Page 1

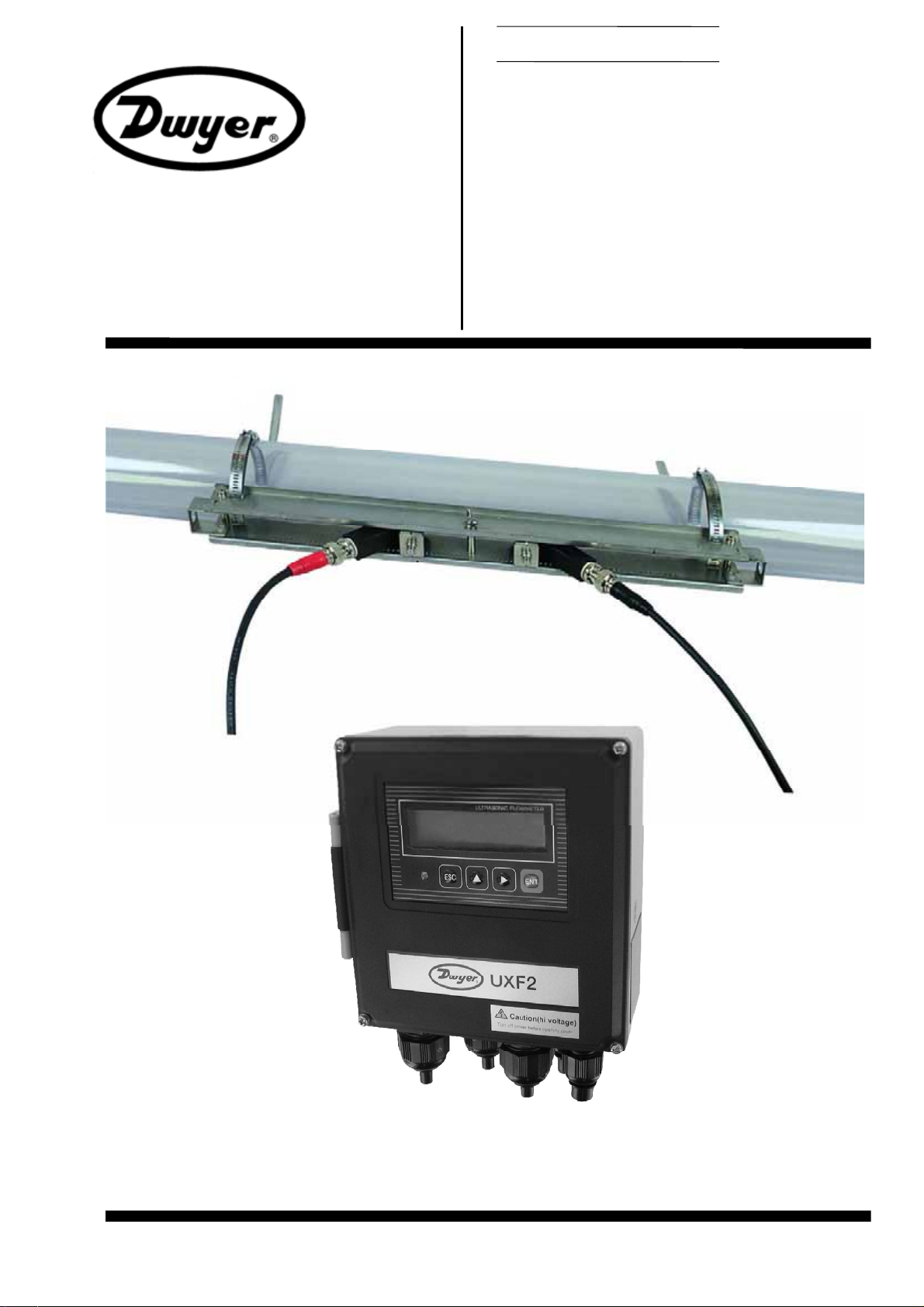

Instruction Manual

ULTRASONIC FLOWMETER

TYPE: UXF2 (Flow transmitter)

SX2 (Detector)

SX3C (Signal cable)

Dwyer Instruments, Inc.

Bulletin F-70

Page 2

Page 3

B

ULLETIN F-7

0

PREFACE

Thank you for purchasing Dwyer Instruments ultrasonic flowmeter Model UXF2.

The instruction manual covers the installation, operation, checkup and maintenance of the flow transmitter (UXF2) and

Detector set (SX3). Review the manual prior to operation.

Before operation, review this instruction manual to ensure correct installation, operation and maintenance

z

of the flowmeter system. Note that incorrect operation may lead to malfunction or personal injury.

The specifications of this flowmeter are subject to change for product improvement without prior notice.

z

Do not attempt to modify the flowmeter without permission. Manufacturer is not responsible for equipment

z

operation or safety compromised as a result of modification without explicit permission. If it is necessary

to modify the flowmeter, contact manufacturer in advance.

z

This instruction manual shall be maintained for reference.

z

After reading the manual, be sure to store it in an accessible location.

z

Manual should be delivered to appropriate operational or technical staff responsible for the flowmeter.

z

If the instruction manual has been lost, request a replacement from the manufacturer.

z

Manufacturer: Dwyer Instruments, Inc.

Type: Described on company nameplate on main frame

Date of manufacture: Desribed on company nameplate on main frame

Product nationality: Japan

Dwyer Instruments, Inc.

Copy of contents of this manual in part or whole is not authorized

z

without written permission.

Contents of this manual are subject to change without prior notice.

z

NOTICE

Issued in June 2007

-i-

Page 4

B

ULLETIN F-70

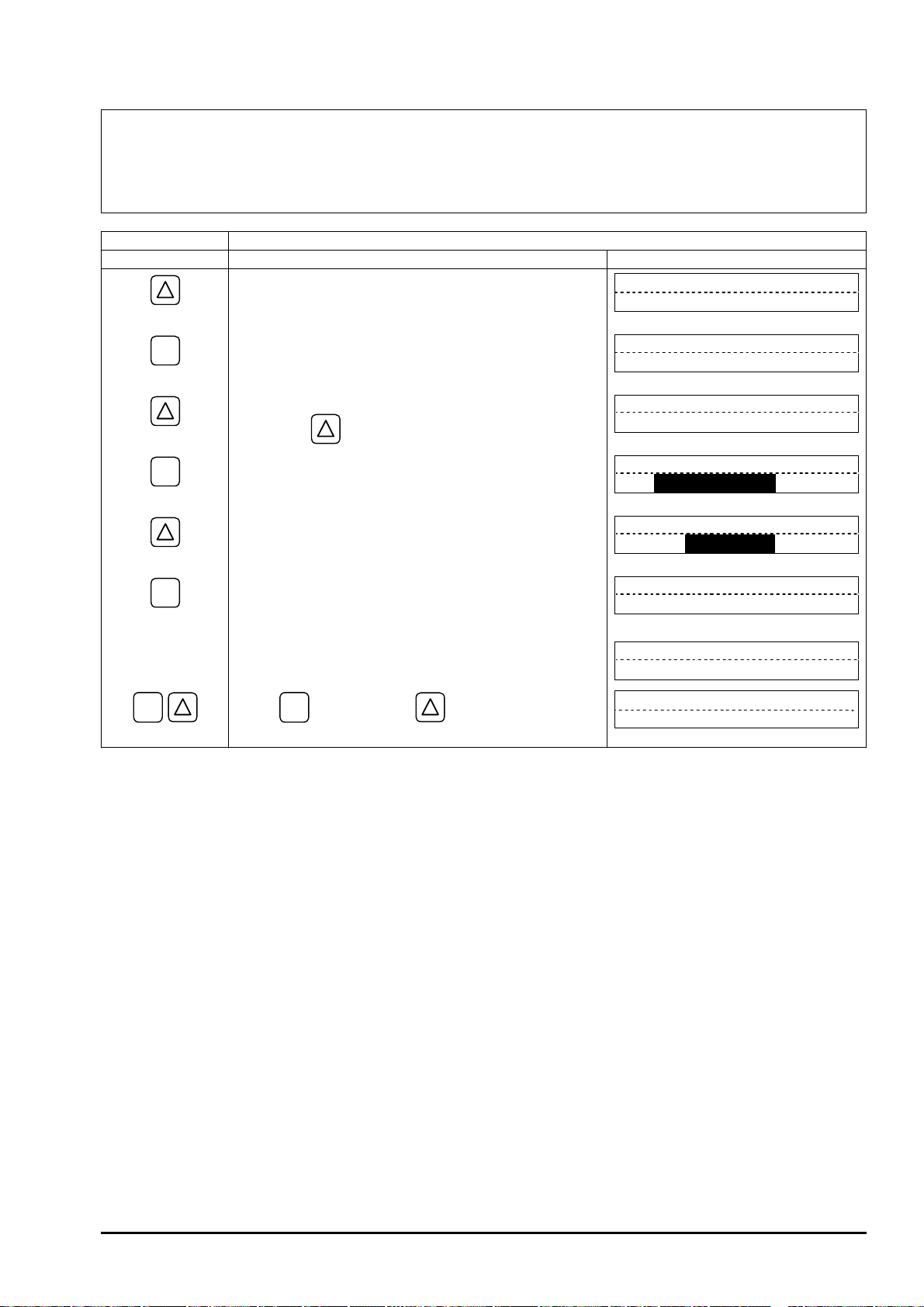

SAFETY PRECAUTION

Before use, read the following safety precaution to ensure correct operation of the flowmeter.

Ɣ

The following items are important for safe operation and must be fully observed. These items are classified

as "DANGER" and "CAUTION".

Warning & Symbol Meaning

Incorrect handling may lead to a risk of death or severe injury.

Incorrect handling may lead to a risk of medium or light injury, or to a risk of

physical damage.

Ɣ

The items noted under "

Ɣ

All the items are important and must be fully observed.

" may also result in serious trouble depending on circumst ances.

Caution on Installation and Piping

z

This product is not an explosion-proof structure. Do not use it in a place

with explosive gases, otherwise, this may result in serious accident such as

explosion, fire, etc.

z

The unit should be installed in a place conforming with the installation

requirements noted in this instruction manual. Installation in an improper

location may lead to a risk of electric shocks, fire, malfunction, etc.

z

The unit should be installed as noted in the manual. Improper installation

will cause failure, trouble or malfunction of the unit.

z

During installation, make sure that the inside of the unit is free from cable

chips and other foreign objects to prevent fire, trouble, malfunction, etc.

z

The items under "Caution on Installation" noted in the manual must be fully

observed; careless installation may result in trouble or malfunction of the

unit.

Caution on Wiring

z

When performing wiring termination to prevent output trouble caused by

moisture, dew condensation or water leak, follow “Section 3.3 Flow

transmitter wiring” described in this manual

z

Before performing the wiring work, be sure to turn OFF the main power to

prevent electric shocks.

z

Do not perform wiring work outdoors on rainy days to prevent insulation

deterioration and dew condensation; otherwise, it can result in trouble,

malfunction, etc.

z

Be sure to connect a power source of correct rating. Connection of a

power source of incorrect rating may lead to a risk of fire and injury.

z

The unit must be grounded as specified to prevent electric shocks or

malfunction.

z

The analog output signal cable should be wired as far away as possible

from high-voltage lines to prevent electrical interference as it will cause

malfunction of the unit.

z

To prevent malfunction of the unit, the analog output signal cable and

power cable should be wired through separate conduits.

- ii -

Page 5

B

ULLETIN F-7

0

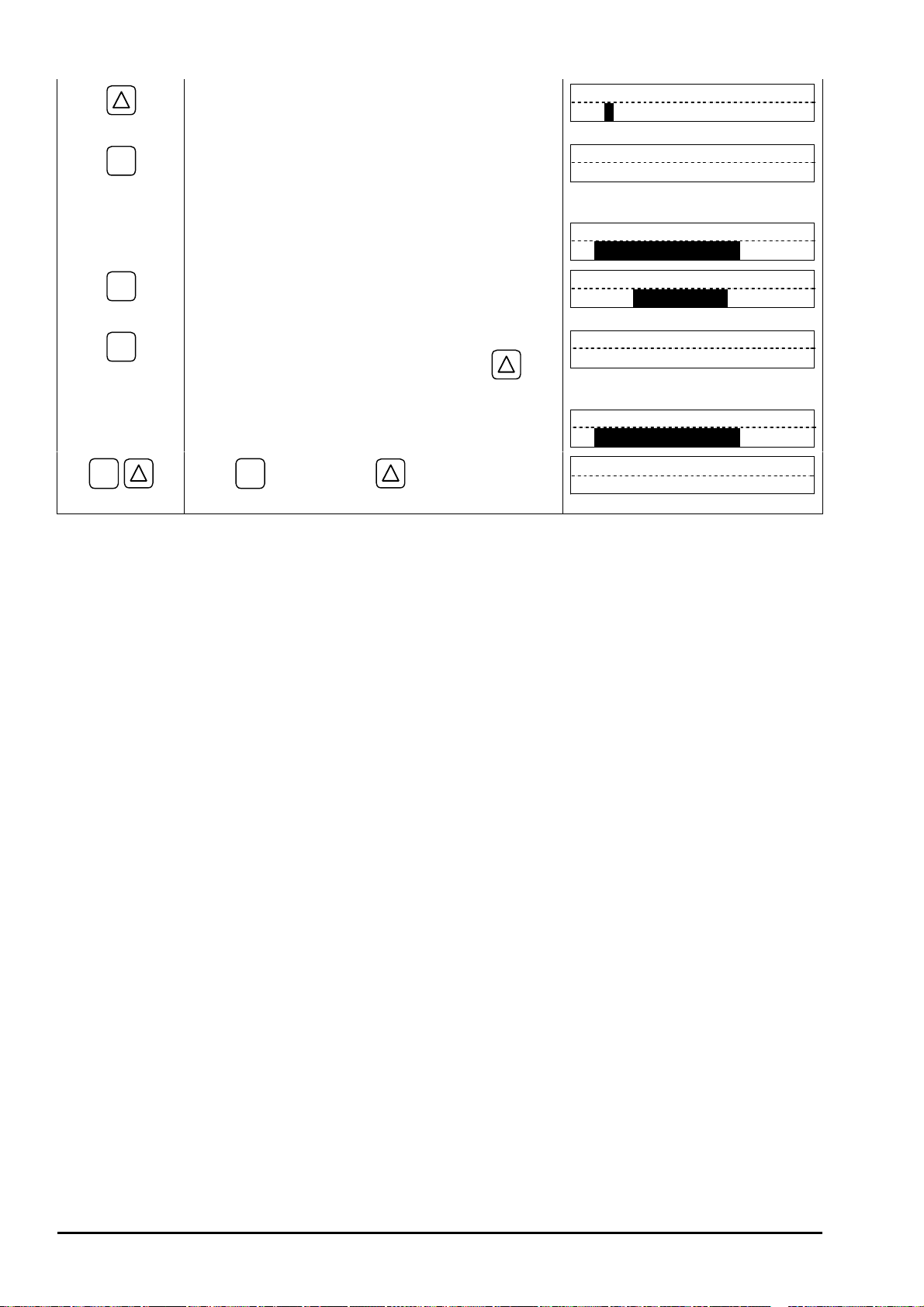

Caution on Maintenance/Inspection

z

The unit should be inspected daily to verify proper measurement

results.

z

When measuring the insulation resistance between the power/output

terminal and the case, follow “Section 5.2.3 How to measure the

insulation resistance” described in this manual.

z

If the fuse is blown, detect and eliminate the cause, and then replace the

fuse with a spare. If there are no spares, replace the fuse with equivalent

specified in this manual (may be procured locally). Use of a

fuse other than specified or its short-circuit may cause an electric shock or

fire. The fuse should be replaced according to “Section 5.3 How to

replace the fuse” described in this manual.

