Page 1

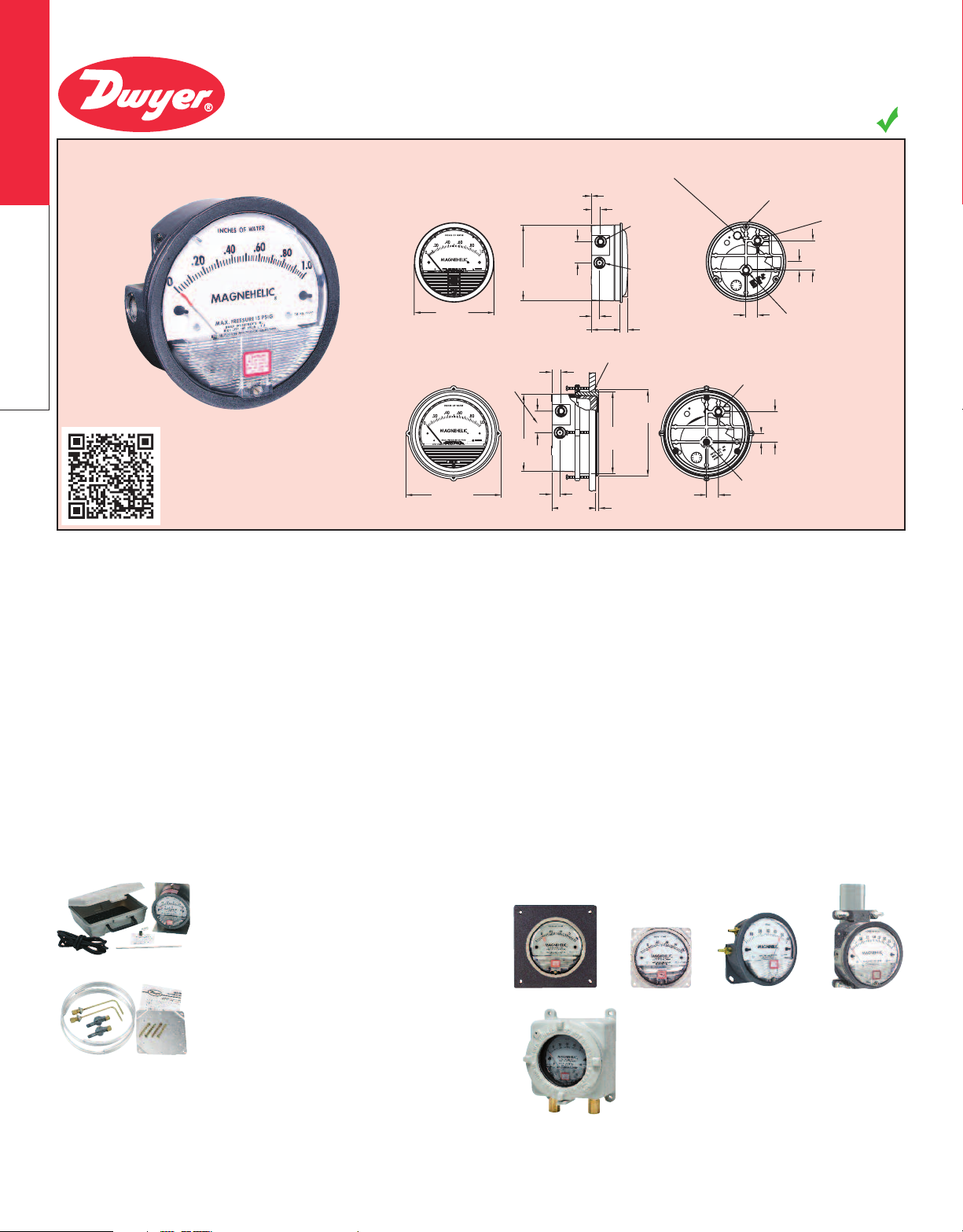

Series

R

oHS

1

/8 FEMALE NPT

H

IGH PRESSURE

C

ONNECTION

1-3/4

[44.45]

1

/2

[

12.70]

1

/8 FEMALE

N

PT LOW

P

RESSURE

C

ONNECTION

11/16

[

17.46]

17/32

[13.49]

ø

4-3/4 [120.65]

P

ANEL CUTOUT

ø

5

[

127]

ø4-47/64

[120.27]

3

/16

[

4.76]

2-17/32

[64.29]

1

5/32

[11.91]

ø4-1/2

[114.3]

1

-1/4

[

31.75]

ø

5-1/2

[

139.70]

