop resistance. See “Electrical

Connections.” The tubing feeding pressure to the instrument can

be run practically any length required, but long lengths will slightly

increase response time. Avoid surfaces with excessive vibration.

POSITION: All models are calibrated with the scale in a vertical

plane and units with ranges under 5 in. w.c. should only be used

in that position due to the sensitivity to gravitational forces which

cannot be corrected by zero adjustment. Higher range models can

operate in other planes but zero (both mechanical electrical) and

span adjustments may be necessary to maintain accuracy.

PRESSURE CONNECTIONS: Two barbed connectors are provided for use with 3/16″ I.D. vinyl or rubber tubing. Attach tubing

from positive pressure source to HI port. Leave LO port vented.

For negative (vacuum) pressure, connect to LO port and leave HI

port vented. For differential pressures, connect the higher to HI

port and lower to LO port.

MOUNTING: Attach the Series 604D Indicating Transmitter to a

vertical surface using the 1″ - #10 pan head sheet metal screws

provided. Mounting holes are located in upper left and lower right

corners of case.

GAGE ZEROING:

After installation, check to confirm that gage reads exactly zero

with both pressure connections open and vented to atmosphere.

If adjustment is necessary, grip case firmly with one hand and

place palm of the other hand flat on clear cover. If difficult to grip,

try placing a thin sheet of rubber between hand and cover. Rotate

counter-clockwise to remove. Zero adjust screw is located at bottom of scale just to left of the indicating pointer and slightly behind

it. Use the .050″ hex allen wrench included. Replace cover.