- iii -

Page 6

B

ULLETIN F-70

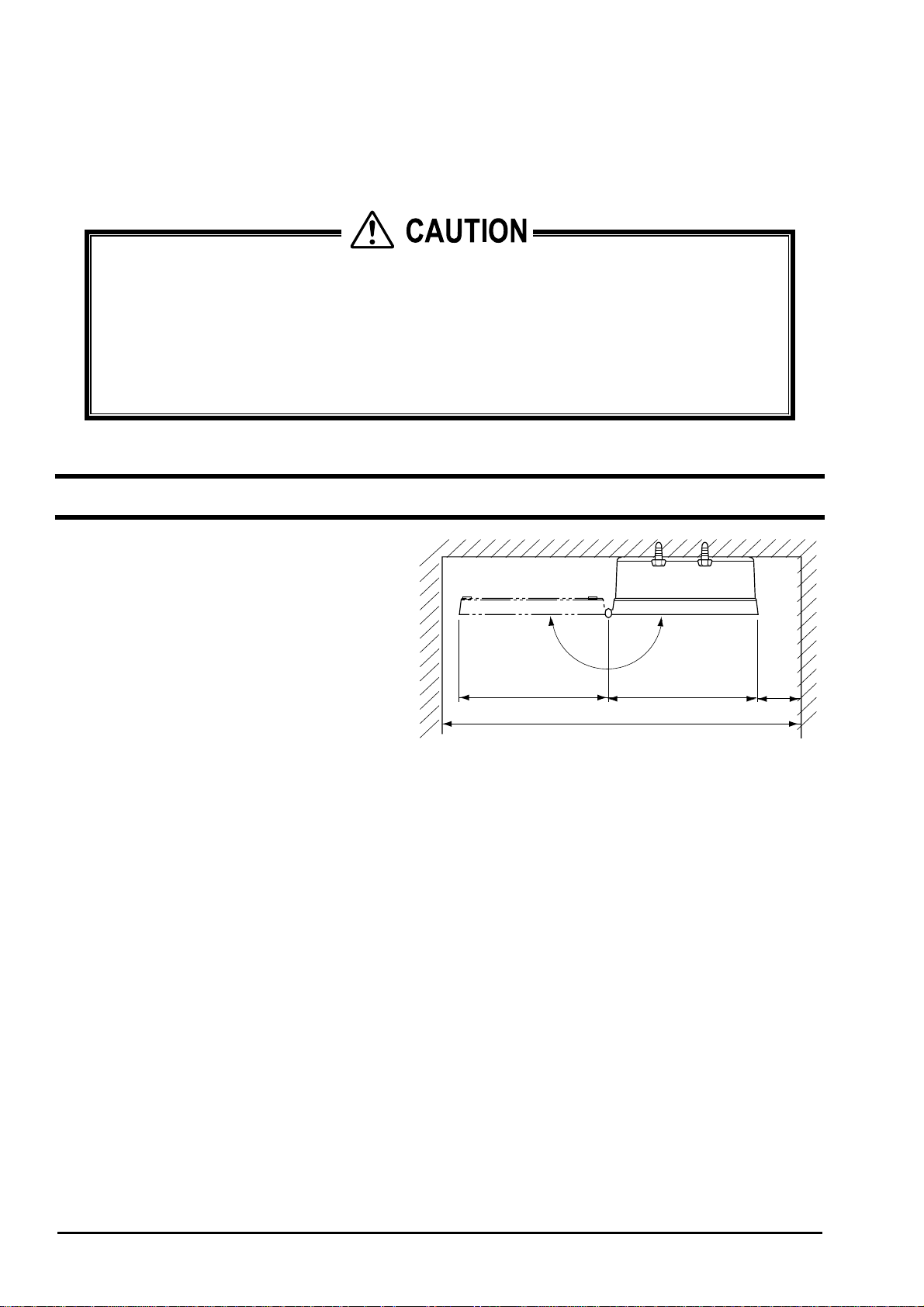

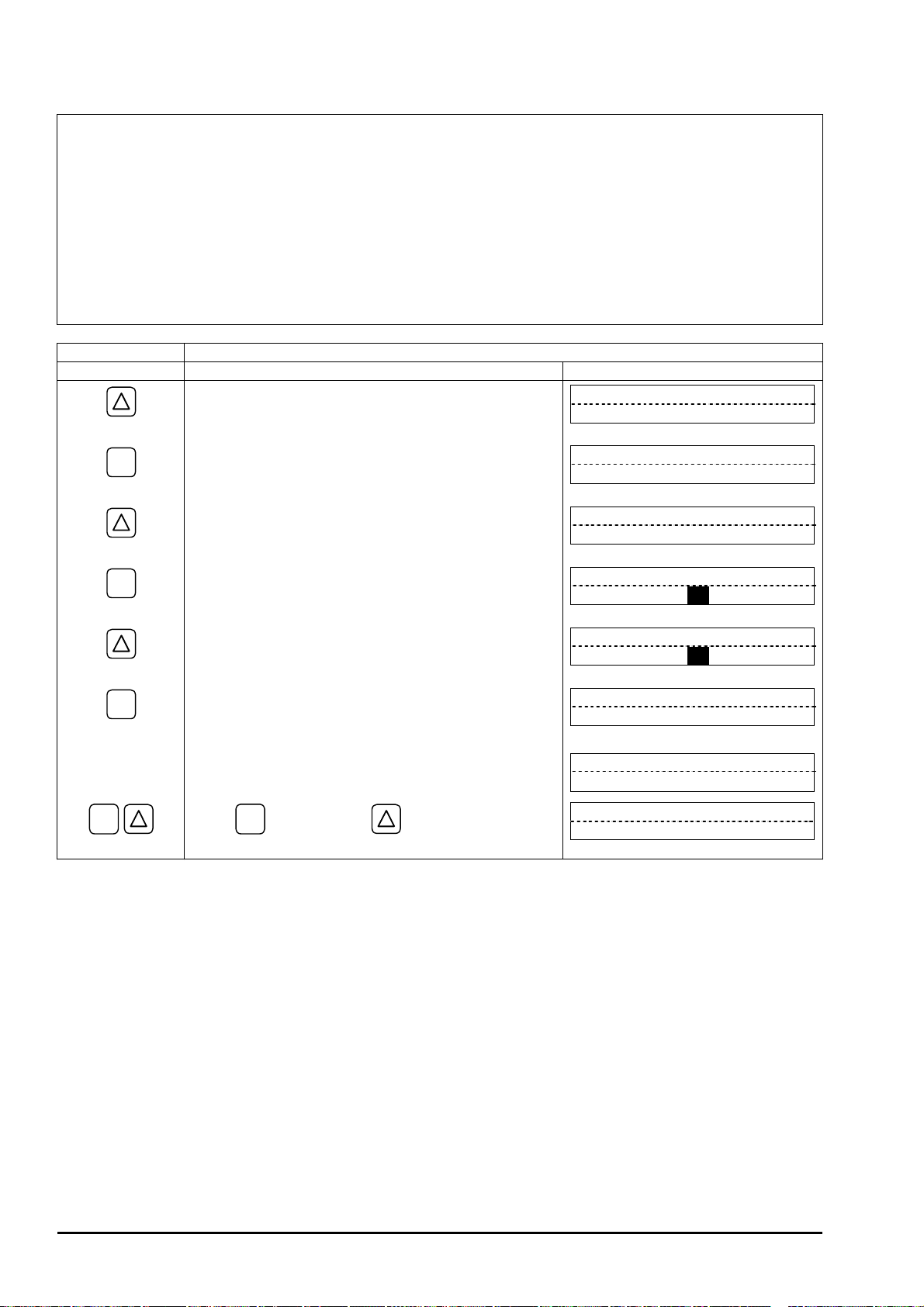

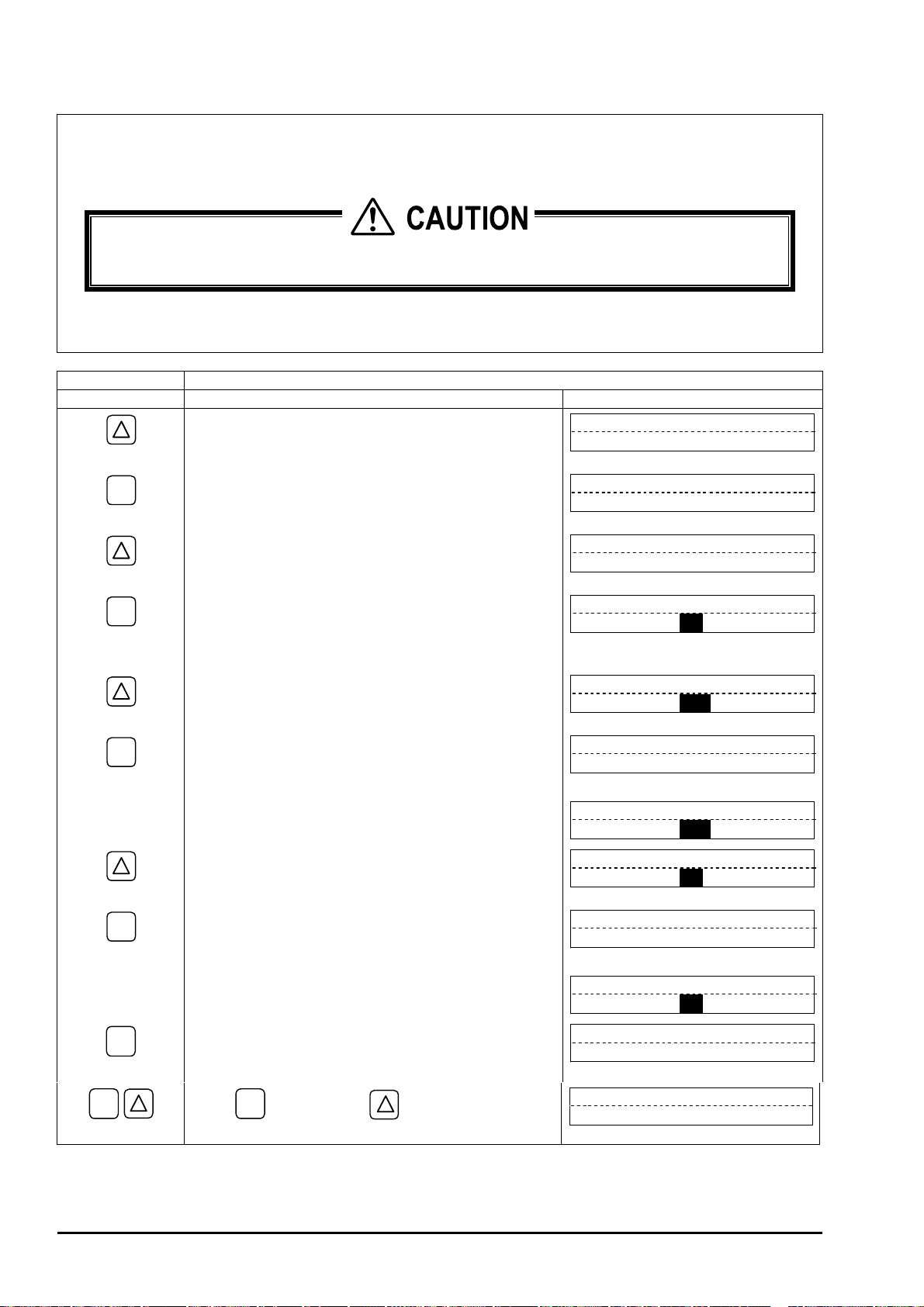

CAUTION ON INSTALLATION LOCATION

(1) Sufficient space is required for daily inspection, proper wiring, etc.

(2) A location not exposed to direct sunshine nor weathering.

(3) Isolation from excess vibration, dust and moisture.

(4) A location not subjected to radiated heat from a heating furnace etc.

(5) A location not subjected to corrosive atmosphere

(6) A location not to be flooded

(7) A place remote from electrical devices (motor, transformer, etc.) which generate electromagnetic

induction noise, electrostatic noise, etc.

(8) A location not subject to excessive fluid pulsation (near pump discharge side)

(9) A location that provides sufficient flow conditioning with the length of the straight pipe.

(10)A place where ambient temperature and humidity are • 20 to +50qC and 90% RH or less for flow

transmitter, and • 20 to +60

C and 90% RH or less for detector set.

q

- iv -

Page 7

B

ULLETIN F-7

0

CONTENTS

PREFACE ·········································································································································· i

SAFETY PRECAUTION ················································································································· ii

CAUTION ON INSTALLATION LOCATION··············································································· iv

CONTENTS·······································································································································v

1. OUTLINE OF PRODUCT·············································································································1

1.1. Outline·····································································································································1

1.1.1. Measuring principle·················································································································1

1.2. Checking the received products······························································································2

1.3. Checking the type and specifications······················································································3

1.4. Names and functions of each part···························································································6

1.4.1. Flow transmitter ······················································································································6

1.4.2. Detector ··································································································································7

2. SELECTION OF INSTALLATION PLACE·················································································8

2.1. Flow transmitter······················································································································8

2.2. Detector···································································································································9

2.2.1. Length of straight pipe·············································································································9

2.2.2. Mounting position ················································································································· 11

3. INSTALLATION AND PROCEDURE PRIOR TO OPERATION·············································12

3.1. Outline of installation procedure···························································································12

3.2. Installation of flow transmitter······························································································13

3.2.1. Wall mounting ·······················································································································13

3.2.2. 2B pipe stand mounting ·········································································································13

3.3. Flow transmitter wiring·········································································································14

3.3.1. Precautions in wiring ·············································································································14

3.3.2. Applied w iring·······················································································································14

3.3.3. Tre atm ent of wiring ports·······································································································14

3.3.4. Wir ing to each terminal·········································································································· 15

3.4. Setting the piping parameters and calculating the sensor unit spacing·································16

3.5. Installation of detector ······ ··································································································18

3.5.1. Outline of detector installation procedure···············································································18

3.5.2. How to treat the mounting surface ·························································································18

3.5.3. How to mount the frame ········································································································18

3.5.4. How to mount the sensor unit ································································································21

3.6. Installation of detector ······································································································23

3.6.1. Outline of detector installation procedure···············································································23

3.6.2. Selection of mounting method ·······························································································23

3.6.3. Processing of detect or mounting surface················································································23

3.6.4. Determination of mounting position

(with Z method for small type)

·············································24

-v-

Page 8

B

ULLETIN F-70

3.6.5. Cable end treatment ···············································································································25

3.6.6. Connection of cable to small detector ····················································································26

3.6.7. Mounting of small detector on pipe························································································29

3.6.7.1. Mounting of detector (SX3-C0) <V method>····························································29

3.6.7.2. Mounting of detector (SX3-D0) <Z method>···························································· 31

3.7. Confirmation of received signal··························································································· 33

3.8. How to remove the sensor unit (SX3-A0/B0)····································································· 34

3.9. Setting the range and total pulse output ··············································································· 35

3.10. How to calibrate zero ········································································································· 38

4. PARAMETERS···························································································································39

4.1. Description on display/setting section·················································································· 39

4.2. Configuration of keys··········································································································· 40

4.3. Initial values of parameters ·································································································· 43

4.4. Parameter protection ············································································································ 45

4.4.1. Parameter protection ON/OFF·······························································································45

4.5. Output setup mode ··············································································································· 46

4.5.1. Adjusting zero point···············································································································46

4.5.2. Setting the da mping ···············································································································47

4.5.3. Setting the low flow rate cutting····························································································48

4.5.4. Setting the LCD indication·····································································································49

4.5.5. Setting the flow rate a n d flow velocity range·········································································50

4.5.5.1. Setting the flow rate range (single range FLOW SPAN-1)········································· 50

4.5.5.2. Setting forward automatic 2 ranges··········································································· 51

4.5.5.3. Setting forward/reverse automatic 2 ranges······························································· 53

4.5.5.4. How to set analog output at error (BURNOUT) ························································55

4.5.6. Setting the total······················································································································ 57

4.5.6.1. Setting the total pulse (pulse value, pulse width)·······················································57

4.5.6.2. Setting the preset value·····························································································60

4.5.6.3. TOTAL mode (total reset, start, stop) ········································································61

4.5.6.4. Determining how to handle the total at error (BURNOUT) ·······································62

4.5.7. Setting the DO o u tput ············································································································ 64

4.5.7.1. Invalidati ng the DO output························································································65

4.5.7.2. How to validate the total pulse output ·······································································66

4.5.7.3. How to validate outputting the FLOW SPAN-2·························································67

4.5.7.4. How to validate the alarm output···············································································68

4.5.7.5. How to validate the flow switch················································································69

4.5.7.6. How to validate the total switch················································································ 71

4.5.8. How to compensate the measurement value···········································································73

4.6. Measure setup mode·············································································································74

4.6.1. How to set the unit system·····································································································74

4.6.2. How to set the flow rate unit·································································································· 75

4.6.3. How to set the total unit········································································································· 76

4.6.4. How to set the piping parameters···························································································77

4.7. Maintenance mode ··············································································································· 79

4.7.1. How to calibrate the analog output·························································································79

4.7.2. How to set the constant current outp ut···················································································80

4.7.3. How to check the action of total pulses··················································································81

4.7.4. How to check the s tatus output·······························································································82

4.7.5. How to validate the test mode (simulated flow ra te output)····················································83

- vi -

Page 9

B

ULLETIN F-7

0

4.7.6. How to validate a serial transmission (RS-232C/RS-485)······················································85

4.7.7. How to validate the synchronization······················································································87

4.7.8. How to select the language ····································································································88

4.7.9. How to set the ID No.············································································································89

4.7.10. How to confirm the software version···················································································90

5. MAINTENANCE AND CHECKUP···························································································91

5.1. Routine checkup····················································································································91

5.2. Periodic checkup···················································································································91

5.2.1. Checking the zero point ·········································································································91

5.2.2. Reapplying silicon-free grease ······························································································· 91

5.2.3. How to measure the insulation resistance···············································································92

5.3. How to replace the fuse·········································································································93

5.4. How to replace the relay ·······································································································94

5.5. How to replace the LCD ·······································································································95

5.6. Selecting the detector············································································································96

5.7. Troubleshooting····················································································································97

5.7.1. If indication is abnormal········································································································97

5.7.1.1. Checking the LCD/LED····························································································97

5.7.1.2. Checking the LED lit in red······················································································98

5.7.1.3. Displaying the data in maintenance mode ·································································99

5.7.2. If keying is abnormal···········································································································100

5.7.3. If measureme nt value is abnormal························································································100

5.7.4. If analog output is abnormal·································································································103

5.7.5. How to check the received waveform··················································································104

5.7.5.1. How to connect the oscilloscope············································································· 104

5.7.5.2. Checking the received waveform ············································································ 105

5.7.6. Remedying a hardware fault ································································································ 106

6. APPENDICES ···························································································································107

6.1. External communication specifications ··············································································107

6.1.1. Communication specifications·····························································································107

6.1.2. Message configuration········································································································· 108

6.1.2.1. Reception················································································································ 108

6.1.2.2. Acknowledge ·········································································································· 108

6.1.2.3. Error acknowledge··································································································108

6.1.3. Error check·························································································································· 108

6.1.4. Function code table·············································································································· 109

6.1.5. Error code table ··················································································································· 109

6.1.6. Cable connection specifications (RS-232C)········································································· 109

6.2. How to make gauge paper···································································································111

6.3. Piping Data··························································································································112

-vii-

Page 10

Page 11

B

ULLETIN F-7

0

1. OUTLINE OF PRODUCT

1.1. Outline

This flowmeter is a clamp-on type ultrasonic flowmeter for permanent use based on transit time measuring methods. The

UXF2 is ideal for clean liquids containing no air bubbles such as pure water. The easy-to-use compact and

lightweight design is intended for integration into mechanical devices.

The flowmeter is applicable to small and medium size pipes of diameter range from 25mm to 600mm providing superior cost

performance.

