Page 1

Bulletin L-VRLS

4

-9/32

[

108.83]

4

-29/64

[

113.03]

1˝ NPT

5

1/64

[

20.19]

10-27/32˝

[275.35]

Ø

3/4

[

18.87]

Model VRLS Vibrating Rod Level Switch

Specifications - Installation and Operating Instructions

he Model VRLS Vibrating Rod Level Switch is an economical choice in level

T

etection of powders and bulk solids. Ideal for silo or hopper applications, its probe

d

esign allows for self-cleaning, ensuring no build-up of material and accurate

d

detection. Sensitivity is adjustable for detection ranging from large granular

material to small powders with low bulk densities.

perating Principle

O

he vibrating probe level switch is a system kept in resonance by piezoelectric

T

lements. When the vibration of the probe is damped by the surrounding medium,

e

the change in resonant frequency is detected by an electronic unit and converted

into a digital switching signal. Sensitivity adjustment for different detected materials

is not frequent, as there is no additional circuitry for signal amplification.

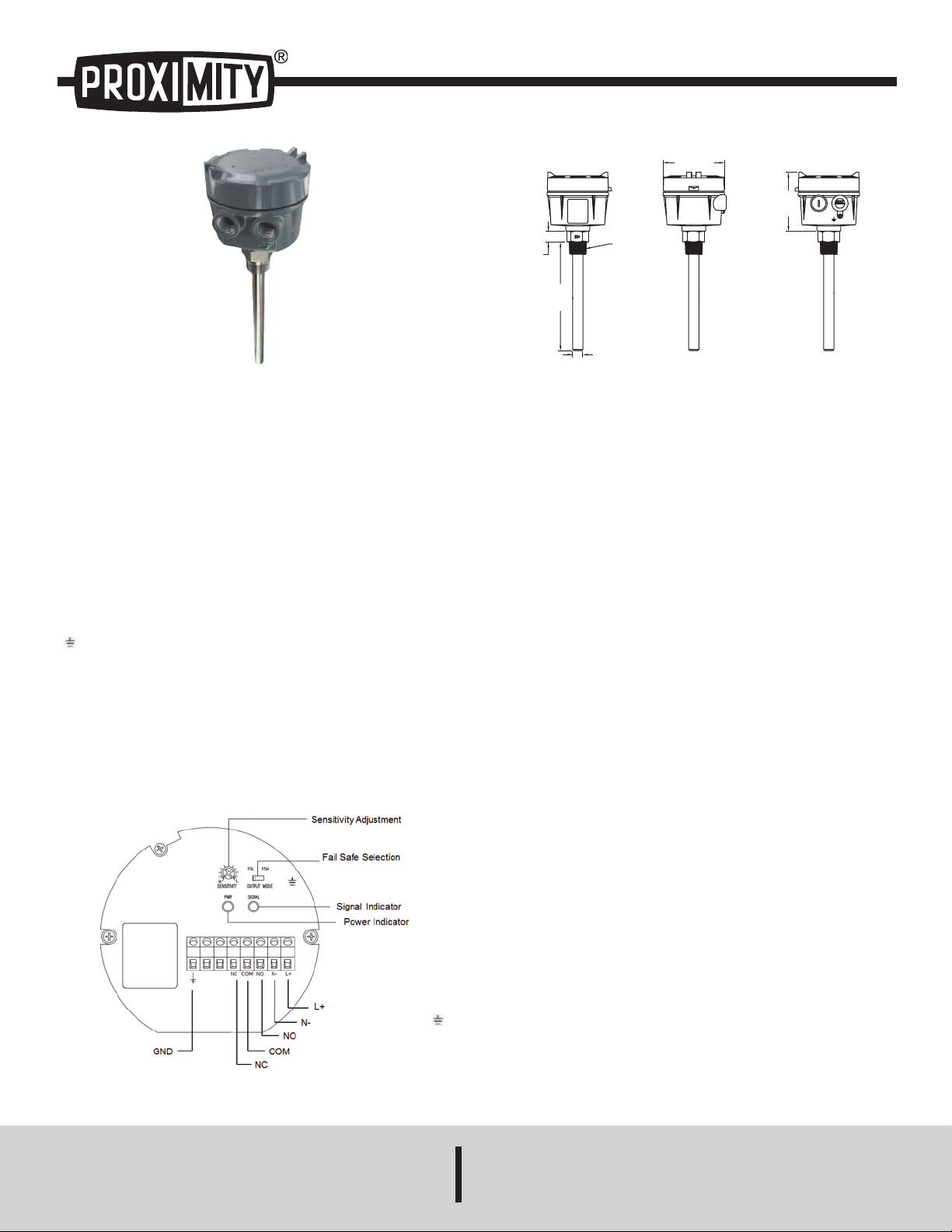

Electrical Connections

Terminal Functions

• L+, N-: Power

• NC, COM, NO: Relay Output

• Ground Connection

Panel Functions

-PWR: Power

-SIGNAL: Output Signal