ELECTRICAL CONNECTIONS

CAUTION: DO NOT EXCEED SPECIFIED SUPPLY VOLTAGE

RATINGS. PERMANENT DAMAGE NOT COVERED BY W ARRANTY WILL RESULT. THIS UNIT IS NOT DESIGNED FOR

120 VAC or 240 VAC LINE OPERATION.

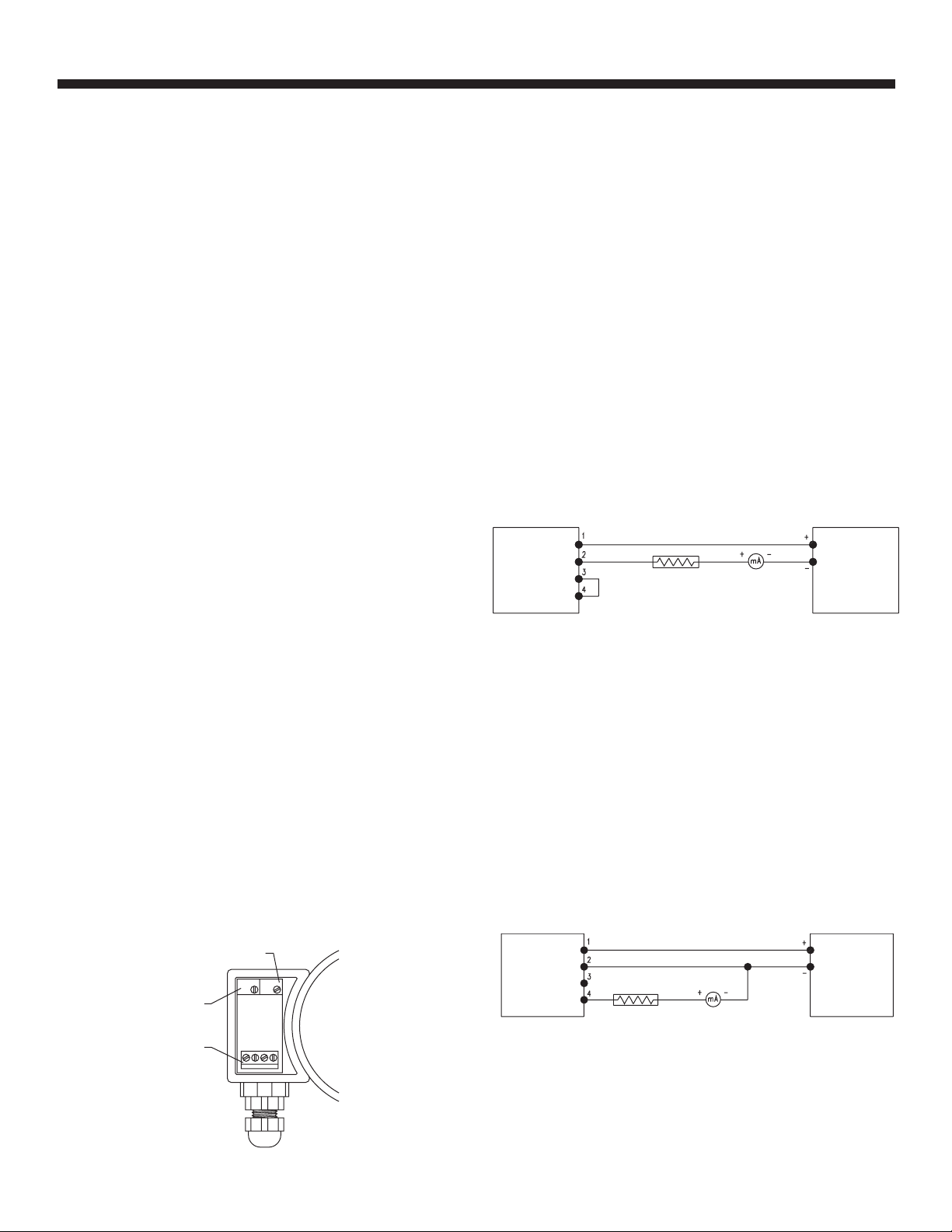

Electrical connections to the Series 604D Indicating Transmitter

are made inside the enclosure on the left side of the unit. Remove

the cover and feed 4 conductor cable through the cable gland at

bottom of housing. Make electrical connections to the 4-screw terminal block shown in Fig. B. See following instructions and drawings for details on your specific application. When connections are

complete, tighten cable gland and replace cover.

Wire Length - The maximum length of wire connecting transmit-

ter and receiver is a function of wire size and receiver resistance.

Wiring should not contribute more than 10% of receiver resistance

to total loop resistance. For extremely long runs (over 1000 ft. [305

m]), choose receivers with higher resistances to minimize size and

cost of connecting leads. Where wiring length is under 100 ft.

(30.48 m), lead wire as small as 22 AWG can be used.

2-Wire Operation - An external power supply delivering 10-35

VDC with minimum current capability of 40 mA DC (per transmitter) must be used to power the control loop. See Fig. C for connection of the power supply, transmitter and receiver. Note the

jumper between terminals 3 and 4. The range of appropriate

receiver load resistance (R

L

) for the DC power supply voltage available is expressed by the formula and graph in Fig. F. Shielded two

wire cable is recommended for control loop wiring. If grounding is

required use negative side of control loop after receiver. In Fig.C

below, if power supply lead to terminal 1 is positive, ground should

be connected to wiring at right of receiver. Otherwise, in 2 wire

operation it is not necessary to observe polarity of control loop

connections.

2-WIRE CONNECTION

SERIES 604D

PRESSURE

TRANSMITTER

JUMPER

WIRE

RECEIVER

POWER

SUPPLY

10-35 VDC

Fig. C

3-Wire Operation - An external power supply delivering 10-35

VDC with minimum current capability of 40 mA DC (per transmitter) is required. See Fig. D for connection of power supply, transmitter and receiver. The range of appropriate receiver load resistance (R

L

) for the DC power supply available is expressed by the

formula and graph in Fig. F. Shielded cable is recommended for

control loop wiring. Do not employ a separate ground in 3 wire

operation. Unit will not function properly and/or damage could

result. Control loop polarity must be observed in the following

respect. Although power supply terminals 1 and 2 are not polarized, the receiver must be connected between terminal 4 of

transmitter and negative side of power supply.

3-WIRE CONNECTION

ZERO ADJUSTMENT

SPAN ADJUSTMENT

TERMINAL BLOCK

1234

Fig. B

SERIES 604D

PRESSURE

TRANSMITTER

RECEIVER

Fig. D

POWER

SUPPLY

10-35 VDC

Page 3

Series 604D Indicating Pressure Transmitter

Specifications - Installation and Operating Instructions

Bulletin E-34

Page 3

4-Wire Operation - An external power supply delivering

10-35 VDC with minimum current capability of 40 mA DC

(per transmitter) or 16-26 VAC with minimum current capability of 80 mA AC (per transmitter) is required. See Fig. E for

connection of power supply, transmitter and receiver. The

range of appropriate load resistance (RL) for the DC or AC

power supply available is expressed by the formulas and

graphs in Figs. F and G. Shielded cable is recommended for

control loop wiring. Do not employ a separate ground in 4

wire operation. Unit will not function properly and /or damage could result. Control loop polarity must be observed,

terminal 3 is negative and terminal 4 is positive. Power supply terminals 1 and 2 are not polarized.

