Page 1

DWYER 1207A

Flue Gas Analyzer

Dwyer Instruments Inc

P.O. Box 373

Michigan City

INDIANA, H6361

USA

Tel: 219 879 8868

Fax: 219 872 9057

Stock No: 18744-2 September 2009

Page 2

CONTENTS

Page No:

DWYER 1207A USER GUIDE 3

1. ANALYZER FEATURES AND KEYPAD 4-5

2. BEFORE USING THE ANALYZER FOR THE FIRST TIME 6

3. BEFORE USING THE ANALYZER EVERY TIME 7

4. USING THE ANALYZER AND ITS FOUR BUTTONS 8-9

5. USING THE DWYER 1207A AS A THERMOMETER OR PRESSURE

METER 10

6. USING THE ROTARY DIAL (STARTING FROM MENU) 11-13

7. MAIN MENU FUNCTIONS 14-17

8. MEASURING MODES 18-24

- MEASURING FLUE GASES 18

- STANDARD COMBUSTION PRINTOUT 19

- STORING A DRAUGHT MEASUREMENT TO PRINT WITH A

COMBUSTION TEST 20

- MEASURING PRESSURE 21

- MEASURING TEMPERATURE 22

- MEASURING AMBIENT AIR (ROOM CO) 23

- MEASURING FLUE DRAUGHT 24

9. WHEN YOU FINISH A COMBUSTION TEST 25

10. ANALYZER PROBLEM SOLVING 26

11. ANALYZER ANNUAL RECALIBRATION AND SERVICE 27

12. ANALYZER SPECIFICATION

13. ELECTROMAGNETIC COMPATIBILITY 30

(NOTE MAY BE SUBJECT TO CHANGE

) 28-29

APPENDIX 1 – MAIN PARAMETERS 31-32

1207A manual Page 2

Page 3

DWYER 1207A

User Guide

The DWYER 1207A Combustion Analyzer measures O

temperature, differential pressure and CO.

It calculates efficiency (Nett, Gross or Condensing), losses, the CO/CO

Poison Index, excess air and CO air free in ppm only.

The analyzer can be upgraded with the addition of a Nitric Oxide sensor either

on initial purchase or as a retrofit as part of an annual service procedure.

In addition the DWYER 1207A Combustion Analyzer’s CO sensor checks

carbon monoxide levels in ambient air - useful when a CO Alarm is triggered

and tests the safety of appliances.

The CO and NO readings can be referenced to the oxygen reading in ppm or

mg/m

It has a protective rubber sleeve with a magnet for “hands–free” operation and

their flue probes work on all combustion appliances and take ambient air

measurements.

The large display shows 4 readings at a time and all data can be printed via an

optional infrared printer. The printed data can be 'live' data, 'frozen' data or

'stored' data. 255 sets of tests can be stored. Note: stored data is lost if the

batteries are removed or are exhausted. Two lines of 16 characters can be added

to the header of printouts.

The analyzer is controlled using 4 buttons and a rotary dial.

The four buttons (from left to right) switch on and off the analyzer, print actual

or frozen data/ switch on and off the backlight, switch on and off the pump and

3

.

differential

2,

ratio,

2

“freeze”/ hold data. The buttons with

settings such as date, time, fuel source, etc. when in MENU mode.

The rotary dial changes the LED indicated display line and selects access to the

menu to make changes to the date, time, fuel, etc.

