Page 1

Series WE34 3-Way Flanged Stainless Steel Ball Valve

Specifications - Installation and Operating Instructions

he modulating actuator accepts a 4 to 20

t

A input for valve positioning. Actuators

m

eature thermal overload protection and

f

ermanently lubricated gear train.

p

The pneumatic double acting actuator

uses an air supply to drive the valve open

nd closed. The actuator has two supply

a

orts, with one driving the valve open

p

nd the other driving the valve closed.

a

pring return pneumatic actuators use

S

the air supply to open the valve, and

internally loaded springs return the valve

to the closed position. Also available is

he SN solenoid valve to electrically

t

witch the air supply pressure between

s

he air supply ports for opening and

t

losing the valve. Actuators are

c

constructed of anodized and epoxy

coated aluminum for years of corrosion

free service.

ower Consumption: See page 8.

P

ycle Time (per 90°):

C

TD01: 4 s;

MD01: 10 s;

TD02 and MD02: 20 s;

TD03 and MD03: 30 s;

D04 and MD04: 30 s.

T

Duty Rating: 85%.

Enclosure Rating: NEMA 4X (IP67).

Housing Material: Powder coated

aluminum.

Temperature Limits: -22 to 140°F

(-30 to 60°C).

Electrical Connection: 1/2˝ female

NPT.

Modulating Input: 4 to 20 mA.

Standard Features: Manual override,

position indicator, and TD models come

with two limit switches.

Electric “TI” and “MI” Series

Power Requirements: 110 VAC,

220 VAC, 24 VAC or 24 VDC.

Power Consumption: See page 8.

Cycle Time (per 90°):

TI01 and MI01: 2.5 s;

TI02 and MI02: 5 s;

TI03 and MI03: 5 s;

TI04 and MI04: 10 s;

TI05 and MI05: 15 s;

TI08 and MI08: 12 s.

Duty Rating:

Two-Position:

TI01-TI07: 25%;

TI08: 100%.

Modulating:

MI01-MI07: 75%;

MI08: 100%.

Enclosure Rating: NEMA 7

Housing Material: Powder coated

aluminum.

Temperature Limits: -40 to 140°F

(-40 to 60°C).

Electrical Connection: 1/2˝ female

NPT.

Modulating Input: 4 to 20 mA.

Standard Features: Position indicator

and two limit switches.

E34-DHD00-L1

W

E34-DDA03-T2

W

WE34-DDA03-AA01-T1-AA01

WE34-DDA03-0008-T2-NN08

WE34-DTI03-T3-A

he Series WE34 incorporates a full port

T

-way flanged SS ball valve for great flow

3

ates with minimal pressure drop. The

r

alve features a blowout-proof stem for

v

added safety, reinforced PTFE seats and

seals for longer life, and a 316 SS (ASTM

CF8M) ball for better performance.

ctuators are direct mounted creating a

A

ompact assembly for tight spaces. Limit

c

witches are able to be mounted directly

s

o the valves allowing for remote position

t

indication.

The Series WE34 can be configured with

ither an electric or pneumatic actuator.

e

lectric actuators are available in

E

eatherproof or explosion-proof, a

w

ariety of supply voltages and two-

v

position or modulating control. Twoposition actuators use the supply voltage

to drive the valve open or closed, while

PECIFICATIONS

S

ALVE

V

Service: Compatible liquids and gases.

Body: 3-way.

Line Sizes: 1/2 to 3˝.

End Connections: 150# ANSI flange.

ressure Limits: 20˝ Hg to 275 psi

P

(-0.7 to 19 bar).

Wetted Materials:

Body and ball: 316 SS (CF8M);

Stem: 316 SS;

Seat: RTFE/PTFE;

Seal, Washer, and Packing: PTFE.

Temperature Limits: -20 to 392°F

(-29 to 200°C).

Other Materials:

O-ring: Fluoroelastomer;

Handle: 304 SS;

Washer: 301 SS;

Stem Nut, Locking Device,

Gland Ring: 304 SS;

Handle Sleeve: PVC.

ACTUATORS

Pneumatic “DA” and “SR” Series

Type: DA series is double acting and

SR series is spring return (rack and

pinion).

Normal Supply Pressure:

DA: 40 to 115 psi (2.7 to 7.9 bar);

SR: 80 psi (5.5 bar).

Maximum Supply Pressure: 120 psi

(8.6 bar).

Air Connections:

DA01: 1/8˝ female NPT;

DA02 to DA08: 1/4˝ female NPT;

SR03 to SR09: 1/4˝ female NPT.

Housing Material: Anodized aluminum

body and epoxy coated aluminum end

caps.

Temperature Limits: -40 to 176°F (-40

to 80°C).

Accessory Mounting: NAMUR

standard.

Electric “TD” and “MD” Series

Power Requirements: 110 VAC,

220 VAC, 24 VAC or 24 VDC (MD

models not available in 24 VDC).

Bulletin V-WE34

.

W.E. ANDERSON,

A DIV. OF DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360 U.S. A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyermail.com

Page 2

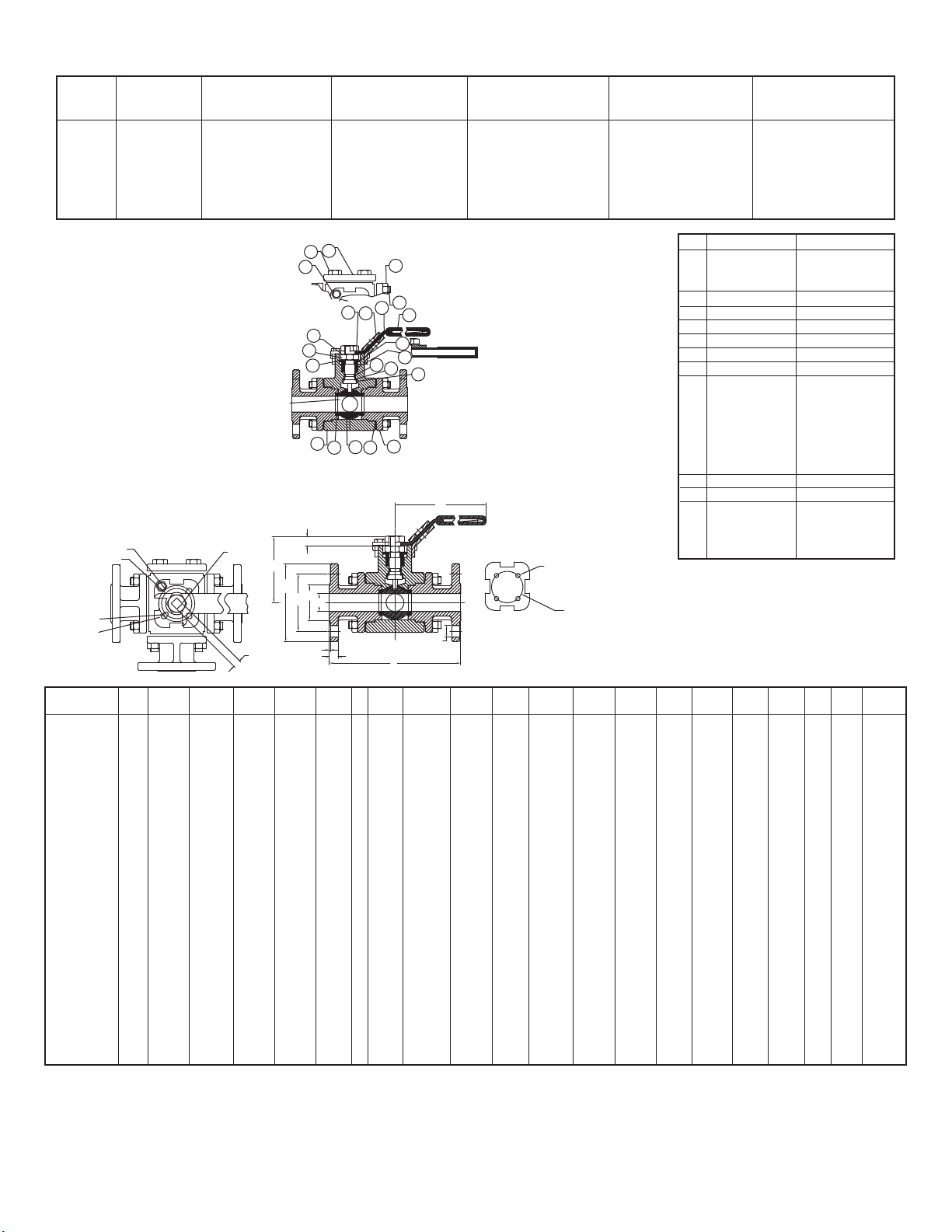

13

1

2

11

14

15

2

1

16

17

1

0

9

8

7

5

H

ANDLE DESIGN

F

OR 1-1/4˝ - 4˝

VENTED BALL

1

4

3

6

2

22

18

19

20

M1

H

H1

ØA1

ØE

ØF

ØA

W

N x ØM

[1-1/4 - 6]