MOUNTING RING

RUBBER PRESSURE RELIEF PLUG

WILL UNSEAT ITSELF WHEN GAGE

IS OVERPRESSURIZED

[3] 6-32 X 3/16 [4.76] DEEP

HOLES EQUALLY SPACED ON

A Ø4-1/8 [104.78] BOLT CIRCLE

FOR PANEL MOUNTING

1/8 FEMALE NPT

HIGH PRESSURE

CONNECTION

1

-3/4

[

44.45]

1

/2

[

12.70]

1

/8 FEMALE NPT LOW

P

RESSURE CONNECTION

11/16

[17.46]

15/32 [11.91]

1-11/16 [42.86]

Ø4-1/2

[114.3]

1

-1/4 [31.75]

1

7/32

[

13.49]

.

025 [.64] SPACE CREATED BY 3 SPACER

P

ADS WHEN SURFACE MOUNTED.

D

O NOT OBSTRUCT. PROVIDES PATH

F

OR RELIEF OF OVERPRESSURE.

1/8 FEMALE

NPT HIGH

PRESSURE

CONNECTION

1/8 FEMALE

NPT LOW

PRESSURE

CONNECTION

7

/16 [11.11]

Ø4-3/4

[120.65]

2000

Magnehelic®Differential Pressure Gages

PRESSURE

Differential Pressure Gages

can here

S

o watch

t

roduct video

p

Select the Dwyer®Magnehelic®gage for high accuracy — guaranteed within 2%

full-scale — and for the wide choice of 81 models available to suit your needs precisely. Using

Dwyer's simple, frictionless Magnehelic

non-corrosive gas pressures — either positive, negative

design resists shock, vibration and over-pressures. No manometer fluid to evaporate,

freeze or cause toxic or leveling problems. It's inexpensive, too.

The Magnehelic®gage is the industry standard to measure fan and blower pressures,

filter resistance, air

levels with bubbler systems and pressures in fluid amplifier or f luidic systems. It also

checks gas-air ratio controls and automatic valves, and monitors blood and respirator y

pressures in medical care equipment.

MOUNTING

A single case size is used for most models of Magnehelic

flush or surface mounted

vertical position, many ranges above 1˝ may be used at any angle by simply rezeroing. However, for maximum accuracy, they must be calibrated in the same

position in which they are used. These characteristics make Magnehelic

ideal for both stationary and portable applications. A 4-9/16˝ hole is required for

flush panel mounting. Complete mounting and connection fittings, plus instructions,

are furnished with each instrument.

ACCESSORIES

velocity, furnace draft, pressure drop across orifice plates, liquid

with standard hardware sup

®

gage movement, it quickly

u

Model A-432 Portable Kit

Combine carrying case with any Magnehelic

of standard range, except high pressure

connection. Includes 9 ft (2.7 m) of 3/16˝ ID rubber

tubing, standhang bracket and terminal tube with

holder.

Indicate Positive, Negative or Differential, Accurate within 2%

(vacuum) or differential. The

plied. Although calibrated for

indicates low air or

®

gages. They can be

®

gages

®

gage

of

SPECIFICATIONS

Service: Air and non-combustible,

compatible gases (natural gas option

available). Note: May be used with

hydrogen. Order a Buna-N diaphragm.

Pressures must be less than 35 psi.

Wetted Materials: Consult factory.

Housing: Die cast aluminum case and

bezel, with acrylic cover. Exterior finish

is coated gray to withstand 168 hour

salt spray corrosion test.

Accuracy: ±2% of FS (±3% on - 0,

-100 Pa, -125 Pa, 10MM and ±4% on

- 00, -60 Pa, -6MM ranges), throughout

range at 70°F (21.1°C).

Pressure Limits: -20 in Hg to 15 psig†

(-0.677 to 1.034 bar); MP option: 35

psig (2.41 bar); HP option: 80 psig

(5.52 bar).

Overpressure: Relief plug opens at

approximately 25 psig (1.72 bar),

standard gages only.

†For applications with high cycle rate within gage total pressure rating, next higher

rating is recommended. See Medium and High pressure options.

v

Temperature Limits: 20 to 140°F*

(-6.67 to 60°C). -20°F (-28°C) with low

temperature option.

Size: 4˝ (101.6 mm) diameter dial face.

Mounting Orientation: Diaphragm in

vertical position. Consult factory for

other position orientations.

Process Connections: 1/8˝ female

NPT duplicate high and low pressure

taps - one pair side and one pair back.

Weight: 1 lb 2 oz (510 g), MP & HP 2

lb 2 oz (963 g).