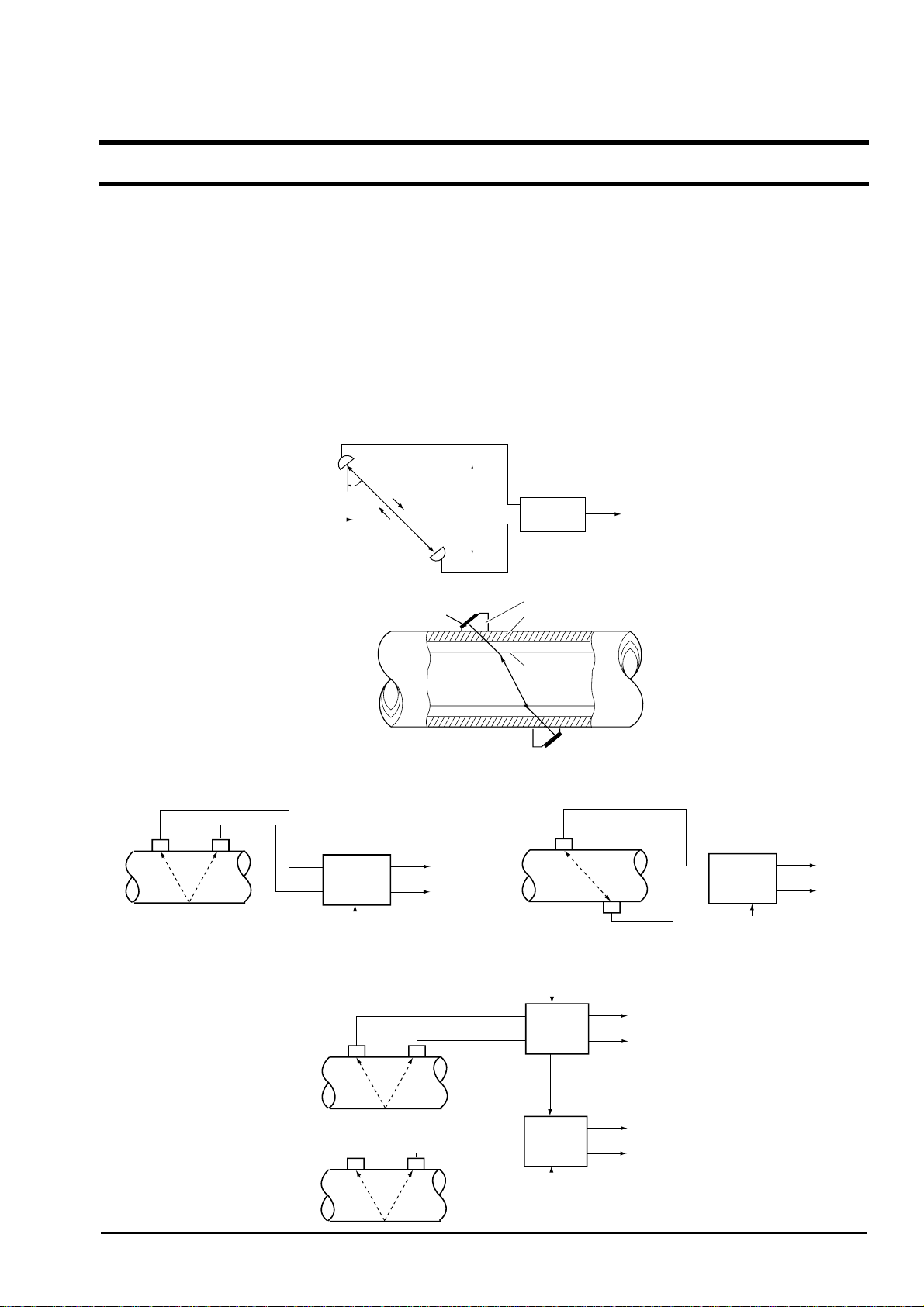

1.1.1. Measuring principle

Measuring principle

Ultrasonic pulses are propagated diagonally from the upstream and downstream sides, and the time difference caused by the

flow is detected to provide the flow rate measurement.

Detector

Upstream sensor

Mounting the detector

Configuration diagram

(1) Single-path system (V method)

Signal cable

Detector

θ

t

2

t

Flow velocity

Downstream sensor

Ultrasonic transducer Pipe

Flow

transmitter

Power supply

1

4 to 20mA

DC

Contact

D

Flow

transmitter

Plastic wedge

Lining

Output signal

(2) Single-path system (Z method)

Signal cable

Detector

Flow

transmitter

4 to 20mA

DC

Contact

Power supply

(3) When synchronizing

Detector

Detector

Signal cable

Signal cable

Power supply

Flow

transmitter

(master)

Synchronizing

signal wiring

Flow

transmitter

Power supply

(slave)

4 to 20mA

DC

Contact

4 to 20mA

DC

Contact

-1-

Page 12

B

ULLETIN F-70

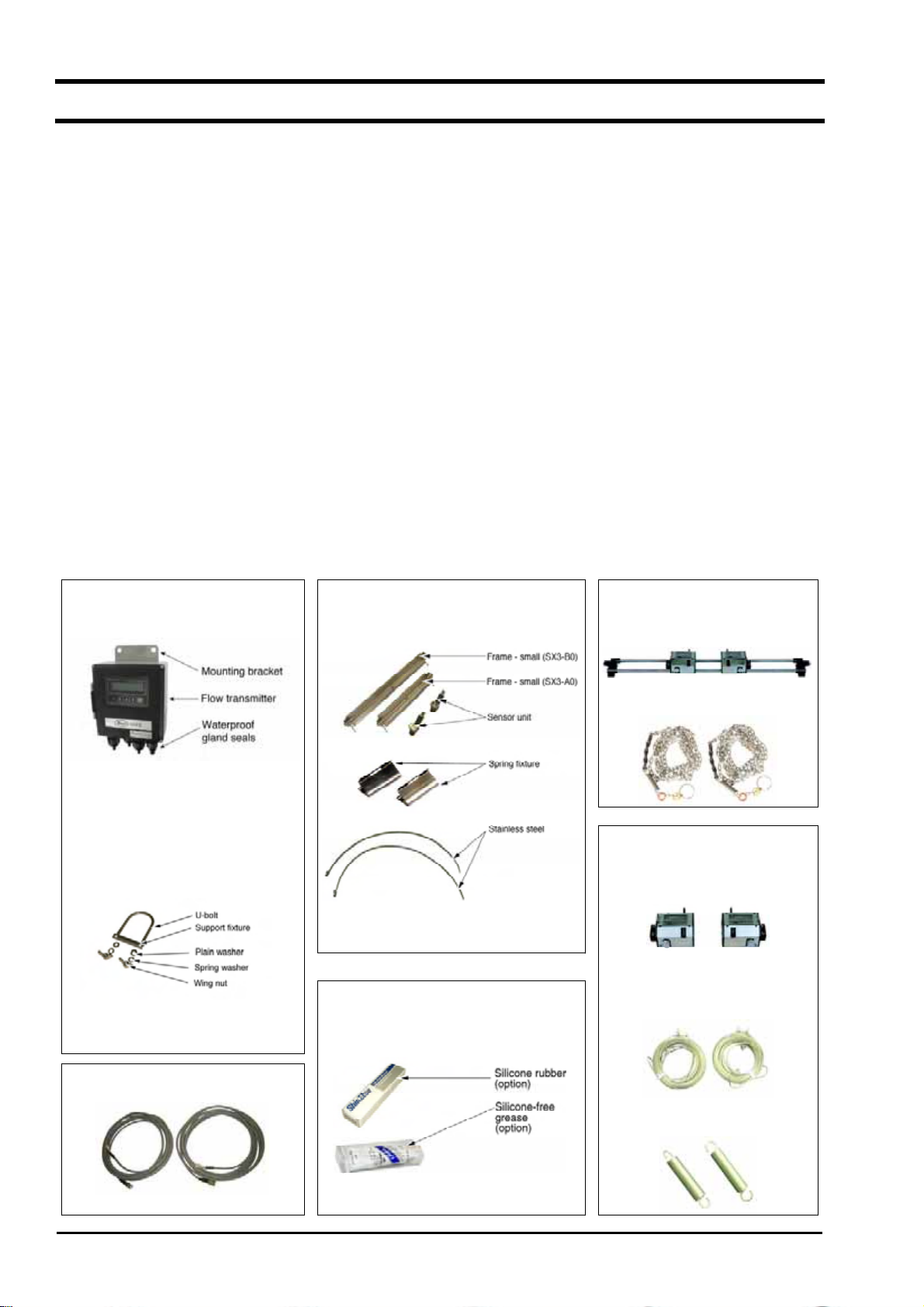

1.2. Checking the received products

Flow transmitter (UXF2)

x

Flow transmitter unit······································································1 set

W aterproof gland ············································································1 set (mounted on main unit)

W all mounting fixture ····································································1 set (mounted on main unit)

Pipe mounting fixture (option) ·······················································1 set

(U bolt, support fixture, 2 wing nuts, 2 spring washers, 2 plain washers)

Detector (SX3-A0/B0)

x

Frame ···························································································1 pc

Sensor unit ······················································································1 set (2 pcs)

Stainless steel belt ···········································································1 set (SX3-A0: 2 pcs. SX3-B0: 4 pcs.)

Spring fixture···················································································2 pcs

Silicone rubber or silicone-free compound (option) ······················1 pc

Detector (SX3-C0)

x

Small detector ················································································1 set (2 pcs)

Chain······························································································1 set (2 pcs)

Detector (SX3-D0)

x

Small detector ·················································································1 set

Wire rope ······················································································1 set (2 pcs)

Mounting spring··············································································1 set (2 pcs)

Signal cable (for SX3-A0/B0) (SX3C: length designated) ·········· 1 set (2 pcs)

x

Signal cable (for SX3-C0/D0) (SX3C: length designated) ·········· 1 set (2 pcs)

x

Instruction manual ··········································································1 copy

x

Belt tightening tool (option) ························································· As ordered

x

Flow transmitter (UXF2)

Piping mounting fixture Detector (SX3-D0)

Detector (SX3-A0, SX3-B0) Detector (SX3-C0)

Small size detector

Chain

Small size detector

Option

Wire rope

Signal cable (SX3C)

Mounting spring

- 2 -

Page 13

B

ULLETIN F-7

0

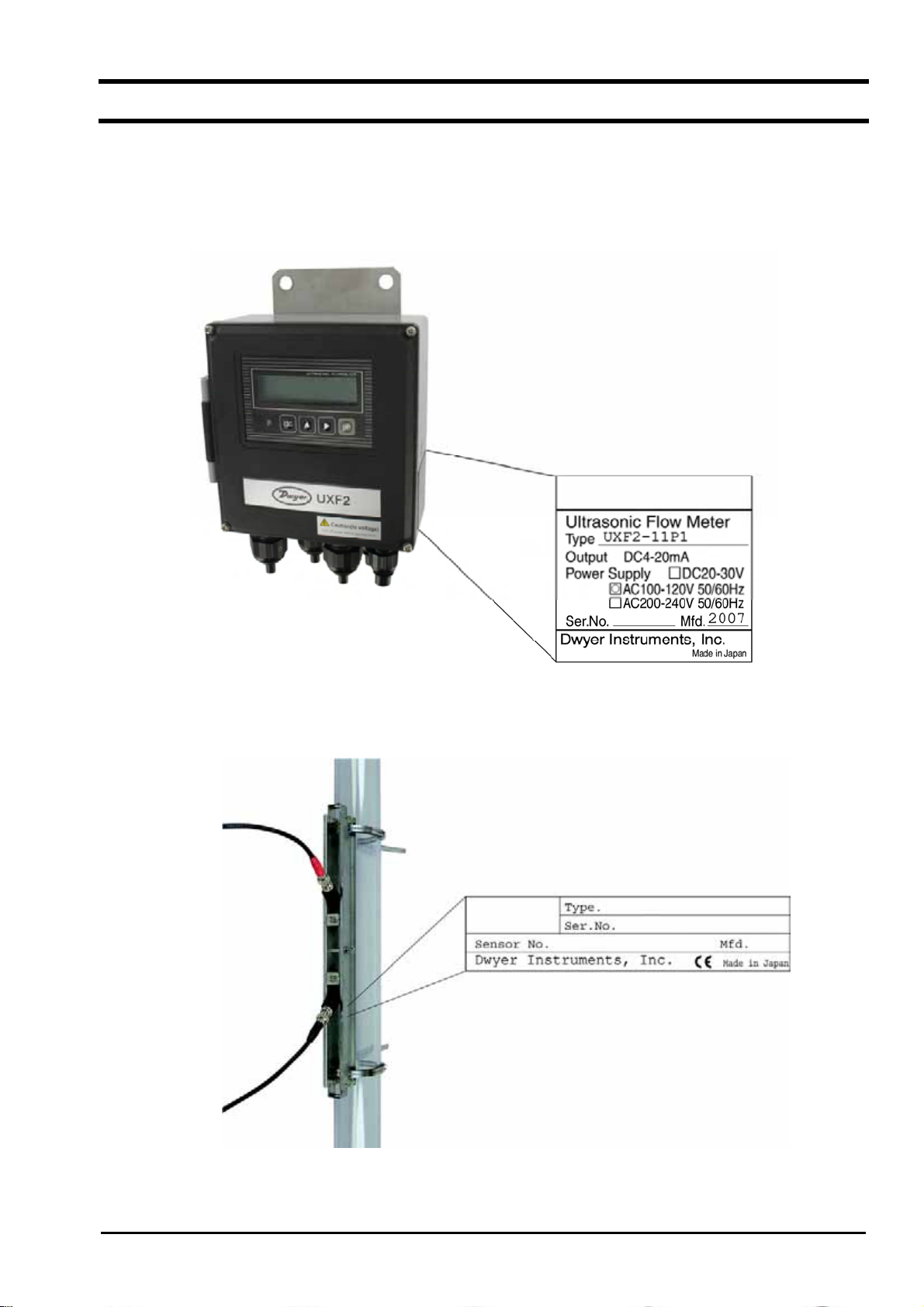

1.3. Checking the type and specifications

The type and specifications of product are indicated on the specifications plate mounted on the flow transmitter and

detector frame. Make sure the models are as ordered referring to the type diagrams given below.

<Flow transmitter (UXF2)>

<Detector (SX3-A0/B0)>

-3-

Page 14

B

ULLETIN F-70

<Detector (SX3-C0/D0)>

- 4 -

Page 15

1021 345678 1191213

B

0

3YYSVLF-

Enclosure (4th digit code)

S

1

4

2

1

0

Y

Y

T

E

F

PAGE BLANK

(Reserved for future use)

Outdoor immersion-proof case

Power supply (5th digit code)

100 to 240V AC±10%, 50/60Hz

20 to 30V DC

Transistor output (6th digit code)

2 Points

Analog output (7th digit code)

1 system

Synchronism (9th digit code)

None

Conduit connections (10th digit code)

G1/2(Female screw)

with water-proof connection

Option (11th digit code)

None

Tag name plate

Use for explosion-proof sensors

Use for explosion-proof sensors with Tag

name plate

ULLETIN F-7

Description

-5-

Page 16

B

ULLETIN F-70

1.4. Names and functions of each part

1.4.1. Flow transmitter (UXF2)

No. Name Description

1 Wiring connection port,

large

2 Wiring connection port,

small

3 Indication and setting unit Indicates and sets the flow rate, etc.

4 Received wave diagnostic

indication

5 Escape key Return to the next-higher layer or cancels the set status.

6 UP key Selects items, numeric values and symbols.

7 Shift key Moves the cursor and selects decimal place.

8 Entry key Enters a selection or registers a setting.

9 LCD indication Indicates the flow rate or setting.

10 Power terminals Power cables are connected.

11 Input/output terminals Signal cable, analog output and DO output cables are connected.

12 Communication board

terminals

13 Fuse holder Houses a fuse.

14 Relay For DO2 output

15 Communication board Mounted if communication synchronization is optionally designated.

16 Arrester board Board for output mounted if arrester is optionally designated.

For power cable, output cable

Wiring connection port for signal cable only

Indicates whether received wave is normal (green) or abnormal (red).

Communication cable is connected (communication board is optional).

- 6 -

Page 17

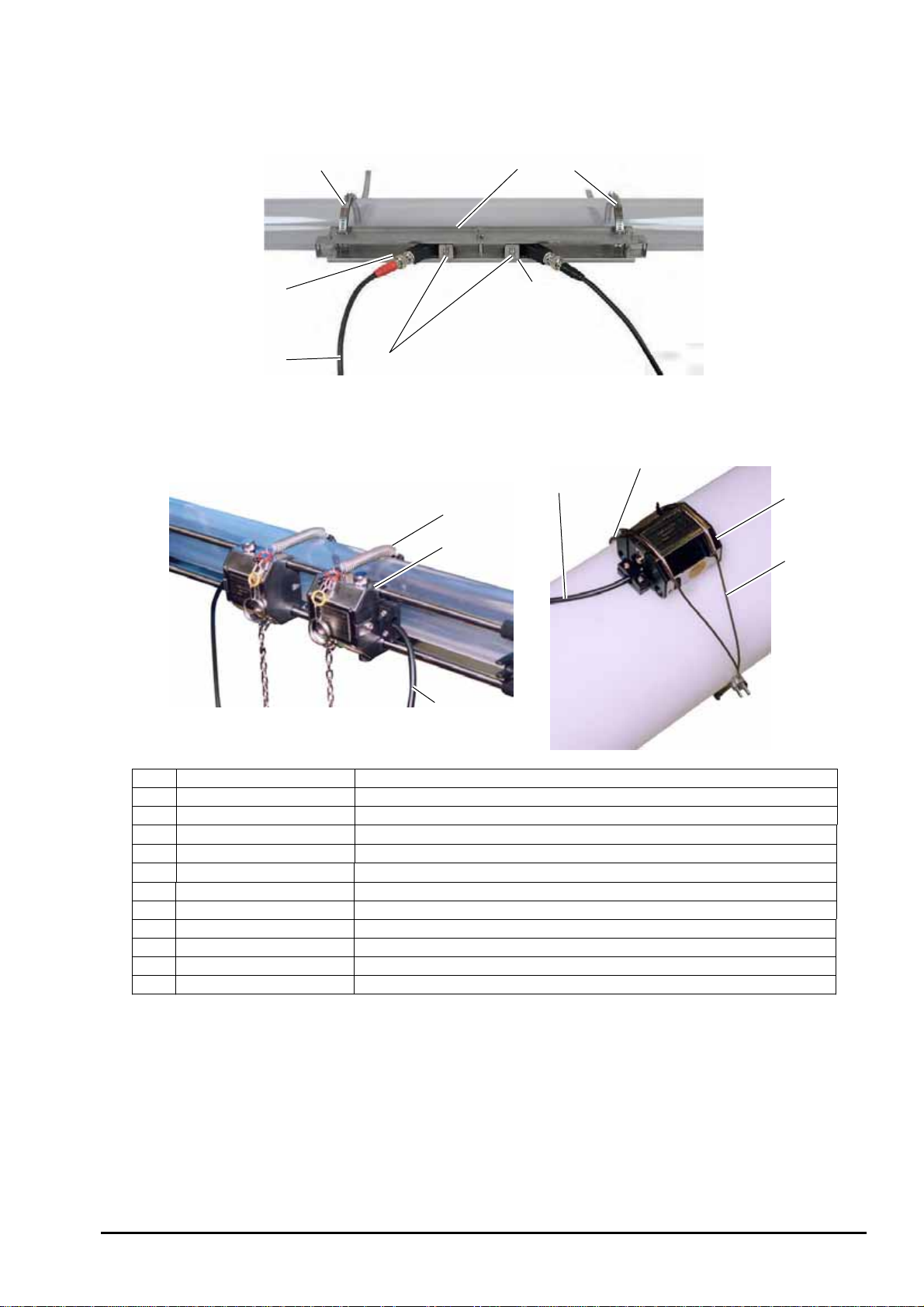

1.4.2. Detector (SX3 Series)

S

B

0

SX3-A0/B0

ULLETIN F-7

3

13

X3-C0/D0

6

7

2

9

8

7

5

11

7

8

10

No. Name Description

1 Frame for small size Fastens the sensor unit on pipe.

2 Sensor unit Sends and receives an ultrasonic wave.

3 Stainless steel belt Fastens the frame on pipe.

4 Spring fixture Removes the play of stainless steel belt.

5 Scale For reading the sensor mounting spacing

6 Fastening hole For positioning and fastening the sensor units

7 Signal cable Transmits send/receive signals.

8 Small size detector Sends and receives an ultrasonic wave.

9 Chain Fastens the detector on pipe.

10 Wire rope Fastens the detector on pipe.

11 Mounting spring Removes the play of wire rope.

-7-

Page 18

B

ULLETIN F-70

2. SELECTION OF INSTALLATION PLACE

Select an installation place taking into account the following factors from the viewpoint of ease of maintenance and

checkup, instrument life, and reliability.

