Page 1

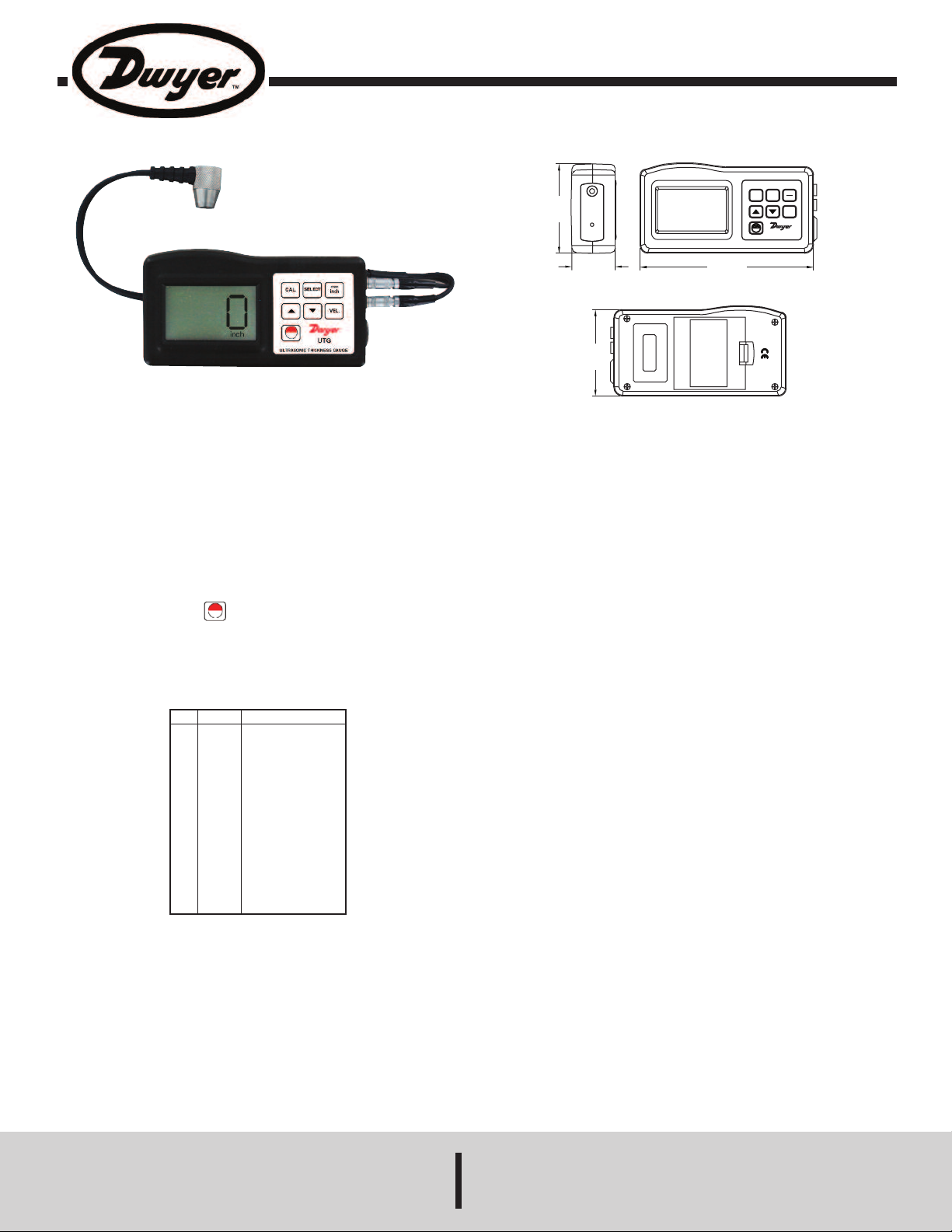

Model UTG Ultrasonic Thickness Gauge

4

-23/32

[

120.00]

2-7/16

[62.00]

1

-3/16

[

30.00]

2

-23/64

[

60.00]

UTC

ULTRASONIC THICKNESS GAUGE

SELECT

VEL.

CAL.

mm

inch

Specifications - Installation and Operating Instructions

Bulletin TE-UTG

The compact Model UTG Ultrasonic Thickness Gauge can measure

the thickness of a variety of materials. The UTG has a wide range of

applications including industrial, automotive, HVAC, and plumbing. The

UTG reads in inches or millimeters, and features an adjustable sound

velocity to allow for an array of materials to be measured. The UTG is

useful when using any pipe-mount ultrasonic transmitter. The UTG

allows the user to find the wall thickness of the pipe when programming

an ultrasonic transmitter without cutting or removing a section of the pipe

to measure it. The UTG is also great for monitoring corrosion in closed

vessels such as boilers and chemical tanks.

MATERIAL SELECTION

1. Press the Power button to turn on the unit.

2. Press the Select button and the display will show the code `Cdxx` or

`XXXX`. `Cd` is the abbreviation for `code` and `xx` is one number

among 01~11. `xxxx` is a 4-digit number which is the sound velocity of

material defined by the user. The `Cdxx`-material relationship is as

follows.

