Page 1

Bulletin 407

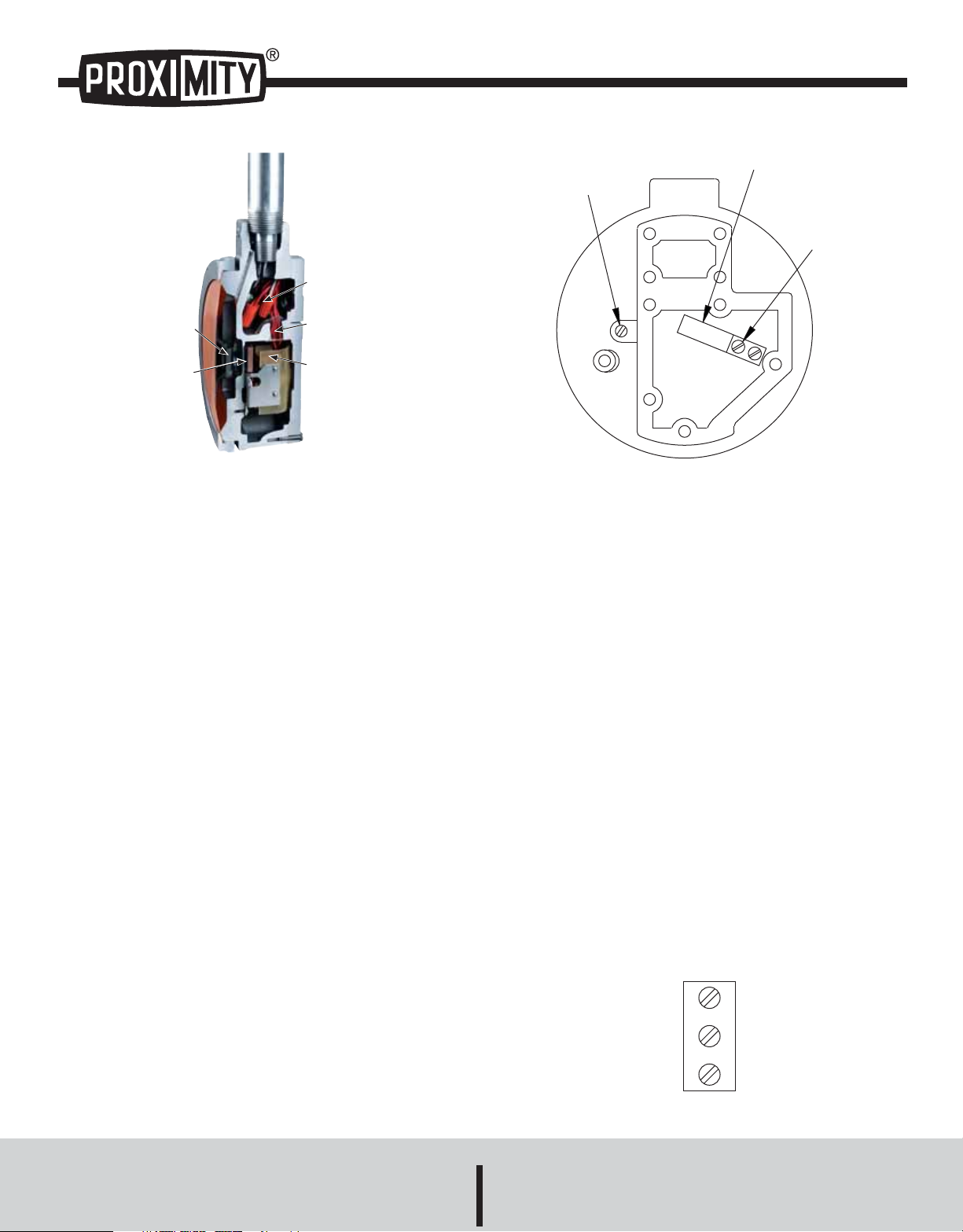

Driving

Magnet

Driven

Magnet

Sealed

Junction Box

Epoxy Seal

Sealed

Switch Cavity

DIAPHRAGM

ADJUSTMENT

SWITCH

ADJUSTMENT SPRING

SWITCH

ADJUSTMENT

SCREW

ELECTRICAL

CONNECTIONS

(REAR VIEW)

NTS

NORMALLY

CLOSED

NORMALLY

OPEN

COMMON

ELECTRICAL RATING

15 AMPS @ 125, 250, OR 480 VAC

Series P/G Explosion Proof Ultra Mag™ Level Switches

Specifications - Installation and Operating Instructions

The Series P/G Ultra Mag™ Level Switch provides level indication by detecting

pressure applied by the bulk material to the sensing diaphragm. The switch is

tripped magnetically, as the result of 2 magnets with like poles repelling one

another. The fields of the magnets perform through the nonferrous wall of the

switch housing. Pins, links and “O” rings, which often cause failure due to moisture,

dirt, and corrosion, are eliminated. The switch enclosure is completely sealed.

