Page 1

12

[307.98]

15

[381.00]

17

[431.80]

1-7/16-18 UNEF

THREADS

1" MPT

THREADS

1-1/2

[38.10]

2-15/16

[74.51]

IN-LINE

THREADS

1" FPT

2-1/2

[63.50]

Bulletin F-60

Series UV In-Line and Panel Mount Polysulfone Flowmeter

Specifications - Installation and Operating Instructions

Picture at

left shown

with optional

Polysulfone

Fittings.

Optional

Polycarbonate

Shield

The Series UV In-Line Polysulfone Flowmeter measures

the flow of water, air, and other compatible media at temperatures up to 212°F (100°C) and pressures up to 150 psi (10.34

bar). This flowmeter’s highly corrosion-resistant materials suit

it ideally for use with de-ionized water and ultra-pure applications, including food processing, medical equipment and

reverse osmosis water systems.

INSTALLATION

1. Select an indoor (only) location that is free from excess

vibration, within the specified temperature limits, and away

from direct sunlight. (Polysulfone is adversely affected by ultraviolet light.)

2. Remove hollow plastic shipping tube from inside flow body.

3. Handle carefully. Hand-tighten aluminum ring.

O-Rings will seal if hand tightened only. Do not

overtighten the

adapters and fittings.

4. Install the flowmeter in an exact vertical plane, one that is in

proper alignment with the existing plumbing. Use wall or other

structural supports at the top and bottom of the unit. Do not

allow the instrument to support the weight of pipes or tubing.

5. Use pipe thread sealant tape. Do not

use pipe dope compounds, which can craze and crack the polysulfone housing.

Hand tighten system pipe fitting to adaptor fitting. If additional

torque is needed to seal pipe joint, use strap wrench on adaptor fitting. Maximum torque is 22 Foot - Pounds.

Teflon, Viton-Reg.TM E.I. du Pont de Nemours & Co.

Drawing at

right shown

with optional

Polysulfone

Fittings.

6. If using solvent-based glues like PVC cement, in the piping

system, do so with the meter’s body removed until glue has

cured, then purge the system before re-installing. Do not solder brass fittings with the body installed, because the heat

generated to solder the brass fittings will damage the flowmeter.

CAUTION: Ball valves and solenoid valves can have a “water

cannon” effect on opening, creating pressure that exceeds the

warrantied ratings and will damage the flowmeter.

SPECIFICATIONS

Service: Compatible liquids.

Wetted Materials: Polysulfone body, Fluoroelastomer O-Rings

and Virgin PTFE float.

Temperature Limits: 35 to 212°F (2 to 100°C); 35 to 130°F (2

to 54°C) for PVC Fitting Option.

Pressure Limit: 150 psi (10.34 bar).

Accuracy: ±2% Full Scale @ 70°F +/-2 F (21.1°C) and 14.7 psia

(In line connection rating only).

Repeatability: +/-1% full scale @ 70+/-2°F (21.1°C) and 14.7

psia (In line connection rating only).

Process Connections: 1˝ female NPT. Optional 90° Polysulfone

Elbow – 1˝ male NPT.

Scale Length: 6˝ (152.40) – 7˝ (177.80), depending on model.

Fitting Torque: Maximum 22 ft - lb.

Weight: 1 lb (457 g) (for 20 GPM range).

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, IN 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

2-20 GPM

3-30 GPM

4-40 GPM

14-100 SCFM

1-10 GPM

5-50 SCFM

.5-5 GPM

2.5-28 SCFM

.25-2.5 GPM

1-13 SCFM

OPERATION AND MAINTENANCE

Once installed, the Series UV In-Line Polysulfone

Flowmeter is self-operating and requires no maintenance

other than an occasional cleaning with mild soap and a

bottle brush. For this purpose, the unit has been designed

so that its body can be removed quickly and easily while

leaving all fittings intact.

When removing float for cleaning, note the floats “up” position. The float is a precision part and must be reassembled

without adverse treatment, i.e. dropping, denting, and surface abrasion.