ØA

ØRa

S

ØRb

ØRa

ØD1

ØD2

1/16

[1.6]

G

L

PO

V

VA

PU

Si

1

3

1

1

2

2

3

A

L

LVE D

/

2

/

4

˝

˝

˝

VE

LA

R

M

O

D

ELS

NEMA 4X Two

z

e

˝

˝

1

/

(gal/min)

6

2

0

5

4

9

2

60

2

˝

380

Cv

1

/

2

650

˝

1000

B

I

LL

O

F

M

A

TER

IM

EN

SIO

N

A

L D

I

A

R

LS

AWIN

Hand Operated

Model

E34-CHD00-T2

W

E34-DHD00-T2

W

E34-EHD00-T2

W

E34-GHD00-T2

W

WE34-HHD00-T2

WE34-IHD00-T2

WE34-JHD00-T2

G

Double Acting

Pneumatic Model

E34-CDA02-T2

W

E34-DDA02-T2

W

E34-EDA03-T2

W

E34-GDA05-T2

W

WE34-HDA06-T2

WE34-IDA07-T2

WE34-JDA08-T2

Spring Return

Pneumatic Model

E34-CSR03-T2

W

E34-DSR03-T2

W

E34-ESR05-T2

W

E34-GSR06-T2

W

WE34-HSR07-T2

WE34-ISR08-T2

WE34-JSR09-T2

Position Electric

(110 VAC) Model

E34-CTD02-T2-A

W

E34-DTD02-T2-A

W

E34-ETD02-T2-A

W

E34-GTD03-T2-A

W

WE34-HTD03-T2-A

WE34-ITD04-T2-A

WE34-JTD04-T2-A

I

t

e

m

D

1

B

2

C

3

B

4

Ball Seat

5

Stem

6

Gasket

7

T

8

O

9

P

1

0

Gland Ring

1

1

Spring Washer

1

2

Stem Nut

1

3

Stop Washer

1

4

H

1

5

L

1

6

H

1

7

Handle Cover

1

8

Cap-A

1

9

Cap-A Bolt

2

0

Stop Pin

2

1

Bolt

2

2

Nut

escription

ody

ap

all

hrust Washer

-Ring

acking

andle Washer

ocking Device

andle

NEMA 4X

Modulating Electric

(110 VAC) Model

E34-CMD01-T2-A

W

E34-DMD01-T2-A

W

E34-EMD02-T2-A

W

E34-GMD03-T2-A

W

WE34-HMD03-T2-A

WE34-IMD04-T2-A

WE34-JMD04-T2-A

aterial

M

STM A351-CF8M

A

PTFE

SUS 304

PTFE

EEK + PTFE

P

luoroelastomer

F

TFE

P

SUS 304

PVC

ASTM A351-CF8M

SUS 304

Model

Number

WE34-CHD00-L

WE34-DHD00-L

WE34-EHD00-L

WE34-GHD00-L

WE34-HHD00-L

WE34-IHD00-L

WE34-JHD00-L

WE34-CHD00-T

WE34-DHD00-T

WE34-EHD00-T

WE34-GHD00-T

WE34-HHD00-T

WE34-IHD00-T

WE34-JHD00-T

N

4

4

4

4

4

4

4

4

4

4

4

4

4

4

M

in(mm)

5/8˝

(16)

5/8˝

(16)

5/8˝

(16)

5/8˝

(16)

3/4˝

(19)

3/4˝

(19)

3/4˝

(19)

5/8˝

(16)

5/8˝

(16)

5/8˝

(16)

5/8˝

(16)

3/4˝

(19)

3/4˝

(19)

3/4˝

(19)

L

in(mm)

5-53/64˝

(148)

6-1/64˝

(153)

6-39/64˝

(168)

8-45/64˝

(221)

10˝

(254)

11-13/16˝

(300)

12˝

(305)

5-53/64˝

(148)

6-1/64˝

(153)

6-39/64˝

(168)

8-45/64˝

(221)

10˝

(254)

11-13/16˝

(300)

12˝

(305)

H

in(mm)

3-5/32˝

(80)

3-5/16˝

(84)

3-25/32˝

(96)

3-5/32˝

(171)

3-5/16˝

(176)

3-25/32˝

(198)

3-5/32˝

(216)

3-5/32˝

(80)

3-5/16˝

(84)

3-25/32˝

(96)

3-5/32˝

(171)

3-5/16˝

(176)

3-25/32˝

(198)

3-5/32˝

(216)

Page 2

H1

in(mm)

23/64˝

(9)

23/64˝

(9)

7/16˝

(11)

3/4˝

(19)

3/4˝

(19)

61/64˝

(24)

61/64˝

(24)

23/64˝

(9)

23/64˝

(9)

7/16˝

(11)

3/4˝

(19)

3/4˝

(19)

61/64˝

(24)

61/64˝

(24)

W

in(mm)

4-27/32˝

(123)

4-27/32˝

(123)

6-1/64˝

(153)

7-15/16˝

(201.5)

7-15/16˝

(201.5)

9-59/64˝

(252)

9-59/64˝

(252)

4-27/32˝

(123)

4-27/32˝

(123)

6-1/64˝

(153)

7-15/16˝

(201.5)

7-15/16˝

(201.5)

9-59/64˝

(252)

9-59/64˝

(252)

ØD1

in(mm)

1-27/64˝

(36)

1-27/64˝

(36)

1-21/32˝

(42)

2-49/64˝

(70)

2-49/64˝

(70)

4-1/64˝

(102)

4-1/64˝

(102)

1-27/64˝

(36)

1-27/64˝

(36)

1-21/32˝

(42)

2-49/64˝

(70)

2-49/64˝

(70)

4-1/64˝

(102)

4-1/64˝

(102)

ØD2

in(mm)

1-21/32˝

(42)

1-21/32˝

(42)

1-31/32˝

(50)

-

-

-

-

-

-

-

1-21/32˝

(42)

1-21/32˝

(42)

1-31/32˝

(50)

-

-

-

-

-

-

-

-

ISO

F03/04

F03/04

F04/05

F07

F07

F10

F10

F03/04

F03/04

F04/05

F07

F07

F10

F10

S

in(mm)

23/64˝

(9)

23/64˝

(9)

7/16˝

(11)

43/64˝

(17)

43/64˝

(17)

7/8˝

(22)

7/8˝

(22)

23/64˝

(9)

23/64˝

(9)

7/16˝

(11)

43/64˝

(17)

43/64˝

(17)

7/8˝

(22)

7/8˝

(22)

ØRa

in(mm)

1/8˝

(3)

1/8˝

(3)

9/64˝

(3.5)

M8

M8

M10

M10

1/8˝

(3)

1/8˝

(3)

9/64˝

(3.5)

M8

M8

M10

M10

ØRb

in(mm)

1/8˝

(3)

1/8˝

(3)

9/64˝

(3.5)

-

-

-

-

-

-

-

1/8˝

(3)

1/8˝

(3)

1/8˝

(3)

-

-

-

-

-

-

-

Port

L

L

L

L

L

L

L

T

T

T

T

T

T

T

M1

M12x

1.75

M12x

1.75

M14x

2.0

-

-

-

-

M12x

1.75

M12x

1.75

M14x

2.0

-

-

-

-

Cv

(gal/min)

26

50

94

260

380

650

1000

26

50

94

260

380

650

1000

ØA1

in(mm)

3-1/2˝

(89)

3-55/64˝

(98)

4-1/4˝

(108)

5˝

(127)

6˝

(152)

7-1/64˝

(178)

7-31/64˝

(190)

3-1/2˝

(89)

3-55/64˝

(98)

4-1/4˝

(108)

5˝

(127)

6˝

(152)

7-1/64˝

(178)

7-31/64˝

(190)

ØE

in(mm)

2-3/8˝

(60.5)

2-49/64˝

(70)

3-1/8˝

(79.5)

3-57/64˝

(98.5)

4-3/4˝

(120.5)

5-1/2˝

(139.5)

6˝

(152.5)

2-3/8˝

(60.5)

2-49/64˝

(70)

3-1/8˝

(79.5)

3-57/64˝

(98.5)

4-3/4˝

(120.5)