Standard Accessories: Two 1/8˝ NPT

plugs for duplicate pressure taps, two

1/8˝ pipe thread to rubber tubing

adapter, and three flush mounting

adapters with screws. (Mounting and

snap ring retainer substituted for three

adapters in MP & HP gage

accessories.)

Agency Approval: RoHS. Note: -SP

models not RoHS approved.

A-605B Air Filter Gage Accessory Kit, Air filter kit with two plastic open/close

valves, two 4˝ steel static tips, plastic tubing and mounting flange

A-605C Air Filter Gage Accessory Kit, Air filter kit with two plastic open/close

valves, two plastic static tips, plastic tubing and mounting flange

4

DWYER INSTRUMENTS, INC. | www.dwyer-inst.com

Model A-605 Air Filter Gage Accessory Kit

Adapts any standard Magnehelic

an air filter gage. Includes aluminum surface

mounting bracket with screws, two 5 ft (1.5 m)

lengths of 1/4˝ aluminum tubing two static pressure

tips and two molded plastic vent valves, integral

compression fittings on both tips and valves.

®

gage for use as

Flush, Surface, Integrated Plate or Pipe Mounted

Enclosure Mounted

uSee page 7 (Magnehelic®Gage Mounting Accessories)

vOver Protection Note: See page 5 (Series 2000)

Page 2

Series

2000

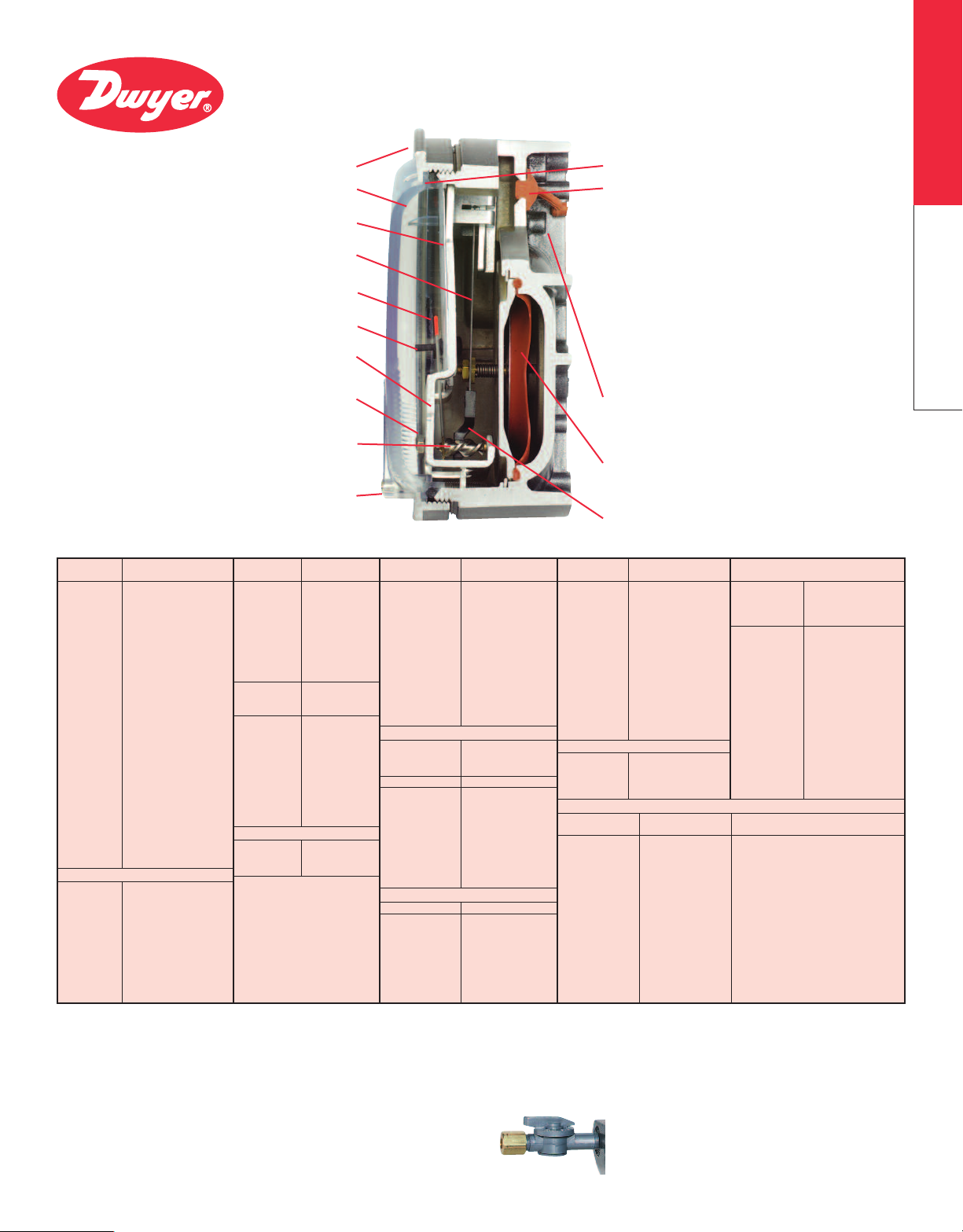

ezel provides flange for flush mounting in panel.

