Page 1

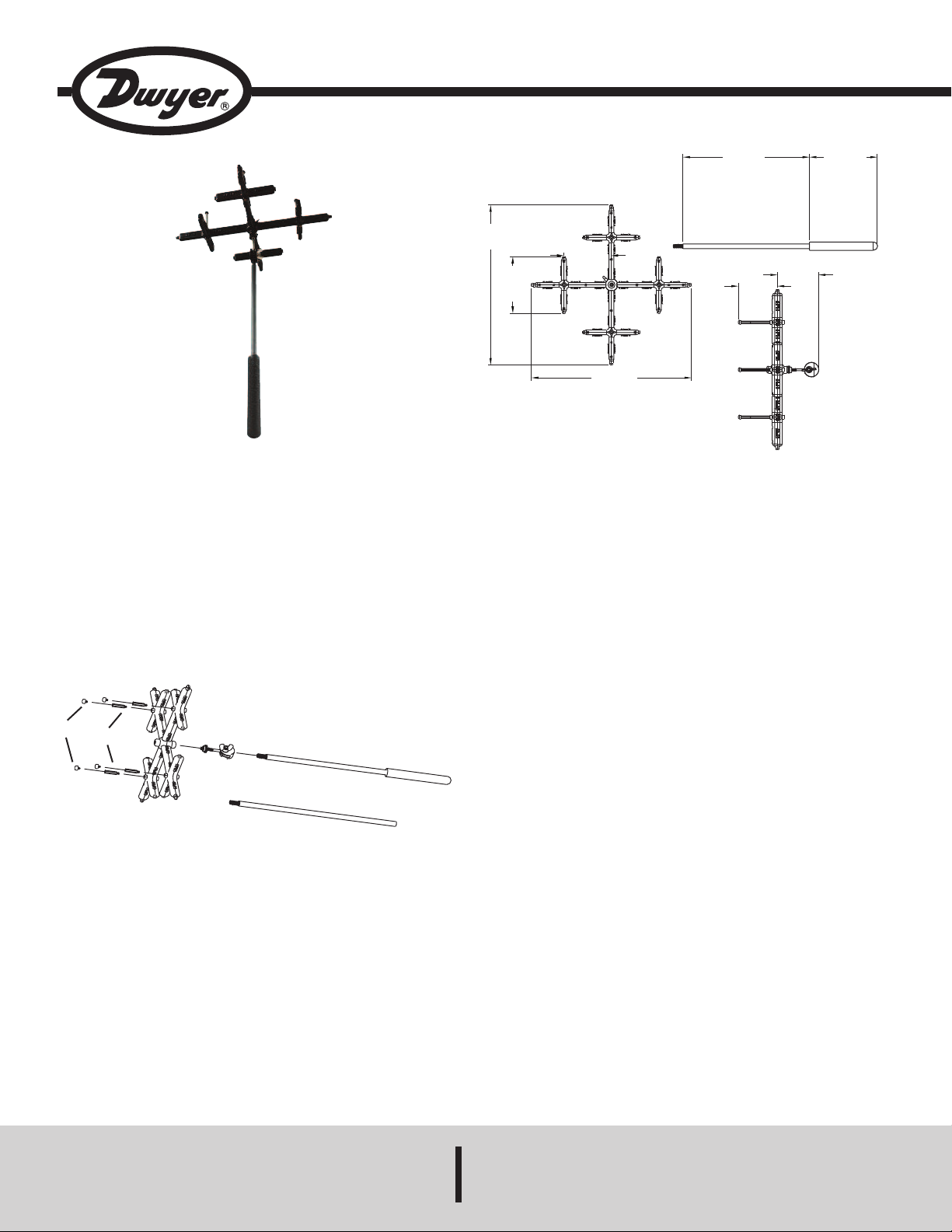

1

6-15/32

[

418.34]

1

6-15/32

[

418.34]

5-27/32

[148.34]

T

YP.

4

-7/8

[

123.95]

T

YP.