(1) A place where ambient temperature and humidity are –20 to +50qC and 90% RH or less for flow

transmitter (UXF2), and –20 to +60qC and 90% RH or less for detector SX3.

(2) A place not exposed to direct sunshine nor effects of weather.

(3) Sufficient space for daily inspection, wiring, etc.

(4) A location not subject to radiated heat from a heating furnace, etc.

(5) A location not subjected to corrosive atmosphere.

(6) A location not subject to flooding.

(7) A location free from excessive vibration, dust, dirt and moisture.

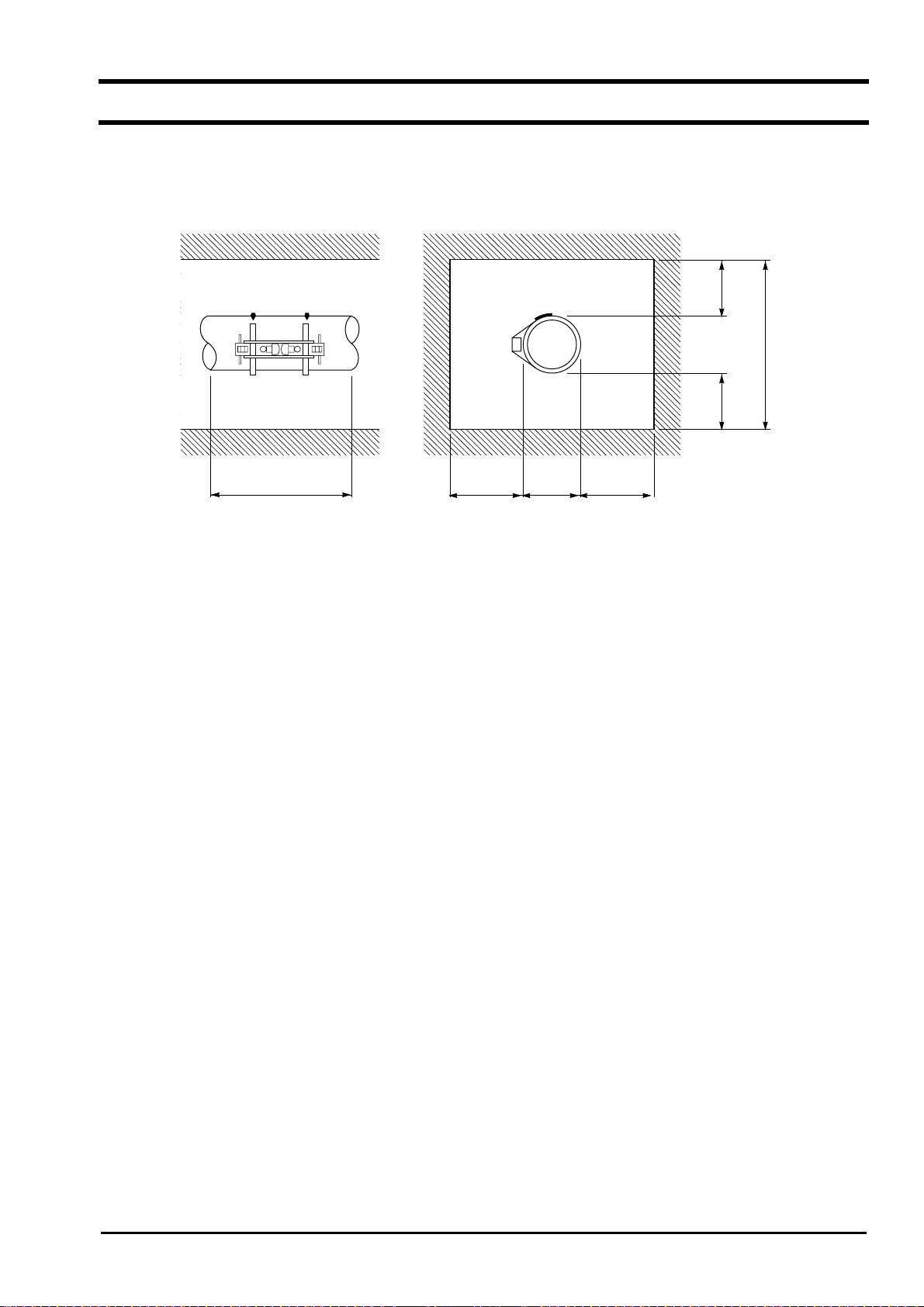

2.1. Flow transmitter

Secure at least 100 mm of space between the flow

transmitter and nearby wall. Also secure a space for

opening the front cover for maintenance.

Secure a cable wiring space under the enclosure.

N

E

P

O

133 100133

370 min.

Top view of mounting

min.

- 8 -

Page 19

B

ULLETIN F-7

0

2.2. Detector

The measuring accuracy is considerably affected by the detector mounting place, i.e., status of piping for measuring a flow

rate. Select a place which meets the condition in section 2.2.1. (Length of straight pipe). Also, sufficiently secure a

space for installation and maintenance in accordance with the following diagram.

2000min.

Note

200min. 200min.

D + 1200 min. 600min. D 600min.

D: Pipe diameter

Necessary space for detector mounting place

2.2.1. Length of straight pipe

The length of upstream and downstream straight pipe of the ultrasonic detector should be long enough to ensure accurate

measurements.

-9-

Page 20

B

ULLETIN F-70

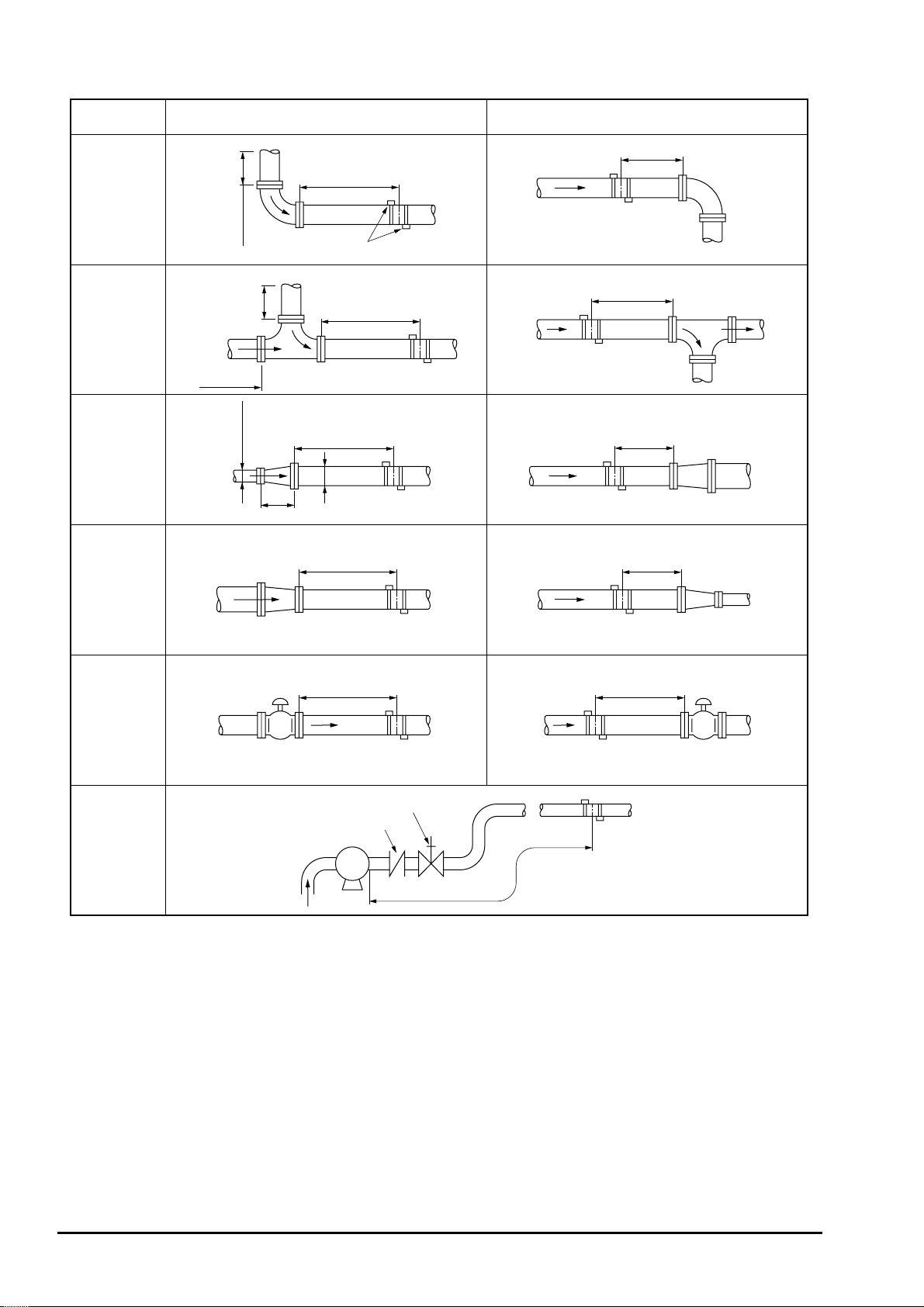

(D: Nominal diameter of pipe)

Name Straight length of upstream piping Straight length of downstream piping

L≥5D

L≥10D

90° bend

Tee

Diffuser

Reducer

10D min.

0.5D min.

10D min.

10D min.

1.5D min.

Detector

L≥50D

L≥30D

D

L≥10D

L≥10D

L≥5D

L≥5D

Valve

Pump

Note: Quoted from JEMIS-032

L≥30D

Flow controlled upstream

Check valve

Stop valve

P

L≥10D

Flow controlled downstream

L≥50D

- 10 -

Page 21

2.2.2. Mounting position

B

0

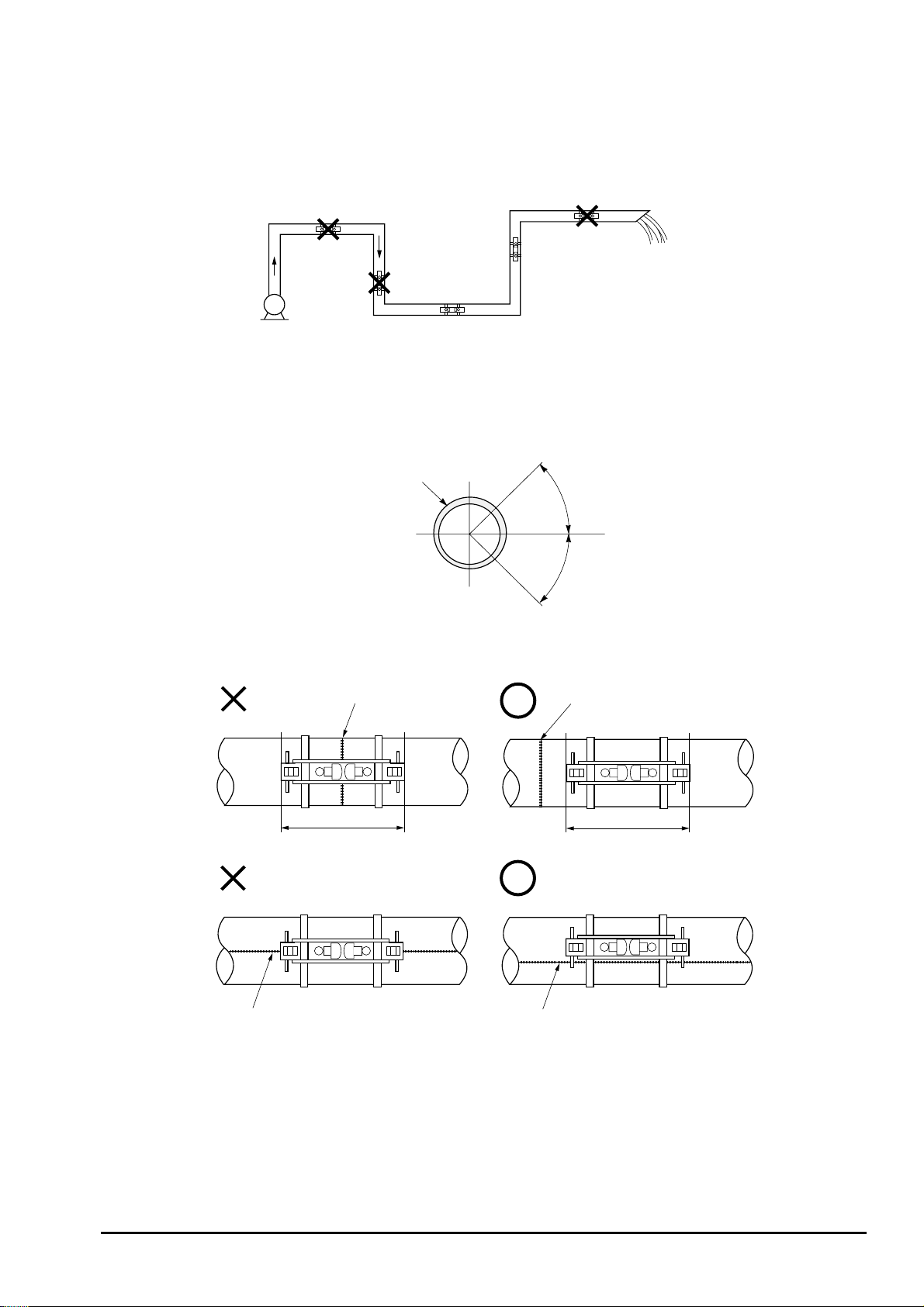

The detector can be installed vertically, horizontally or in any position provided the following:

(1) The piping must completely be filled with fluid when it flows.

ULLETIN F-7

Air tends to accumulate.

May not

completely be

filled with liquid.

Pump

May not completely be filled with liquid.

Good

Good

(2) In case of horizontal piping, mount the detector within r45q from the horizontal plane. Otherwise, the measurement

could be impossible if bubbles stay in the upper part of piping or if deposits are accumulated in the lower part of

piping. In case of vertical piping, the detector may be mounted at any position on its periphery provided that the

flow is upward.

Pipe

45°

Horizontal

45°

(3) Do not mount the detector on a distorted part, flange or welding.

Weldment

Welding is included.

Welding is partly involved.

Avoid Welding.

Weldment

Off the Welding.

-11-

Page 22

B

ULLETIN F-70

3. INSTALLATION AND PROCEDURES PRIOR

TO OPERATION

3.1. Outline of installation procedure

(1) Select the flow transmitter and detector installation places.

(2) Install and wire the flow transmitter.

(3) Turn on powe r.

(4) Set the piping parameters, and calculate the sensor unit spacing (if already programmed, check the sensor unit

spacing).

(5) Mount the frame on the piping to measure on.

(6) Mount the sensor unit.

(7) Set the measurement range.

(8) Adjust zero point.

(9) Start a measurement.

- 12 -

Page 23

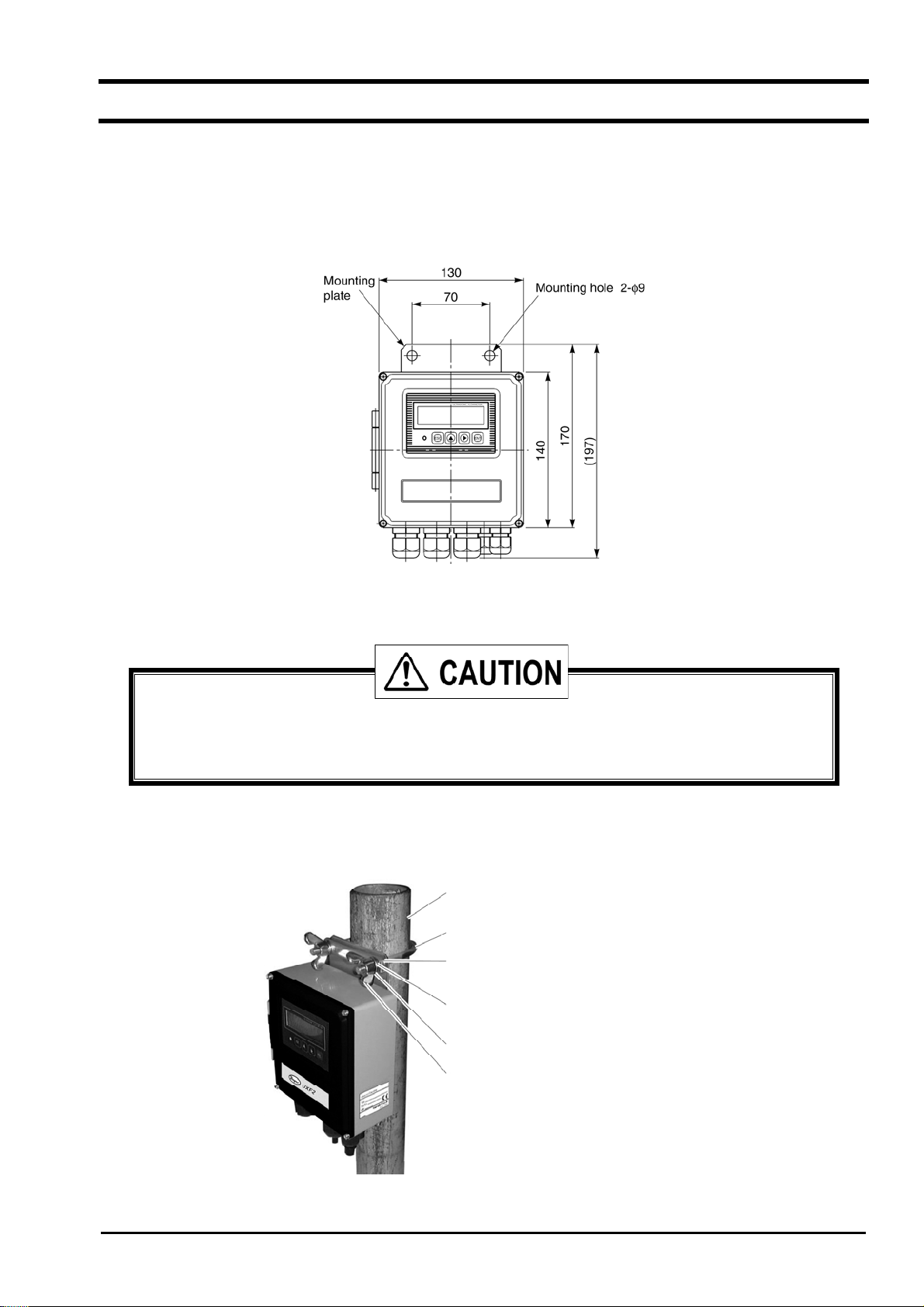

3.2. Installation of flow transmitter

3.2. Installation of flow transmitter

The flow transmitter may be mounted on a wall or 2B pipe stand (option).