1207A manual Page 3

, and arrows also change

Page 4

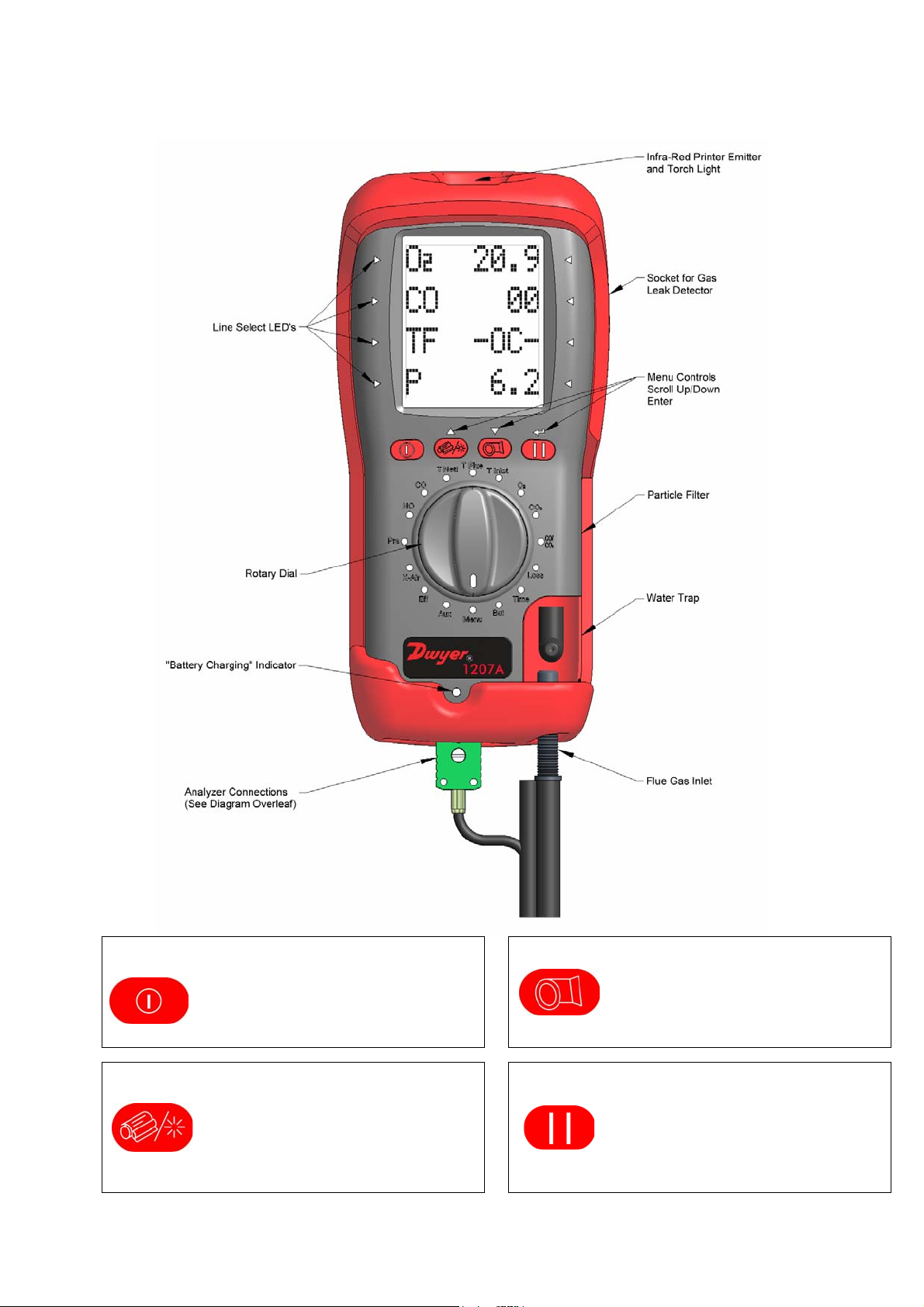

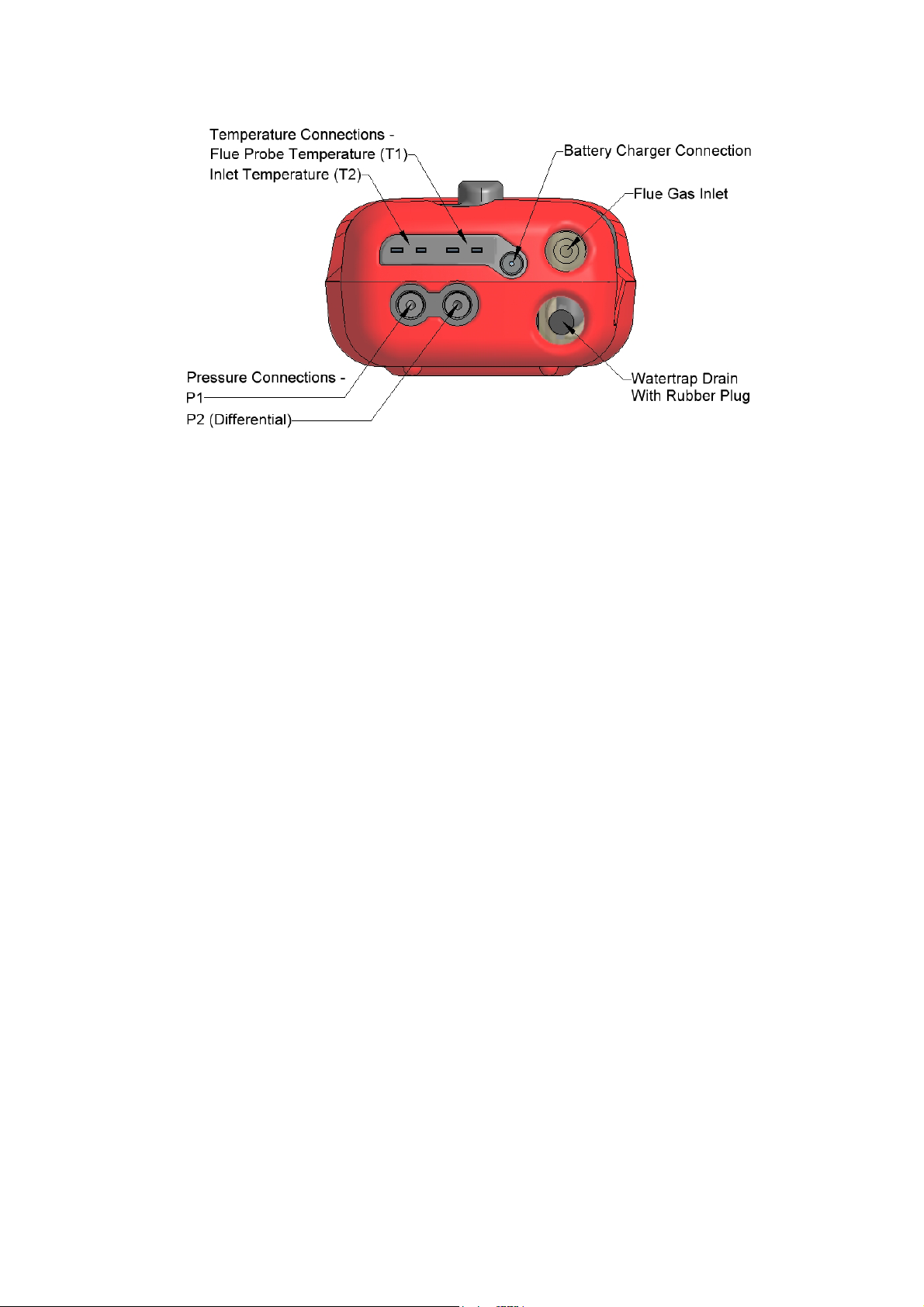

1. ANALYZER FEATURES AND KEYPAD

ON / OFF

Turns the analyzer ON / OFF

PRINT / BACKLIGHT

Press to print “live” or “frozen”

data. Press again to abort.

Press for 2+ seconds to switch

backlight & torch ON / OFF

1207A manual Page 4

PUMP / CAL PRESSURE

Turns the pump ON / OFF

Press for 2+ seconds to zero the

pressure sensor

LINE SELECT / FREEZE

Press to select active line on

display as indicated by LED’s

Press for 2 seconds to “HOLD”

Press longer to “LOG”

Page 5

1207A manual Page 5

Page 6

2. BEFORE USING THE ANALYZER FOR THE FIRST

TIME:

Turn over the analyzer, remove its’ protective rubber sleeve and fit 4 “AA” batteries in the

battery compartment. Take great care to ensure they are fitted with the correct battery

polarity. Then replace the battery cover and protective rubber sleeve. Always check that the

analyzer is working correctly after replacing batteries.