4 WIRE CONNECTION

SERIES 604D

PRESSURE

TRANSMITTER

POWER

SUPPLY

10-35 VDC

16-26 VA C

Fig. E

POWER SUPPLY VOLTAGE-VDC (2, 3, OR 4 wire)

1500

1400

Ω)

1300

1200

1100

1000

900

800

700

600

500

400

300

200

TOTAL RECEIVER RESISTANCE (

100

50

RL MAX. = Vps-10.0

05

MAXIMUM VALUE (1300Ω)

20 mA DC

OPERATING

REGION

10 13 15 20 25 30 35 40

VDC

Fig. F

Voltage Input - Series 604D Indicating Pressure

Transmitters can be easily adapted for receivers requiring

1-5 VDC or 2-10 VDC input. Insert a 249 OHM, 1/2watt

(1-5 VDC) or 499 ohm (2-10 VDC) resistor in series with the

current loop but in parallel with the receiver input. Locate

this resistor as close as possible to the input. Because

resistor accuracy directly influences output signal accuracy,

we recommend use of a precision ±0.1% tolerance resistor

to minimize this effect. See Figs. H and J.

3-WIRE CONNECTION (1-5/2-10 VDC OUTPUT)

SERIES 604D

PRESSURE

TRANSMITTER

POWER

SUPPLY

10-35 VDC

Fig. H

4-WIRE CONNECTION (1-5/2-10 VDC OUTPUT)

SERIES 604D

PRESSURE

TRANSMITTER

POWER

SUPPLY

10-35 VDC

16-26 VA C

Fig. J

POWER SUPPLY VOLTAGE-VAC (4 wire)

1400

MAXIMUM VALUE (1200Ω)

R MAX=65(Vps)-560

L

OPERATING

REGION

05

10

16

15

20 252630

RECEIVER RESISTANCE (Ω)

1200

1100

1000

900

800

700

600

Fig. G

Page 4

Series 604D Indicating Pressure Transmitter

Specifications - Installation and Operating Instructions

Bulletin E-34

Page 4

OUTPUT RANGING

Each Series 604D Indicating Transmitter is factory calibrated to produce 4 mA at zero scale reading and 20 mA at full

scale reading. The following procedure should be used to

check the accuracy of the transmitter output.

1. With unit connected to its companion receiver, insert an

accurate milliammeter with a full scale reading of approximately 30 mA in series with the current loop.

2. Connect a controllable source of pressure to one leg of a

tee, one leg to the high pressure port of the unit being tested and the third leg to a test gage or manometer with 2% or

better accuracy. Be sure the low pressure port is vented to

atmosphere. This calibration check must be done in the

same position in which the unit will be operated. Vertical is

recommended.

3. Apply electrical power to the system and allow 10 minutes warm-up time for components to stabilize.

4. With no pressure applied to the system adjust ZERO control inside electrical enclosure to produce exactly 4 mA current.

5. Apply full scale pressure as observed on the test gage or

manometer and adjust SPAN control for exactly 20 mA current.

MULTIPLE RECEIVER INSTALLATION

An advantage of the standard 4-20 mA DC output signal

used in Series 604D Transmitters is the compatibility with a

wide range of receivers. Devices such as the A-701 Digital

Readout, A-702 Digital Readout with alarms, an analog

panel meter, a chart recorder and other process control

equipment can be operated simultaneously. It is only necessary that all devices be designed for a standard 4-20 mA

input, the proper polarity of input connections be observed

and the combined receiver resistances must not exceed the

maximum for the current loop. If any receiver indicates a

negative or downscale reading, the signal input leads are

reversed.

MAINTENANCE

After final installation of the Series 604D Indicating Pressure

Transmitter, no routine maintenance is required. A periodic

check of output calibration is recommended following the

procedure described under OUTPUT RANGING.

Otherwise, the transmitters are not field repairable and

should be returned, freight prepaid, to the address below if

service is needed. Be sure to include a clear description of

the problem plus any application information available.

Dwyer Instruments, Inc.

Attn: Repair Dept.

102 Highway 212

Michigan City, IN 46360

6. ZERO and SPAN controls are slightly interactive so steps

4 and 5 should be repeated until outputs are consistently 4

and 20 mA, respectively.

7. Remove the milliammeter and test gage from the setup,

make connections to system pressure source(s) and place

unit in service.

©Copyright 2001 Dwyer Instruments, Inc. Printed in U.S.A. 1/01 FR# 01-440830-00 Rev.1

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Lit-By Fax: 888/891-4963

Loading...

Loading...