Page 1

Bulletin PC-VBT

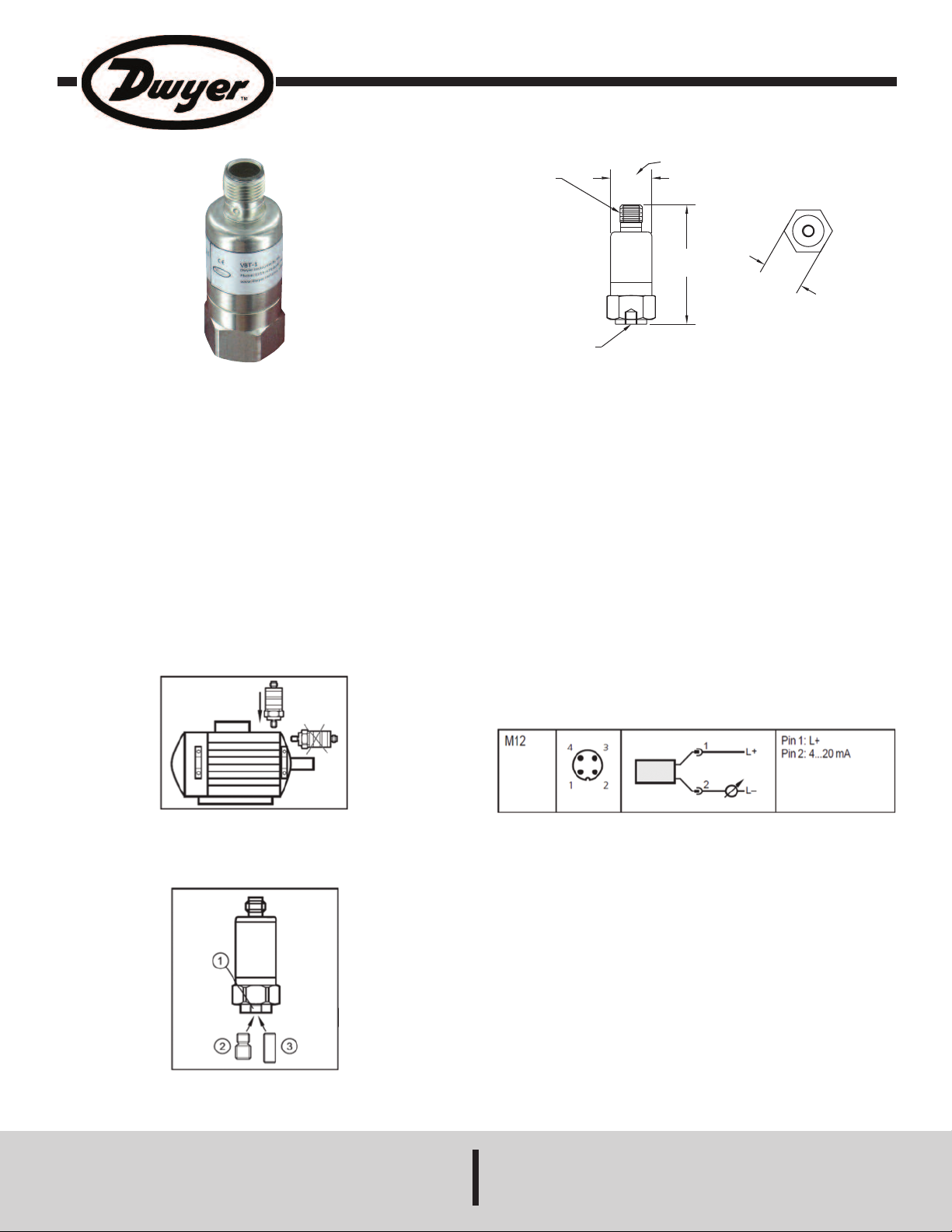

2-1/2˝

[63.25]

7

/8˝

[

22.23]

1/4˝-28 UNF

M

12 CONNECTOR

Ø7/8˝

[22.00]

Series VBT Vibration Transmitter

Specifications - Installation and Operating Instructions

he Series VBT Vibration Transmitter continuously detects the vibration in a

T

ystem and monitors for unusual operating conditions and potential failure. The

s

vibration is converted into an analog signal at the current output. The VBT requires

no setup, and there is no software required for configuration. The 2-wire loop power

peration, combined with standard M12 micro cable connector and interchangeable

o

mounting studs (1/4˝-28 UNF/M8 (2) or the 1/4˝-28 UNF), makes for a fast and

reliable installation.

SAFETY INSTRUCTIONS

Please read the product description prior to setup of the unit. Ensure that the

•

roduct is suitable for your applications without any restrictions.

p

• The unit conforms to the relevant regulations and EC directives.

• Improper or unintended use may lead to malfunctions of the unit or to unwanted

effects in your application.

• That is why installation, electrical connection, setup, operation and maintenance

of the unit must only be carried out by qualified personnel authorized by the

machine operator.

INSTALLATION

1. Mount only in a thick housing wall. See Figure 1.

2. Ensure that the signal direction is correct.

Figure 1

3. Select either 1/4˝-28 UNF/M8 (2) or the 1/4˝-28 UNF (3) threaded adapter and

insert into the unit (1). Both adapters are supplied. Tighten using a 3 mm allen key.

Tightening torque 8 Nm. See Figure 2.

SPECIFICATIONS

Housing Material: 316 SS.

emperature Limit: -22 to 221°F (-30 to 105°C).

T

ccuracy: < ±3%.

A

onnections: M12 connector.

C

Enclosure Rating: NEMA 6 (IP68).

Electrical Rating: 9.6 to 32 VDC.

Mounting Orientation: Any position.

Nonlinearity: < ±0.25% of span.

requency Range: 10 to 1000 Hz.

F

utput Signal: 4 to 20 mA.

O

Repeatability: < 0.5%.

Weight: 0.28 lb (0.125 kg).

Agency Approval: CE.

4. Drill and tap a hole at the mounting location: See Figure 2

• M8 hole/depth min. 10 mm. For (2)

• Or 1/4˝ UNF hole/depth min. 13 mm. For (3)

5. Tighten the sensor with a tightening torque of 8 Nm.

WIRING

The unit must be connected by a qualified electrician. The national and international

regulations for the installation of electrical equipment must be adhered also. See

Figure 3.

Figure 3

MAINTENANCE/REPAIR

Upon final installation of the Series VBT, no routine maintenance is required. The

Series VBT is not field serviceable and should be returned if repair is needed. Field

repair should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website.

Contact customer service to receive a Return Goods Authorization number before

shipping the product back for repair. Be sure to include a brief description of the

problem plus any additional application notes.

Figure 2

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 5/14 FR# R6-443974-00 Rev. 1

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Loading...

Loading...