5-1/2˝

(139.5)

6˝

(152.5)

in(mm)

1-3/8˝

(35)

1-11/16˝

(43)

2-1/16˝

(51)

2-7/8˝

(73)

3-5/8˝

(92)

4-9/64˝

(105)

5˝

(127)

1-3/8˝

(35)

1-11/16˝

(43)

2-1/16˝

(51)

2-7/8˝

(73)

3-5/8˝

(92)

4-9/64˝

(105)

5˝

(127)

in(mm)

31/64˝

(12.1)

31/64˝

(12.1)

31/64˝

(12.1)

9/16˝

(14.3)

5/8˝

(15.9)

11/16˝

(17.5)

3/4˝

(19.1)

31/64˝

(12.1)

31/64˝

(12.1)

31/64˝

(12.1)

9/16˝

(14.3)

5/8˝

(15.9)

11/16˝

(17.5)

3/4˝

(19.1)

ØA

in(mm)

Size

19/32˝

1/2˝

(15)

51/64˝

3/4˝

(20)

63/64˝

1˝

(25)

1-37/64˝

1-1/2˝

(40)

1-31/32˝

2˝

(50)

2-9/16˝

2-1/2˝

(65)

3˝

3˝

(76)

19/32˝

1/2˝

(15)

51/64˝

3/4˝

(20)

63/64˝

1˝

(25)

1-37/64˝

1-1/2˝

(40)

1-31/32˝

2˝

(50)

2-9/16˝

2-1/2˝

(65)

3˝

3˝

(76)

G

ØF

Page 3

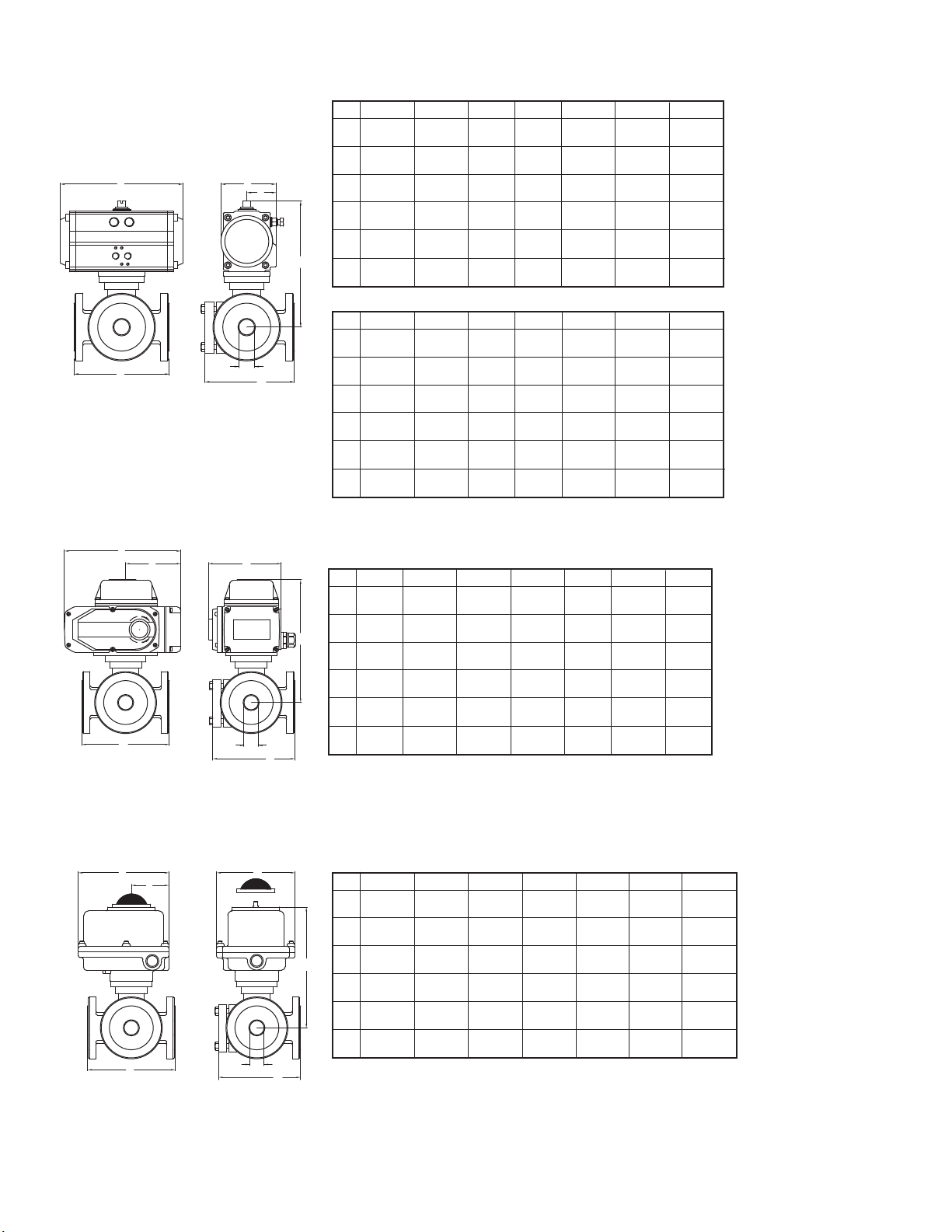

A

W/ ELECTRIC ACTUATOR

E

D

C

F

B

SIZE

G

6

2

W

/ PNEUMATIC ACTUATOR

E

D

C

F

B

G

SIZE

W/ EXPLOSION-PROOF ELECTRIC ACTUATOR

E

D

C

F

B

SIZE

G

OPEN

U

T

O

M

A

TED

V

A

L

VE

D

R

AW

I

N

G

S

D

oubl

e

A

c

t

i

ng

Pne

um

a

t

i

c

A

c

t

ua

t

or

3

/

4

˝

1

˝

1

-

1

/

2

˝

2

Si

B

C

D

E

F

G

Spr

Si

B

C

D

E

F

G

z

e

1

/

2

˝

5

-

5

/

8

˝

6

-

5

/

8

˝

9

5

-

1

/

2

˝

1

4

3

.

6

mm

1

4

0

.

5

m

m

2

2

-

3

7

1

5

-

7

1

4

8

5

-

3

1

4

5

1

-

5

4

1

4

-

1

1

1

4

i

ng

R

z

e

1

/

2

8

-

1

1

5

6

3

-

1

8

2

5

-

7

1

4

8

6

-

5

1

6

9

1

-3

4

6

m

4

-1

11

4

-

/

4

˝

7

1

m

m

6

˝

/

8

˝

1

5

m

m

5

-

/

4

˝

1

4

m

m

1

-

/

8

˝

4

1

m

m

4

-

/

2

˝

11

m

m

e

t

ur

n

Pne

3

/

˝

8

-

/

8

˝

1

5

.

5

m

m

3

-

/

4

˝

8

2

m

m

6

˝

/

8

˝

1

5

m

m

6

-

/

8

˝

1

6

m

m

1

-

/4

˝

4

6

m

4

-

/2

˝

11

m

m

3

mm

3

3

5

5

mm

5

7

um

4

1

9

1

mm

3

5

9

3

mm

5

7

/

4

mm

/

4

mm

/

8

/

8

mm

˝

/

4

.

6

/

4

mm

/

8

mm

/

4

/

8

mm

˝

˝

˝

˝

a

˝

mm

˝

˝

˝

˝

1

3

8

6

1

6

1

1

4

5

1

t

i

c

A

c

1

7

1

4

1

6

1

8

2

2

5

5

1

7

2

6

6

6

3

˝

8

˝

0

6

0

5

3

0

1

/

mm

5

/

8

5

/

9

3

/

mm

1

/

4

t

ua

1

/

2

1

5

/

8

1

/

9

1

/

mm

1

/

4

mm

4

˝

8

˝

mm

8

˝

mm

4

˝

4

˝

mm

t

8

˝

mm

mm

8

˝

mm

4

˝

mm

8

˝

4

˝

mm

-

2

3

4

˝

1

0

8

-

2

2

8

-

2

0

2

-

5

5

6

-

1

7

or

1

-

9

-

2

4

4

-

1

0

8

-

2

2

9

-

2

4

2

-

5

7

6

-

1

7

1

4

1

3

1

1

9

1

mm

7

5

1

5

6

1

8

3

1

1

2

1

.

5

7

/

5

/

4

mm

mm

/

4

mm

/

4

mm

/

8

/

8

mm

/

2

/

8

mm

/

4

.