B

lear plastic face is highly resistant to breakage. Provides

C

ndistorted viewing of pointer and scale.

u

recision litho-printed scale is accurate and easy to read.

P

alibrated range spring is flat spring steel. Small amplitude

C

f motion assures consistency and long life. It reacts to

o

ressure on diaphragm. Live length adjustable for calibration.

p

ed tipped pointer of heat treated aluminum tubing is easy

R

o see. It is rigidly mounted on the helix shaft.

t

ointer stops of molded rubber prevent pointerover-travel

P

ithout damage.

w

Wishbone” assembly provides mounting for helix, helix

“

earings and pointer shaft.

b

eweled bearings are shock-resistant mounted;provide

J

irtually friction-free motion for helix. Motion damped with

v

igh viscosity silicone fluid.

h

Helix is precision made from an alloy of high magnetic

permeability. Mounted in jeweled bearings, it turns freely,

following the magnetic field to move the pointer across

the scale.

Zero adjustment screw is conveniently located in the plastic

cover, and is accessible without removing cover.

O-ring seal provides pressure tightness.

Magnehelic®Gage Models & Ranges

-ring seal for cover assures pressure integrity of case.

O

VERPRESSURE PROTECTION

O

lowout plug is comprised of a rubber plug on the rear which

B

unctions as a relief valve by unseating and venting the gage

f

nterior when over pressure reaches approximately 25 psig

i

1.7 bar). To provide a free path for pressure relief, there are

(

our spacer pads which maintain 0.023˝ clearance when gage

f

s surface mounted. Do not obstruct the gap created by these

i

ads.

p

he blowout plug is not used on models above 180˝ of water

T

ressure, medium or high pressure models, or on gages

p

hich require an elastomer other than silicone for the

w

iaphragm.

d

he blowout plug should not be used as a system

T

verpressure control. High supply pressures may still cause

o

he gage to fail due to over pressurization, resulting in

t

roperty damage or serious injury. Good engineering

p

ractices should be utilized to prevent your system from

p

xceeding the ratings or any component.

e

ie cast aluminum case is precision made and iridite-dipped

D

o withstand 168 hour salt spray corrosion test. Exterior

t

inished in baked dark gray hammerloid. One case size is

f

used for all standard pressure options, and for both surface

and flush mounting.

Silicone rubber diaphragm with integrally molded O-ring is

supported by front and rear plates. It is locked and sealed in

position with a sealing plate and retaining ring. Diaphragm

motion is restricted to prevent damage due to overpressures.

Samarium Cobalt magnet mounted at one end of range spring

rotates helix without mechanical linkages.

PRESSURE

Differential Pressure Gages

*

*

Range Inches

of Water

.05-0-.2

0-.25

0-.50

0-1.0

0-2.0

0-3.0

0-4.0

0-5.0

0-6.0

0-8.0

0-10

0-12

0-15

0-20

0-25

0-30

0-40

0-50

0-60

0-80

0-100

0-120

0-150

0-160

0-180

0-250

0.125-0-0.125

.25-0-.25

.5-0-.5

1-0-1

2-0-2

5-0-5

10-0-10

15-0-15

Model

2201

2202

2203

2204

2205

2210*

2215*

2220*

2230**

Model

2000-15CM

2000-20CM

2000-25CM

2000-50CM

2000-80CM

2000-100CM

2000-150CM

2000-200CM

2000-250CM

2000-300CM

Zero Center Ranges

2300-4CM

2300-10CM

2300-30CM

†These ranges calibrated

for vertical scale position.

