Page 1

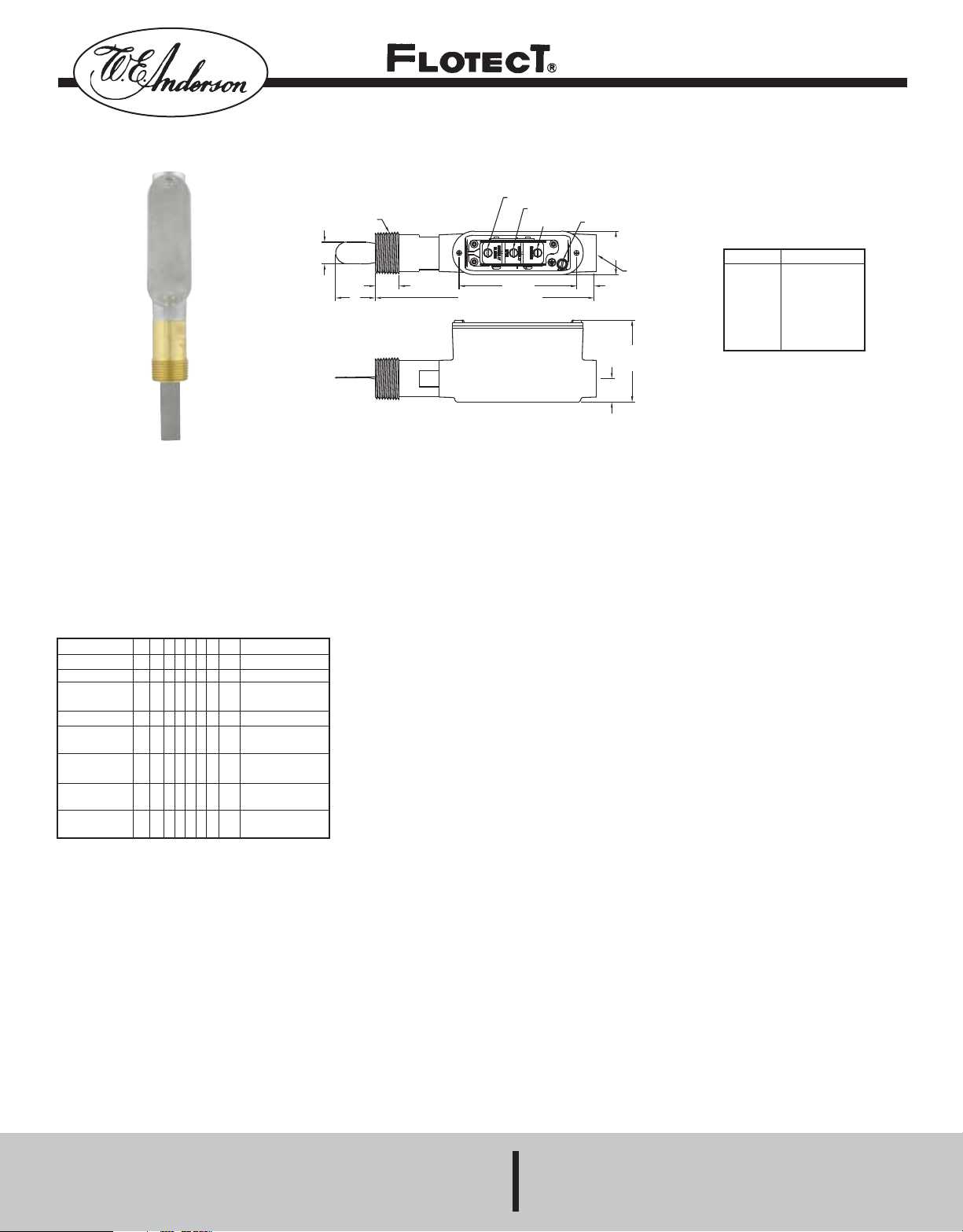

Series V7 Vane Operated Flow Switch

2X 47/64

[18.65]

2-37/64

[65.48]

1/2 FEMALE

NPSM

1-3/8

[34.93]

GROUND

COMMON

NORMALLY OPEN

NORMALLY CLOSED

1 NPT

6-31/32 [177.00]

3.702

.554

11/16

[17.46]

3/4

[19.05]

A

®

Specifications - Installation and Operating Instructions

Bulletin F-V7

The Series V7 Flotect®Flow Switch is an inexpensive switch for use with com-

patible liquids to start or stop electronic operated equipment when flow or no-flow

conditions occur. Magnetic operation is simple and dependable with no mechanical

linkages or seals to wear or leak. Lower body is machined solid metal bar stock assuring no leak points, no matter how long the unit is in service. Design is standard

weatherproof, meeting NEMA 4X, for application versatility. Robust vane design is

rigid and field trimmable for set point adjustment.

B

S

W

Example

Series

Construction

Lower Body

Circuit Type

Connection

Size

Vane Size

Tee & Tee

Material

Options

V7

V7

330

W

B

S

S

NNST

0

ST

RV

V7-WBS-30N-ST

V7 Flow Switch

Weatherproof

Brass

316 SS

SPDT

1˝

Full length vane

with template

No Tee

SS tag

Reinforced vane

Pipe Size

1

1-1/4

1-1/2

2

3

4

SPECIFICATIONS

Service: Liquids compatible with wetted materials that are non-coating and non-

crystallizing.

