Page 1

™

Series VPT Positioner Transmitter

20 4030

LCD

LCD

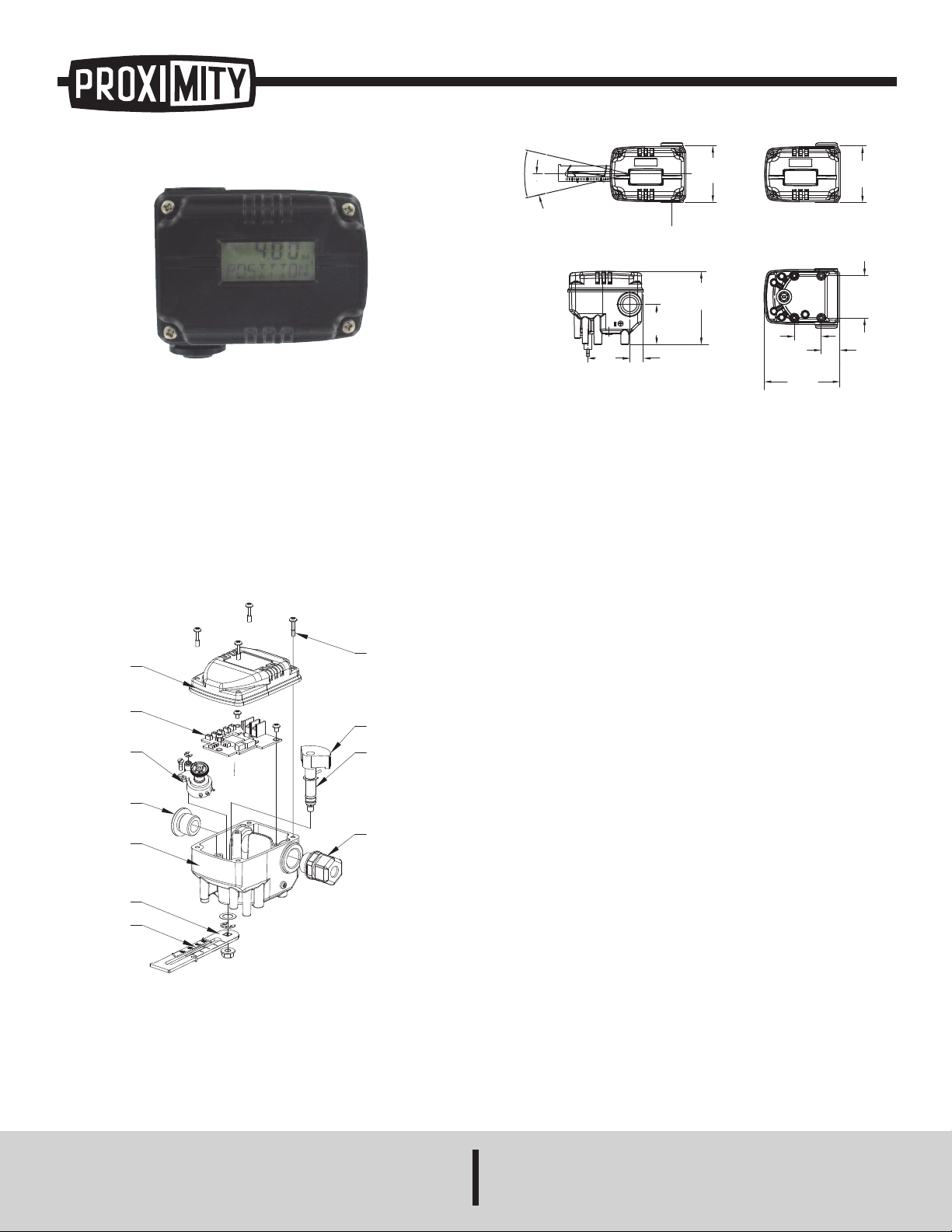

VPT-L

VPT-R

2

-29/32

[

74.00]

2-11/64

[55.00]

4

5/64

[

17.80]

2

-1/16

[

52.50]

3

-49/64

[

95.50]

3-7/8

[98.60]

1-3/8

[35.00]

6

1/64

[

24.30]