4

[

101.60]

4

-1/4

[

107.95]

7

[

177.79]

1

3

[

330.20]

Model 160G Averaging Air Flow Grid

Installation and Operating Instructions

he Model 160G Averaging Air Flow Grid is a precision sensing instrument used

T

o measure face air velocity on grills, diffusers, registers, exhaust hoods, coils,

t

filters, dampers and similar restrictions. With its 16 sensing points, the 160G Air

Flow Grid provides an average flow sensing area across its 16.5˝ length and width.

Included color coded tubing connects to the integral barbed fittings, providing a

differential pressure signal to a gage or manometer where the readings can be

converted into a velocity or flow reading. The 160G comes standard with an 18˝

handle and two 17˝ extensions offering a maximum reach of approximately 52˝.

The uniquely designed swivel and tightening nut allows the user to position the

sensing grid at any angle for ease of use in hard to reach locations. Store in the

separate UHH-C2 hard carrying case with foam cut-outs perfectly sized for the

160G, as well as various other instruments in the AQTI Air Quality Test Instruments

line.

Assembly

B

A1 or A2

C

Attach the Stand-Offs

The 160G comes with two sets of stand-offs (Parts A1 and A2 in Figure 1) that are

different heights and they can be connected to each other to form a third different

height. The stand-offs ensure the air flow grid is sitting perpendicular to the grill to

get the most accurate readings. Once the proper height stand-off is chosen, the

bumpers (Part B in Figure 1) should be attached to the stand-offs to prevent the

160G from scratching the surface around the grill. The stand-offs can be screwed

into the top side of the air flow grid (Part C in Figure 1).

Attach the Handle

Three rods are included to reach a maximum of 52˝. The rod with the handle grip

(Part E1 in Figure 1) is 18˝ long and will always be used. 17˝ extension rods (Parts

E2 and E3 in Figure 1) will be added to achieve longer lengths. The extension rods

will thread into the female thread on the swivel (Part D in Figure 1). Next, the male

thread on the swivel will thread into the air flow grid (Part C in Figure 1) on the

D

Figure 1

E2 & E3

E1

Bulletin TE-160G

PECIFICATIONS

S

ervice: Air or compatible gases.

S

etted Materials:

W

Grid: Black polycarbonate;

Swivel: Carbon steel;

Handle: SS;

Bolts: SS;

Wing Nut: SS;

Standoffs: Aluminum with rubber bumpers, two sets: 1.25˝ (31.7 mm)

Tubing: Two 10´ (3 m) lengths of silicone rubber.

Accuracy: ±2% FS.

Temperature Limits: -40 to 257°F (-40° to 125°C).

K Factor: 0.84.

Range: 1000 to 5000 FPM (5 to 25 m/s).

Process Connection: 1/8 to 1/4˝ ID tubing.

Weight: 3.5 lb (1.587 kg).

Agency Approvals: RoHS.

opposite side as the stand-offs. The plastic nut on the swivel will lock the air flow

grid in place and prevent it from spinning once it is tightened. Finally, the user can

adjust the swivel to adjust the angle at which the air flow grid is going to measure.

In order to adjust angle of the swivel, the user will loosen the wing nut located on

the side of the swivel.

Connect Tubing

The tubing provided with the air flow grid is color coordinated to help identify which

tube is going to the high pressure port and which tube is going to the low pressure

ports on both the manometer and the air flow grid. For return air grill, the pressure

port on the side of the swivel is the total/dynamic pressure (high pressure) and the

pressure port on side of the stand-offs is the static (low pressure). For a supply air

grill, the ports would be reversed.

MAINTENANCE/REPAIR

Upon final installation of the Model 160G, no routine maintenance is required. The

Model 160G is not field serviceable and should be returned if repair is needed.

Field repair should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website.

Contact customer service to receive a Return Goods Authorization number before

shipping the product back for repair. Be sure to include a brief description of the

problem plus any additional application notes.

and 2˝ (50.8 mm), 1/8˝ ID / 1/4˝ OD;

©Copyright 2013 Dwyer Instruments, Inc. Printed in U.S.A. 1/13 FR# 72-444048-00

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...