3.2.1. Wall mounting

For wall mounting, use two M8 bolts.

According to the mounting hole dimensions shown below, drill holes on the wall, and tighten M8 bolts.

3.2.2. 2B pipe stand mounting

When mounting on 2B pipe, be sure to use the complete set of fixtures (U bolt, support fixture, plain washer,

spring washer, wing nut) that are provided. Tighten the wing nut by hand. Assemble pipe mounting

components as shown in the figure below and do not overtighten. Overtightening may warp or damage the

plastic enclosure.

Mount the instrument on 2B pipe stand as illustrated below.

2B Pipe stand

U - bolt

Fixture assembly

Plain washer

Spring washer

Wing nut

-13-

Page 24

B

ULLETIN F-70

3.3. Flow transmitter wiring

3.3.1. Precautions in wiring

(1) Use a special coaxial cable (SX3C) as a signal cable between the detector (SX3) and flow

transmitter (UXF2). Continuous lengths are required. Signal cables may not be spliced or joined.

(2) Be sure to pass the signal cables through a metal conduit between the detector and flow transmitter.

Upstream and downstream signal cables may be put in the same conduit but, to avoid an interference, do

not put the power cable together.

(3) For output signal, use a shielded cable, where possible.

(4) To avoid noise interference, do not run cables through conduits carrying heavy duty or high voltage

lines.

(5) If a ground wire is included in the power cable, connect it to ground as it is.

(6) A power switch is not provided on the instrument and must be mounted separately if required.

(7) Cover unused wiring glands and protect from moisture intrusion.

3.3.2. Applied wiring

Use the following cables.

Power cable : 3 or 2 core cabtyre cable.

z

Nominal cross-sectional area 0.75 mm

Finished outer diameter 11 mm.

Output signal cable : 2 or, as required, multiple core cabtyre cable.

z

Finished outer diameter 11 mm.

Detector-flow transmitter cable : Signal cable by type designation (heat-resisting high-frequency coaxial cable having

z

50: of characteristic impedance. In case SX3-A0/B0, provided with oneside waterproof BNC connector).

Finished outer diameter 5 mm.

2

min.

3.3.3. Treatment of wiring ports

The outer case of flow transmitter is waterproof (IP65). However, if installed in a humid place, the wiring ports must be

made airtight to avoid ingress of moisture, condensation, etc. Be sure to use the waterproof glands furnished with the

instrument in order to ensure the waterproof seal. Hermetically seal unused glands with caps provided.

Do not install the instrument where there is a risk of flooding.

- 14 -

Page 25

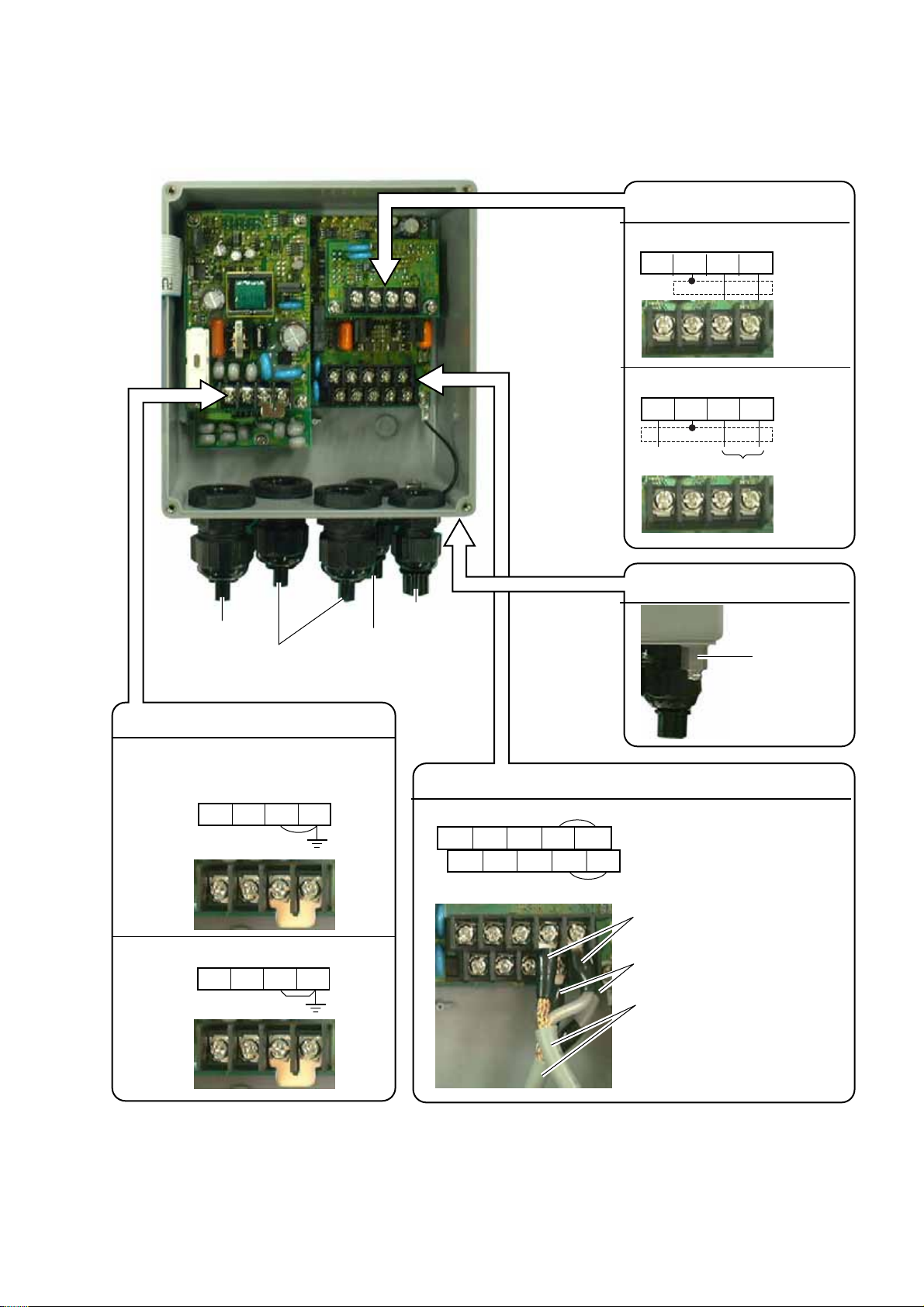

3.3.4. Wiring to each terminal

B

0

Refer to the following diagram for carrying out wiring.

ULLETIN F-7

Communication board terminal block (option)

RS-232C

NC

GND RXD TXD

RS-485 and synchronization

SYNC

SHILD TXDR2 TXDR1

Power cable

Output signal cable

(analog output, DO1, DO2,

communication synchronization)

Downstream

sensor cable

Power board terminal block

AC power source: 100 to 120 or 200 to 240 V AC,

50/60 Hz

LN

GND GND

Upstream

sensor cable

Main board terminal block

Iout(+) DO1(+) DO2(+)

Iout(-) DO1(-) DO2(-)

Upstream sensor

GND HF1

GND HF2

Downstream sensor

Synchronization

RS-485

External ground terminal

Ground terminal

Red (upstream sensor)

DC power source: 20 to 30V DC

+−

GND GND

Black (downstream sensor)

Special signal cable (SX3C)

Iout : Analog output

DO1 : Transistor open collector

DO2 : Relay contact

Notes

1. All screws are M3 on the terminal block. Use crimp-style terminals for M3 and whose outer diameter is 5.8 or

smaller.

2. Be sure to connect to ground the power board terminal block or external ground term in al (class D ground).

3. For output signal, use multiple core cable as required.

-15-

Page 26

B

ULLETIN F-70

3.4. Setting the piping parameters and calculating the

sensor unit spacing

After installation and wiring of the flow transmitter (sensor unit may not be wired), turn on power, input the piping

parameters below, and calculate the sensor unit installation spacing. (If the unit is already programmed, the

following parameters have already been input. Check the installation spacing in this case.)

Item Input

method

Pipe outer diameter Value 10 to 650mm

Pipe material Menu PVC, PVDF, PEEK, PP, CARBON STEEL, STAINLESS STEEL, COPPER,

PIPE S.V (Note 1)

Pipe wall thickness Value 0.1 to 100mm

Lining presence and

material selection

Lining thickness Value 0.1 to 10mm

Fluid type Selection Water, Sea water, FLUID S.V (Note 1)

Kinematic viscosity Value 0.00E–6m2/s to 999.999E–6 m2/s (Note 1)

Detector mounting

method

Detector type Selection SX3 A0, SX3 B0, SX3 C0, SX3 D0

Note 1: In case of material or fluid not included in menus, input its sound velocity and kinematic viscosity of the

fluid. The sound velocity can be entered within the range of 1000 to 3700 m/s for piping or lining

material, or 500 to 2500m/s for fluid. (Refer to section 6.6.)

The operating procedure is as follows (from measurement mode).

Note 2: If the parameter protection is set at "PROTECTION ON", change it to "PROTECTION OFF". If ID NO.

is set at this time, ID NO. must be entered.

Keying

key pressed 3 times.

Menu NO LINING, TA R EPOXY, MORTAR, RUBBER, TEFLON, PYREXGLASS,

LINING S.V (Note 1)

Selection V method, Z method

1st line: [MEASURE SETUP].

Range or menu

LCD indication/comment

ENT

key pressed.

key pressed 3 times.

ENT

key pressed.

ENT

key pressed.

and key pressed.

ENT

pressed to enter.

key pressed.

ENT

key pressed.

key pressed to select.

ENT

key pressed to enter.

key pressed.

ENT

key pressed.

1st line: [SYSTEM UNIT].

1st line: [PIPE PARAMETER].

1st line: [OUTER DIAMETER]. 2nd line: [60.00 mm]. * As selected currently.

Cursor blinks on 2nd line.

Input the outer diameter of a measurement pipe. As necessary, check the piping data

in section 6.6.

: Selects a numeric. : Shifts the place.

Registered after [**COMPLETE**] is indicated about 1 second on 2nd line.

1st line: [PIPE MATERIAL]. 2nd line: [PVC] * As selected currently.

Cursor blinks on 2nd line.

Select the pipe material from menus. If there is no corresponding menu, input the

sound velocity of pipe material on sound velocity input screen

If necessary, refer to piping data in section 6.6.

Registered after [**COMPLETE**] is indicated about 1 second on 2nd line.

1st line: [WALL THICKNESS]. 2nd line: [4.50mm] * As selected currently.

Cursor blinks on 2nd line.

.

- 16 -

Page 27

B

ULLETIN F-7

0

Keying

and key pressed.

ENT

key pressed to enter.

key pressed.

ENT

key pressed.

key pressed to select.

ENT

key pressed to enter.

key pressed.

ENT

key pressed.

and

ENT

key pressed to enter.

key pressed.

LCD indication/comment

Input the wall thickness of the measurement pipe. As necessary, check the piping data

in section 6.6.

: Selects a numeric. : Shifts the place.

Registered after [**COMPLETE**] is indicated about 1 second on 2nd line.

1st line: [LINING MATERIAL]. 2nd line: [NO LINING]. * As selected currently.

If pipe is not lined, press

key to go to selection of next fluid to be measured.

Cursor blinks on 2nd line.

Select the lining material from menus. If there is no corresponding menu, input the

sound velocity of lining material on sound velocity input screen

.

If necessary, see lining data in section 6.6.

Registered after [**COMPLETE**] is indicated about 1 second on 2nd line.

1st line: [LINING THICKNESS]. 2nd line: [2.00 mm]. * As selected currently.

Note: Not indicated if lining material is set at [NO LINING].

Cursor blinks on 2nd line.

Input the lining thickness.

: Selects a numeric.

: Shifts the place.

Registered after [**COMPLETE**] is indicated about 1 second on 2nd line.

key pressed.

ENT

key pressed.

key pressed to select.

ENT

key pressed to enter.

key pressed.

ENT

key pressed.

and

ENT

key pressed to enter.

key pressed.

key pressed twice.

ENT

key pressed.

key pressed.

ENT

key pressed to enter.

1st line: [KIND OF FLUID]. 2nd line: [WATER]. * As selected currently.

Cursor blinks on 2nd line.

Select [WATER] or [SEA WATER]. In case of other fluid, input the sound velocity of

fluid on sound velocity input screen

.

If necessary, see piping data in section 6.6.

Registered after [**COMPLETE**] is indicated about 1 second on 2nd line.

1st line: [KINEMATIC VISCO]. 2nd line: [1.0038E–6m2/s]. * As selected

currently. Kinematic viscosity of water is factory set. If fluid to be measured is

other than water, input the kinematic viscosity referring to piping data in section 6.6.

Cursor blinks on 2nd line.

Input the kinematic viscosity.

: Selects a numeric.

: Shifts the place.

Registered after [**COMPLETE**] is indicated about 1 second on 2nd line.

1st line: [SENSOR TYPE]. 2nd line: [SX3-A0/B0]. * As selected currently.

Cursor blinks on 2nd line.

Select [SX3-A0/B0] or [SX3-C0/D0].

Registered after [**COMPLETE**] is indicated about 1 second on 2nd line.

ESC

key pressed.

ESC

key pressed.

key pressed twice.

1st line: [PIPE PARAMETER]. 2nd line: [S= 16 ( 48mm)] in case SX3-A/B

Note Sensor unit spacing calculated by above settings is indicated for sensor unit

spacing at detector installation.

1st line: [MEASURE SETUP]

Measurement mode is resumed.

-17-

Page 28

B

ULLETIN F-70

3.5. Installation of detector (SX3-A0, SX3-B0)

3.5.1. Outline of detector installation procedure

(1) Treat the surface to mount on the detector.

(2) Mount the frame.

(3) Mount the sensor unit.

3.5.2. How to treat the mounting surface

By thinner, sandpaper, etc., eliminate rust, pitch, convex and concave from the pipe surface to mount on the detector by the

frame length to occupy.

Note: 1. If jute is wound on the pipe, peel off the jute over the entire periphery by frame length (L) + 200 mm

beforehand.

Jute winding

Pipe

L+200mm

Fig. 3-1 L: Frame length (SX3-A0: 228 mm, SX3-B0 348 mm)

3.5.3. How to mount the frame

Mount the frame carefully not to cut your fingers with stainless steel belt.

z

(1) Pass the spring fixture on the stainless steel belt as

shown in Fig. 3-2.

Stainless steel belt

Spring fixture

(2) Pass the stainless steel belt through 2 belt holes on

the frame as shown in Fig. 3-3.

Frame

Fig. 3-2

Fig. 3-3

- 18 -

Page 29

B

ULLETIN F-7

0

(3) Make sure the obtained status is as shown in Fig. 3-4.

Fig. 3-4

(4) As shown in Fig. 3-5, apply the frame on the pipe

section subjected to a surface treatment.

(6) Adjust the frame so as to be in parallel with the pipe,

put the spring fixture to the side of the frame as

shown in Fig. 3-7, and tighten the stainless steel belt

so that the frame will tightly be fitted.

Fig. 3-7

(7) After tightening both stainless steel belts, slide the

spring fixture to the opposite to the frame as shown in

Fig. 3-8.

Fig. 3-5

(5) Temporarily tighten the first stainless steel belt on the

pipe as shown in Fig. 3-6.

Fig. 3-6

Fig. 3-8

Note: When removing the frame set to the piping and

set it to a different position, use new stainless

steel belts.

