Page 1

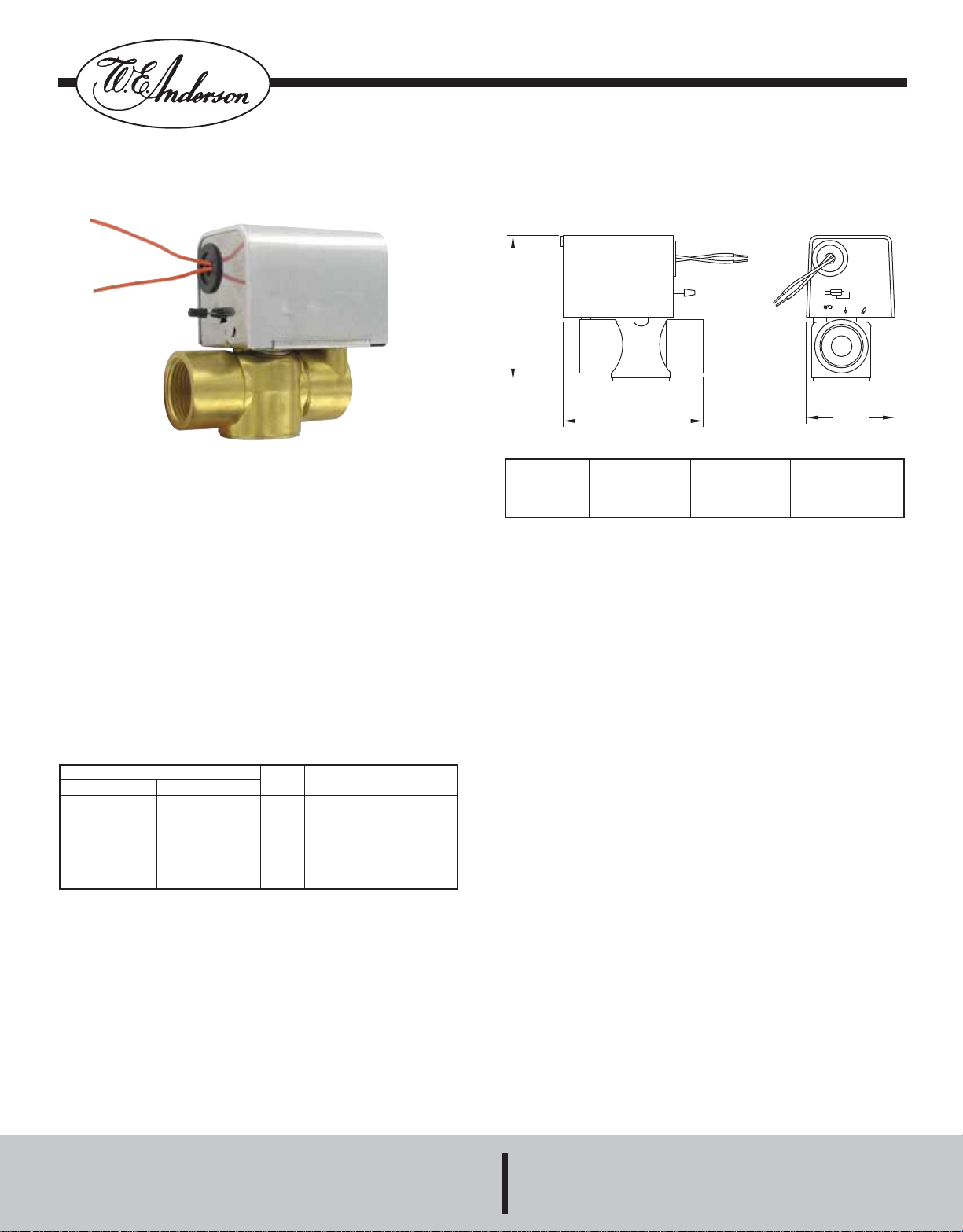

Series ZV1 Two-Way Zone Valves

Bulletin V-24

®

Specifications - Installation and Operating Instructions

A

B

Size

1/2˝

3/4˝

1˝

A [in (mm)]