-FSH (Fail Safe High): After power is connected, signal indicator lamp will turn on

and the switch will close. When probe detects material, the signal indicator lamp

will turn off and the switch will open.

-FSL (Fail Safe Low): After power is connected, the signal indicator lamp will turn

off and the switch will remain open. When probe detects material, the signal

indicator lamp will turn on and the switch will close.

SPECIFICATIONS

Service: Dry powder or bulk materials compatible with wetted materials.

Sensitivity: Min. bulk density of 20 lb/ft

etted Materials: 304 SS.

W

emperature Limits:

T

mbient: -40 to 140°F (-40 to 60°C);

A

Process: -40 to 176°F (-40 to 80°C).

Pressure Limit: 150 psi (10 bar).

Power Requirement: 20 to 250 VAC/VDC, 50/60 Hz.

Power Consumption: 15 VA.

nclosure: Aluminum, painted.

E

Enclosure Rating: IP65.

Switch Type: SPDT.

Electrical Rating: 5 A @ 250 VAC.

Electrical Connections: Screw terminals.

Conduit Connection: 1/2˝ female NPT x 2.

Process Connection: 1˝ male NPT.

Indication Lights: Internal: green and red LED.

Sensing Delay: 0 to 6 s.

Weight: 4.4 lb (2.0 kg).

3

(320 kg/m3).

Electrical Connections

DWYER INSTRUMENTS, INC.

Terminal Fu

• L+, N-

• NC, COM,

•

n

ctio

ns:

:

Power

NO:

Ground

Relay Output

Connection

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

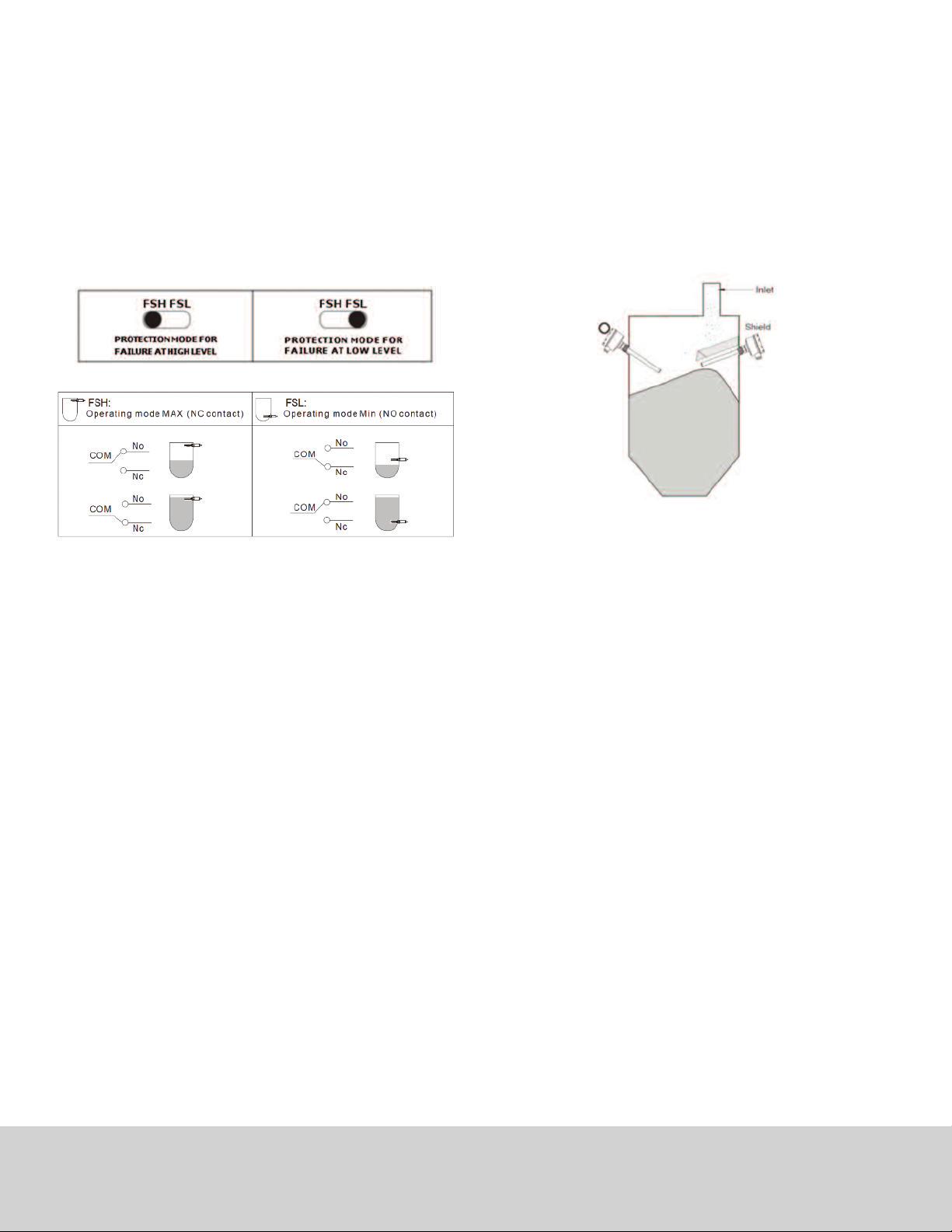

utput Indication

O

. Before wiring, please select the appropriate input power supply (L+/N-) 20-250

1

AC/VDC, 50/60Hz.

V

When operating in either FSH mode, the output will function as follows:

A. The signal indicator lamp will light up if the level switch detects no material or the

bin is empty. The NO and COM contacts of the relay will be conducting.

. The signal indicator lamp will turn off if the level switch detects material. The NC

B

nd COM contacts of the relay will be conducting.

a

hen operating in either FSL mode, the output will function as follows:

W

A. The signal indicator lamp will light up if the level switch detects material. The NC

and COM contacts of the relay will be conducting.

B. The signal indicator lamp will turn off if the level switch detects material. The NC

nd COM contacts of the relay will be conducting.

a

HECK OPERATION-VERIFY SWITCH OPERATION

C

igure 3 - Failure-Mode Switch

F

nstallation

I

hen installing VRLS, the following should be noted.

W

Top Mounting

-Avoid installing directly under substance inlet to prevent damage to the probe.

-Angle of mounting should be taken into consideration during installation to prevent

alse alarm.

f

ide Mounting

S

It is highly recommended to use a shield to protect the vibrating probe level switch.

-

The cover should be parallel to the probe and of the same length.

-Incline the device at approximately 20 degrees when installing.

Keep conduit facing downward to prevent moisture from getting inside the housing

hile in operation.

w

All wiring should employ 18 AWG cable.

-

igure 5 - Side Mounting Installation

F

Figure 4 - Diagram of Relay Output

Sensitivity Calibration

In order to adjust the sensitivity of the switch, the following procedure should be

followed:

1. If level switch has already been installed, confirm sensitivity before materials are

added.

2. By default, the output mode of the switch is set to FSH. This can be adjusted as

needed for each particular application.

3. Based on the particular application, the sensitivity can be adjusted by rotating the

SENSITIVITY knob to an appropriate selectable sensitivity setting.

Typically, the sensitivity knob is set as follows:

- SENSITIVITY L: Low Sensitivity

- SENSITIVITY H: High Sensitivity

L: Suitable for detecting a medium that has a large volume or density such as a

plastic material.

H: Suitable for detecting a medium that has a smaller volume or density such as rice

bran.

MAINTENANCE/REPAIR

Upon final installation of the Model VRLS no routine maintenance is required. The

Model VRLS is not field serviceable and should be returned if repair is needed. Field

repair should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping the

product back for repair. Be sure to include a brief description of the problem plus any

additional application notes.

©Copyright 2013 Dwyer Instruments, Inc. Printed in U.S.A. 3/13 FR# R4-444060-00 Rev. 4

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...