Set the analyzer’s correct time, date, fuel source, etc., after it is switched on and calibrated –

See USING THE ROTARY DIAL below. These settings are stored when the analyzer is

switched off.

Using Re-Chargeable Batteries.

This analyzer has been designed for use with both alkaline and rechargeable Nickel Metal

Hydride (NMiH). No other battery types are recommended.

WARNING

The battery charger unit must only be used when NMiH batteries are fitted.

NMiH batteries are entirely suitable for top up charging at any time, even for shorts periods.

Alkaline batteries are not re-chargeable. Attempting to recharge Alkaline batteries may result

in damage to the product and may create a fire risk.

Ensure the batteries are fitted in the correct manner.

Charger

Ensure that you use the correct charger. The part number is KMCU450/US.

An in-vehicle adapter can be used to top up the analyzer's batteries from a 12 volt vehicle

battery. The part number is KMCU450/ 12.

Trickle Charging

subsequently charge overnight for approx. 8 hours.

Fast Charging

analyzer off. The display will then show "BATTERY CHARGING".

Battery Disposal

Always dispose of depleted batteries using approved disposal methods that protect the

environment.

: On first charging, charge for at least 12 hours continuously,

: With the analyzer switched on connect the charger and then switch the

1207A manual Page 6

Page 7

3. BEFORE USING THE ANALYZER EVERY TIME:

Check the water trap is empty and the particle filter is not dirty:

- To empty water trap, unplug its’ rubber stopper and re-plug once it is empty.

- To change the filter, remove protective rubber sleeve, pull out the water trap unit from

the analyzer, remove the water trap’s particle filter from its’ spigot and replace.

Reconnect the water trap and rubber protective sleeve.

Connect the flue probe into the bottom of the analyzer’s water trap and connect the probe’s

temperature plug to the socket next to the water trap – check the plug’s orientation is correct

otherwise incorrect temperature measurements will occur.

After switch on, check fuel source, date and time are correct and battery power is sufficient.

SAFETY WARNING

This analyzer extracts combustion gases that may be toxic in relatively low concentrations.

These gases are exhausted from the back of the instrument. This analyzer must only be used

in well-ventilated locations by trained and competent persons after due consideration of

all the potential hazards.

Sensor manufacturers recommend users of portable gas detectors containing electrochemical

sensors conduct a “bump” check before relying on the unit to verify an atmosphere is free

from hazard.

A “bump” test is a means of verifying that an instrument is working within acceptable limits

by briefly exposing to a known gas mixture formulated to change the output of all the sensors

present. (This is different from a calibration where the instrument is also exposed to a known

gas mixture but is allowed to settle to a steady figure and the reading adjusted to the stated gas

concentration of the test gas.)

For Oxygen monitors a level of confidence that the unit is working adequately may be gained

by exhaling over the sensor inlet and viewing the reduction in reading obtained.

1207A manual Page 7

Page 8

4. USING THE ANALYZER AND ITS FOUR BUTTONS:

Switching ON

the Analyzer

Switching OFF

the Analyzer

Press to switch the unit ON in fresh air outside the property about

to be tested. This lets the analyzer auto calibrate its’ sensors properly.

On switch on, the analyzer beeps four times and displays the fuel

previously selected, the date and time and model number. Its’ bottom line

counts down from 60 until the sensors are ready to use – This normally

takes 20 - 30 seconds but may take longer as sensors get older. If the

analyzer will not auto calibrate, its’ sensors need to be replaced or

recalibrated by an authorized repair center.

If the inlet probe is connected to the analyzer during its’ countdown the

measured temperature from the inlet probe will be used as the inlet

temperature.

If the inlet probe is not connected and you connect the flue probe’s

temperature plug to the analyzer during countdown the measured

temperature from the flue probe will be used as the inlet temperature.

If neither probe is connected during countdown the analyzer’s internal

ambient temperature will be used as the inlet temperature.

Press to switch the analyzer OFF. The display counts down from

30 with the pump on to clean the sensors with fresh air – If the probe is

still connected, make sure analyzer and probe are in fresh air.

Press / if you want to stop the countdown and return to

making measurements.

Note: the analyzer will not switch off until the CO reading is below

20 ppm.

Using UP /

DOWN /

ENTER Buttons

Printing Data

1207A manual Page 8

Use the / / keys to change settings (such as time, date

and fuel) when the rotary dial is turned to MENU.

Press and quickly release the key to start the analyzer printing. The

analyzer displays "PRINTING" until this is completed. Press and release

the key again to abort printing.

Make sure the printer is switched on, ready to accept data and its’ infrared

receiver is in line with the analyzer’s emitter (on top of the analyzer).

Page 9

Backlight

Tasklight

Switching

PUMP on / off

Zeroing the

pressure sensor

“Freezing” the

display

Press and hold to toggle the display's backlight.

Note: use of the backlight increases the current drain on the batteries.

Comes on with the display's backlight... see above.

The analyzer normally operates with the pump on. Press quickly

to switch the pump off and on.

When the pump is switched off, the analyzer displays "PUMP OFF"

approx every 30 seconds.

NOTE: the pump will not switch off if the CO reading is above

20 ppm. This helps to protect the CO sensor from damage.

NOTE: the pump cannot be switched off with the rotor set to

-----------MENU.

Press and hold the key until the top line display shows ZERO

CAL.

Press and hold the / key until a second beep is heard to

freeze all readings. The display flashes and readings can be printed by

pressing key. Press and hold the / key again until a

second beep is heard to go back to “live” measurements.

The

function is inhibited when the display LEDs are flashing.