The unit performs as follows:

1. When the diaphragm is forced inward by the product bulk material, the

“driving” magnet moves inward, as does its magnetic field.

2. The field of the “driving” magnet repels the field of the “driven” magnet

attached to the switch arm, and the switch is tripped.

3. Deactivation occurs when product is removed from the vessel and the

diaphragm and “driving” magnet returns to their original positions.

SENSITIVITY ADJUSTMENT

The P/G Ultra Mag™ offers a sensitivity adjustment that is accessible from outside

of the bin and easily adjusted with a screwdriver. This enables the user to adjust

the sensitivity of the unit, should vessel contents change, without removing the unit

from the vessel. Turning the adjustment screw inward increases operating forces,

and turning the screw outward decreases operating forces. A maximum of 4 turns

is available. When the screw is bottomed, the force is at a maximum. With 4 turns

out the diaphragm force is at a minimum. Normal setting is two turns out. See

Figure 1.

SWITCH ADJUSTMENT

The switch adjustment determines whether actuation occurs early in diaphragm

travel or late. Turning the screw inward retards action and causes the switch to trip

late. Backing the screw out results in early actuation when the diaphragm is slightly

depressed. A center switching position is desirable.

Regardless of the position (angle) in which the control is eventually mounted, the

switch should trip at mid travel of the diaphragm. “Break” (switch off) should never

occur within the last 1/4 of travel outward. “Make” (switch on) should not occur after

3/4 travel inward.

MOUNTING

A choice of either suspension or flange mounting is available to match your

application. Flange mounting is the best choice for control of low or intermediate

level in vessels containing granular product that does not “bridge”, “rathole”, or

otherwise build up on vessel walls. Choose suspension mounting for high level in

vessels and for better operation with “bridging” product. Note that the mounting

configuration is represented by the letter “S” for suspension or “F” for flange.

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A.

SPECIFICATIONS

Service: Compatible powder or bulk solids.

Wetted Materials:

Mounting Flange: Aluminum or 304 SS.

Diaphragm: Urethane, Buna-N, PTFE, Silicone Rubber,

Polyester, Fluoroelastomer, White Buna-N (food grade), or EPDM.

Temperature Limits: Depends on diaphragm material.

Standard switch: -40 to 185°F (-40 to 85°C), high temperature switch: -40 to

350°F (-40 to 176°C).

Pressure Limit: 60 psig (4.14 bar).

Enclosure Rating: General purpose or weatherproof and explosion-proof.

Electrical Connections: 18 gage solid core, 600 volt TEW 105°C, style 1015.

Epoxy sealed at conduit entrance. 12˝ (304.8 mm) long.

Conduit Connection: 1/2˝ female NPT.

Process Connection: For flanged models standard is 8-3/8˝ (212.725 mm)

diameter bolt hole circle.

Mounting Orientation: Flange mount or suspend depending on model.

Set Point Adjustment: Internal screw.

Weight: 7 lb (3.18 kg).

Options: Suspension kits and flange adaptor rings.

Agency Approvals: UL and CSA.

WIRING

The P/G Ultra Mag™ has a 1/2˝ NPT conduit connection. Remove the back plate

to access the single pole double throw snap-switch. The switch rating is: 15A @

125, 250, or 480 VAC. There are three terminals on the snap-switch: “Common”,

“Normally Open”, and “Normally Closed”.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