2

-11/64

[

55.00]

26° [MAX. 34°]

1

3°

2

-29/32

[

74.00]

BASE COVER

PCB BOARD

POSITION

BLIND PLUG

BASE BODY

FEEDBACK SPRING

FEEDBACK LEVER

CABLE CONNECTOR

MAIN GEAR

TRANSMETTER ASS'Y

MAIN SHAFT

C

OVER BOLT

Specifications - Installation and Operating Instructions

Bulletin V-VPT

The Series VPT Valve Position Transmitter is an ideal way to track

position of valve. With both linear and rotary motion monitoring available,

this Valve Position Transmitter can suit a wide variety of applications.

Using a resistance gear in conjunction with a potentiometer, the change

in resistance outputs a proportional current signal which is sent to the

controller. The standard LCD display allows operator to monitor the

precise position of valve.

Series VPT Parts and Assembly

Below is the assembly for the VPT-LA1 and VPT-RA1, with the only

difference being the feedback lever.

SPECIFICATIONS

Input Signal: 0 to 30°(LA1); 0 to 90°(RA1).

Output Signal: 4 to 20 mA DC.

Supply Voltage: 9 to 28 VDC.

Enclosure: Aluminum.

Electrical Connection: M20 cable gland.

Linearity: ±1% FS.

Hysteresis: ±0.2% FS.

Sensitivity: ±0.2% FS.

Enclosure Rating: IP67.

Operating Temperature: -22 to 185°F (- 30 to 85°C).

Weight: 1.3 lb (0.6 kg).