- 19 -

Page 30

B

ULLETIN F-70

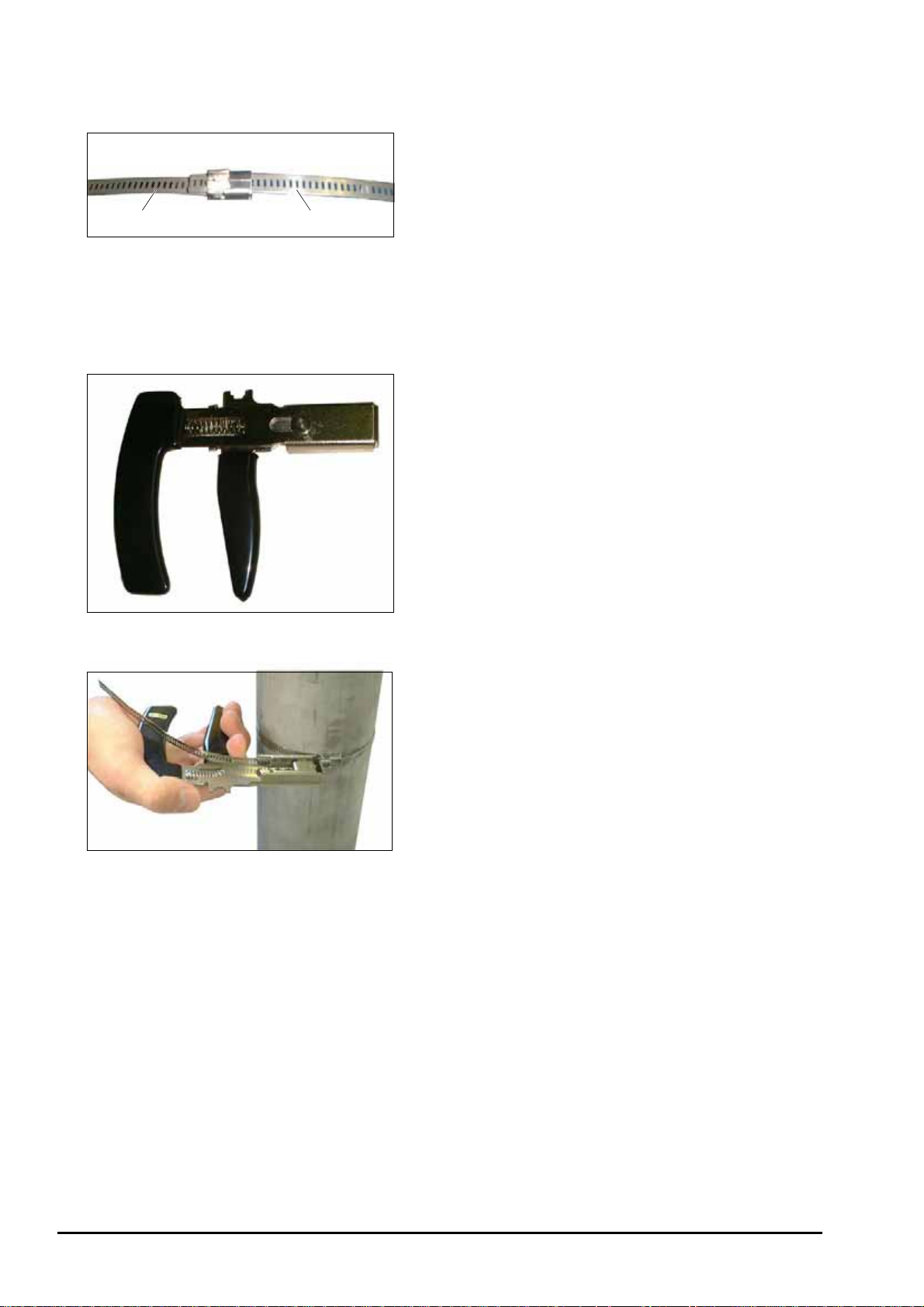

Mounting on pipe whose diameter is 150 mm or larger

As shown in Fig. 3-9, connect 2 stainless steel belts.

First steel belt

Fig. 3-9

Tightening tool

Use of an optional tool (Fig. 3-10) facilitates tightening

the stainless steel belt (Fig. 3-11).

Fig. 3-10

Second steel belt

Fig. 3-11

- 20 -

Page 31

B

ULLETIN F-7

0

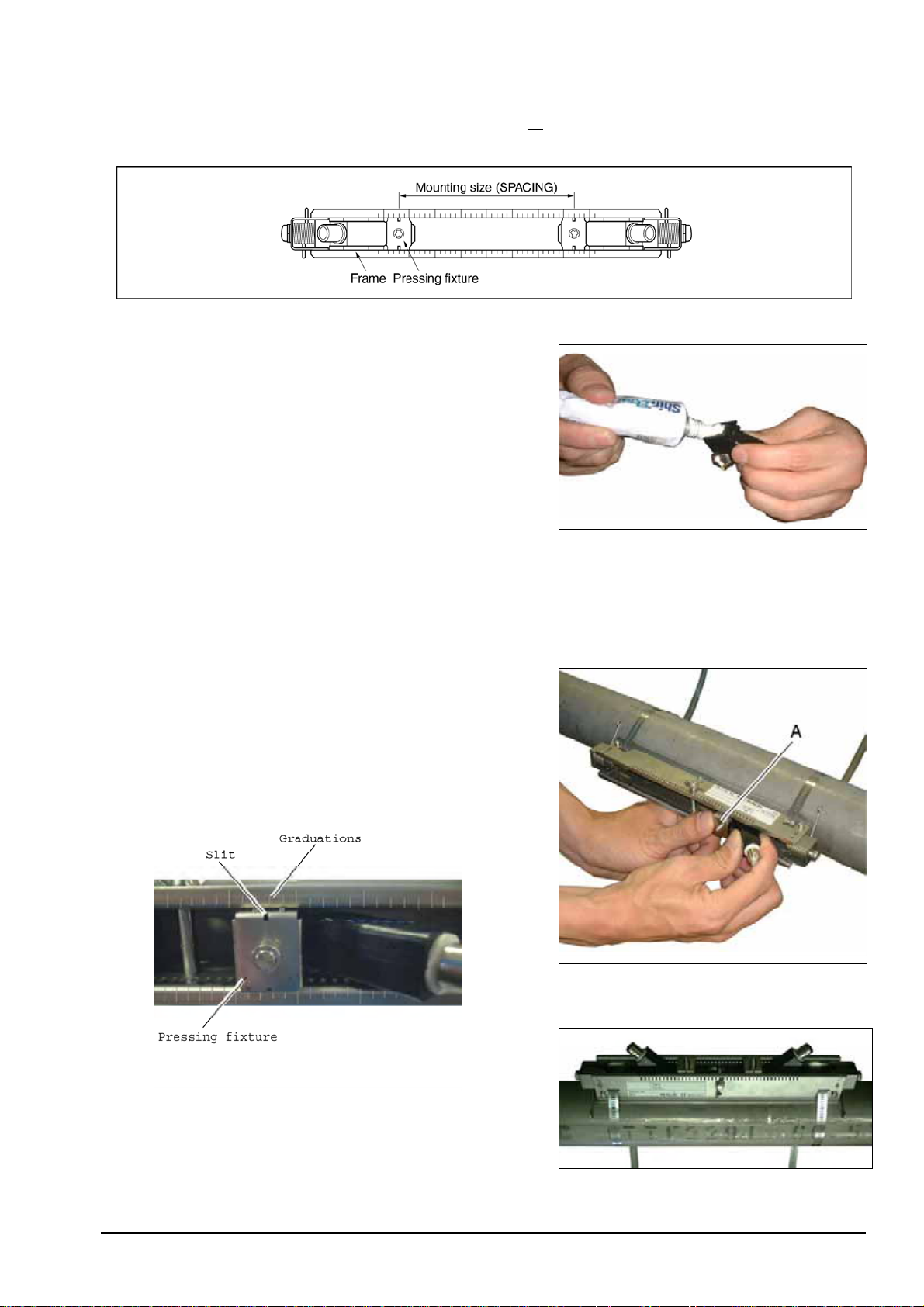

3.5.4. How to mount the sensor unit

(1) Mount both sensor units spaced at the SPACING value [S= **] (number of graduations on frame) indicated after

setting the piping parameters.

Fig. 3-12

(2) Before mounting the sensor unit into the frame, sufficiently

apply silicone filler (or silicone-free grease

entire transmission surface of the sensor unit, taking care not

to introduce bubbles (Fig. 3-13).

Note) When using silicone-free grease, pay attention to the

fluid temperature range. The fluid temperature range is

shown below.

Silicone rubber: 20 to 100qC

Silicone-free grease: 0 to 60qC

When using silicone-free grease, reapply it on the

transmission surface of the sensor unit approximately

once every 6 months. (Silicone rubber need not be

reapplied.)

(3) Then insert the sensor unit into the frame, align the slit

provided on the pressing fixture of the sensor unit with

graduations located on the frame top surface (see Fig. 3-14),

and press the sensor unit until the fixture claws are engaged

with the frame side square holes. Mount both sensor units

so as to be roughly symmetrical with respect to the frame

(see Fig. 3-15).

Note

) over the

Fig. 3-13

Fig. 3-14

Position of the slit and the graduation

(Magnified view of section A)

Fig. 3-15

- 21 -

Page 32

B

ULLETIN F-70

Mount the sensor units so that their BNC connectors face outward (Fig. 3-16a). If at least one is mounted

opposite, measurement is not possible (Fig. 3-16b, c). The pressing fixture claws must be completely

engaged with square holes provided on sides of the frame. Otherwise, the sensor and pipe will not correctly

get in contact with each other, and measurement error will occur..

Fig. 3-16a

Fig. 3-16b

Fig. 3-16c

(4) Connect the signal lines with BNC connectors of the sensor units. At this time, do not mistake the upstream and

downstream sides for each other. Connect the red BNC connector upstream, and the black BNC connector

downstream (see Fig. 3-17).

Fig. 3-17

- 22 -

Page 33

3.6. Installation of detector (SX3-C0, SX3-D0)

B

0

3.6.1. Outline of detector installation procedure

(1) Selection of detector mounting method

(2) Processing of detector mounting surface

(3) Determination of mounting position (with Z method for small type)

(4) Cable end treatment

(5) Connection of cable to small detector

(6) Mounting of small detector on pipe

3.6.2. Selection of mounting method

There are two ways for mounting the detector, the V method and the Z method (See Fig. 3-18).

ULLETIN F-7

Approx. D

Detector

D

V method

D

Approx. D/2

Detector

Z method

Fig. 3-18

The Z method should be used in the following cases.

Ɣ

Where a mounting space is not available. (As shown in the figure above, the mounting dimension with

the Z method is about half of that with the V method).

Ɣ

When measuring fluid of high turbidity such as sewage.

Ɣ

When the pipe has a mortar lining.

Ɣ

When the pipe is old and has a thick accumulation of scale on its inner wall.

Selection standard

For an inside diameter of more than 300 mm, the Z method is recommended for mounting.

Detector

Small type

detector

SX3-C0, SX3-D0

Z

method

V

method

:Range noted in specifications

13 25 50 100

:Range specified with piping material

(FRP,PVC or other plastic materials)

200 300 600

250

Inside diameter (mm)

3.6.3. Processing of detector mounting surface

Using thinner and/or sandpaper, remove pitch, rust and unevenness over a width of (L) + 200mm on the pipe

circumference where the detector is mounted.

Note) If there is a jute winding on the pipe circumference, remove it and carry out the above processing.

Jute winding

Pipe

L+200mm

-23-

Page 34

B

ULLETIN F-70

3.6.4. Determination of mounting position

(with Z method for small type)

Carry out the following to determine the mounting position.

Gauge paper is necessary for this work. (Refer to 6.5. “How to make gauge paper”.)

(1) Align the edge of gauge paper with a point about 100mm from

one end of the processed section, and wrap the paper around

the pipe so that the line drawn on the paper is parallel with the

pipe shaft. (The paper should be taped to prevent slipping.)

At this time, make sure that the paper edge is even.

(2) Extended the line drawn on the paper and mark a straight line A

on the pipe.

(3) Mark a line along on edge of the paper. Assume the intersection of

0

the line and the straight line A is A

.

100mm

Edge should be even.

Straight line A

A

0

V method

Example) L = 200mm

A

2

200mm

A

0

(4) Remove the gauge paper and measure

the mounting dimension from A

.

0

Then , draw a line which crosses the

straight line A (determine the position

).

A

2

A0 and A2 are the mounting position.

Z method

A

0

Straight line B

0

1

A

B

1

B

B0, B

1

A

0

,

A

(4) Measure the circumference of the pipe from the

point A

between the point B

, and mark a line (straight line B)

0

and B1 obtained at 1/2 of

0

the circumference.

Example) L = 100mm

100mm

B2B

0

A

0

B

B

0

2

1

- 24 -

(5) Put a mark at point B

0

and remove the gauge

paper.

Measure the mounting dimension from B

mark a line crossing the straight line B (determine

the position B

).

2

In this way, the mounting position is determined.

A0 and B2 are the mounting position.

and

0

Page 35

B

ULLETIN F-7

0

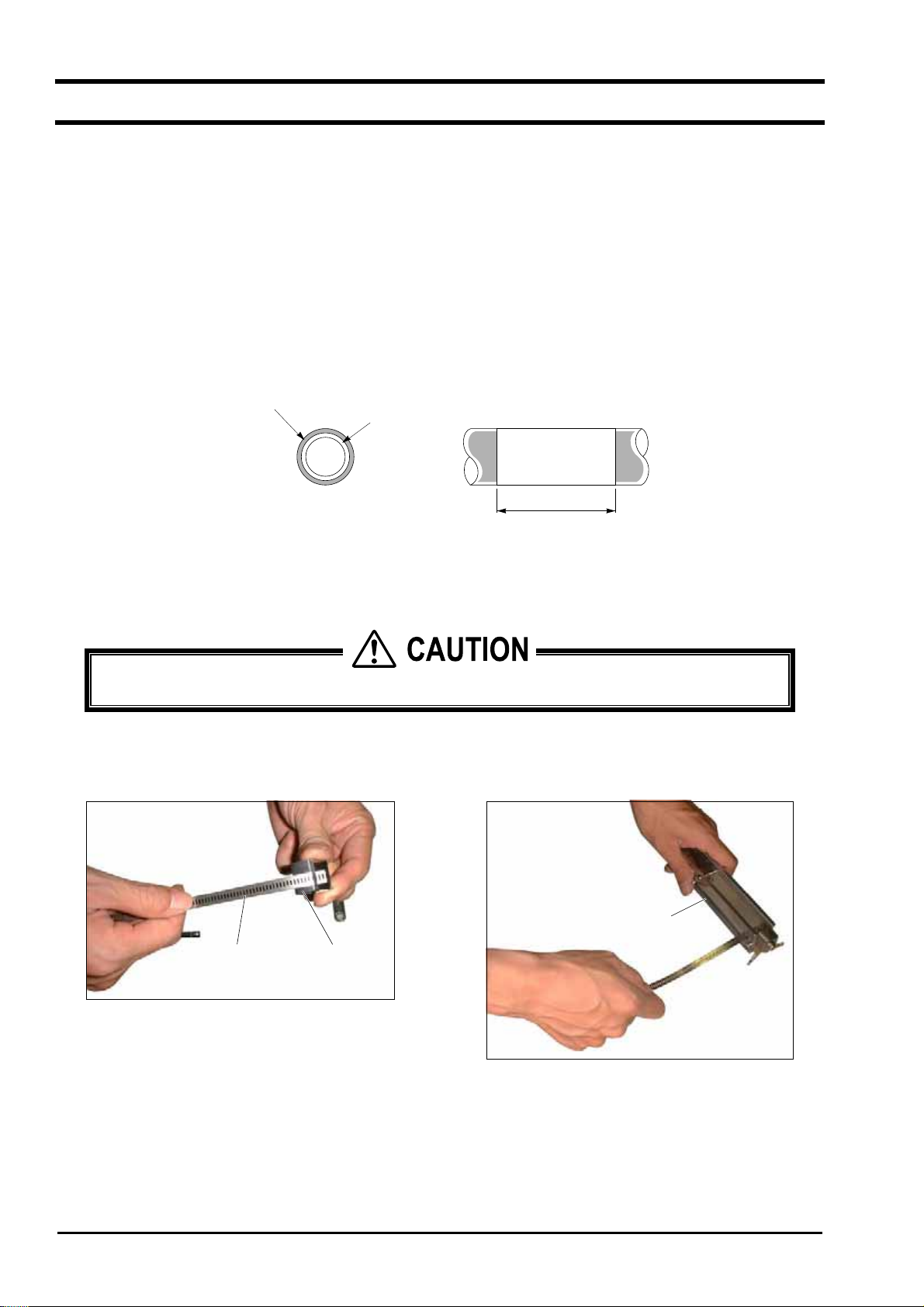

3.6.5. Cable end treatment

The end of coaxial cable is treated at the factory prior to delivery. If the cable needs to be cut

before use, the conductor and the shielding wires should be treated using clamp terminals.

Shielding wire (black, G)Conductor (white, +)

Clamp terminal

Note) When cutting the coaxial cable, make sure that the upstream side and the downstream side are the

same

length.

-25-

Page 36

B

ULLETIN F-70

3.6.6. Connection of cable to small detector

(1) Loosen the retaining knobs on the detector using a

screwdriver, then remove the cover from the

detector.

(2) Mount the sensors so that the upstream and

downstream sensors can be distinguished from

each other. Remove the cable clamp.

Note) In case of removing the cable clamp, be

careful not to lose the nut.

Fig. 3-19

Fig. 3-20

- 26 -

Page 37

B

ULLETIN F-7

0

(3) Insert the coaxial cable through the cable lead-in port

and loosen the terminal screws (G, +).

Note) At this time, temporarily remove the resistor.

(5) Secure the coaxial cable with the cable clamp. Note:

resistor not shown.

Fig. 3-23

Fig. 3-21

(4) Connect the cable to the teminal (black to G terminal,

red to + terminal). Then tighten the cable together

along with with the resistor.

(6) Remove any foreign matter from the terminals, and

seal the terminal block with silicone filler. Resistor

is not shown.

• Cut off the tip of the silicone filler tube.

Apply silicone to the terminal block while pressing

the head of the tube against the bottom of terminals.

At this time, care should be taken to prevent entry

of air bubbles.

Fig. 3-22

Fig. 3-24

- 27-

Page 38

B

ULLETIN F-70

(7) Reinstall the cover onto the detector.