Storing a set of

readings

Press and hold the

Note: this STORE function is inhibited if the display LEDs are flashing.

/ key for approx. 4 seconds.

Note: this STORE function is inhibited in normal operation if the pump is

switched off.

Changing the

display's active

line

Press and release the

the display line that you wish to change. While the LEDs are flashing

turn the rotary dial to display the parameter that you want. If the rotary

dial is not turned the active line will go back to its previous setting after

/ key until the illuminated LEDs point at

approx. 5 secs.

1207A manual Page 9

Page 10

5. USING THE DWYER 1207A AS A THERMOMETER OR

PRESSURE METER

With the analyzer switched off, press and hold down the button and then press and

release the button, then release the button.

The DWYER 1207A will now operate as a fixed display pressure meter/thermometer with the

pump off and inhibited.

The display will show: pressure

flue temp

inlet temp

differential temp

The rotary dial display indications will now be locked apart from MENU. Readings can be

held and logged in the normal way. Up to 8 sets of readings can be logged.

Exit this mode by switching the DWYER 1207A off.

The standard printout for this mode is as follows:

DWYER 1207A 1.0

Serial No. 123456789

DATE 11/01/09

TIME 09:53:23

..............................................

PRS INWG 0.001

T1 48

T2 15

∆T 33

1207A manual Page 10

Page 11

6. USING THE ROTARY DIAL (starting from Menu):

Rotating the dial selects the displayed parameter, unless MENU is selected or the

pressure/temperature mode has been selected.

ROTARY DIAL POSITIONS

MENU

BAT

TIME

LOSS

CO/CO2 ratio

CO

2

O

2

T inlet

T Flue

Switches to MENU function.

Displays estimated battery life.

If battery voltage falls below a pre-set limit, the display flashes

"LOW BAT" every 10 seconds. See Page 6 to change the batteries

or re-charge, if applicable.

Displays Time.

Displays calculated losses when O2 values are less than 18%.

Measured CO divided by calculated CO2 when O2 values are less

than 18%

.

Displays calculated Carbon Dioxide values once O2 values are

below 18%.

Displays Oxygen values in %.

Displays the inlet probe temperature.

Displays flue probe temperature.

If the flue probe’s temperature sensor is broken or open circuit it

displays - OC -.

1207A manual Page 11

Page 12

T Nett

CO

NO

(if fitted)

PRS

X AIR

EFF

AUX

Displays the difference between flue and inlet / ambient

temperatures.

If the flue probe’s temperature sensor is broken or open circuit it

displays - OC -.

Displays Carbon Monoxide values in PPM as CO

in ppm normalized ac COn

Display value in mg/m3 as COm

in mg/m3 normalized as COĦ

Displays Nitric Oxide values in PPM as NO

in ppm normalized as NOn

Display value in mg/m3 as NOm

in mg/m3 normalized as NOĦ

Display the measured pressure or draft value in user selected units.

Displays calculated excess air when O2 values are less than 18%.

Displays calculated efficiency when O2 values are less than 18%

EFFn, EFFg or EFFc as selected by the user.

Addition user selectable displays.

Rotate the dial to MENU and use the or buttons to select the following function

for change:

When you have selected the function to change, press

Repeat this to scroll through the menu and select (using the

to select.

key) and change (using the

/ keys) the function.

The final, logical returns you to the main menu display.

To exit the Menu function you can normally rotate the dial to another position - Unless the

final logical is pressed, no changes are made.

1207A manual Page 12

Page 13

The exception is:

STORE DELETE where the key must be pressed to confirm the

change and exit. If you rotate the dial before pressing the

instrument will beep continuously. You must rotate the dial back to

MENU and press before you can continue.

In STORE View mode the rotary dial is used to select the saved parameter to be displayed.

Use the / keys to change the Test number. To exit the View mode press .

1207A manual Page 13

Page 14

7. MAIN MENU FUNCTIONS

There are six menu headings each with its own sub-menu

SETUP

PRESSURE

STORE

REPORTS

SCREEN

SERVICE

Fuel selection

Efficiency calculation

Time and date setting

Temperature unit

Gas units

Oxygen referencing

Language

Exit

Smoothing

Resolve (number of decimal points resolution)

Number of decimal points resolution

Units

Time

Exit

View

Auto store

Delete

Exit

Pressure

Temperature

Room CO

Draught

Exit

Contrast

Auxiliary display

Header

Exit

Password protected

1207A manual Page 14

Page 15

SETUP

SET FUEL

N < -C- > G

SET TIME

SET DATE

C <---> F

PPM < - > MG

NATU GAS

L OIL

PROPANE

BUTANE

L.P.G.

PELLETS

N

C

G

xx: yy: zz

HH: MM: SS

MM- DD- YY

DD- MM- YY

YY- MM- DD

F

C

ppm

MG/M3

Set fuel type

Nett

Condensing

Gross efficiency calculation

Set time values

Choose date format then set date

values

Fahrenheit

Centigrade

Parts per million

Milligrams per cubic meter

O2 REF

LANGUAGE

NO

YES

English

French

Italian

German

Spanish

Dutch

Swedish

Set reference value

Set language

1207A manual Page 15

Page 16

PRESSURE

SMOOTH

POINTS

PS UNITS

OFF

ON

LOW

HIGH

inH2O

mBAR

mmH2O

Pa

kPa

PSI

mmHg

hPa

Select smoothing

Select decimal point resolution

Select pressure units

STORE up to 255 sets of combustion test results can be stored

VIEW

TEST xxx Enter test number to be viewed then

use rotary dial to select display.

If less than 9 set of readings are stored

rotate the dial then use the up/down

buttons to change the LOG number.

AUTO STO

DEL ALL

YES/NO If YES set logging time interval in

minutes.

YES/NO Clears stored values.

REPORT

There are dedicated report formats for the following tests:

Pressure

Temperature

Room CO

Draught

All report menus follow the format TEST / VIEW / DEL ALL.

