Page 1

Bulletin AV-3-VTT

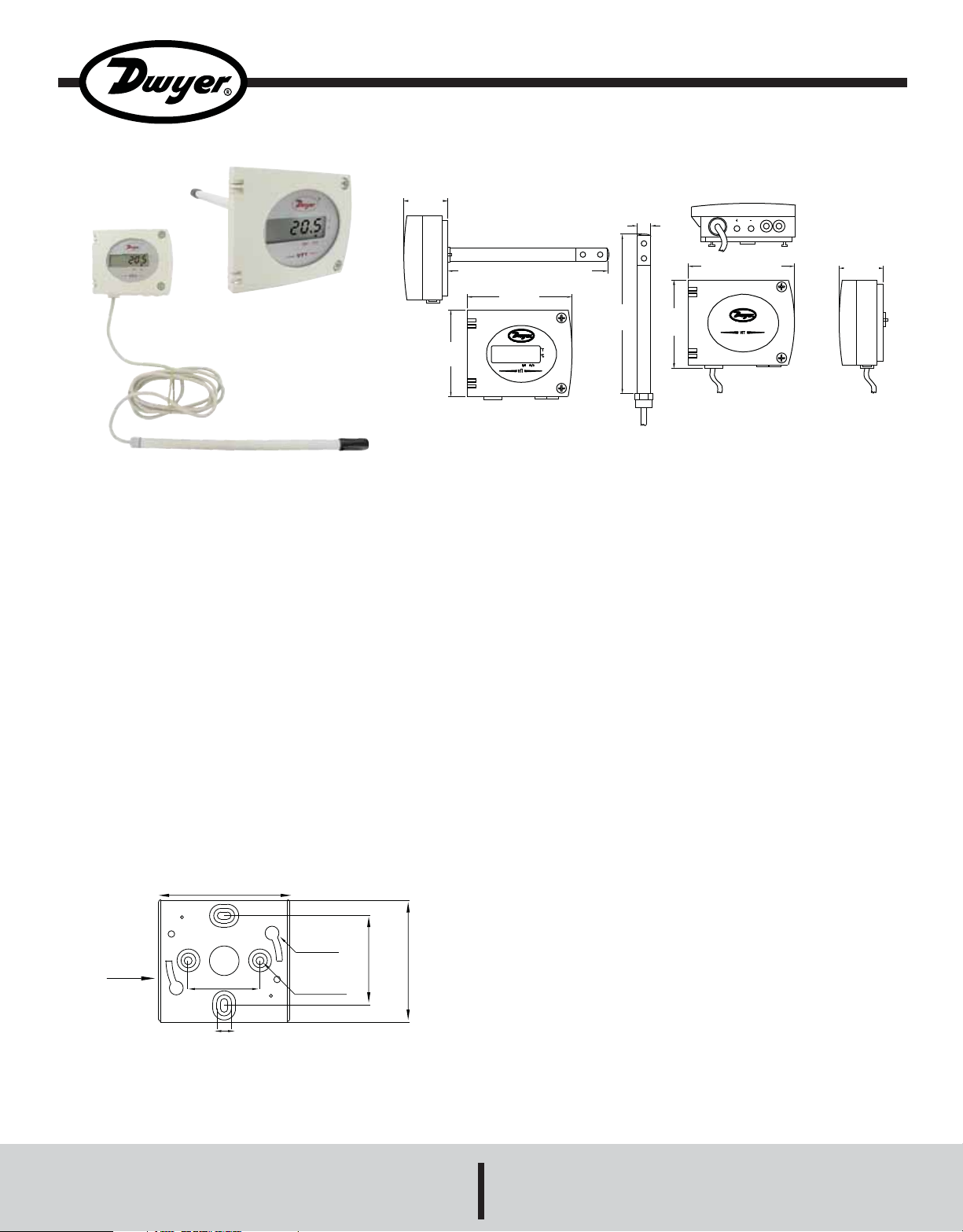

Series VTT Hot-Wire Air Velocity/Temperature Transmitter

Specifications - Installation and Operating Instructions

1-21/32

[42.00]

3-17/64

[83.00]

(SHOWN WITH DUCT MOUNT PROBE)

The Series VTT Hot-Wire Air Velocity and Temperature Transmitter provides

a versatile unit for air velocity and temperature needs. The VTT offers five fieldselectable ranges as well as operating in metric (m/s, °C) or English (fpm, °F)

units. The VTT can measure up to 30 m/s (6000 fpm) and 50°C (122°F). The units

are available with or without an LCD display which alternates between velocity and

temperature. Series VTT can be ordered in duct mount or remote mount

configurations with 4-20 mA or 0-10V output. The VTT is a useful transmitter for

many common HVAC applications.

INSTALLATION

Position: The Series VTT Hot-wire probe should be oriented perpendicular to the

airflow for best reading. Ensure that the red dot on the airflow probe is facing

against the airflow by removing the screw on the tip of the probe and rotating the

probe tip 1/4, 1/2, or 3/4 of a turn.

Mounting: The Series VTT can be mounted in any orientation, provided that the

airflow probe is oriented correctly to the flow.

Wall Mount Installation:

Mount the ABS plate on the wall (this plate is supplied with the transmitter). Drilling:

Ø 6 mm (with the screws and pins supplied with the transmitter). Insert the

transmitter on the plate (see A on the drawing below) and rotate its housing in

clockwise direction until you hear a “click” which confirms that the transmitter is

correctly installed). For the model with duct mount, an additional drilling of Ø 14

mm must be done before mounting the plate.