Wetted Materials: Vane: 301 SS, Process Connection: brass or 316 SS, Magnet:

ceramic, Other: 301, 302 SS.

Upper Body Material: Die cast aluminum.

Process Temperature Limits: -40 to 250°F (-40 to 121°C).

Maximum Ambient Temperature: 181°F (83°C).

Pressure Limits: 250 psi (17.2 bar).

Enclosure Rating: Weatherproof, meets NEMA 4X (IP66).

Switch Type: SPDT snap switch.

Electrical Rating: 10A @ 125, 250, 480 VAC; 1/8 hp @ 125 VAC, 1/4 hp @ 250

VAC.

Electrical Connections: 3 screw type, common, normally open and normally

closed.

Conduit Connection: 1/2˝ NPSM.

Process Connection: 1˝ male NPT. Contact factory for optional tees.

Pipe Size: 1 to 4 inch.

Mounting Orientation: Horizontal or vertical (actuation flow rates are based on

horizontal pipe runs in the vertical position). Will not work in vertical pipe with down

flow.

Set Point Adjustment: Vane is trimmable, see set point chart.

Weight: 1 lb 2 oz (500 g).

Approvals: UL353.

DIM A

1-17/64 [32.15]

1-19/32 [40.48]

1-53/64 [46.43]

2-11/64 [55.17]

2-11/64 [55.17]

2-11/64 [55.17]

W.E. ANDERSON DIV., DWYER

INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46361 U.S.A.

OPERATING PRINCIPLE

The flow switch is installed in a pipe to indicate flow/no-flow status. The paddle or

vane moves against a spring mechanism in the direction of flow with respect to the

amount of flow in the pipe. A magnet is located on the end of the vane inside the

lower housing. A second magnet located inside the upper housing moves from

magnetic attraction with the magnet attached to the vane. This upper magnet is

attached to a lever arm that activates a snap switch. The upper housing and lower

housing are separated by solid metal with no linkages or mechanisms to fail or

wear creating leaks. The spring mechanism returns the vane to the original position

as flow decreases.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

INSTALLATION

Unpacking

Remove the V7 from the shipping carton and remove any packaging material.

Inspect for damage. If damage is found, notify the carrier immediately.