4.15 (105.5)

4.15 (105.5)

4.31 (109.5)

C [in (mm)]

2.48 (63)

2.48 (63)

2.48 (63)

C

B [in (mm)]

3.54 (90)

3.66 (93)

3.74 (95)

ZV1 Series Zone Valves are ideal for flow control in hot and cold water

HVAC systems. Zone valves are typically used in conjunction with a thermostat to control room temperature. Units are available in 1/2˝, 3/4˝, and

1˝ sizes with 24 or 120 VAC power supply. Easy to install these units are

direct replacements for competitor units. Manual override lever is easily

accessible externally. Consult factory for 220 VAC power supply, optional auxiliary switches, and BSP or sweat connections.

Model

Normally Open

ZV1022-NO

ZV1024-NO

ZV1032-NO

ZV1034-NO

ZV1042-NO

ZV1044-NO

Normally Closed

ZV1022

ZV1024

ZV1032

ZV1034

ZV1042

ZV1044

Cv

3.78

3.78

3.78

3.78

8.02

8.02

Size

Supply Voltage

1/2˝

120 VAC

1/2˝

24 VAC

3/4˝

120 VAC

3/4˝

24 VAC

1˝

120 VAC

1˝

24 VAC

SPECIFICATIONS

Service: Compatible fluids.

Body: 2-way.

Line Size: 1/2˝ to 1˝.

End Connections: Female NPT (optional BSP, sweat connections).

Pressure Limits: Maximum: 300 psi (20.7 bar); Close-off: 1/2˝ to 3/4˝: 22

psi (1.5 bar), 1˝: 14.5 psi (1 bar).

Temperature Limits: Ambient: 32 to 104°F (0 to 40°C); Process: 0 to

201°F (0 to 94°C).

Wetted Materials: Brass, stainless steel, NBR.

Flow Characteristic: Quick opening.

Power Requirements: 120 VAC or 24 VAC, ±10%, 50/60 Hz. (Optional

220 VAC).

Power Consumption: 6.5 W.

Input: On/off.

Electrical Connection: 22 AWG, 5˝ (127 mm) long.

Cycle Time: Opening time: 11 seconds; Closing time: 5 seconds.

Enclosure Rating: General purpose.

Housing Material: Aluminum.

W.E. ANDERSON DIV., DWYER INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46361 U. S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