Fig. 3-25

- 28 -

Page 39

B

ULLETIN F-7

0

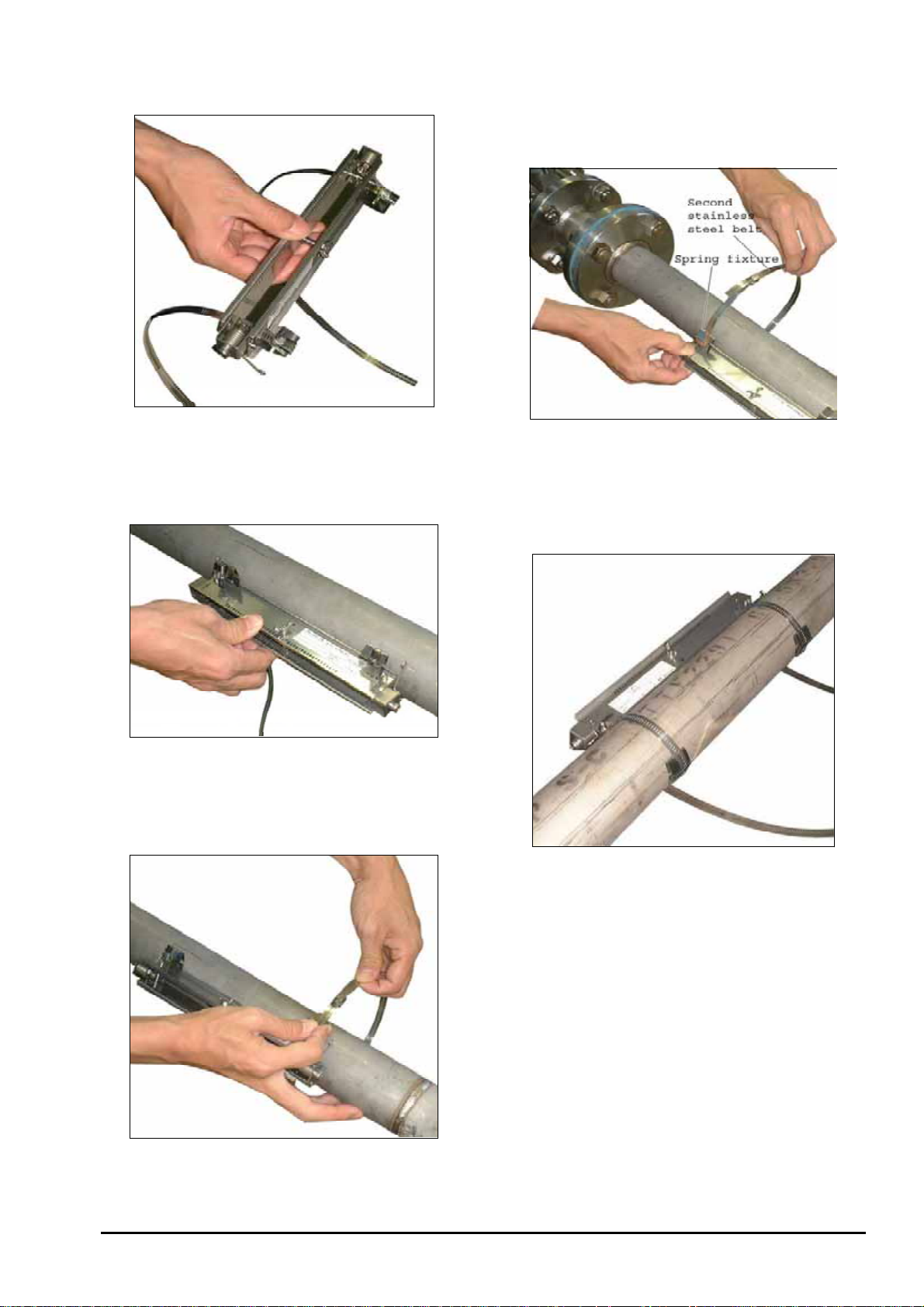

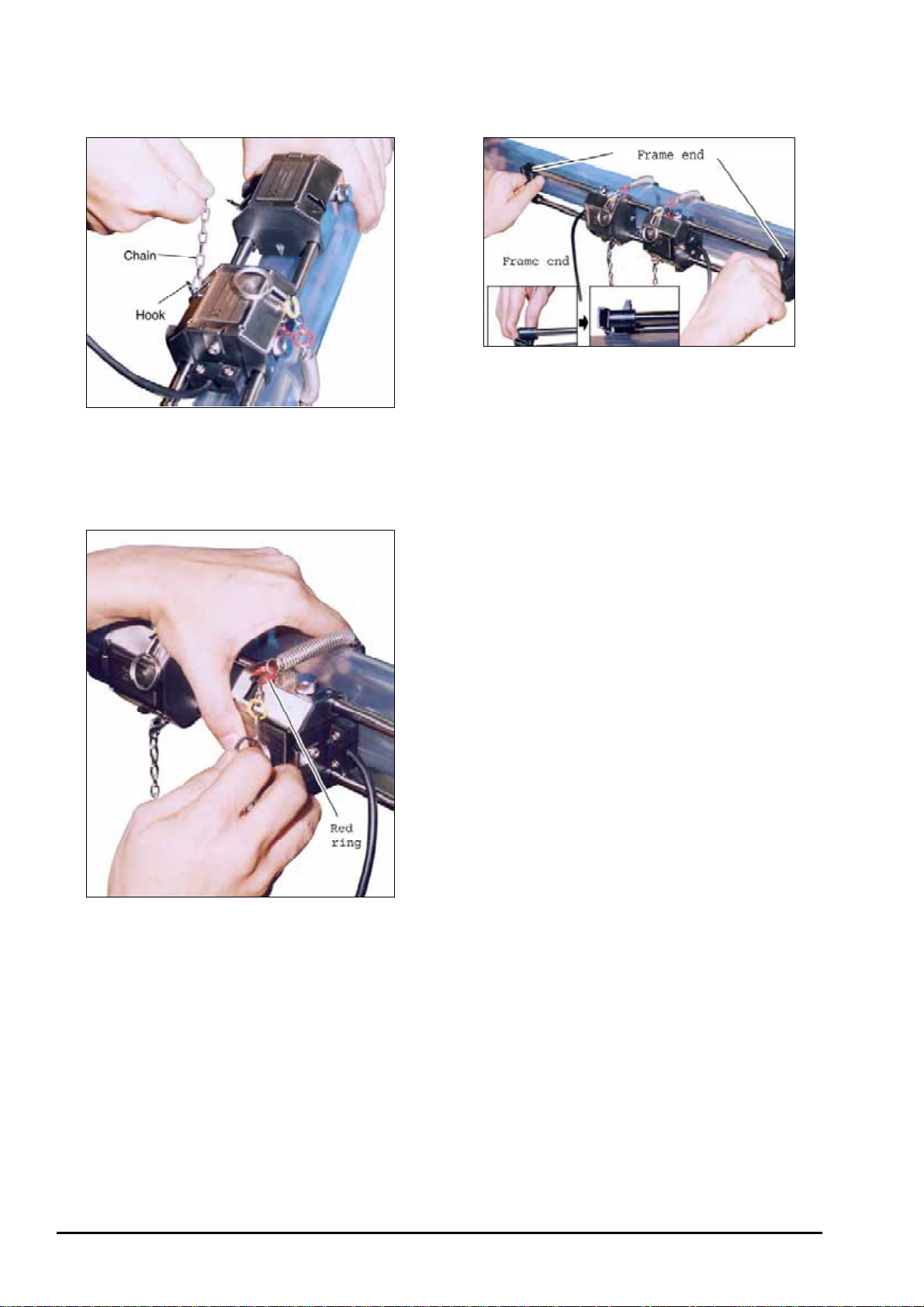

3.6.7. Mounting of small detector on pipe

The small type detector is mounted on pipe with a diameter of ø50 to 300 (V method) or ø300 to 600 (Z method) for

measurements.

3.6.7.1. Mounting of detector (SX3-C0) <V method>

Mount the detector using the following procedure.

For mounting, have a ruler, scale, or caliper handy for measurement.

(1) Loosen the retaining knob A (4 places), slide the

detectors to match the mounting dimension, place a

scale on the mounting dimension reference surface C

and adjust the separation distance (dimension). Then

tighten the retaining knobs “A”.

(2) Spread silicone filler over the whole transmitting side

of the detector. Ensure enough silicone is applied

smoothly without bubbles and thoroughly to prevent

air gaps.

Clean the surface of the pipe as required and mount

the detector.

Fig. 3-26

Fig. 3-27

(3) Raise the end of the pipe fitted with the detector, and

attach the yellow ring (on the chain) to the hook.

Fig. 3-28

-29-

Page 40

B

ULLETIN F-70

(4) Attach the other chain end to the other hook of

detector, and secure it loosely in place.

Fig. 3-29

(5) Pull the red ring and attach it to the hook.

Use the same procedure for the other sensor.

(6) Turn over the frame end so that the sensor makes

flush contact with the pipe.

Fig. 3-31

(7) Press the sensor firmly and uniformly against the pipe.

Ensure that the sensor makes a flush contact with the

pipe.

Fig. 3-30

- 30 -

Page 41

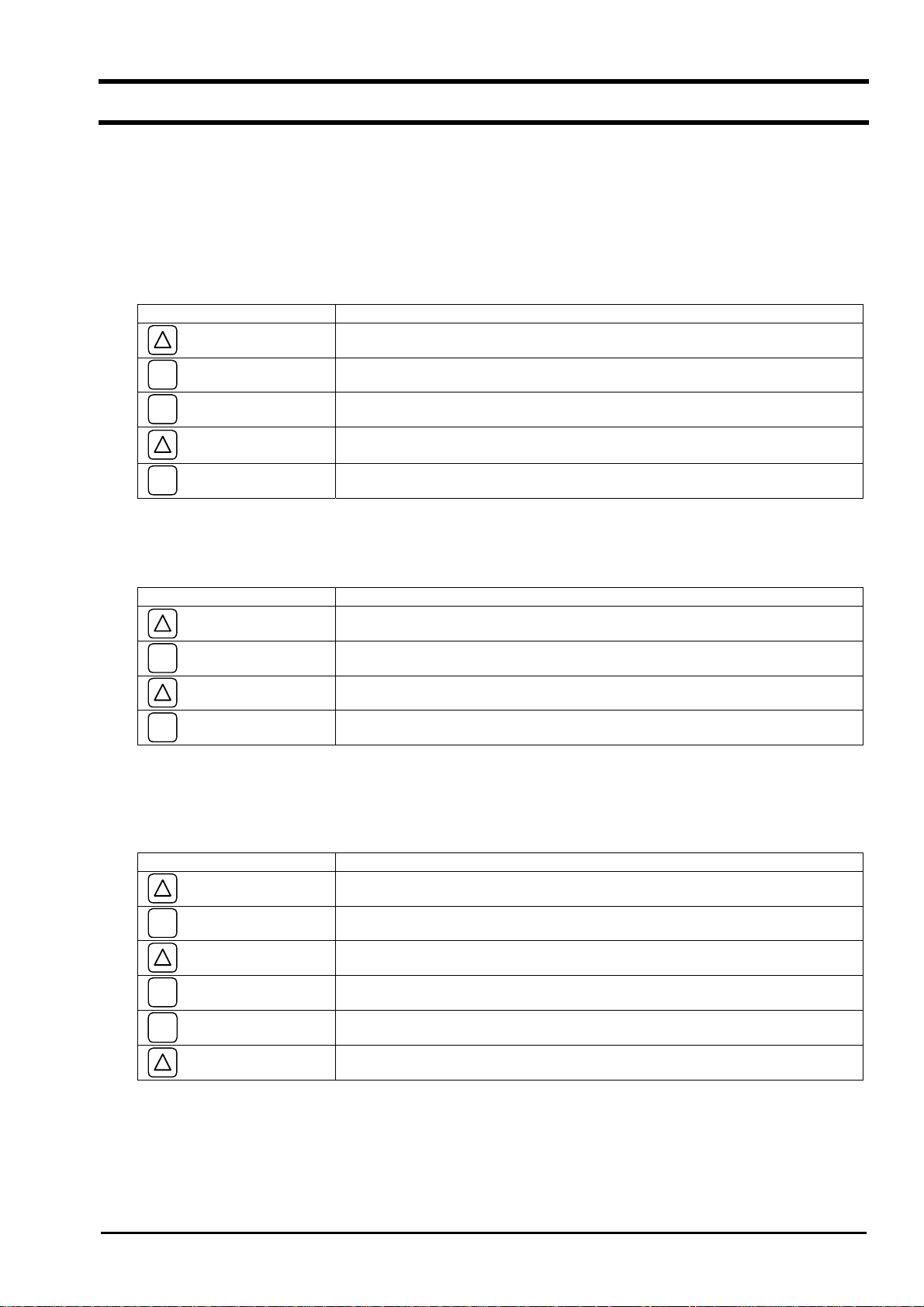

3.6.7.2. Mounting of detector (SX3-D0) <Z method>

B

0

Mount the detector using the following procedure:

ULLETIN F-7

(1) Provide wire rope for the upstream and the

downstream detectors. Make sure that the length of

the wire rope is longer than the circumference of the

pipe.

Fig. 3-32

(2) Lay the wire rope around the pipe at the position of

the upstream detector. Then hook the mounting

spring onto the wire rope ends.

(4) Clean the surface of the pipe, then mount the detector.

Fig. 3-35

(5) Press the detector against the pipe. Align the center of

the detector using the intersection of the marking

line and the mounting dimension as a guide.

Fig. 3-33

(3) Spread silicone filler over the whole transmitting side

of the detector smoothly without bubbles. Ensure

there are no air gaps or bubbles.

Fig. 3-36

(6) Make sure that the center mark on the detector is

aligned with the marking line. Then, connect the

coaxial cable to the transmitter.

Note) Do not pull the coaxial cable. If it is pulled,

the detector is shifted which results in

incorrect measurements due to poor contact.

Fig. 3-34

Fig. 3-37

-31-

Page 42

B

ULLETIN F-70

(7) After mounting the upstream sensor, mount the

downstream sensor in the same way.

!

Cable side

Upstream

sensor

Transmitting mark side

Downstream

sensor

Cable sideTransmitting mark side

- 32 -

Page 43

B

ULLETIN F-7

0

3.7. Confirmation of received signal

After connecting the signal line, make sure the red LED on the flow transmitter has turned green. It takes about

10 to 20 seconds until the color changes to green.

The green color indicates the received signal is normal. The red color indicates the received signal is abnormal. If the

LED remains red and does not turn green, examine the

engagement, etc.) and

parameter settings, and check whether the piping is filled with fluid

sensor installation status

(sensor spacing, sensor orientation, claw

.

Fig. 3-38

-33-

Page 44

B

ULLETIN F-70

3.8. How to remove the sensor unit (SX3-A0, SX3-B0)

If the sensor unit has to be detached from the frame such as for changing the spacing between the sensor units, proceed as

follows:

(1) Loosen the wing nut located at the middle of the

frame with 3 to 4 turns (Fig. 3-39).

Note 1: Do not loosen the wing nut completely.

Fig. 3-39

(2) By hand, hold the frame close to the pressing fixture

for a sensor unit to release.

Press the plastic section which extends from the

frame of the sensor unit just enough to open the

frame a little (about 1 mm). At this time, the claws

of the sensor unit fixture are disengaged from the

frame (Fig. 3-40).

(3) Disengage the opposite claws of the sensor unit

pressing fixture from the frame (Fig. 3-41).

Fig. 3-41

(4) Ensure the claws are disengaged from both sides, and

remove the sensor unit from the frame (Fig. 3-42).

Note 2: Do not open the frame excessively. Otherwise,

it may bend, so reinstalling the sensor may be

difficult or the frame may become deformed.

Fig. 3-40

Fig. 3-42

(5) Repeat this procedure for the other sensor.

Note 3: After removing both sensor units, retighten the

loosened wing nut.

- 34 -

Page 45

3.9. Setting the range and total pulse output

B

0

The range is set by the following procedure.

According to a selected range value, an analog output (4-20 mA DC) is set.

A pulse is outputted every time the integrated value reaches a pulse value.

(Note: Must be completed after setting the piping parameters in Section 3.4.)

(1) Selecting a unit system: Metric or inch system

Note: Factory set at "Metric system". For metric units, skip to step (2) below.

Proceed to the following menu from the measurement mode.

Keying LCD indication/comment

key pressed 3 times.

ENT

key pressed.

ENT

key pressed.

1st line: [MEASURE SETUP].

1st line: [SYSTEM UNIT]. 2nd line: [METRIC]. * As selected currently.

2nd line blinks.

ULLETIN F-7

key pressed.

ENT

key pressed.

(2) Selecting a flow rate unit: L/s, m3/h or other flow rate unit.

Follows the operation from (1) above.

Keying LCD indication/comment

key pressed 1 times.

ENT

key pressed.

key pressed.

ENT

key pressed.

Select a unit system out of metric system: [METRIC] and inch system:

[ENGLISH].

Registered after [**COMPLETE**] is displayed about 1 sec on 2nd line.

1st line: [FLOW UNIT], 2nd line: [L/s] * As selected currently.

2nd line blinks.

Repeatedly until a desired flow rate unit is selected.

Registered after [**COMPLETE**] is displayed about 1 sec on 2nd line.

(3) Selecting a total unit: mL, L, m3, or other total unit.

* Must be selected when total indication or total pulse output is used.

Follows the operation from (2) above.

Keying LCD indication/comment

key pressed 1 times.

1st line: [TOTAL UNIT], 2nd line: [mL] * As selected currently.

ENT

key pressed.

key pressed.

ENT

key pressed.

ESC

key pressed.

key pressed twice.

* Carrying out the operation in (1) to (3) above completes setting of the unit system, flow rate unit and total unit.

2nd line blinks.

Repeatedly until a desired total unit is selected.

Registered after [**COMPLETE**] is displayed about 1 sec on 2nd line.

1st line: [MEASURE SETUP]

Resumes the measurement mode.

-35-

Page 46

B

ULLETIN F-70

(4) Setting the range: to full scale.

Proceed to the following from the measurement mode.

Keying LCD indication/comment

key pressed twice.

ENT

key pressed.

1st line: [OUTPUT SETUP].

1st line: [ZERO ADJUST].

key pressed 4 times.

ENT

key pressed.

ENT

key pressed to enter.

ENT

key pressed.

and key

pressed.

ENT

key pressed.

ESC

key pressed 3 times.

key pressed 3 times.

1st line: [RANGE]. 2nd line: [FLOW RATE].

2nd line blinks.

1st line: [FLOW SPAN-1]. 2nd line: [10.0 L/s]. * As selected currently.

Cursor blinks on 2nd line.

Until the range is set to a desired value. Setting is available from 0.3 to 10 m/s

in terms of velocity.

Operate

to select a numeric or point, and to shift the place.

Registered after [**COMPLETE**] is displayed about 1 sec on 2nd line.

1st line [OUTPUT SETUP].

Resumes the measurement mode.

- 36 -

Page 47

(5) Setting the total pulse and preset value, and starting the total

B

0

Set the pulse value, pulse width and preset value.

Then, reset the total value to a preset value (factory set at 0), and start a total.

Proceed to the following from the measurement mode.

Keying LCD indication/comment

key pressed twice.

ENT

key pressed.

1st line: [OUTPUT SETUP]

1st line: [ZERO ADJUST]

ULLETIN F-7

key pressed 4 times

ENT

key pressed.

key pressed.

ENT

key pressed.

key pressed.

ENT

key pressed.

and key

pressed for composing a

pulse value.

ENT

key pressed.

key pressed.

ENT

key pressed.

key pressed.

ENT

key pressed.

key pressed.

1st line: [RANGE], 2nd line: [FLOW RATE]

2nd line blinks

2nd line: [TOTAL]

1st line: [TOTAL MODE], 2nd line [START]

3

1st line: [PULSE VALUE], 2nd line: [1m

] * As selected currently.

Cursor blinks on 2nd line.

Compose a desired pulse value. (See 4.5.6.1)

: Selects a numeric or decimal point. : Shifts the place.

[**COMPLETE**] appears about 1 second on 2nd line, and then pulse value is

registered.

1st line: [PULSE WIDTH]. 2nd line: [5.0 ms]. * As selected currently.

Cursor blinks on 2nd line.