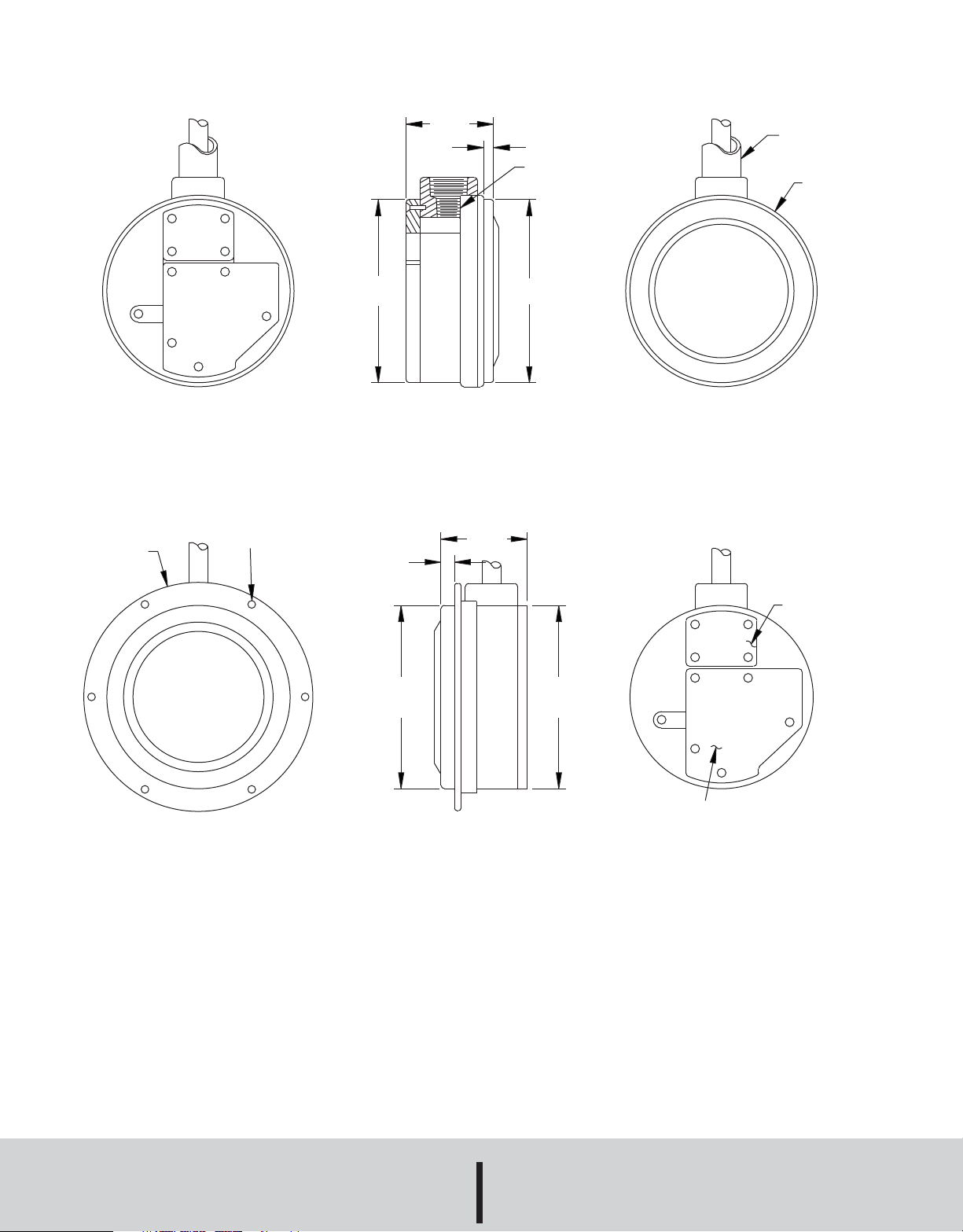

REAR VIEW

FRONT VIEWLEFT SIDE VIEW

7-1/4˝

DIA

7-1/4˝

DIA

3-3/8˝

3/8˝

CONDUIT ENTRANCE

1/2 NPT

DIAPHRAGM

7-1/2˝ DIA

SUSPENSION PIPE

1˝ NPT

3-3/8˝

3/8˝

7-1/4˝

DIA

7-1/4˝

DIA

9-1/8˝ DIA

MOUNTING HOLES (6)

5/16˝ DIA ON 8-3/8˝ DIA

BOLT CIRCLE

DIAPHRAGM

JCT. BOX

COVER

SWITCH CAVITY COVER

REAR VIEW

FRONT VIEWRIGHT SIDE VIEW

SUSPENSION MOUNTING

MODELS P-S-D-A ; G-S-D-A

FLANGE OR SIDE MOUNTING

MODELS P-F-D-A ; G-F-D-A

MAINTENANCE

The P/G Ultra Mag is not field serviceable and should be returned if

repair is needed (field repair should not be attempted and may void

warranty). Be sure to include a brief description of the problem plus any

relevant application notes. Contact customer service to receive a return

goods authorization (RGA) number before shipping.

©Copyright 2010 Dwyer Instruments, Inc. Printed in U.S.A. 2/10 FR# 85-443635-00 Rev. 1

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A.

Loading...

Loading...