The TEST functions are described later.

1207A manual Page 16

Page 17

SCREEN

CONTRAST

AUX

HEADER

SET xx Lighten or darken the display

Selected Fuel

Assign the AUX rotary dial position

Pressure units

COM

Date

CO air free

O2 Reference value

Header 1

Header 2

2 lines each of 20 characters

1207A manual Page 17

Page 18

8. MEASURING MODES

MEASURING FLUE GASES

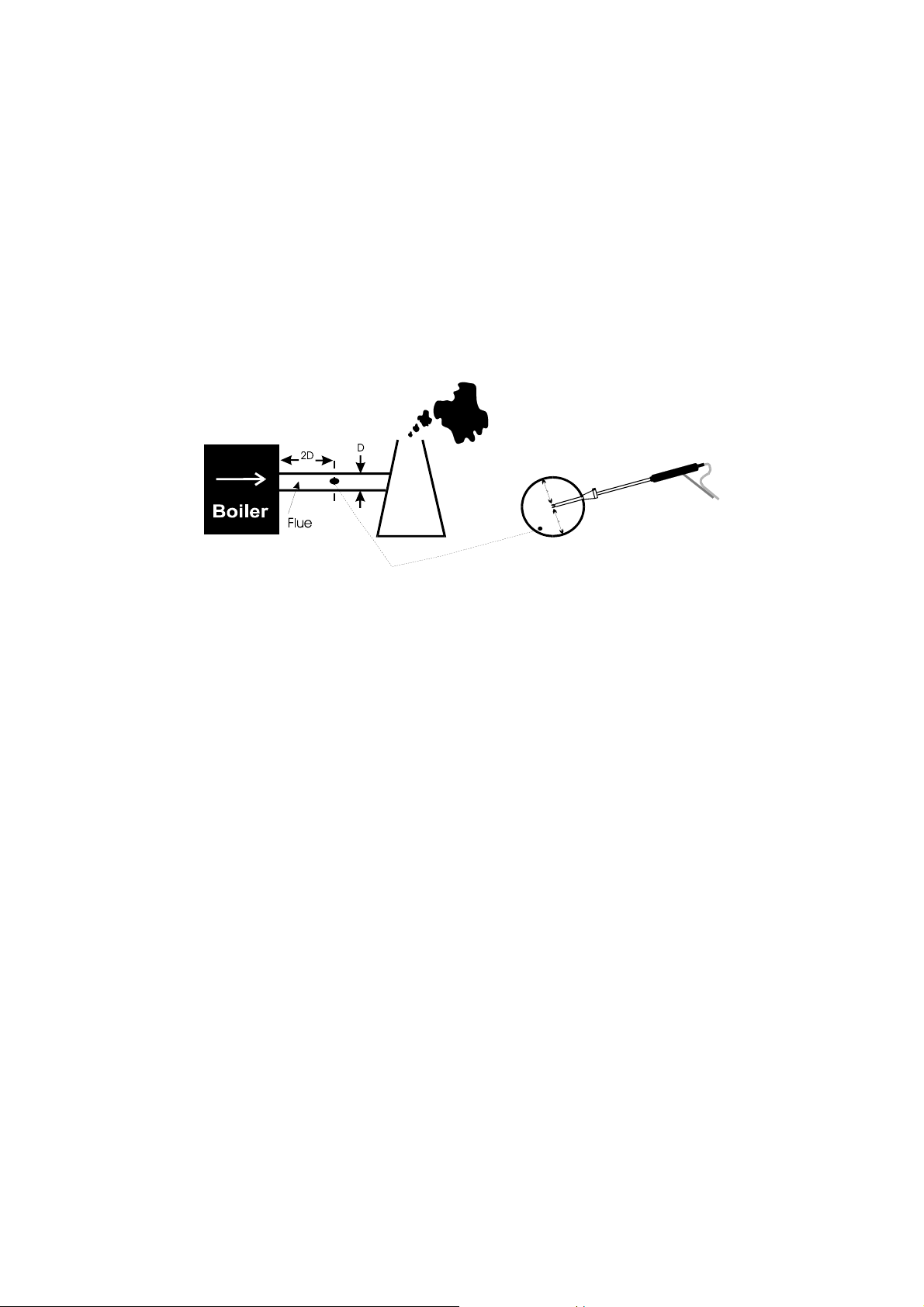

After the countdown is finished and the analyzer is correctly set up, put its’ flue probe into the

appliance’s sampling point. The ideal sampling point is at least two flue diameters

downstream of any bend.

Put the probe tip in the flue center. With balanced flues, make sure the probe is positioned far

enough into the flue so no air can ‘back flush’ into the probe.

Use the probe’s depth stop cone to fix it in flue diameters from 1/4 to 4/5 inch, 6 to 21 mm. Its

maximum operating temperature is 1112°F / 600°C.

Make sure you do not exceed the analyzer’s operating specifications. In particular:

• Do not exceed the flue probe’s maximum temperature

• Do not exceed the analyzer’s internal temperature operating range

• Do not put the analyzer on a hot surface

• Do not exceed the water trap’s levels

• Do not let the analyzer’s particle filter become dirty and blocked

View the displayed data to ensure that stable operating conditions have been achieved and the

readings are within the expected range.

Press PRINT or press HOLD first to “freeze” or store the readings before printing.

1207A manual Page 18

Page 19

STANDARD COMBUSTION PRINTOUT

DWYER 1207A 1.0 /product code

Serial No. 123456789 /serial number

/user header 1

/user header 2

DATE 11/01/09

TIME 09:53:23

..............................................

FUEL NATU GAS

O2 % 5.1

CO2 % 9.0

CO ppm 400

NO ppm n/f /NO sensor not fitted

FLUE oF 48

INLT oF 15

NETT oF 33

EFF (C) 102.1 /condensing efficiency

PRS INWG 0.001

Losses % -2.1

XAIR % 32.1

CO/CO2 0.0044

PI 0.44

O2 ref % 0.0

SMOKE......................................