Phone: 219/879-8000 www.dwyer-inst.com

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

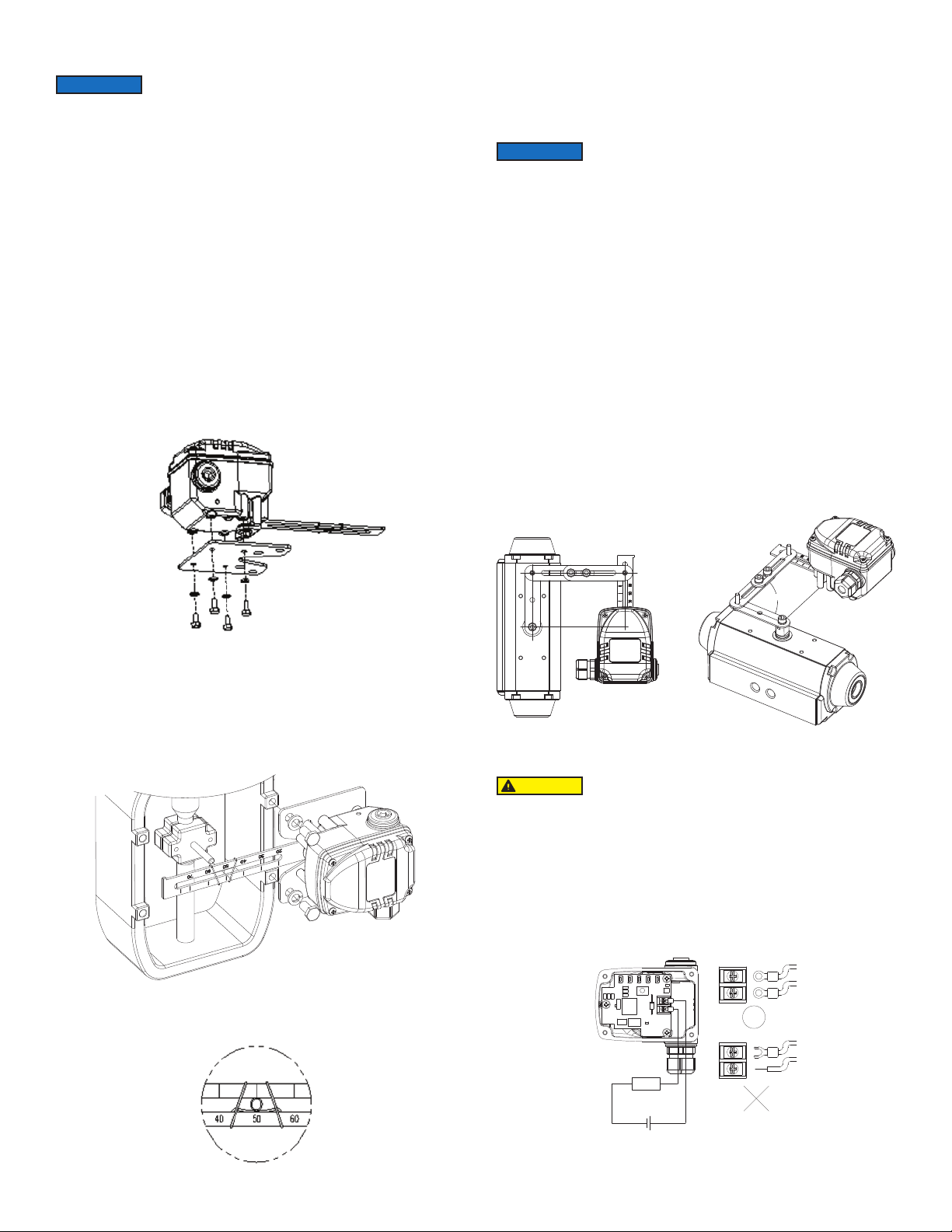

Installation

LEVER PIN

CONNECTOR LEVER

FORK

ACTUATOR

90°

4mA

8mA

12mA

16mA

20mA

LOAD

OUTPUT

4~20mA DC

10~30V DC

NOTICE

Before installation, be sure to be aware of the following:

-Always wear safety equipment and follow safety procedures.

-As a safety precaution during installation, it is advised to shut down

valve and actuator temporarily.

-In order to prevent total shut down of system, please utilize by-pass

valve or other similar device and dissemble the valve on which the

position transmitter will be installed.

-In explosive area, please make sure no explosive gases are present at

time of installation.

Installing VPT-LA1 with Bracket

1. It is necessary to make a proper bracket to attach on the actuator

yoke. Please refer to actuator and VPT dimensions to make proper

bracket size.

The most important considerations in the design of the bracket are as

follows:

-VPT-LA1 feedback lever should be at 50% of valve stroke.

- Feedback level connection bar of actuator clamp should be connected

in the position so that the valve stroke and the numbers carved on

feedback lever are fitted. If the bracket meets the above conditions, the

VPT-LA1 can be installed very easily.

6. Insert the connection bar attached to the actuator clamp into the slot

of the VPT-LA1’s feedback lever. In order to reduce hysteresis, it should

appear as shown in step 5.

7. Check that the VPT-LA1’s feedback lever is level at 50% of valve

stroke. If not, move bracket or feedback link until it is level.

OTICE

N

nd 100%, check to see if the feedback lever is touching the lever stopper (located

a

n the backside of VPT-LA1). If touching, the VPT-LA1 should be installed further

o

away from the center of the actuator yoke.

fter installing the VPT-LA1, operate the valve stroke from 0 to

A

00% by using the air filter regulator on the actuator. At both 0

1

8. Once the VPT-RA1 is installed according to the above procedures,

tighten the bolts and nuts of the bracket and feedback lever connection

bar completely.

Installing VPT-RA1 with Bracket

The VPT-RA1 is designed for rotary motion valves such as Dwyer

Instruments’ ball and butterfly valves using rack and pinion, scotch yoke

or complex type actuators whose stem is rotated 90°.

1. Before installing the VPT-RA1, please set the actuator to the default

position. For single action type valves, the actuator will automatically

default itself when the air pressure shuts down. For double action type

valves, the default position must be set manually according to the

actuator’s specifications.

2. Please refer to the actuator and VPT-RA1’s dimensions in order to

make the proper bracket. See below diagram for installation with bracket.

3. After the appropriate bracket is made, install the VPT-RA1 on the

actuator and fasten all bolts and nuts completely.

2. Assemble VPT-LA1 and bracket with bolts. Use standard bolts in bolt

holes on the backside of the unit.

3. After assembling VPT-LA1 and bracket with bolts, attach it using bolt

holes of actuator yoke. Do not tighten completely. There must be some

space.