• Accuracy +/-3%

• • Accuracy +/-4%

*MP option standard

**HP option standard

Model

2000-00N†••

2000-00†••

2000-0†•

2001

2002

2003

2004

2005

2006

2008

2010

2012

2015

2020

2025

2030

2040

2050

2060

2080

2100

2120

2150

2160

2180

2250

Zero Center Ranges

2300-00†••

2300-0†•

2301

2302

2304

2310

2320

2330

VELOCITY AND VOLUMETRIC FLOW UNITS

Scales are available on the Magnehelic®that read in velocity units (FPM, m/s) or

volumetric flow units (SCFM, m3/s, m3/h). Stocked velocity units with dual range

scales in inches w.c. and feet per minute are shown above. For other ranges contact

the factory.

When ordering volumetric flow scales please specify the maximum flow rate and its

corresponding pressure. Example: 0.5 in w.c. = 16,000 CFM.

Range

PSI

0-1

0-2

0-3

0-4

0-5

0-10

0-15

0-20

0-30

Range,

CM of

Water

0-15

0-20

0-25

0-50

0-80

0-100

0-150

0-200

0-250

0-300

2-0-2

5-0-5

15-0-15

Model

2000-6MM†••

2000-10MM†•

2000-15MM

2000-25MM

2000-30MM

2000-50MM

2000-80MM

2000-100MM

2000-125MM

2000-150MM

2000-200MM

2000-250MM

2000-300MM

Zero Center Ranges

2300-6MM†••

2300-10MM†•

2300-20MM†•

Model

2000-60NPA†••

2000-60PA†••

2000-100PA†•

2000-125PA†•

2000-250PA

2000-300PA

2000-500PA

2000-750PA

2000-1000PA

Zero Center Ranges

Model

2300-60PA†••

2300-100PA†•

2300-120PA

2300-200PA

2300-250PA

2300-300PA

2300-500PA

2300-1000PA

CONTACT US | U.S. 219/879-8000 | U.K. (+44) (0)1494-461707 | A.U. (+61) (0) 2 4272 2055 | China +852-23181007

Range MM

of Water

0-6

0-10

0-15

0-25

0-30

0-50

0-80

0-100

0-125

0-150

0-200

0-250

0-300

3-0-3

5-0-5

10-0-10

Range, Pa

10-0-50

0-60

0-100

0-125

0-250

0-300

0-500

0-750

0-1000

Range, Pa

30-0-30

50-0-50

60-0-60

100-0-100

125-0-125

150-0-150

250-0-250

500-0-500

ACCESSORIES

A-321, Safety Relief Valve

A-448, 3-piece magnet kit for mounting Magnehelic

surface

A-135, Rubber gasket for panel mounting

A-401, Plastic Carry Case

Model

2000-0.5KPA

2000-1KPA

2000-1.5KPA

2000-2KPA

2000-2.5KPA

2000-3KPA

2000-4KPA

2000-5KPA

2000-8KPA

2000-10KPA

2000-15KPA

2000-20KPA

2000-25KPA

2000-30KPA

Zero Center Ranges

2300-1KPA

2300-2KPA

2300-2.5KPA

2300-3KPA

Dual Scale English/Metric Models

Model

2000-00D†••

2000-0D†•

2001D

2002D

2003D

2004D

2005D

2006D

2008D

2010D

2015D

2020D

2025D

2050D

2060D

Range,

kPa

0-0.5

0-1

0-1.5

0-2

0-2.5

0-3

0-4

0-5

0-8

0-10

0-15

0-20

0-25

0-30

.5-0-.5

1-0-1

1.25-0-1.25

1.5-0-1.5

Range,

in w.c.

0-.25

0-0.5

0-1.0

0-2.0

0-3.0

0-4.0

0-5.0

0-6.0

0-8.0

0-10

0-15

0-20

0-25

0-50

0-60

A-310A 3-Way Vent Valves

In applications where pressure is continuous and the

Magnehelic®gage is connected by metal or plastic tubing

which cannot be easily removed, we suggest using Dwyer

A-310A vent valves to connect gage. Pressure can then be

removed to check or re-zero the gage.

Dual Scale Air Velocity Units

For use with pitot tube

Model

2000-00AV†••

2000-0AV†•

2001AV

2002AV

2005AV

2010AV

Range,

Pa or kPa

0-62 Pa

0-125 Pa

0-250 Pa

0-500 Pa

0-750 Pa

0-1.0 kPa

0-1.25 kPa

0-1.5 kPa

0-2.0 kPa

0-2.5 kPa

0-3.7 kPa

0-5 kPa

0-6.2 kPa

0-12.4 kPa

0-15 kPa

Range in

W.C./

Velocity

F.P.M.

0-.25/

300-2000

0-.50/

500-2800

0-1.0/

500-4000

0-2.0/

1000-5600

0-5.0/

2000-8800

0-10/

2000-12500

®

gage directly to magnetic

5

Loading...

Loading...