5

/

4

mm

/

2

mm

/

4

mm

8

mm

˝

˝

˝

˝

˝

˝

˝

˝

mm

˝

˝

˝

˝

˝

9

-

2

5

4

-

1

0

1

0

2

5

9

-

2

4

2

-

5

7

7

-

1

9

2

˝

1

0

2

6

4

-

1

2

1

0

2

5

1

0

2

7

2

-

6

4

7

-

1

9

7

/

1

1

/

1

˝

4

1

/

2

1

/

.

5

5

/

5

-

3

4

3

/

2

˝

4

-

7

5

1

/

mm

5

/

5

8

˝

mm

4

˝

mm

mm

2

˝

mm

4

˝

mm

8

˝

mm

/

8

mm

4

˝

mm

mm

/

8

mm

2

˝

8

˝

mm

2

-

1

/

2

˝

3

/

.

5

/

4

mm

/

mm

7

/

mm

/

2

/

8

mm

/

2

.

5

/

8

.

5

/

mm

mm

/

4

/

8

mm

8

˝

mm

˝

8

˝

8

˝

˝

˝

˝

mm

˝

mm

8

˝

˝

˝

˝

1

2

-

1

/

4

˝

3

1

2

mm

5

-

3

/

8

˝

1

0

1

mm

1

2

˝

3

0

5

mm

1

3

-

1

/

8

˝

3

3

2

mm

2

-

7

/

8

˝

7

0

mm

9

-

5

/

8

˝

2

4

6

mm

3

˝

1

2

-

7

/

8

˝

3

2

8

.

5

mm

6

˝

1

5

3

mm

1

2

˝

3

0

5

mm

1

5

-

1

/

8

˝

2

7

5

mm

3

˝

7

7

mm

9

-

5

/

8

˝

2

4

6

mm

11

-

1

2

8

1

4

-

3

1

0

1

11

-

7

3

0

0

1

0

-

2

7

5

2

-

1

6

4

mm

9

-

1

2

3

3

2

-

1

˝

1

2

˝

3

0

3

5

-

3

1

3

7

11

-

7

3

0

0

˝

1

3

˝

3

3

2

2

-

3

7

0

mm

9

-

1

2

3

3

Siz

B

C

D

E

F

G

Si

B

C

D

E

F

G

e

ze

1

/2

˝

6

˝

1

5

1

m

4

-1

/2

11

3

m

5

-7

/8

1

4

8

m

6

-1

/4

1

6

0

m

3

˝

7

7

m

4

-1

/2

11

4

m

1

/2

˝

11

-1

28

3.

9-3/

2

38

.

5

-7/8˝

148

mm

8-1/2˝

2

16.7 mm

5˝

125

.8 mm

4-1/

114 mm

m

˝

m

˝

m

˝

m

m

˝

m

/8˝

3

mm

8

˝

9 mm

2˝

3

/

4

˝

6

˝

1

5

1

4

-

1

/

11

3

6

˝

1

5

3

6

-

1

/

1

6

0

3

˝

7

7

mm

4

-

5

/

11

7

3/

11-3/

287.

9-3/

238.

6˝

153 mm

8-1/

216.

5˝

125.

4-5/8˝

117 mm

mm

2

˝

mm

mm

4

˝

mm

8

˝

mm

4˝

8˝

3 mm

8˝

9 mm

2˝

7 mm

8 mm

1

˝

6

-

1

/

1

6

4

4

-

1

/

11

3

6

-

5

/

1

6

8

6

-

1

/

1

6

0

3

˝

7

7

mm

5

-

1

/

1

3

4

1˝

9-

247.

9-3/

238.

6-5/

168 mm

8-1/

216.

5˝

125.

5-1/4˝

134 mm

2

˝

.

5

mm

2

˝

mm

8

˝

mm

4

˝

mm

4

˝

mm

3/

4˝

3 mm

8˝

9 mm

8˝

2˝

7 mm

8 mm

1

-

1

8

-

1

2

0

8

4

-

1

11

3

8

-

3

2

2

1

6

-

1

1

6

0

3

˝

7

7

mm

6

-

7

1

7

5

1-

11-1/

286.

8-1/

216 mm

8-3/

221 mm

8-1/

216 mm

5-3/

136.

6-7/8˝

175 mm

/

2

/

4

.

5

/

2

mm

/

4

mm

/

4

mm

/

8

mm

1/

˝

˝

mm

˝

˝

˝

˝

2˝

2˝

4˝

2˝

8˝

4˝

1 mm

4 mm

2

˝

9

-

3

2

3

7

4

-

3

1

2

1

1

0

˝

2

5

4

7

-

3

1

9

6

3

-

7

9

8

mm

7

-

5

1

9

5

2˝

11-1/

291.

8-1/

216 mm

10˝

254 mm

8-1/

216 mm

5-

136.

7-5/8˝

195 mm

/

8

mm

/

4

mm

mm

/

4

mm

/

8

/

8

mm

3/

˝

˝

˝

˝

˝

2˝

2˝

8˝

2

1

2

6

1

11

3

1

2

5

1

9

2

2˝

1 mm

4 mm

-

1

/

2

0

-

7

7

6

.

5

-

1

/

4

5

8

mm

-

7

/

0

0

mm

0

˝

5

5

mm

-

1

/

4

3

4

mm

-

1

/

8

3

3

mm

2-

12-

308.

8-1/

216 mm

11300 mm

8-1/

216 mm

5-3/

136.

9-1/8˝

233 mm

˝

/

8

˝

8

˝

˝

˝

mm

˝

1/

2˝

1/

2˝

7/

2˝

8˝

8˝

6 mm

8˝

4 mm

3

˝

11

2

8

6

-

1

1

5

1

2

3

0

1

0

2

5

5

-

1

1

3

9

-

5

2

4

-

1

/

4

˝

5

mm

/

4

˝

8

mm

˝

5

mm

˝

5

mm

/

4

˝

4

mm

/

8

˝

6

mm

3˝

15-3/

390.

10˝

254 mm

12˝

305 mm

10˝

254 mm

6-

1/

4˝

158.

9-5/8˝

246 mm

8˝

1 mm

8 mm

Page 3

Page 4

NEUMATIC ACTUATOR

P

ote: For optimal operation, pneumatic actuators should be run with a supply of

N

lean, lubricated air.

c

Spring Return Actuator Operation

Air to PORT 2 (the left hand port) causes the actuator to turn counter clockwise

(CCW). Loss of air to PORT 2 causes air to exhaust and the actuator turns

ockwise (CW). This is the FAIL CLOSE operation.

c

ouble Acting Actuators Operation

D

ir to PORT 2 (the left hand port) causes the actuator to turn counter clockwise

A

(CCW). Air to PORT 1 (the right hand port) causes the actuator to turn clockwise

(CW).

neumatic Actuator Maintenance

P

outine maintenance of pneumatic actuator:

R

Keep the air supply dry and clean

•

• Keep the actuator surface clean and free from dust

• Periodic checks should be done to make sure all fittings are tight

• Pneumatic actuators are supplied with lubrication to last the entire life span of the

actuator under normal operating conditions.

he outer surface of the pneumatic actuator should be clean to avoid friction or

T

orrosion. All fittings and connections should be tight to prevent leaks during

c

operation. Check the bolts mounting the valve to the actuator to make sure they

have not come loose during shipping or installation. Make sure the valve and

actuator are not rubbing or jamming against other components during operation.

The actuator should be inspected annually to make sure all fittings and bolts are

ight and nothing has come loose during operation.

t

isassembling Pneumatic Actuators

D

ARNING

W

emoved, and that the actuator has been disassembled from the valve.

r

1. Loosen the end cap fasteners (22) with a wrench (size varies depending on

actuator model). On the spring return actuator, alternate 3 to 5 turns on each

fastener until the springs are completely decompressed. Use caution when

removing the cap since the springs are under load until the fasteners are fully

extended.

2. Remove the pinion snap ring (10) with a lock ring tool. The indicator (7) may now

be removed.

3. Turn the pinion shaft (2) counter clockwise until the pistons are at the full end of

travel. Disengage the pistons (11) from the pinion. (NOTE: Low pressure air--3 to 5

psi MAXIMUM--might be required to force the pistons completely from the body.)

Note the position of the pistons before removing them from the actuator body.

4. Remove the pinion through the bottom of the actuator. The actuator is now

completely disassembled.