....................................................

1207A manual Page 19

Page 20

STORING A DRAUGHT MEASUREMENT TO PRINT WITH A

COMBUSTION TEST

Rather than print a draught test report and then a combustion test report it is possible to

combine the two sets of results on one printout by taking a draught reading first and storing it

for printing later.

The following sequence must be followed:

With PRESSURE on the top line and with the rotary dial pointing to Prs... and with the pump

off..... then if LOG is activated the current pressure reading will be stored in the draught

register with its current scaling. All the conditions must be met and no other values will be

logged. As this occurs the top line display briefly shows "DRAUGHT".

While the instrument is in this mode activating LOG again will overwrite the stored reading.

The stored reading is cleared whenever the analyzer is switched off or by entering any

REPORT menu.

Resuming normal operation adds the stored DRAUGHT reading to any combustion printout

or any combustion log. In such cases the printout changes so instead of "PRS" being printed

"DRGT" is printed instead.

NOTE: Whenever there is a stored DRAUGHT reading the current pressure reading is

ignored and the stored reading is always used.

WARNING: This means that if a user stores a draught reading from one appliance and goes

to another appliance without switching off or re-entering the reports menu his printouts and

logs will show the last stored draught reading and its scaling.

1207A manual Page 20

Page 21

MEASURING PRESSURE

The analyzer can be used to measure pressure by connecting tubing to the appropriate ports.

Standard Pressure Report ....

this mode is accessed via the MENU function.

This mode allows a tightness test to be carried out automatically.

The times for the test can be set by the user.

From the start of the test the analyzer waits 60 secs to allow temperature stabilization, then

records and displays the pressure reading at the start of a 120 second countdown. The live

pressure reading is displayed during the 120 second countdown and then locked at the end of

the countdown. The display then shows start pressure and finish pressure. The summary

results can then be printed as below:

Pressure Test Printout

DWYER 1207A 1.0

Serial No. 123456789

..............................................

Tightness Test

..............................................

LOG 03

TIME 14:58 11/01/09

PRS_1 INWG 20.110

PRS_2 INWG 19.998

Duration mins 2:00

................................................

customer

................................................

appliance

.................................................

Ref:

..................................................

1207A manual Page 21

Page 22

MEASURING TEMPERATURE

The analyzer can be used as a normal single input or differential thermometer, ideal for

measuring flow and return temperatures or for setting up hot water temperature/flow on a

combi boiler.

Standard Temperature Report ....

DWYER 1207A 1.0

Serial No. 123456789

..............................................

Temp Test

..............................................

LOG 05

TIME 10:15 11/01/09

T1

T2 oF 24.1

∆T oF 30.0

...............................................

Customer

...............................................

Appliance

...............................................

Ref:

.................................................

o

F 54.1

this mode is accessed via the MENU function.

1207A manual Page 22

Page 23

MEASURING AMBIENT AIR (ROOM CO)

The analyzer's CO sensor can be used to detect spillage from appliances. A standard spillage

test can be conducted where the analyzer automatically records 16 sets of 1 minute samples

and prints the results as below:

Standard Room CO Report ....

DWYER 1207A 1.0

Serial No. 123456789

..............................................

Room CO Test

..............................................

LOG 05

TIME 16:58 11/01/09

TEST CO ppm

0 1

1 5

2 7

3 9

4 10

5 13

6 16

7 24

8 30

9 28

10 18

11 14

12 10

13 6

14 4

15 3

........................................

MAXIMUM CO 30

.........................................

Customer

.........................................

Appliance

..........................................

Ref:

...........................................

this mode is accessed via the MENU function.

1207A manual Page 23

Page 24

MEASURING FLUE DRAUGHT

STANDARD DRAUGHT REPORT

DWYER 1207A 1.0

Serial No. 123456789

..............................................

Draught

..............................................

TIME 15:58 11/01/09

PRS INWG 0.54

..............................................

customer

..............................................

appliance

..............................................

Ref:

...............................................

1207A manual Page 24

Page 25

9. WHEN YOU FINISH A COMBUSTION TEST

Remove its’ probe from the flue - THE PROBE WILL BE HOT - and let it cool. Do not put

the probe in water which will be sucked into the analyzer, damaging its’ pump and sensors.

When the analyzer’s readings return to ambient levels, switch it off. The analyzer counts

down from 30 before switch off with the pump running to self clean its sensors.

1207A manual Page 25

Page 26

10. ANALYZER PROBLEM SOLVING

If any problems are not solved with these solutions, contact us or an authorized repair center.

Fault symptom Causes / Solutions

• Oxygen too high

• CO2 too low

• Oxygen reading (- - - -)

• CO reading (- - - -)

• Batteries not holding charge

• Analyzer not running on mains

adapter

• Analyzer does not respond to flue

gas

• Net temperature or Efficiency

calculation incorrect

• Air leaking into probe, tubing, water trap, connectors

or internal to analyzer.

• Oxygen cell needs replacing.

• Analyzer was stored in a cold environment and is not

at normal working temperature.

• Oxygen cell or CO sensor needs replacing.

• Pump is switched off.

• Batteries exhausted.

• AC charger not giving correct output.

• Fuse blown in charger plug.

• Particle filter blocked.

• Probe or tubing blocked.

• Pump not working or damaged with contaminants.

• Ambient temperature set wrong during Automatic

Calibration.

• Flue temperature readings erratic • Temperature plug reversed in socket.

• Faulty connection or break in cable or plug.

• T flue or T nett displays (- - - -) • Probe not connected.

• X-Air, EFF, COa or CO2 display

(- - - -)

• Analyzer just continually beeps

• BAT only shows 65 with fully

charged NiMh batteries fitted

• Oxygen reading is above 18%.

• Turn dial back to MENU and press

• This is not a problem and is to be expected as NiMh

batteries only deliver 1.25 V per cell whereas

Alkalines deliver 1.5 V per cell. Fresh alkalines might

give a BAT value of 80 or so.