4. Connect VPT-LA1 feedback lever to the actuator clamp. The slot

length on the VPT-LA1 feedback lever is .26” (6.5 mm), so the diameter

of the connection bar should be less than .24” (6.3 mm).

5. Connect the air filter regulator with the actuator temporarily. Set the

supply pressure of the air filter so that the actuator clamp is at 50% of

valve stroke.

Power Connection

CAUTION

1. Before connecting terminal, power must be shut off.

2. Use ring type terminal against oscillation, impact, etc.

3. In order to protect Position Transmitter, the ground terminals should be

grounded.

4. Use twisted cable with conductor sectional area at least 0.0019 in²

(1.25 mm²), and suitable for 600V as on conductor table of NEC Article

310. Outer diameter of cable should be .25 to .39” (6.35 to 10 mm). Use

shielded wire against electromagnetic waves and noise.

5. Do not install the cable near equipment such as a high-capacity

transformer or motor.

Page 3

Adjustment of Potentiometer

Calibration S/W

4mA

8mA

12mA

16mA

20mA

Setting Lamp

Setting point S/W

5-POINT

2-POINT

The potentiometer is deigned to output a 12 mA signal when the

feedback lever is at 50%. In case of dislocation of the potentiometer,

please note the following before re-setting the potentiometer:

-Power must be turned off before adjusting the potentiometer.

-Be sure there is no remaining current on the PCB.

-Excessive force is unnecessary when disconnecting the potentiometer

from the PCB. Excessive force may cause damage to the transmitter.

1. Locate the potentiometer under the PCB and disconnect. Do not use

excessive force.

2. Unfasten the lock screw which locks the potentiometer gear and

remove potentiometer body from the lag-gear.

3. Fix the feedback lever at 50% and measure the resistance.

4. Rotate the pinion gear until resistance value reaches approximately

5K ohms.

5. After setting the resistance value, rotate the stopper to the normal

position and fasten the lock screw.

6. Reconnect the potentiometer to the PCB and reinstall the PCM onto

the Position Transmitter’s body.

Adjustment of Setting Points

The Series VPT Position Transmitter can be calibrated by either of the

following options.

1. 2 Point Setting: By setting the minimum and maximum points 0 and

100%, the values between the outputs are calculated and calibrated

automatically.

2. 5 Point Setting: By setting 5 points 0, 25, 50, 75, and 100%, the

outputs can be set accordingly. In general, a 5 point setting is much more

accurate.

Adjustment of Calibration

1. Input a 4 mA signal to the positioner in order to move the valve stroke

to its default position.

2. After the valve stroke reaches its default position, press the “4 mA”

button for approximately 3 to 4 seconds. The indicator light will light up,

indicating that the 4 mA position has been calibrated.

3. Please repeat the above steps for 8, 12, 16, and 20 mA settings for

the 5 point setting. For the 2 point setting, repeat the above steps only

for 20 mA.

Troubleshooting

1. VPT has no output signal

A. Check the input signal to the VPT.

B. Check power connection and polarity of terminals.

2. Input and output signals for the positioner differ greatly.

A. Check the input signal value and voltage. Insufficient voltage can

affect the input signal value.

B. Check the installation of the positioner. If the positioner is not properly

installed, reinstall properly using the positioner’s manual.

C. Reset positioner’s zero and span values. Inaccurate zero and span

settings can lower accuracy and linearity.

D. Check the installation of the VPT. If it is installed improperly, refer back

to installation section of manual.

3. Sudden change in VPT’s output signal value.

A. Make sure the VPT’s lever is placed at 50%. If not, the VPT needs to

be re-installed and adjusted to place lever at 50%.

B. Adjust the potentiometer. The potentiometer’s resistance should be at

approximately 10K ohms at the 50% point.

MAINTENANCE/REPAIR

Upon final installation of the Series VPT, no routine maintenance is

required. The Series VPT is not field serviceable and should be returned

if repair is needed. Field repair should not be attempted and may void

warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our

website. Contact customer service to receive a Return Goods

Authorization number before shipping the product back for repair. Be

sure to include a brief description of the problem plus any additional

application notes.

Page 4

©Copyright 2011 Dwyer Instruments, Inc. Printed in U.S.A. 12/11 FR# RB-443955-00

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...