Pneumatic Actuators Bill of Materials

Before beginning disassembly, ensure that the air supply to the

ctuator has been disconnected, all accessories have been

a

I

n

s

p

e

c

t

i

o

n

I

t

e

m

Fa

i

l

ure

s

P

ne

um

a

t

a

c

t

ua

t

or w

ope

ra

t

e

P

ne

um

a

t

a

c

t

ua

t

or runs

s

l

ow

l

y

eassembling Pneumatic Actuators

R

WARNING

1. Apply a light film of grease to all O-rings and the pinion before replacing.

. Put the pinion (2) back through the actuator with the flats of the pinion shaft

2

unning parallel with the body.

r

. When reassembling the actuator, make sure that the piston racks are square to

3

the actuator body and returned to their original orientation. (NOTE: The normal

operation of all spring return pneumatic actuators is FAIL CLOSED. To change the

orientation to FAIL OPEN, rotate the racks 180º to create a reverse operation.

4. When replacing springs in a spring return actuator, ensure that the springs are

replaced in their identical position in the end cap from which they were removed.

(NOTE: In some circumstances, you might want to change the standard 80 pound

spring set to fit your application and available air pressure.

5. Seal the end caps with a petroleum lubricant and bolt to actuator body.

6. Check the seal of the actuator by covering seal areas (pinion, end caps) with

soapy water and using low pressure air to the actuator to ensure that no bubbles

are produced.

Part Number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

1

.

C

h

e

i

c

i

c

on’

t

Quantity

1

1

1

1

1

1

1

1

1

1

1

1

1

4

2

2

2

2

5 to 12

2

1

1

8

2

2

2

2

c

t

h

e

c

o

i

l

s

o

l

e

n

o

i

2

.

T

h

e

b

e

c

a

u

s

3

.

T

h

e

a

c

t

u

a

t

o

s

m

a

s

h

e

4

.

T

h

e

b

e

c

a

u

s

a

n

d

m

o

1

.

T

h

e

i

n

s

u

f

f

i

c

2

.

A

r

e

o

c

o

n

s

u

m

t

h

e

a

c

t

u

3

.

T

h

e

u

n

d

e

r

s

i

Be sure the actuator surfaces are free of debris and scratches

before reassembling.

Part Name

Cylinder

Output Shaft

O-ring

Bearing

Adjusting Cam

Thrust Bearing

Bearing

O-ring

Bearing

Gasket

Damping Ring

Position Indicator

Screw

Position Indicating

Inserts

Piston

Guide Ring

O-ring

Guide Ring

Spring Assembly

O-ring

Left End Cap

Right End Cap

End Cap Bolt

O-ring

Gasket

Nut

Adjusting Bolt

s

k

t

h

e

s

o

l

e

n

o

i

d

v

b

u

r

n

t

o

d

s

p

o

o

a

c

t

u

a

t

o

e

o

f

d

e

p

n

e

u

m

r

i

s

d

i

s

d

.

p

n

e

u

m

e

o

f

l

o

w

i

s

t

u

r

e

.

a

i

r

s

u

p

p

i

e

n

t

.

t

h

e

r

p

n

i

n

g

t

h

e

a

t

o

r

t

o

p

n

e

u

m

z

e

d

f

o

r

a

u

t

o

r

i

s

t

h

l

?

r

w

i

l

l

n

o

t

m

b

r

i

s

i

n

t

h

e

a

t

i

c

l

i

n

e

t

o

t

o

r

t

e

d

o

r

a

t

i

c

l

i

n

e

i

s

t

e

m

p

e

r

a

l

y

p

r

e

s

s

u

e

u

m

a

t

i

c

d

a

i

r

r

e

q

u

i

r

o

p

e

r

a

t

e

?

a

t

i

c

a

c

t

u

a

t

t

h

e

a

p

p

l

i

c

C

o

r

r

e

c

t

i

v

e

A

c

t

i

o

l

v

e

.

I

s

1

.

R

e

p

l

e

o

v

e

g

e

a

r

s

.

t

h

e

f

r

o

z

e

n

t

u

r

e

s

r

e

i

s

e

v

i

c

e

s

e

d

f

o

r

o

r

i

s

a

t

i

o

n

.

Material

Extruded Aluminum Alloy

Stainless Steel

Fluorine Silicon Rubber

Nylon46

Stainless Steel

Nylon46

Nylon46

Fluorine Silicon Rubber

Nylon46

Stainless Steel

Stainless Steel

PPPP+30%GF

PPPP+30%GF

PPPP+30%GF

Casting Aluminum Alloy

Nylon46

Fluorine Silicon Rubber

Fluorine-Carbon Composite Material

Alloy Spring Steel

Fluorine Silicon Rubber

Casting Aluminum Alloy

Casting Aluminum Alloy

Stainless Steel

Fluorine Silicon Rubber

Stainless Steel

Stainless Steel

Stainless Steel

a

v

a

l

v

e

c

o

2

.

D

i

s

a

s

c

l

e

a

n

t

h

r

e

a

s

s

e

m

3

.

R

e

p

l

a

t

h

e

a

c

t

u

4

.

W

a

r

m

a

n

d

r

e

m

s

u

p

p

l

y

l

i

1

.

I

n

c

r

e

a

p

r

e

s

s

u

r

e

i

n

t

h

e

s

u

p

i

p

e

l

i

n

e

.

2

.

I

n

c

r

e

a

r

e

d

u

c

e

t

d

e

v

i

c

e

s

s

a

m

e

t

i

m

3

.

R

e

p

l

a

a

l

a

r

g

e

r

n

c

e

t

h

e

s

o

l

e

n

o

i

l

o

r

s

e

m

e

d

e

b

l

e

t

c

e

p

a

t

o

r

.

t

h

e

o

v

e

n

e

s

.

s

e

t

a

n

d

p

p

l

y

s

e

t

h

e

n

o

p

e

r

e

.

c

e

t

h

a

c

t

u

i

r

e

m

o

v

e

d

e

b

l

e

t

h

e

a

c

b

r

i

s

a

n

d

h

e

a

c

t

u

a

t

n

e

u

m

a

t

i

c

p

n

e

u

m

a

t

i

m

o

i

s

t

u

r

e

f

h

e

a

i

r

s

u

p

l

o

o

k

f

o

r

l

p

r

e

s

s

u

r

e

h

e

a

i

r

s

u

p

u

m

b

e

r

o

f

a

t

i

n

g

a

t

t

h

e

a

c

t

u

a

t

o

a

t

o

r

.

d

b

r

i

s

t

u

a

t

o

o

r

.

l

i

n

e

t

c

l

i

n

e

r

o

m

p

l

y

e

a

k

s

p

l

y

o

e

r

w

i

t

h

.

r

,

o

s

r

Page 4

Page 5

D

M

A

A

A

A

A

A

A

A

A

Spr

M

A

A

A

A

A

A

A

A

A

oubl

ode

C

T-

C

T-

C

T

C

T-

C

T-

C

T-

C

T

C

T-

C

T-

i

ode

C

T-

C

T

C

T-

C

T

C

T-

C

T

C

T-SR

C

T

C

T

ng

D

D

-

D

D

D

D

-

D

D

D

SR

-

SR

SR

-

SR

SR

-

SR

-SR

-SR

e

A

c

t

i

ng

A

c

t

ua

t

or

T

or

que

D

A

D

oubl

e

-

A

c

t

i

on O

ut

put

T

orque

(

l

b-

i

i

nd

n)

1

1

5

ps

a

ure

7

1

3

9

i

i

1

4

2

3

0

0

5

2

9

8

7

5

11

4

8

1

6

4

9

2

4

5

0

4

3

4

0

6

5

3

3

t

i

c

A

c

t

ua

t

or (

l

b-

i

n)