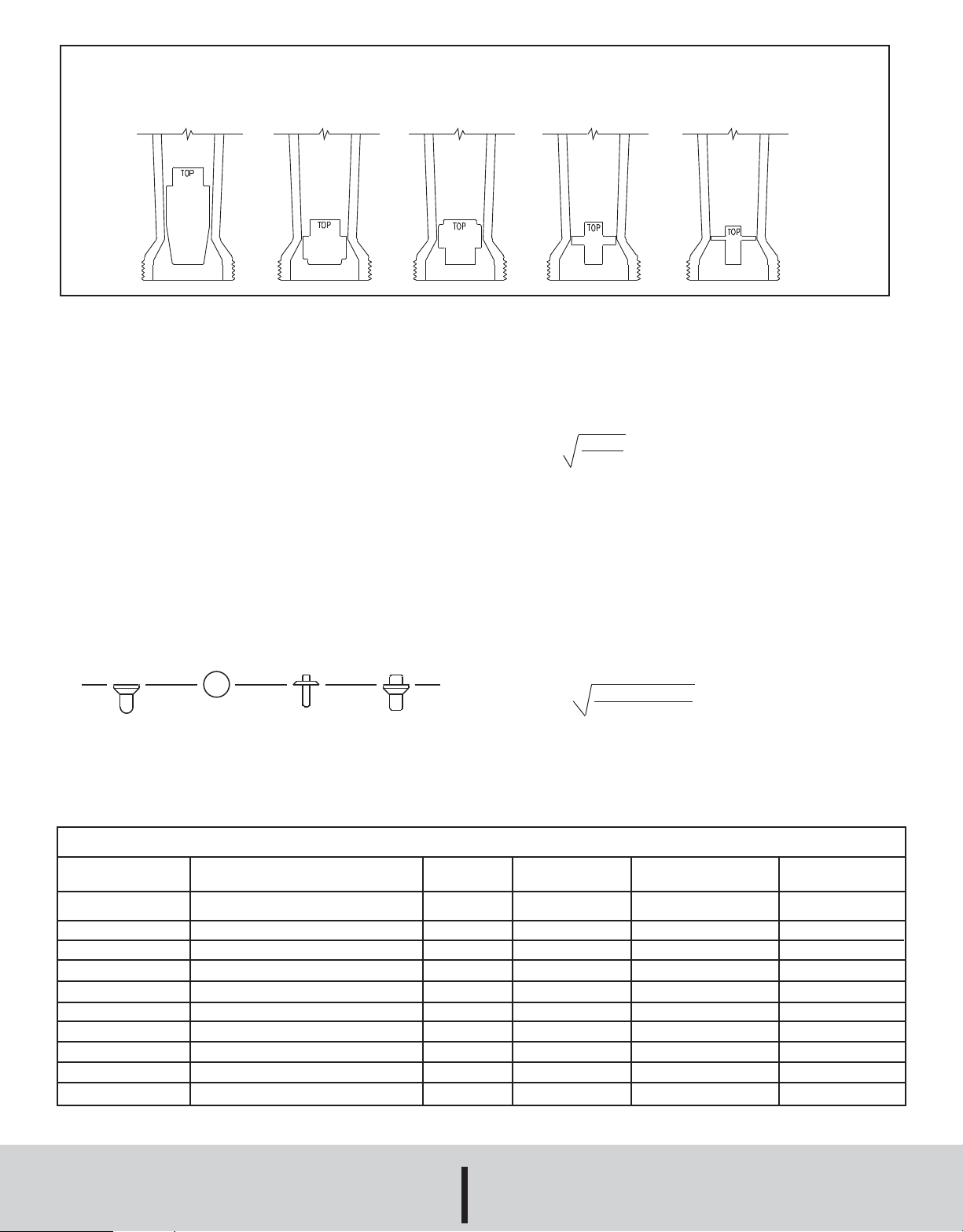

The standard technique for reading a Variable Area Flowmeter is

to locate the highest point of greatest diameter on the float, and

then align that with the theoretical center of the scale graduation.

In the event that the float is not aligned with a grad, an extrapolation of the float location must be made by the operator as to its

location between the two closest grads. The following are some

sample floats shown with reference to the proper location to read

the float.

Variable Area Flowmeters used for gases are typically labeled with

the prefix “S” or “N”, which represents “Standard” for English units

or “Normal” for metric units. Use of this prefix designates that the

flowmeter is calibrated to operate at a specific set of conditions,

and deviation from those standard conditions will require correc-

tion for the calibration to be valid. In practice, the reading taken

from the flowmeter scale must be corrected back to standard

conditions to be used with the scale units. The correct location to

measure the actual pressure and temperature is at the exit of the

flowmeter, except under vacuum applications where they should

be measured at the flowmeter inlet. The equation to correct for

nonstandard operating conditions is as follows:

2

Q

= Q1x P1x T

Where: Q1= Actual or Observed Flowmeter Reading

Example: A flowmeter with a scale of 10-100 SCFH Air. The float

is sitting at the 60 grad on the flowmeter scale. Actual Pressure is

measured at the exit of the meter as 5 psig. Actual Temperature

is measured at the exit of the meter as 85°F.

2

Q

= 60.0 x (14.7 + 5) x 530

2

Q

= 68.5 SCFH Air

2

Q

1

P

2

P

1

T

2

T

2

1

P2x T

= Standard Flow Corrected for Pressure and

Temperature

= Actual Pressure (14.7 psia + Gage Pressure)

= Standard Pressure (14.7 psia, which is 0 psig)

= Actual Temperature (460 R + Temp °F)

= Standard Temperature (530 R, which is 70°F)

14.7 x (460 + 85)

Models and Ranges

Model Number

UV-0112

UV-1112

UV-2112

UV-3112

UV-4112

UV-5112

UV-A112

UV-B112

UV-C112

UV-D112

©Copyright 2009 Dwyer Instruments, Inc. Printed in U.S.A. 7/09 FR# 443147-00 Rev. 6

DWYER INSTRUMENTS, INC.

Range

0.25-2.5 GPM (1-9.5 LPM)

0.5-5.0 GPM (2-19 LPM)

1.0-10.0 GPM (4-38 LPM)

2.0-20.00 GPM (8-76 LPM)

3.0-30.00 GPM (12-112 LPM)

4.0-40.00 GPM (20-150 LPM)

1-13 SCFM (30-370 LPM)

2.5-28 SCFM (70-780 LPM)

5-50 SCFM (70-1400 LPM)

14-100 SCFM (400-2800 LPM)

Medium

Water

Water

Water

Water

Water

Water

Air

Air

Air

Air

Phone: 219/879-8000 www.dwyer-inst.com

Body

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Fitting Material

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

P.O. BOX 373 • MICHIGAN CITY, IN 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Float

Virgin PTFE

Virgin PTFE

Virgin PTFE

Virgin PTFE

Virgin PTFE

Virgin PTFE

Virgin PTFE

Virgin PTFE

Virgin PTFE

Virgin PTFE

Loading...

Loading...