.

1207A manual Page 26

Page 27

11. ANALYZER ANNUAL RECALIBRATION AND SERVICE

Although sensor life is typically more than two years, the analyzer should be re-calibrated and

serviced annually to stop any long-term sensor or electronics drift or accidental damage.

Local regulations may require more frequent re-calibration.

Contact us or an authorized repair center for more information.

1207A manual Page 27

Page 28

12. ANALYZER SPECIFICATION

(NOTE MAY BE SUBJECT TO CHANGE)

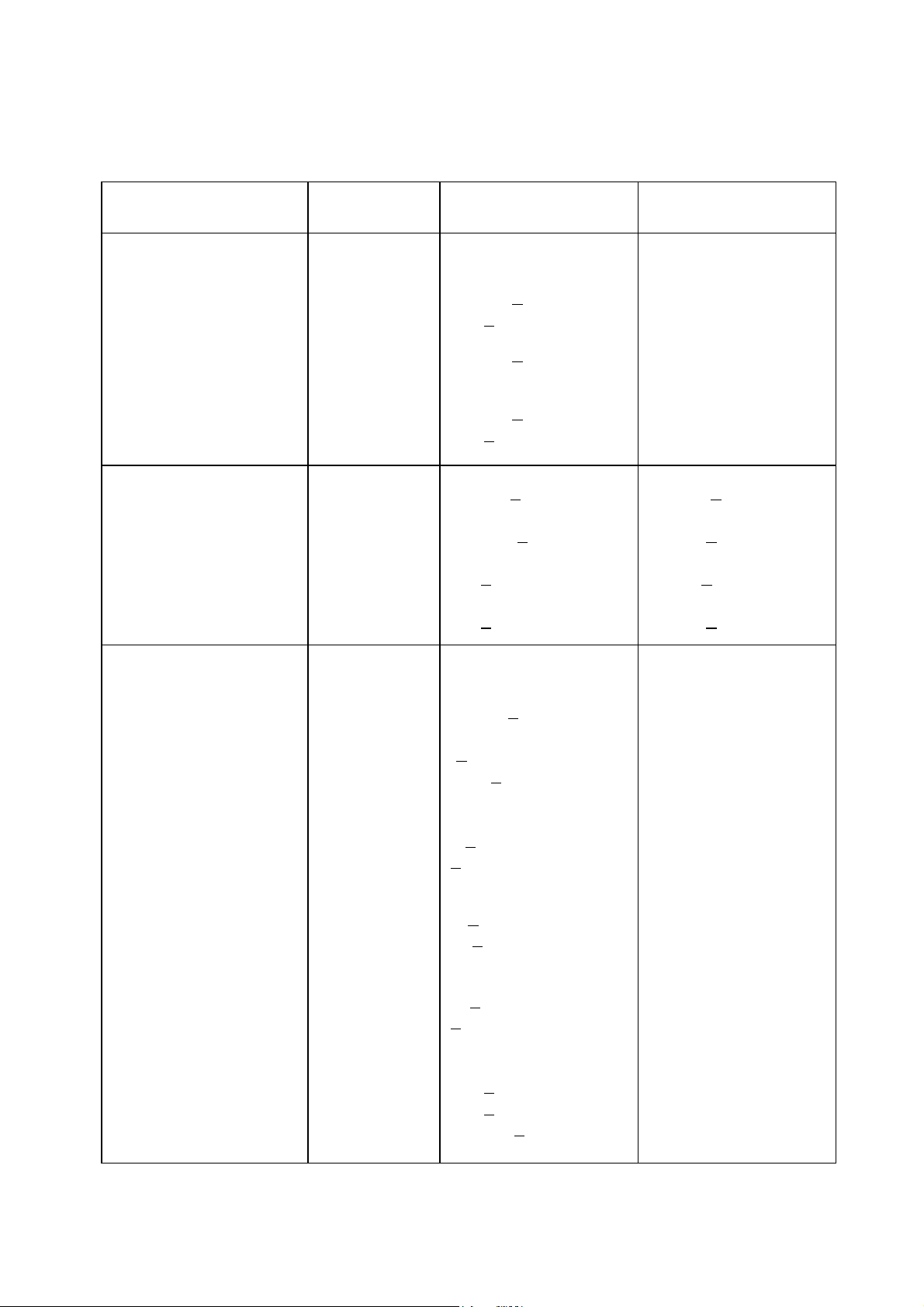

Parameter

Temp Measurement

Flue Temperature

Inlet Temperature

(Internal Sensor)

Inlet Temperature

(External Sensor)

Pressure Measurement

Gas Measurement

Oxygen

Carbon Monoxide (CO)

(low range)

Carbon Monoxide (CO)

(high range)

Nitric Oxide (NO)

(low range)

Nitric Oxide (NO)

(high range)

*2

Carbon Dioxide

Efficiency

*2

Excess Air*2

Resolution

0.1°C/F

0.1°C/F

0.1°C/F

0.1 Pa

0.1 Pa

1 Pa

0.01 hPa

0.1%

1 ppm

1 ppm

1 ppm

1 ppm

0.1%

0.1%

0.1%

+0.3% reading

±0.3% reading

+0.3% reading

+3% of reading

+3% of reading

+10 ppm <100 ppm *1

+

+10 ppm <100 ppm

+

5% reading >100 ppm

+2 ppm <30 ppm*1

+5 ppm > 30 ppm

+5 ppm <100 ppm

+5% reading >100 ppm

+

+

Accuracy

+2.0°C

+1.0°C

+2.0°C

+0.5 Pa

+3 Pa

+0.2%*1

5% reading

0.3% reading

1.0% reading

+0.2%

Range

0-600°C / 32-1112oF

0-50°C / 32-122oF

0-600°C / 32-1112oF

+20 Pa

+100 Pa

+2000 Pa

+80 hPa

0-21%

0-2000 ppm nom

4000 ppm max

for 15 minutes

0-4,000 ppm

0 to 100 ppm

0 to 1000 ppm

0-30%

0-99.9%

0-250%

1207A manual Page 28

Page 29

Pre-programmed Fuels

Dimensions

Weight

Handset

Probe

Ambient Operating Range

Storage Capacity

Battery Life

AC Battery Charger

(optional)

*1

Using dry gases at STP

Natural gas, Light Oil, Propane, Butane, LPG, Wood Pellets.