1

1

0

ps

i

1

1

5

ps

i

S

pri

ng T

orque

9

0

°

0

0

°

9

0

°

0

°

9

0

°

S

t

a

rt

E

nd

S

t

2

1

5

3

8

2

6

5

0

8

2

6

11

7

5

1

6

2

8

3

1

7

8

4

5

5

6

6

9

11

a

1

8

9

2

3

3

2

6

4

0

5

5

6

6

9

7

0

8

8

8

1

0

2

5

1

2

1

5

0

8

1

7

2

7

0

5

3

4

3

7

3

6

4

8

5

7

0

7

7

4

S

rt

E

nd

9

1

2

0

5

1

9

3

5

3

2

5

6

0

1

3

5

7

6

7

5

6

0

111

0

8

5

5

1

6

3

5

1

0

3

2

9

3

0

2

9

4

4

0

7

4

3

2

6

6

2

2

2

°

t

a

r

t

E

n

6

7

7

8

3

1

4

3

5

d

7

0

6

1

2

0

4

1

8

0

1

2

6

3

6

3

8

6

7

6

9

6

1

6

9

3

8

6

3

1

5

7

5

4

9

2

4

0

7

1

0

0

ps

i

1

1

0

1

2

3

2

5

9

4

5

6

7

5

4

9

9

0

1

4

1

2

1

1

3

7

4

5

6

3

c

t

i

ng P

°

8

5

5

0

1

8

5

5

7

0

9

9

1

ps

1

3

5

2

8

5

5

0

2

8

3

0

1

0

8

9

9

1

5

6

1

2

2

3

2

3

2

4

1

1

6

2

6

1

9

5

ne

um

A

i

r P

re

s

s

1

0

0

ps

i

9

0

°

0

°

E

nd

S

t

a

rt

1

6

4

1

8

9

2

8

0

3

3

6

4

8

1

5

7

5

6

0

9

7

2

7

8

8

3

1

0

3

3

1

2

9

1

4

1

7

2

3

3

2

8

0

4

3

1

7

3

9

9

2

4

8

4

6

0

5

3

A

i

r P

re

s

s

ure

l

4

0

ps

i

5

0

ps

i

6

0

ps

i

7

0

ps

i

8

0

ps

i

9

0

ps

A

0

1

4

9

6

1

7

4

8

6

9

A

0

2

1

0

4

1

3

0

1

5

A

0

3

1

8

2

A

0

4

A

0

5

A

0

6

A

0

7

A

0

8

A

0

9

R

e

t

l

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

1

0

2

3

0

2

3

3

9

6

4

5

6

7

7

8

4

5

1

1

4

9

7

1

2

2

5

3

2

ur

n

A

c

t

ua

Spr

i

ng

Q

ua

nt

i

t

y

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

5

2

8

2

7

4

7

7

4

5

3

9

5

5

9

4

0

9

8

5

1

0

5

6

1

2

6

8

8

t

7

7

1

2

2

4

5

1

6

3

3

7

9

or

T

or

que

7

0

ps

i

0

°

9

0

°

St

a

r

t

End

1

1

1

8

6

1

9

9

1

4

3

3

4

8

2

5

4

4

3

0

3

1

2

6

0

8

4

5

8

7

8

3

6

6

3

1

6

8

2

1

2

0

2

3

8

3

0

3

1

4

8

3

4

7

9

2

2

7

4

8

1

8

1

2

0

3

5

6

9

1

2

3

7

1

9

3

6

5

2

8

6

0

3

9

3

7

9

2

9

3

1

1

3

5

4

7

8

1

6

9

0

6

1

9

2

9

9

3

9

4

2

4

5

0

6

S

8

0

ps

i

0

°

9

0

°

St

a

End

r

t

1

3

7

1

1

2

2

4

5

1

8

9

4

2

4

3

3

0

5

2

9

4

1

1

7

5

0

5

9

9

9

9

4

8

7

4

2

0

5

1

6

5

8

2

4

3

8

6

2

6

0

4

6

3

3

3

7

1

3

3

i

1

1

0

2

3

3

4

1

1

6

7

9

8

9

1

1

2

7

7

1

9

0

1

3

3

6

7

5

0

6

9

R

S

i

ngl

e

A

9

0

ps

0

°

9

0

S

t

a

rt

E

1

6

3

1

3

2

9

1

2

3

4

9

9

4

0

6

2

8

5

1

8

9

1

7

4

1

2

0

6

1

0

2

4

3

0

1

9

3

4

2

9

2

6

5

1

9

5

3

9

ELECTRIC ACTUATORS

Electric Installation

1. Operate valve manually and place in the open position.

2. Remove any mechanical stops the valve might have. (DO NOT REMOVE ANY

PARTS NECESSARY FOR THE PROPER OPERATION OF THE VALVE, SUCH AS

THE PACKING GLAND, PACKING NUT, ETC.)

3. Ensure that the actuator output shaft and valve stem are aligned properly. If they

are not, operate the valve manually until they are correct.

4. Remove actuator cover.

5. Bring power to the actuator. CAUTION: Make sure power is OFF at the main box.

6. Wire the actuator per the diagram attached to the inside of the cover. Special

actuators (those with positioner boards, etc.) will have diagrams enclosed inside the

cover.

7. Securely tighten bolts used to mount the actuator to a mounting bracket or directly

to the valve mounting pad if it is ISO5211 compliant.

8. Cycle the unit several times and check the open and closed positions of the valve.

Cams are pre-adjusted at the factory; due to the variety of valve designs and types

however, slight adjustments might be required.

9. Replace cover and tighten screws.

To Set The Open Position

1. Cycle the valve to the open position by applying power to terminals. The top cam

and switch control this position. In the open position, the set screw in the top cam

will be accessible.

2. If the valve is not open completely:

A. Slightly loosen the set screw on the top cam.

B. Rotate the cam clockwise (CW) by hand until the switch makes contact.

Contact is made when a slight click can be heard. By making incremental CW

movements of the top cam, the valve can be positioned precisely in the desired

position.

C. When the top cam is set, tighten the set screw securely.

3. If the valve opens too far:

A. Apply power to terminals. This will begin to rotate valve CW. When

valve is fully open and in the exact position desired, remove power from actuator.

B. Loosen the set screw in the top cam.

C. Rotate the top cam counterclockwise (CCW) until the switch arm drops off the

round portion of the cam onto the flat section. A slight click can be heard as the

switch changes state.

D. Continue applying power to terminals until valve is in the desired position.

To Set The Closed Position

1. Apply power to terminals to move the valve toward the closed position. The

bottom cam and switch control the closed position. In the closed position, the set

screw in the bottom cam will be accessible.

2. If the valve is not closed completely:

A. Slightly loosen the set screw on the bottom cam.

B. Rotate the cam counter-clockwise (CCW) by hand until the switch makes

contact. Contact is made when a slight click can be heard. By making incremental

CCW movements of the bottom cam, the valve can be positioned precisely in the

desired position.

C. When the top cam is set, tighten the set screw securely.

3. If the valve closes too far:

A. Apply power to terminals. This will begin to rotate valve CCW. When

valve is fully closed and in the exact position desired, remove power from

actuator.

B. Loosen the set screw in the top cam.

C. Rotate the top cam clockwise (CW) until the switch arm drops off the round

portion of the cam onto the flat section. A slight click can be heard as the switch

is no longer making contact with the round part of the cam.

D. Continue applying power to terminals until valve is in the desired position.

Page 5

Page 6

1

23

4

5

6

7

8

9

10

N

HOT

A.C.

SUPPLY

POWER

P

SC MOTOR

CAPACITOR

S

W. #2

OPTIONAL

BRAKE

SW. #1 CLOSE LIMIT

SW. #2 OPEN LIMIT

SWITCH LAYOUT

OPTIONAL HEATER

& THERMOSTAT

NO

NC

L

L

1

23

4

5

6

7

8

9

10

N

HOT

A.C.

SUPPLY

POWER

DPDT CONTROL SWITCH

SHOWN FOR ILLUSTRATION

ONLY

FIELD WIRING

P

SC MOTOR

CAPACITOR

SW. #1

N

OTES:

P

OWER TO TERMINALS ONE & TWO OPENS THE VALVE

(

CCW ROTATION)

POWER TO TERMINALS ONE & THREE CLOSES THE VALVE

(

CW ROTATION)

TERMINALS 4 & 5 ARE FOR LIGHT INDICATION

WIRING DIAGRAM ILLUSTRATES THE ACTUATOR IN THE

OPEN POSITION

GROUND

SCREW

OPTIONAL

BRAKE

SW. #1 CLOSE LIMIT

SW. #2 OPEN LIMIT

SWITCH LAYOUT

OPTIONAL HEATER

& THERMOSTAT

C

NC

NO

C

NO

L

L

LIGHTS FOR REMOTE

POSITION INDICATION

OPTIONAL EQUIPMENT

FIELD WIRING

+

-

DC

MOTOR

CA

M

CA

M

SW.

#1

SW.