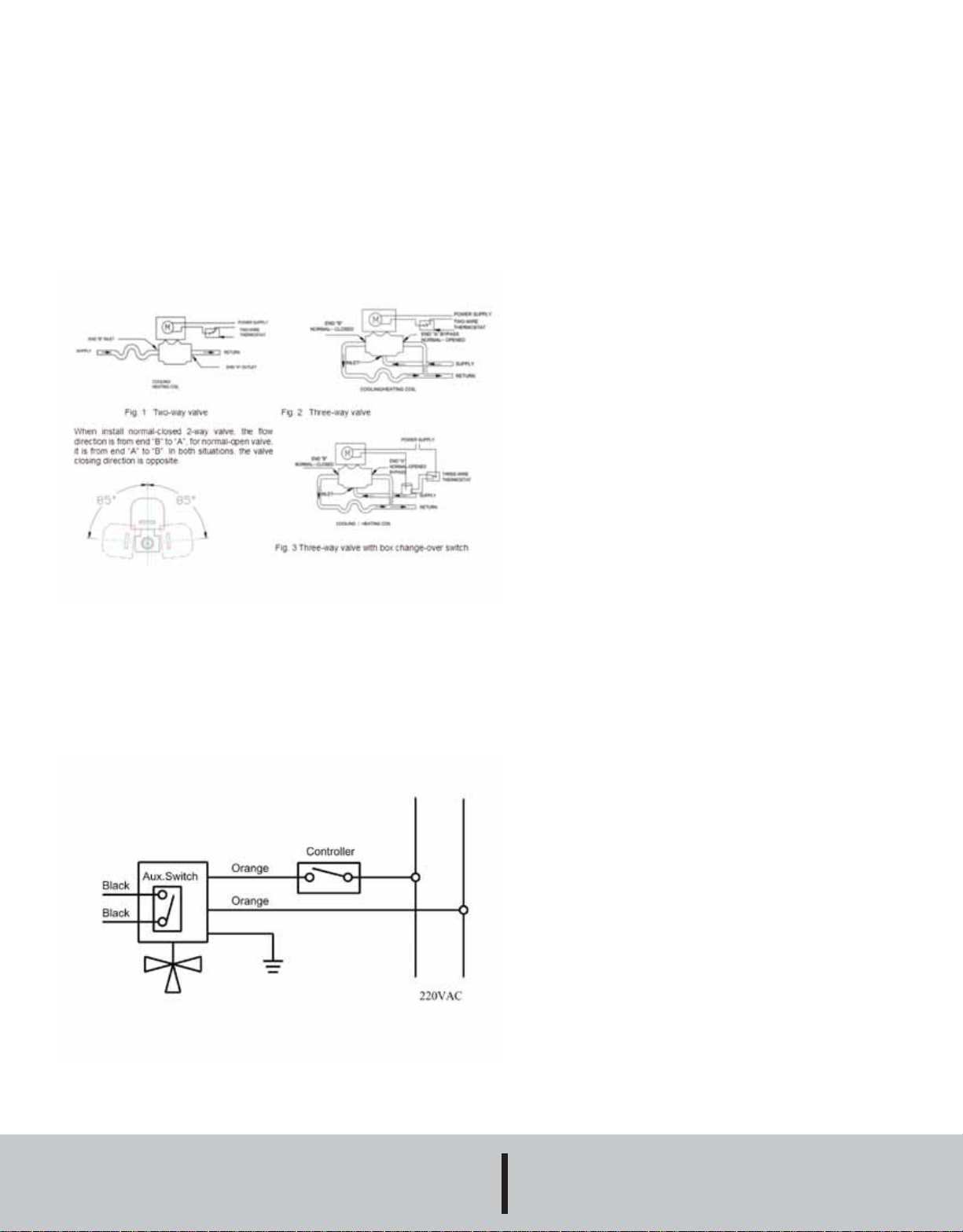

Instructions for Operation

2-way and diverting 3-way valve are installed as Figure 1, 2 and 3

shows. For high building, pressure reducing valves should be installed

on branch pipes at ground floor.

Note: When the valve is mounted on a horizontal pipe, the angle must

be positioned at less than 85°(see Figure 4).

When the valve is mounted on a vertical pipe, it must be prevented from

dripping.

Manual operating lever: Move the manual operating lever slowly and

hold in the retaining notch, and then the valve is in normal-opened

position. When the valve is first powered on, the lever goes back to the

automatic position again.

MAINTENANCE

Upon final installation of the Series ZV1 Two-Way Zone Valves, no

routine maintenance is required. A periodic check of the system

calibration is recommended. The Series ZV1 is not field serviceable and

should be returned if repair is needed (field repair should not be

attempted and may void warranty). Be sure to include a brief description

of the problem plus any relevant application notes. Contact customer

service to receive a return good authorization number before shipping.

Fig. 4

When installing a diverting 3-way valve, end “B” is the supply to the coil,

end “A” is the by-pass. There is no mark for an inlet. End “A” and “B” are

marked on the bottom of the valve.

When the valve has an auxiliary micro switch, the wiring diagram is as

following:

©Copyright 2010 Dwyer Instruments, Inc. Printed in U.S.A. 3/10 FR # RB-443459-30 Rev.2

W.E. ANDERSON DIV., DWYER INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46361 U. S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...