Select 5.0 ms, 10 ms, 50 ms, 100 ms or 200 ms. (See 4.5.6.1)

[**COMPLETE**] appears about 1 second on 2nd line, and then pulse width is

registered.

3

1st line: [TOTAL PRESET]. 2nd line: [0 m

]. * As selected currently.

ENT

key pressed.

and

pressed.

ENT

key pressed.

key pressed 3 times.

ENT

key pressed.

key pressed.

ENT

key pressed.

ENT

key pressed.

key pressed twice.

ENT

key pressed.

ESC

key pressed 3 times.

key pressed 3 times.

key

Cursor blinks.

Compose a desired preset value.

: Selects a numeric or decimal point.

: Shifts the place.

[**COMPLETE**] appears about 1 second on 2nd line, and then preset value is

registered.

1st line: [TOTAL MODE]. 2nd line: [START]. * As selected currently.

2nd line blinks.

2nd line: [RESET]. * Make sure beforehand total value can be reset.

[**COMPLETE**] appears about 1 second on 2nd line, and then total value is

reset.

2nd line: [STOP]. * Total stops.

Cursor blinks on 2nd line.

2nd line: [START].

[**COMPLETE**] appears about 1 second on 2nd line.

2nd line: [START]. * Total starts.

1st line: [OUTPUT SETUP].

Measurement mode is resumed.

-37-

Page 48

B

ULLETIN F-70

3.10. How to calibrate zero

Completely close the valves upstream and downstream of the flow meter before calibrating zero.

Notes

1. If there is no valve or if the fluid flow cannot be stopped, select "CLEAR" when "ZERO ADJUST". In this

case, the zero point may slightly be off and manual zero point cannot be set.

2. If parameters are set at "PROTECTION ON", select "PROTECTION OFF" beforehand.

3. SET ZERO: Saves the current flow status as zero. CLEAR: Sets the calibration value for zero point to "0".

The following is the zero point adjustment procedure from measurement mode.

Keying LCD indication/comment

key pressed twice.

ENT

key pressed.

ENT

key pressed.

1st line: [OUTPUT SETUP]

1st line: [ZERO ADJUST]. 2nd line: [CLEAR]. * As selected currently.

2nd line blinks.

key pressed.

ENT

key pressed to register.

key pressed.

ESC

key pressed 3 times.

Note: 4. If [CLEAR] has been selected and executed at this time, any saved manual zero calibration

value will be cleared

2nd line: [SET ZERO].

On 2nd line about 1 sec, [**COMPLETE**] is displayed, and zero calibration is

performed (Note 4).

1st line: [OUTPUT SETUP]

Measurement mode is resumed.

.

- 38 -

Page 49

4. PARAMETERS

B

0

4.1. Description on display/setting section

The display/setting section is illustrated below.

LED

ULLETIN F-7

ż LED display: Indicates whether the received wave is normal or

(Green) : Received wave is normal.

(Red) : Received wave is abnormal.

Parameter display and settings are selected through front panel keypad entries.

ESC

Escape key : Returns to a higher menu level or cancels the current item setting operation.

UP key : Selects an item, value or symbol.

SHIFT key : Moves the cursor, decimal point, etc.

ENT

Entry key : Enters a selection or registers a setting.

abnormal.

-39-

Page 50

B

ULLETIN F-70

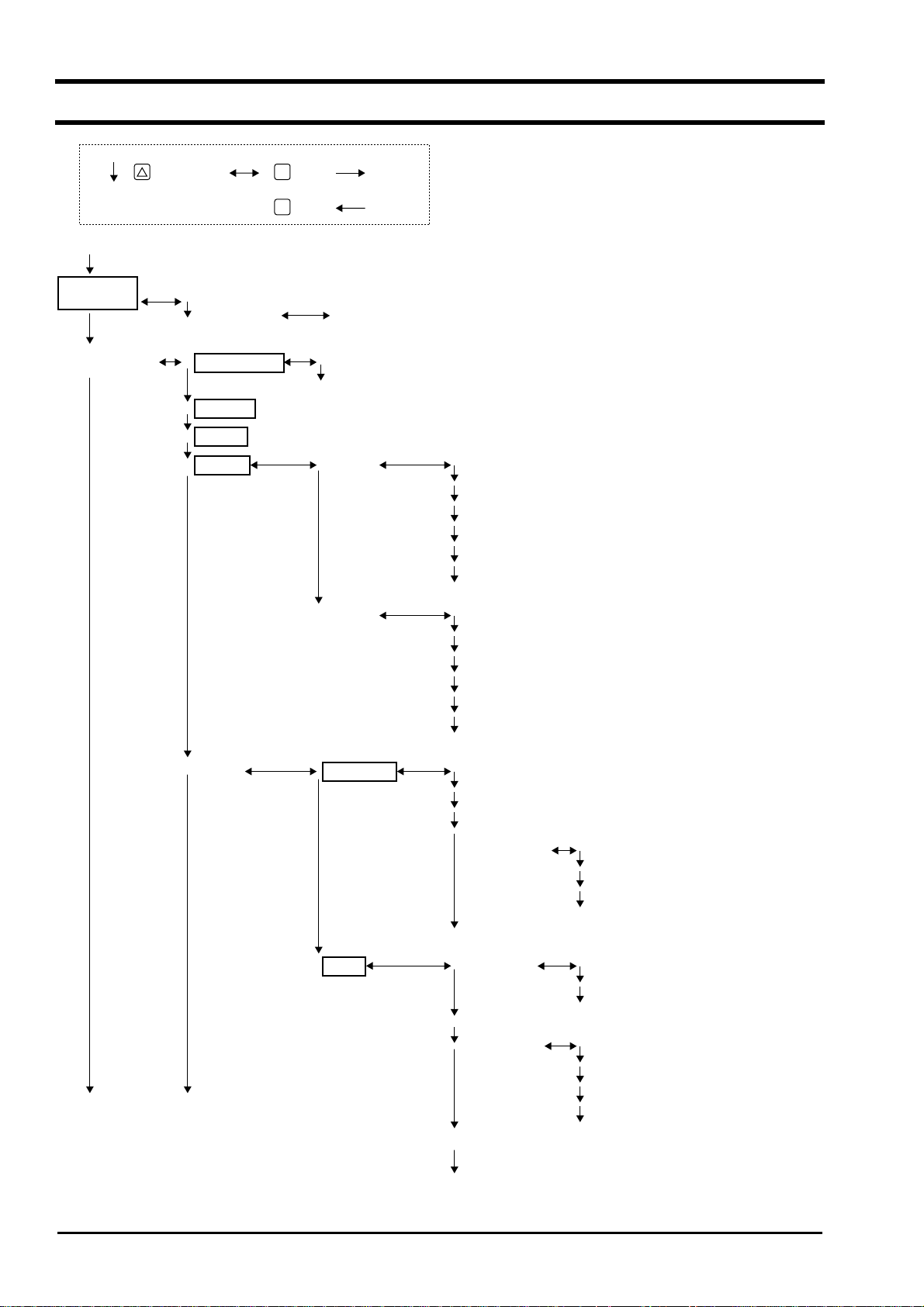

4.2. Configuration of keys

key: key for:

Measurement Mode

Par.

Protection

OUTPUT SETTING

(Section 4.4.1.)

ENT

ESC

key for

Protection ON

Protection OFF

ZERO ADJUST CLEAR

(Section 4.5.1.) SET ZERO

DAMPING (Section 4.5.2.)

CUTOFF (Section 4.5.3.)

DISPLAY

(Section 4.5.4.)

INPUT ID NO

1st.ROW VELOCITY

2nd.ROW VELOCITY

FLOW RATE

FLOW RATE(%)

+TOTAL(ACTUAL)

+TOTAL(PULSE)

–

TOTAL(ACTUAL)

–

TOTAL(PULSE)

FLOW RATE

FLOW RATE(%)

+TOTAL(ACTUAL)

+TOTAL(PULSE)

–

TOTAL(ACTUAL)

–

TOTAL(PULSE)

RANGE

FLOW RATE

(Section 4.5.5.)

TOTAL

(Section 4.5.6.)

FLOW SPAN-1

FLOW SPAN-2

HYSTERESIS

BURNOUT

(CURRENT) HOLD

BURNOUT TIMER

TOTAL MODE

PULSE VALUE

PULSE WIDTH

TOTAL PRESET

OVER SCALE

UNDER SCALE

ZERO

START

STOP

RESET

5.0ms

10.0ms

50.0ms

100.0ms

200.0ms

- 40 -

Page 51

B

ULLETIN F-7

0

DO1 OUT

(Section 4.5.7.)

NOT USED

+TOTAL PULSE

–

FLOW SPAN-2

ALARM

FLOW SWITCH

TOTAL SWITCH

DO2 OUT

(Section 4.5.7.)

OUTPUT COMPENSATION

(Section 4.5.8.)

NOT USED

+TOTAL PULSE

–

FLOW SPAN-2

ALARM

FLOW SWITCH

TOTAL SWITCH

TOTAL PULSE

TOTAL PULSE

BURNOUT(TOTAL)

BURNOUT TIMER

ALL

HARDWARE FAULT

PROCESS ERROR

UPPER SWITCH

LOWER SWITCH

ALL

HARDWARE FAULT

PROCESS ERROR

UPPER SWITCH

LOWER SWITCH

HOLD

COUNT

CONTACT ACTION

CONTACT ACTION

ACTIVE ON

ACTIVE OFF

ACTIVE ON

ACTIVE OFF

MEASURE SETUP

SYSTEM UNIT

(Section 4.6.1.)

FLOW UNIT

(Section 4.6.2.)

TOTAL UNIT

(Section 4.6.3.)

(Section 4.6.4.)

PIPE PARAMETER

(S= )

METRIC

ENGLISH

L/S

L/min

L/h

ML/d

m3/s

etc.

mL

L

m3

km3

Mm3

etc.

OUTER DIAMETER

PIPE MATERIAL

WALL THICKNESS

PVC

PVDF

PEEK

PP

CARBON STEEL

STAINLESS STEEL

COPPER

PIPE S.V

-41-

Page 52

B

ULLETIN F-70

MAINTENANCE

MODE

LINING MATERIAL

For NO LINING

LINING THICKNESS

KIND OF FLUID

KINEMATIC VISCO

SENSOR MOUNTING

SENSOR TYPE

CURRENT

CALIBRATION

CURRENT OUPUT SETTING (Section 4.7.2.)

TOTAL PULSE (Section 4.7.3.)

STATUS OUTPUT

(Section 4.7.4.)

TEST MODE

(Section 4.7.5.)

COMMUNICATION

(Section 4.7.6.)

(Section 4.7.1.)

4mA

20mA

ON

OFF

NOT USED

SETTING

COM.MODE

COM.BAUD RATE

COM.PARITY

COM.STOP BIT

COM.SLAVE NO.

NO LINING

TAR EPOXY

MORTAR

RUBBER

TEFLON

PYREXGLASS

LINING S.V

WATER

SEA WATER

FLUID S.V

V

Z

SX3A/SX3B

SX3C/SX3D

INPUT DATA

TRACKING TIME

RS-232C

RS-485

2400BPS

4800BPS

9600BPS

19200BPS

NON.

ODD

EVEN

1BIT

2BITS

- 42 -

SYNCHRONIZATION

(Section 4.7.7.)

LANGUAGE

(Section 4.7.8.)

REGISTER ID No.

(Section 4.7.9.)

VER. No. (Section 4.7.10.)

EEPROM INITIAL

LCD/LED CHECK

(Section 5.7.1.)

DATA DISPLAY

(Section 5.7.1.)

MASTER

SLAVE

ENGLISH

JAPANESE

GERMAN

FRENCH

SPANISH

Page 53

B

ULLETIN F-7

0

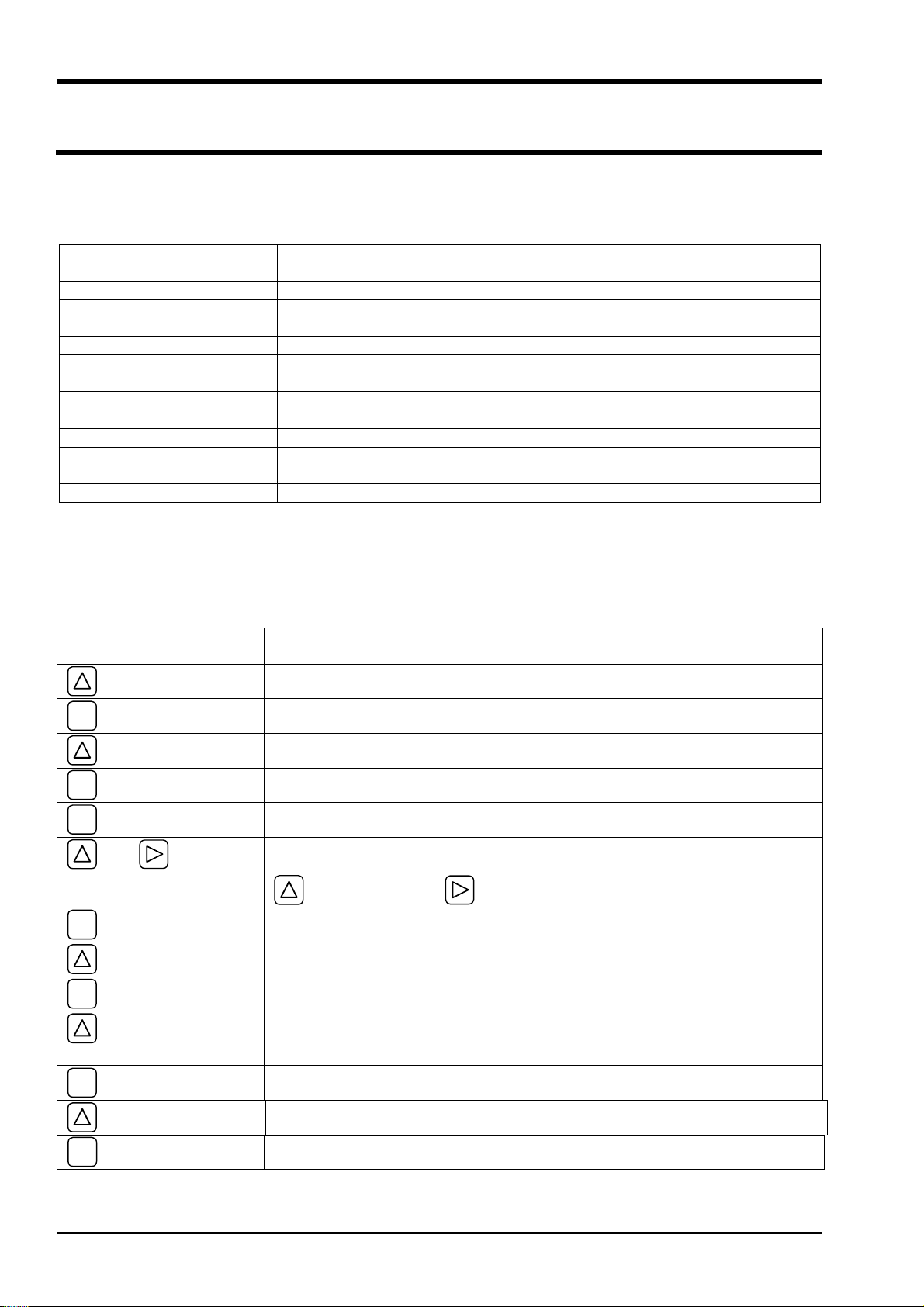

4.3. Initial values of parameters

The following provides factory set values.

No. Setting item Settable range Initial value Settable value

1 Parameter protection 2 menus PROTECTION ONPROTECTION ON,

PROTECTION OFF

2 ID No. 0000 to 9999 0000

3 Unit system 2 menus Metric Metric (metric system),

English (inch system)

4 Flow rate unit

12 menus

m3/h

(Metric system)

12 menus

(Inch system)

5 Total unit

8 menus

3

m

(Metric system)

10 menus

(Inch system)

6 Pipe outer diameter 10.00 to 650mm 60.00mm [mm, in]

7 Pipe material 10 menus

PVC PVC, PVDF, PEEK, PP, CARBON STEEL,

Sound velocity: 1000

to 3700 m/s.

8 Wall thickness 0.1 to 50.00mm 4.50mm [mm, in]

9 Lining material 7 menus

No lining No lining, tar epoxy, mortar, rubber, Teflon,

Sound velocity: 1000

Measurement conditions

to 3700m/s

10 Lining thickness 0.01 to 50.00 ––– [mm, in]

11 Fluid type 3 menus

Water Water, sea water,

Sound velocity:

500 to 2500m/s

12 Kinematic

viscosity

13 Sensor mounting

0.0001 to 999.9999

×10–6m

2

1.0038

/s

×10–6m2/s

2 menus V V, Z

method

14

Sensor type 2 menus Specified by the

12th digit of

type code.

15 Zero adjustment 2 menus Clear

(unadjusted)

16 Damping 0 to 100sec 5sec sec

17 Low flow rate

cutting

18 Display 1st line

contents

19 Display 1st line

decimal point

Output conditions

0 to 5 m/s in terms of

0.150 m3/h [The unit selected at No. 4]

flow velocity

7 menus Flow velocity

(m/s)

00000.000

position

20

Display 2nd line

7 menus Flow rate (m3/h) Flow velocity, flow rate (ACTUAL),

contents

L/s L/min L/h ML/d m3/s m3/min

3

m

/h Mm3/d BBL/s BBL/min

BBL/h MBBL/d

gal/s gal/min gal/h Mgal/d ft

3

ft

/min ft3/h Mft3/d BBL/s BBL/min

BBL/h MBBL/d

mL L m3 km3 Mm3 mBBL BBL

kBBL

gal kgal ft3 kft3 Mft3 mBBL BBL

kBBL ACRE-in ACRE-ft

STAINLESS STEEL, COPPER,

other (sound velocity: ____ [m/s, ft/s])

Pyrexglass,

other (sound velocity: ____ [m/s, ft/s])

other (Sound velocity: [m/s, ft/s])

2

[×10–6m

/s, ft2/s]

SX3A/B, SX3C/D

Set zero, clear (factory set at clear)

Flow velocity, flow rate (ACTUAL),

flow rate (%), forward total,

reverse total, forward total pulse,

reverse total pulse

(move to desired decimal position)

flow rate (%), forward total,

reverse total, forward total pulse,

reverse total pulse

3

/s

-43-

Page 54

B

ULLETIN F-70

No. Setting item Settable range Initial value Settable value

21 Display 2nd line

decimal point

position

00000.000