REMOTE PROBE ASSEMBLY

(SHOWN IN 150 MM LENGTH)

33/64 [13.00]

SHOWN IN 150 MM LENGTH

3-15/16

[100.00]

MODELS VTT-X-D-X-X

SPECIFICATIONS

Service: Clean air and compatible, non-combustible gases.

Accuracy: Air Velocity: ±3% of reading ±60 fpm (±0.3 m/s); Temperature: ±0.5%

of reading ±0.6°F (±0.4°C).

Temperature Limits: Ambient: 32 to 122°F (0 to 50°C); Storage: 14 to 158°F

(-10 to 70°C).

Power Supply: 24 VAC/VDC (±10%) 3-4 wires.

Current Consumption: 4-20 mA Output: 80 mA maximum; 0-10V Output: 40

mA.

Response Time: Air velocity: 2 seconds to 1/e (63%) of final value;

Temperature: 5 seconds to 1/e (63%) of final value.

Maximum Loop Resistance: 4-20 mA Output: 500 Ω; 0-10V Output: 1 kΩ.

Display: 5 digit; Resolution 1 fpm (0.1 m/s) 1.0°F (0.1°C). Alternates between

velocity and temperature.

Electrical Connection: Screw terminal block.

Cable Length (Remote Probe): 6.56 ft (2 m).

Enclosure Rating: ABS rated NEMA 4X (IP65).

Mounting: Can be mounted in any orientation. Probe must be aligned with

airflow.

Weight: With Display: 0.32 lb (145 g); Without Display: 0.24 lb (110 g).

Agency Approvals: CE.

Airflow: The Series VTT is intended for use with clean, dry air. Particulates in the

air may cause damage to the sensitive airflow probe. Dust accumulation may

impair the velocity measurement and may require cleaning.

5-29/32

[150.00]

3-17/64

[83.00]

3-15/16 [100.00]

(SHOWN WITH REMOTE PROBE MOUNTING)

MODELS VTT-X-N-X-X

1-21/32

[42.00]

Position of the measuring element in the air flow

The probe must be placed perpendicular to the air flow. For duct mount probes,

you can place the probe’s head front to the air flow, and keep the housing straight:

• Locate the red point marked on the probe’s head.

• Remove the screw located on the tip of the probe’s body.

• Rotate the probe’s head by 1/4 turn, 1/2 turn, or 3/4 turn, in order to place the red

spot front to the air flow.

• Replace the screw on the probe’s body.

ABS

plate

73 mm

+

+ +

40 mm

A

+

A

Ø 8 mm

Ø 4,5 mm

50 mm

68 mm

7 mm

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

passive input

Configurations

32 to 122°F

1234

-4 to 176°F

1234

-58 to 122°F

1234

32 to 212°F

1234

Configurations

0 to 50°C

1234

-20 to 80°C

1234

-50 to 50°C

1234

0 to 100°C

1234

Field Selectable Temperature Ranges

ELECTRICAL CONNECTIONS

Configurations

0 to 1000 fpm 0 to 2000 fpm 0 to 3000 fpm 0 to 4000 fpm 0 to 6000 fpm

0 to 5 m/s 0 to 10 m/s 0 to 15 m/s 0 to 20 m/s 0 to 30 m/s

Configurations

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

Field Selectable Velocity Ranges

air velocity

maximum possible

measurements ranges

based on working

temperatures

temperature

0°C 10°C 20°C 30°C 50°C40°C

V max. f(T°)

30 m/s

25 m/s

20 m/s

15 m/s

10 m/s

5 m/s

0-10V MODEL (4-Wire)

TRANSMITTER SETUP

To configure the Series VTT, unscrew the two screws on the housing of the

transmitter, and remove the cover to reveal the DIP switches.

0-10V MODEL (3-Wire)

4-20 mA MODEL (4-Wire)

These DIP switches are used to control the units and ranges of the temperature

and air velocity of the transmitter as shown below.

Please Note: Before attempting to alter the DIP switch settings, ensure that the

transmitter is not powered.

Note: The standard temperature range should be 0-50°C or 32-122°F. If you select

a different temperature setting, the air velocity may not operate outside the

performance range shown in the velocity range versus temperature diagram

below.

4-20 mA MODEL (3-Wire)

MAINTENANCE

In general the Series VTT should require very little maintenance. In some

installations dust may accumulate on the sensor over time. This can be removed

by carefully brushing the probe with a small camel hairbrush. If too much force is

applied during cleaning, the sensor of the Series VTT may be damaged. Therefore,

a trained technician should perform the cleaning operation. A jet of air may also

dislodge the accumulated buildup however, again, the sensor is delicate and this

operation should be done carefully with clean regulated air. Using a shop air supply

may exert enough force to damage the sensor. Most air supplies of this sort will

©Copyright 2010 Dwyer Instruments, Inc. Printed in U.S.A. 6/10 FR# R1-443704-00 Rev. 1

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

also contain water or oil that could damage the sensor. Technical grade denatured

or isopropyl alcohol may be used where the dust accumulation does not respond

to brushing. Do not use water. Always disconnect the power when performing a

cleaning operation. With the above exceptions, these items are not field repairable

and should be returned to Dwyer Instruments, Inc. for repair. Please contact a

customer service representative for a return goods authorization.

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...