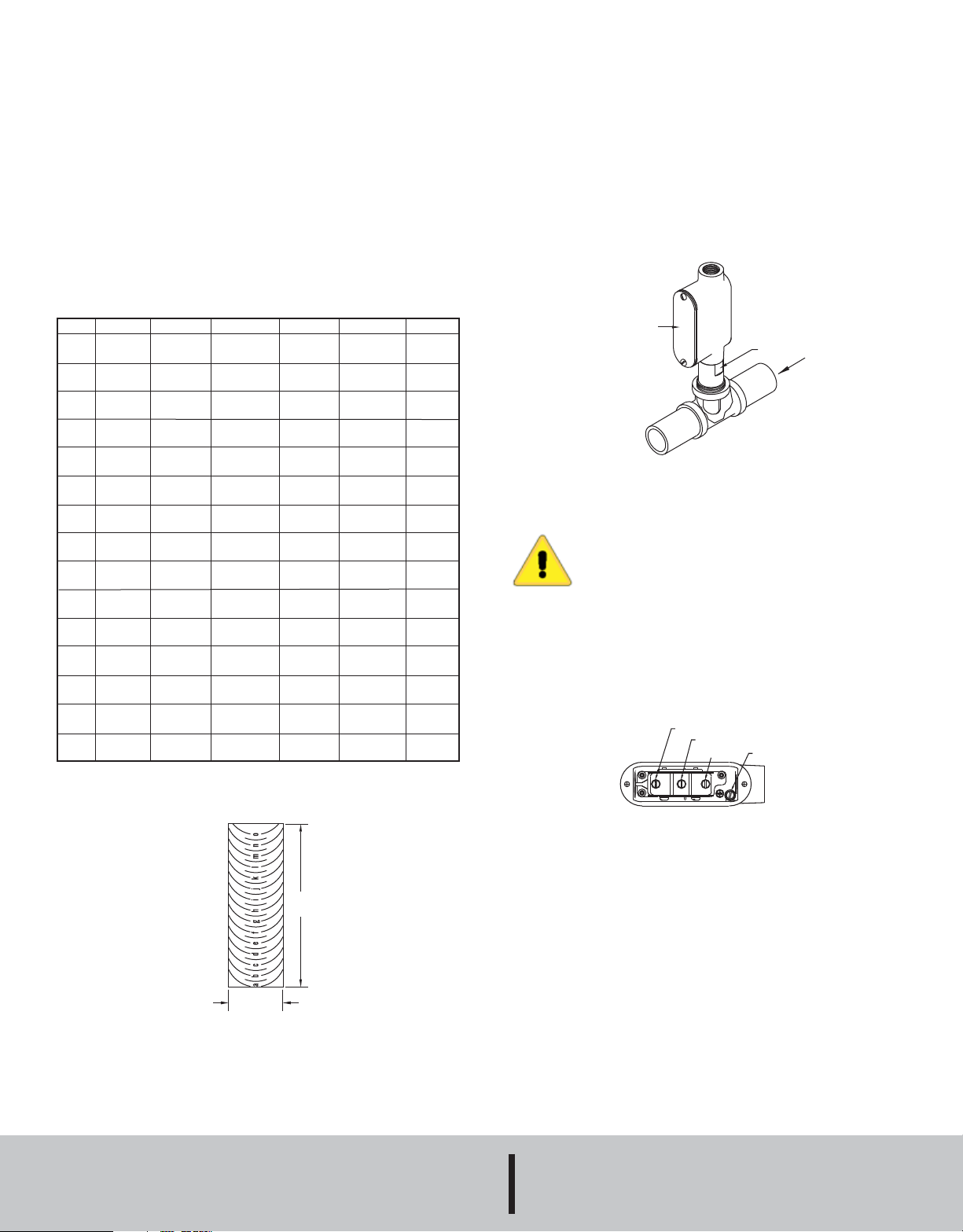

Set Point

The switch can be installed in any position but the actuation/deactuation flow rates

are based on horizontal pipe runs and are nominal values. The V7 enables the

installer to choose the approximate actuation/deactuation flow rates by trimming

the full size vane according to the template on the vane as shown in Figure 1.

Flows in the following chart are based on installation in standard tees, except the

four inch which is in a 4˝ x 1˝ pipe saddle.

Approximate Actuation-Deactuation Flow Rates for Cold Water

Actuate GPM [lpm]/Deactuate GPM [lpm]

Vane

a (full

vane)

b

c

d

e

f

1˝ NPT

1-1/4˝ NPT

8.13 [30.8]/

7.63 [28.9]

1-1/2˝ NPT

7.5 [28.4]/

6.7 [25.4]

8.3 [31.5]/

7.7 [29.1]

8.3 [31.4]/

7.5 [28.4]

9.8 [37.1]/

9.2 [34.8]

11.65 [44.1]/

10.9 [41.3]

2˝ NPT

12.8 [48.5]/

12.1 [45.8]

12.7 [48.1]/

12 [45.4]

14 [53]/

13.6 [51.5]

13.7 [51.8]/

13.4 [50.7]

16.9 [64]/

15.6 [59.1]

3˝ NPT

31.6 [119.6]/

29.6 [112]

4˝ NPT

58 [218]/

52 [197

g

h

i

j

7.5 [28.4]/

6.8 [25.7]

k

l

m

n

o

Mounting

Location

• The process pressure and temperature, and ambient temperature must be

within specified limits.

• Make sure the cover is easily accessible to allow for wiring.

Install unit into piping with 1˝ NPT bushing with housing cover facing perpendicular

to flow, see Figure 2 below. When bushings are used they must be back drilled to

allow proper clearance. Bore the I.D. to 1˝ (25 mm). The depth of the bore must

leave internal threads 9/16˝ (14 mm) high for proper engagement between lower

housing of the switch and the bushing. When threading into pipe use wrench on

flats on lower housing only. Check proper vane travel and switch operation after

mounting.

SWITCH MUST

BE MOUNTED

PERPENDICULAR

TO THE FLOW

WRENCH ON FLATS

FLOW

FIGURE 2

ELECTRICAL CONNECTIONS

Installation must be made in accordance with local codes and

regulations. Wire according to switch action required. The N.O.

(normally open) contacts will close and N.C. (normally closed)

contacts will open when flow increases to the actuation point. The

contacts will return to “normal condition” when flow decreases to

the deactuation point.

The conduit connection must be made such that condensation is not allowed to

enter the switch housing. If necessary install a conduit breather in a separate

conduit body to prevent buildup of moisture. If nonmetallic conduit is used the

protective ground may be connected to the internal ground connection screw. Use

90°C copper conductors only.

NORMALLY CLOSED

NORMALLY OPEN

CLOSED

NORMALLY

OPEN

COMMON

NORMALLY

COMMON

GROUND

FIGURE 3

MAINTENANCE & REPAIR

1-7/8

[47.52]

Inspect and clean wetted parts at regular intervals. The cover should be in place at

all times to protect the internal components from dust, dirt and weather.

Disassembly or modifications made by the user will void the warranty and could

impair the continued safety of the product. If repair is required obtain a Return

Goods Authorization (RGA) number and send the unit, freight prepaid, to the

address below. Please indicate a detailed description of the problem and

conditions under which the problem was encountered.

5/8

[15.88]

FIGURE 1

Dwyer Instruments, Inc.

Attn: Repair Department

102 Indiana Highway 212

Michigan City, IN 46360

©Copyright 2010 Dwyer Instruments, Inc. Printed in U.S.A. 2/10 FR# 82-443693-00 Rev. 3

W.E. ANDERSON DIV., DWYER

INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46361 U.S.A.

Loading...

Loading...