#2

12

3

4

5

6

COIL

DC VOLTAGE

SPDT SWITCH SHOWN FOR

ILLUSTRATION ONLY

REVERSING RELAY SUPPLIED BY CUSTOMER

-

+

FIELD WIRING

OPERATION:

POWER TO 1 & 2 FOR CCW ROTATION

POWER TO 3 & 4 FOR CW ROTATION

TERMINALS 5 & 6 FOR FIELD LIGHT

INDICATION CONNECTION

SW.#1

SW.#2

SWITCH #1 OPEN SWITCH

SWITCH #2 CLOSE SWITCH

ACTUATOR SHOWN IN OPEN

POSITION

C

O

M

CO

M

N

C

N

O

N

C

N

O

C

NO

NC

C

NO

NC

lectric Actuators Wiring Diagram: ACT-TI & ACT-MI

E

iring Diagrams for

I01-TI10: 120 VAC, TI01-TI10: 220VAC, TI01-TI10: 24 VAC

T

W

Wiring Diagrams for

TI01-TI10: 12VDC, TI01-TI10: 24 VDC

Page 6

Page 7

iring Diagrams for

8

7

6

5

4

3

2

1

6

5

4

3

2

1

J

1

J2

4-20mA POSITIONER

PSC MOTOR

CAPACITOR

SW. 1, CLOSE

SW. 2, OPEN

S

W.2

SW.1

BRAKE

OPTIONAL

1PH-60HZ

POWER SUPPLY

4-20mA CONTROL

SIGNAL

0-10VDC or 0-5VDC

CONTROL SIGNAL

REMOVE JP2, JP3 & JP4

1K OHM FEEDBACK

POTENTIOMETER

BLU

R

ED

WHT

BLK

B

L

K

B

L

K

WHT

FIELD

WIRING

N

HOT

-

+

+

NOTE:

ACTUATOR SHIPPED IN OPEN

POSITION, 20mA REPRESENTS OPEN

P

OSITION. DO NOT ADJUST FEEDBACK

POTENTIOMETER OR LIMIT SWITCHES

T

HEY ARE FACTORY SET AND DO NOT

REQUIRE CALIBRATION. TO

CALIBRATE THE OPEN AND CLOSE

POSITION USE THE ZERO (4mA) AND

SPAN (20mA) TRIM POTENTIOMETERS.

TO CALIBRATE OPERATE ACTUATOR

T

O CLOSE POSITION AND ADJUST WITH

ZERO TRIM POT THEN OPERAT TO

OPEN POSITION AND SET USING SPAN

TRIM POT. NO FUTHER CALIBRATION IS

NECESSARY.

HEATER &

THERMOSTAT

OPTIONAL

WIRING DIAGRAM FOR 1Ph/60Hz ELECTRIC

ACTUATOR WITH 4-20mA, 0-5Vdc OR 0-10Vdc CONTROL.

JP2

RED

G

REEN

JP3

JP4

F

U

S

E

DEAD

BAND

JP1

ZERO

SPAN

C

NO

NC

C

NO

NC

JP2

RED

GREEN

JP3

JP4

JP2

RED

GREEN

JP3

JP4

JUMPER SET FOR

FAIL OPEN UPON

LOSS OF CONTROL

S

IGNAL

JUMPER SET FOR

FAIL CLOSE UPON

LOSS OF CONTROL

SIGNAL

JUMPER AS SHOWN BELOW IS FAIL IN

LAST POSITION UPON LOSS OF SIGNAL

G

R

N

R

E

D

C

NO

NC

C

NO

NC

9

10

1

1

1

2

1

3

1

4

SW. 3, CLOSE

S

W. 4, OPEN

AUXILIARY SWITCHES

O

PTIONAL

S

W.4

SW.3

OPTIONAL EQUIPMENT

FIELD WIRING

8

7

6

5

4

3

21

6

5

4

3

2

1

J1

J2

4-20mA POSITIONER

PSC MOTOR

CAPACITOR

SW. 1, CLOSE

SW. 2, OPEN

SW.2

SW.1

BRAKE

OPTIONAL

1PH-60HZ

POWER SUPPLY

4-20mA CONTROL

SIGNAL

0-10VDC or 0-5VDC

CONTROL SIGNAL

REMOVE JP2, JP3 & JP4

1K OHM FEEDBACK

POTENTIOMETER

BLU

RED

WHT

BLK

B

L

K

B

L

K

WHT

FIELD

WIRING

N

HOT

-

+

+

NOTE:

ACTUATOR SHIPPED IN OPEN

POSITION, 20mA REPRESENTS OPEN

POSITION. DO NOT ADJUST FEEDBACK

POTENTIOMETER OR LIMIT SWITCHES

THEY ARE FACTORY SET AND DO NOT

REQUIRE CALIBRATION. TO

CALIBRATE THE OPEN AND CLOSE

POSITION USE THE ZERO (4mA) AND

SPAN (20mA) TRIM POTENTIOMETERS.

TO CALIBRATE OPERATE ACTUATOR

TO CLOSE POSITION AND ADJUST WITH

ZERO TRIM POT THEN OPERAT TO

OPEN POSITION AND SET USING SPAN

TRIM POT. NO FUTHER CALIBRATION IS

NECESSARY.

HEATER &

THERMOSTAT

OPTIONAL

WIRING DIAGRAM FOR 1Ph/60Hz ELECTRIC

ACTUATOR WITH 4-20mA, 0-5Vdc OR 0-10Vdc CONTROL.

JP2

RED

GREEN

JP3

JP4

F

U

S

E

DEAD

BAND

JP1

ZERO

SPAN

C

NO

NC

C

NO

NC

JP2

RED

GREEN

JP3

JP4

JP2

RED

GREEN

JP3

JP4

JUMPER SET FOR

FAIL OPEN UPON

LOSS OF CONTROL

SIGNAL

JUMPER SET FOR

FAIL CLOSE UPON

L

OSS OF CONTROL

SIGNAL

JUMPER AS SHOWN BELOW IS FAIL IN

LAST POSITION UPON LOSS OF SIGNAL

G

R

N

R

E

D

C

NO

NC

C

NO

NC

9

10

11

12

13

14

SW. 3, CLOSE

SW. 4, OPEN

AUXILIARY SWITCHES

OPTIONAL

SW.4

SW.3

OPTIONAL EQUIPMENT

FIELD WIRING

I01-MI10: 120 VAC, MI01-MI10: 220 VAC, MI01-MI10: 24 VAC

M

W

MI01-MI10: 12 VDC, MI01-MI10: 24 VDC

Wiring Diagrams for

Page 7

Page 8

lectric Actuators Wiring Diagram: ACT-TD & ACT-MD

E

Wiring Diagrams for

D01-TD09: 120 VAC, TD01-TD09: 220 VAC, TD01-TD09: 24 VAC

T

ote: To speed up installation of the control wires to the ACT-MDXX modulating

N

ctuator, it is recommended to remove the control module from the actuator. The

a

ontrol module can be removed by removing the two mounting screws on the left

c

nd right of the control module. Install the control wires to the correct terminal points

a

and then reinstall the control module.

Electric Actuator Maintenance

nce the actuator has been properly installed, it requires no maintenance. The gear

O

rain has been lubricated and in most cases will never be opened.

t

uty Cycle Definition

D

“Duty Cycle” means the starting frequency.

Fomula: Running Time (Running Time Rest Time) x 100% = duty cycle

Rest Time = Running Time x (1 - duty cycle) duty cycle

or example: The running time is 15 seconds

F

0% duty cycle 15 x [(1 - 30%) / 30%] = 35 The rest time will be 35 seconds

3

•

•

•

•

•

•

75% duty cycle 15 x [(1 - 75%) / 75%] = 5 The rest time will be 5 seconds

If the duty cycle is higher, the rest time will be shortened. It means the starting

frequency will be higher.

hermal Overload

T

ll actuators are equipped with thermal overload protection to guard the motor

A

against damage due to overheating.

iring Diagrams for

W

D01-TD06: 24 VDC

T

Wiring Diagrams for

MD01-MD09: 120 VAC, MD01-MD09: 220 VAC, MD01-MD09: 24 VAC

Mechanical Overload

All actuators are designed to withstand stall conditions. It is not recommended to

ubject the unit to repeated stall conditions.

s

xplosion-Proof Electric Actuators

E

WARNING

. DO NOT under any circumstances remove the cover of the

1

ctuator while in a hazardous location. Removal of the cover

a

while in a hazardous location could cause ignition of hazardous atmospheres.

2. DO NOT under any circumstances use an explosion-proof electric actuator in a

hazardous location that does not meet the specifications for which the actuator was

designed.

3. Always verify that all electrical circuits are de-energized before opening the

actuator.

4. Always mount and cycle test the actuator on the valve in a non-hazardous

location.

5. When removing the cover, care must be taken not to scratch, scar of deform the

flame path of the cover and base of the actuator, since this will negate the NEMA

rating of the enclosure.

6. When replacing the cover, take care that the gasket is in place to assure proper

clearance after the cover is secured.

7. All electrical connections must be in accordance with the specifications for which

the unit is being used.

8. Should the unit ever require maintenance, remove from the hazardous location

before attempting to work on the unit.

If the actuator is in a critical application, it is advisable to have a standby unit in stock.