0.77kg / 2.2lb handset with protective cover

200mm / 7.9” x 45mm / 1.8” x 90mm / 3.5”

L300mm / 11.8” x Dia 6mm / 0.25” with 200mm / 7.8” long

stainless steel shaft, type K thermocouple and 3m / 10ft long

neoprene hose

+0°C to +40°C / 32-104°F

10% to 90% RH non-condensing

99 Combustion tests

20 Pressure tests

20 Tightness tests

20 Temperature tests

20 Room CO tests

4 AA cells

>12 hours using Alkaline AA cells

Input: 110VAC/220 VAC nominal

Output: 10 VAC off load

*2

Calculated

1207A manual Page 29

Page 30

13. ELECTROMAGNETIC COMPATIBILITY

European Council Directive 89/336/EEC requires electronic equipment not to generate

electromagnetic disturbances exceeding defined levels and have adequate immunity levels for

normal operation. Specific standards applicable to this analyzer are stated below.

As there are electrical products in use pre-dating this Directive, they may emit excess

electromagnetic radiation levels and, occasionally, it may be appropriate to check the analyzer

before use by:

Use the normal start up sequence in the location where the analyzer will be used.

Switch on all localized electrical equipment capable of causing interference.

Check all readings are as expected. A level of disturbance is acceptable.

If not acceptable, adjust the analyzer’s position to minimize interference or switch off,

if possible, the offending equipment during your test.

At the time of writing this manual (February 2009) we are not aware of any field based

situation where such interference has occurred and this advice is only given to satisfy the

requirements of the Directive.

This product has been tested for compliance with

the following generic standards:

EN 61000-6-3

EN 61000-6-1

and is certified to be compliant

Specification EC/EMC/KI/K450 details the

specific test configuration, performance and

conditions of use.

Please Note:

Batteries used in this instrument should be disposed of in accordance with

current legislation and local guidelines.

At the end of the product's life it should be re-cycled in accordance with current

legislation and local guidelines.

1207A manual Page 30

Page 31

Appendix 1 - Main Parameter:

Here are the legends used and what they mean:

O2 : Oxygen reading in percentage (%).

O2R: Oxygen reference setting. '----' means switched off or set to 0%.

T Flue: Temperature measured by the flue gas probe in Centigrade or Fahrenheit. It

displays ‘- OC -’ if the flue probe is disconnected.

T Nett : Nett temperature calculated by deducting the AMBIENT or INLET

temperature from the measured FLUE temperature. Displays in either

Fahrenheit (°F) or Centigrade (°C) or and will display ‘- OC -’ if the flue

probe is not connected.

T inlet: Temperature measured by the inlet temperature probe in Centigrade or

Fahrenheit. It displays ‘- OC -’ if the flue probe is disconnected.

CO: Carbon Monoxide reading displayed in ppm (parts per million). ‘- - -’ is

displayed if there is a fault with the CO sensor or the instrument has not set

to zero correctly, switch off instrument and try again.

COm: Carbon Monoxide displayed in mg/m3.

COn: Carbon Monoxide in ppm normalized to the O2R value.

COĦ: Carbon Monoxide in mg/m3 normalized to the O2R value.

COa Carbon Monoxide calculation as if there were 0% Oxygen present. This is

only displayed in ppm.

CO2 : Carbon Dioxide calculation determined by fuel type. This is only displayed

when a combustion test is being carried out. ‘-O>-’ is displayed while in

fresh air.

EFF : Combustion efficiency calculation displayed in percentage either as Gross

(G) or Nett (N) or Condensing Nett (C) - Use MENU to change. The

calculation is determined by fuel type and uses the calculation in British

Standard BS845. The efficiency is displayed during a combustion test, ‘-

O>-’ is displayed while in fresh air.

X - AIR : Excess air calculated from the measured oxygen and type of fuel used.

Displays reading during a combustion test. ‘-O>-’ is displayed while in

fresh air.

Loss : Losses calculated from Oxygen and type of fuel. Displays reading during a

combustion test. ‘-O>-’ is displayed while in fresh air.

1207A manual Page 31

Page 32

BAT Displays the Battery power available in %.

When the LO BAT symbol appears this indicates the batteries are at less

than 10% of charge and should be replaced, readings may be affected if

used with low power batteries. Warning: all stored readings are lost when

the batteries are removed or become exhausted.

DATE : Date shown as day, month and year. The order can be changed using the

menu function. Date is recorded when each combustion test is printed.

TIME : The time is shown in hours and minutes, expressed in “Military” time or the

24hr clock. Time is recorded when each combustion test is printed.

Note! When changing the batteries on the instrument the memory will

store the date and time for up to one minute, if outside this time it may be

necessary to re-enter the details.

Date and time may also need to be reset if re-chargeable batteries are allowed to

totally discharge.

SYMBOLS used on the display:

P Poison Index: measured CO divided by calculated CO2 multiplied by 100

R CO/CO2 Ratio: measured CO divided by calculated CO2

lambda Excess Air

AMB Either the internal temperature of the analyzer or the inlet temperature as

measured during the start up sequence

loss triangle Loss%: losses = 100 minus efficiency %

delta T Nett Temperature

TF Flue Temperature

eff symbol Efficiency %

Ħ mg/m3 normalized

PO Pump off

-O>- Oxygen greater than 18% so calculation is disabled

-OC- Open circuit temperature input

1207A manual Page 32

Loading...

Loading...