No.

CODE

Material

1

cd01

Steel

2

cd02

Cast Iron

3

cd03

Aluminum

4

cd04

Red Copper

5

cd05

Brass

6

cd06

Zinc

7

cd07

Quartz Glass

8

cd08

Polyethylene

9

cd09

PVC

10

cd10

Gray Cast Iron

11

cd11

Nodular Cast Iron

12

xxxx

Sound Velocity

SPECIFICATIONS:

Service: Steel, cast iron, aluminum, red copper, brass, zinc, quartz

glass, polyethylene, PVC, gray cast iron, nodular cast iron, other.

Selectable option for special materials with known sound propagation

rate.

Range: 0.047 to 7.874˝ (1.2 to 200 mm).

Accuracy: ±0.5%.

Resolution: 0.001˝ / 0.1 mm.

Sound Velocity: 1118 to 20132 mph (500 to 9000 m/s).

Temperature Limits: 32 to 122°F (0 to 50°C).

Humidity Limit: < 80%.

Display: 4 digits, 0.394˝ (10 mm) LCD.

Power Requirement: (4) 1.5 V AAA alkaline batteries, not included, user

replaceable.

Weight: 5.78 oz (164 g).

Agency Approvals: CE.

3. Press the Up button or Down button to select the material code to

measure, and then press the Select button to confirm. The display will

show `0`. If you select a material code but do not confirm the selection,

the code will automatically change to `0` after several seconds. In such

case, the meter will still reserve the material code before exiting.

4. A 4-digit number will be shown on the display when the Up button is

pressed when the display shows `Cd11` or by pressing the Down button

when the display shows `Cd01`. The 4-digit number is the last sound

velocity to be define by the user. By selecting this velocity, you could

measure the thickness of the same material as previously selected.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

5. It is unnecessary to select the material code once the material code is

confirmed (automatically stored to the memory of the meter) unless the

material to measure is different from before.

6. To browse the material code selected, press the Select button. To quit

browsing, press the Select button again or wait till the code automatically

changes to `0` after several seconds or the meter will automatically return

to measurement state if measuring.

CALIBRATION

1. Drop a little lubricating oil on the 5 mm standard block (see below).

Standard Block

2. Press the Calibration (CAL) button, and the word `CAL` will be shown

on the display.

3. Press the sensor on the standard block. If the coupling symbol is

on the display and the standard block is coupling well, `5.0` mm (or

`0.197`”) and `CAL` will be shown on the display also. When the reading

is steady, press the CAL button to confirm and then the unit will return to

measuring state.

4. The calibration result will be auto-saved to the unit once confirmed. It

is unnecessary to calibrate frequently unless you suspect an inaccuracy

in the measurement.

MEASURING PROCEDURE

1. Press the Power button to turn on the unit.

2. Press the mm/inch button to select the right measurement unit.

3. Apply a little lubricating oil onto the sensor, and be sure that there is a

good coupling and the symbol is on. Press the sensor onto the

material surface to measure on the premise that the material code

selected is right. The reading on the display is the measurement value.

4. The reading is held until a new measurement value is made. The last

value is held on the display until the unit is powered off.

5. There are 2 methods to turn off the power to the unit. Manual shut off

can be done at any time by pressing the power button, or auto power off

signified by a beeping sound that occurs after about 1 minute from the last

key operation.

MEASURING BY VELOCITY SETTING

1. Press the VEL. button and the display will show the velocity that was

set last.

2. If measuring the thickness of a material with known velocity, the

velocity can be changed by pressing the Up or Down button to the value

of the known velocity. The increment is in 10 m/s every time when

pressing the up or down button, and increment of 100 m/s if pressing the

button for more than about 4 seconds.

3. Drop a little lubricating oil onto the material to be measured and press

the sensor onto the surface. The reading on the display is the thickness

of the material if the sensor is coupling well.

4. When measuring the thickness of a sample with a known thickness just

get the sample of known thickness. Then repeat the last two steps until

the measurement value is the same as the known thickness. In such a

case, the set value is the velocity of the material to measure, with this

process you can measure any unknown thickness of same material.

5. To browse the velocity, press the VEL. button. To quit browsing, press

the VEL. button again or wait till the unit automatically shows `0`.

6. By using the velocity measurement, it is easy to measure the thickness

of any hard material.

BATTERY REPLACEMENT

1. When the battery symbol appears on the display, it is time to replace

the batteries.

2. Remove the battery cover from the instrument and remove the

batteries.

3. Install the new batteries ensuring to pay close attention to the polarity.

MAINTENANCE/REPAIR

Upon final installation of the Model UTG, no routine maintenance is

required. The Model UTG is not field serviceable and should be returned

if repair is needed. Field repair should not be attempted and may void

warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our

website. Contact customer service to receive a Return Goods

Authorization number before shipping the product back for repair. Be

sure to include a brief description of the problem plus any additional

application notes.

©Copyright 2013 Dwyer Instruments, Inc. Printed in U.S.A. 11/13 FR# R2-444087-00

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...