Page 8

Page 9

Electric Actuators Performance Rating

D01

T

oltage

V

ycle Time

C

uty Cycle (Two-Position)

D

AMP Draw

Torque

D01

M

oltage

V

ycle Time

C

D01 Duty Cycle (Modulating)

M

AMP Draw

Torque

D02 and MD02

T

oltage

V

ycle Time

C

Duty Cycle (Two-Position)

Duty Cycle (Modulating)

AMP Draw

Torque

TD03 and MD03

Voltage

ycle Time

C

uty Cycle (Two-Position)

D

uty Cycle (Modulating)

D

AMP Draw

Torque

D04 and MD04

T

oltage

V

Cycle Time

Duty Cycle (Two-Position)

Duty Cycle (Modulating)

AMP Draw

Torque

TD05 and MD05

Voltage

Cycle Time

Duty Cycle (Two-Position)

Duty Cycle (Modulating)

AMP Draw

Torque

TD06 and MD06

Voltage

Cycle Time

Duty Cycle (Two-Position)

Duty Cycle (Modulating)

AMP Draw

Torque

TI01 and MI01

Voltage

Cycle Time

Duty Cycle (Two-Position)

Duty Cycle (Modulating)

AMP Draw

Torque

TI02 and MI02

Voltage

Cycle Time

TI01 Duty Cycle (Two-Position)

MI01 Duty Cycle (Modulating)

AMP Draw

Torque

(MD Not Available in 24 VDC)

MD Not Available in 24 VDC)

(

(MD Not Available in 24 VDC)

(MD Not Available in 24 VDC)

(MD Not Available in 24 VDC)

10 VAC

1

s

4

5%

8

0.24 A

177 in-lb

1

1

8

0.24 A

265 in-lb

10 VAC

1

0 s

2

85%

85%

0.24 A

442 in-lb

110 VAC

0 s

3

5%

8

5%

8

0.57 A

885 in-lb

10 VAC

1

30 s

85%

85%

0.65 A

1770 in-lb

110 VAC

30 s

85%

85%

1.12 A

3540 in-lb

110 VAC

45 s

85%

85%

1.18 A

5210 in-lb

110 VAC

2.5 s

25%

75%

0.55 A

100 in-lb

110 VAC

5 s

25%

75%

0.75 A

200 in-lb

10 VAC

0 s

5%

2

2

85%

85%

0.16 A

442 in-lb

220 VAC

3

8

8

0.35 A

885 in-lb

220 VAC

30 s

85%

85%

0.57 A

3540 in-lb

20 VAC

2

s

4

5%

8

0.16 A

177 in-lb

20 VAC

0 s

0 s

5%

5%

20 VAC

2

30 s

85%

85%

0.37 A

1770 in-lb

220 VAC

45 s

85%

85%

0.60 A

5210 in-lb

220 VAC

2.5 s

25%

75%

0.38 A

100 in-lb

220 VAC

5 s

25%

75%

0.38 A

200 in-lb

4 VAC

2

s

4

5%

8

0.28 A

177 in-lb

20 VAC

2

0 s

1

5%

8

0.16 A

265 in-lb

4 VAC

2

0 s

2

85%

85%

1.28 A

442 in-lb

24 VAC

0 s

3

5%

8

5%

8

2.03 A

885 in-lb

4 VAC

2

30 s

85%

85%

3.57 A

1770 in-lb

24 VAC

30 s

85%

85%

5.13 A

3540 in-lb

24 VAC

45 s

85%

85%

6.04 A

5210 in-lb

24 VAC

2.5 s

25%

75%

2.44 A

100 in-lb

2

4

8

1.28 A

177 in-lb

4 VAC

2

0 s

1

5%

8

1.28 A

265 in-lb

4 VDC

2

0 s

2

85%

1.28 A

442 in-lb

24 VDC

0 s

3

5%

8

2.03 A

885 in-lb

24 VAC

5 s

25%

75%

3.2 A

200 in-lb

4 VDC

s

5%

4 VDC

2

30 s

85%

3.57 A

1770 in-lb

24 VDC

30 s

85%

5.13 A

3540 in-lb

24 VDC

45 s

85%

6.04 A

5210 in-lb

24 VDC

2.5 s

25%

75%

2.44 A

100 in-lb

24 VDC

5 s

25%

75%

3.2 A

200 in-lb

TI03 and MI03

Voltage

Cycle Time

uty Cycle (Two-Position)

D

uty Cycle (Modulating)

D

MP Draw

A

orque

T

TI04 and MI04

Voltage

ycle Time

C

uty Cycle (Two-Position)

D

uty Cycle (Modulating)

D

MP Draw

A

Torque

I05 and MI05

T

oltage

V

Cycle Time

Duty Cycle (Two-Position)

Duty Cycle (Modulating)

MP Draw

A

orque

T

TI06 and MI06

oltage

V

ycle Time

C

uty Cycle (Two-Position)

D

Duty Cycle (Modulating)

AMP Draw

Torque

I07 and MI07

T

oltage

V

ycle Time

C

Duty Cycle (Two-Position)

Duty Cycle (Modulating)

AMP Draw

Torque

TI08 and MI08

Voltage

Cycle Time

Duty Cycle (Two Position)

Duty Cycle (Modulating)

AMP Draw

Torque

TI09 and MI09

Voltage

Cycle Time

Duty Cycle (Two-Position)

Duty Cycle (Modulating)

AMP Draw

Torque

TI10 and MI10

Voltage

Cycle Time

Duty Cycle (Two-Position)

Duty Cycle (Modulating)

AMP Draw

Torque

MAINTENANCE/REPAIR

Upon final installation of the Series WE, only routine maintenance is required. The

Series WE is not field serviceable and should be returned if repair is needed. Field

repair should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sale” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping

the product back for repair. Be sure to include a brief description of the problem

plus any additional application notes

110 VAC

5 s

5%

2

5%

7

.75 A

0

00 in-lb

3

110 VAC

0 s

1

5%

2

5%

7

.75 A

0

400 in-lb

10 VAC

1

15 s

25%

75%

.75 A

0

25 in-lb

6

10 VAC

1

5 s

1

5%

2

75%

1.1 A

1000 in-lb

10 VAC

1

0 s

3

25%

75%

1.1 A

1500 in-lb

110 VAC

12 s

100%

100%

2.6 A

2000 in-lb

110 VAC

14 s

100%

100%

2.99 A

3840 in-lb

110 VAC

68 s

100%

100%

2.99 A

5000 in-lb

220 VAC

5 s

5%

2

5%

7

.38 A

0

00 in-lb

3

220 VAC

0 s

1

5%

2

5%

7

.38 A

0

400 in-lb

20 VAC

2

15 s

25%

75%

.38 A

0

25 in-lb

6

20 VAC

2

5 s

1

5%

2

75%

0.38 A

1000 in-lb

20 VAC

2

0 s

3

25%

75%

0.38 A

1500 in-lb

220 VAC

12 s

100%

100%

2.4 A

2000 in-lb

220 VAC

14 s

100%

100%

2.4 A

3840 in-lb

220 VAC

68 s

100%

100%

2.4 A

5000 in-lb

24 VAC

5 s

5%

2

5%

7

.2 A

3

00 in-lb

3

24 VAC

0 s

1

5%

2

5%

7

.2 A

3

400 in-lb

4 VAC

2

15 s

25%

75%

.2 A

3

25 in-lb

6

4 VAC

2

5 s

1

5%

2

75%

3.2 A

1000 in-lb

4 VAC

2

0 s

3

25%

75%

3.2 A

1500 in-lb

24 VAC

12 s

100%

100%

20 A

2000 in-lb

24 VAC

14 s

100%

100%

20 A

3840 in-lb

24 VAC

68 s

100%

100%

20 A

5000 in-lb

24 VDC

5 s

5%

2

5%

7

.2 A

3

00 in-lb

3

24 VDC

0 s

1

5%

2

5%

7

.2 A

3

400 in-lb

4 VDC

2

15 s

25%

75%

.2 A

3

25 in-lb

6

4 VDC

2

5 s

1

5%

2

75%

3.2 A

1000 in-lb

4 VDC

2

0 s

3

25%

75%

3.2 A

1500 in-lb

24 VDC

12 s

100%

100%

20 A

2000 in-lb

24 VDC

14 s

100%

100%

20 A

3840 in-lb

24 VDC

68 s

100%

100%

20 A

5000 in-lb

Page 9

Page 10

Page 10

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 7/14 FR# VA-444176-00 Rev.4

W.E. ANDERSON,

A DIV. OF DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360 U.S. A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyermail.com

Loading...

Loading...