Page 1

Model ULTM Ultrasonic Level Transmitter

TM

Specifications - Installation and Operating Instructions

Bulletin L-ULTM

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

able of Contents

T

able of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

T

ist of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

L

Notices and Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

hapter 7. USB Driver Installation on a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

C

hapter 8. Reference Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

C

Chapter 9. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Chapter 1. Introduction

. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1

. Series ULTM Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2

. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

3

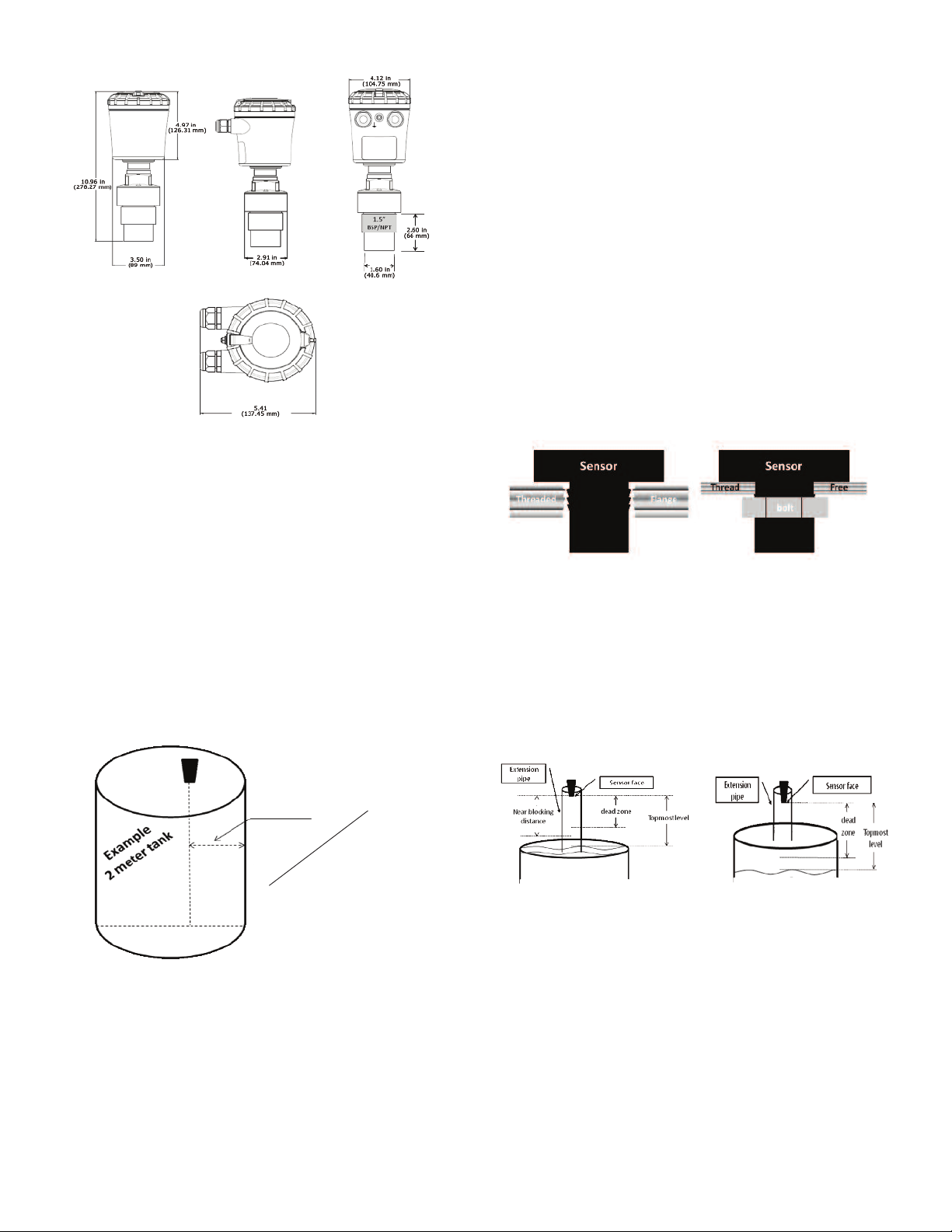

. Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

4

Chapter 2. Installation Guidelines

1. Physical Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

. Tank Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2

. Dead Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3

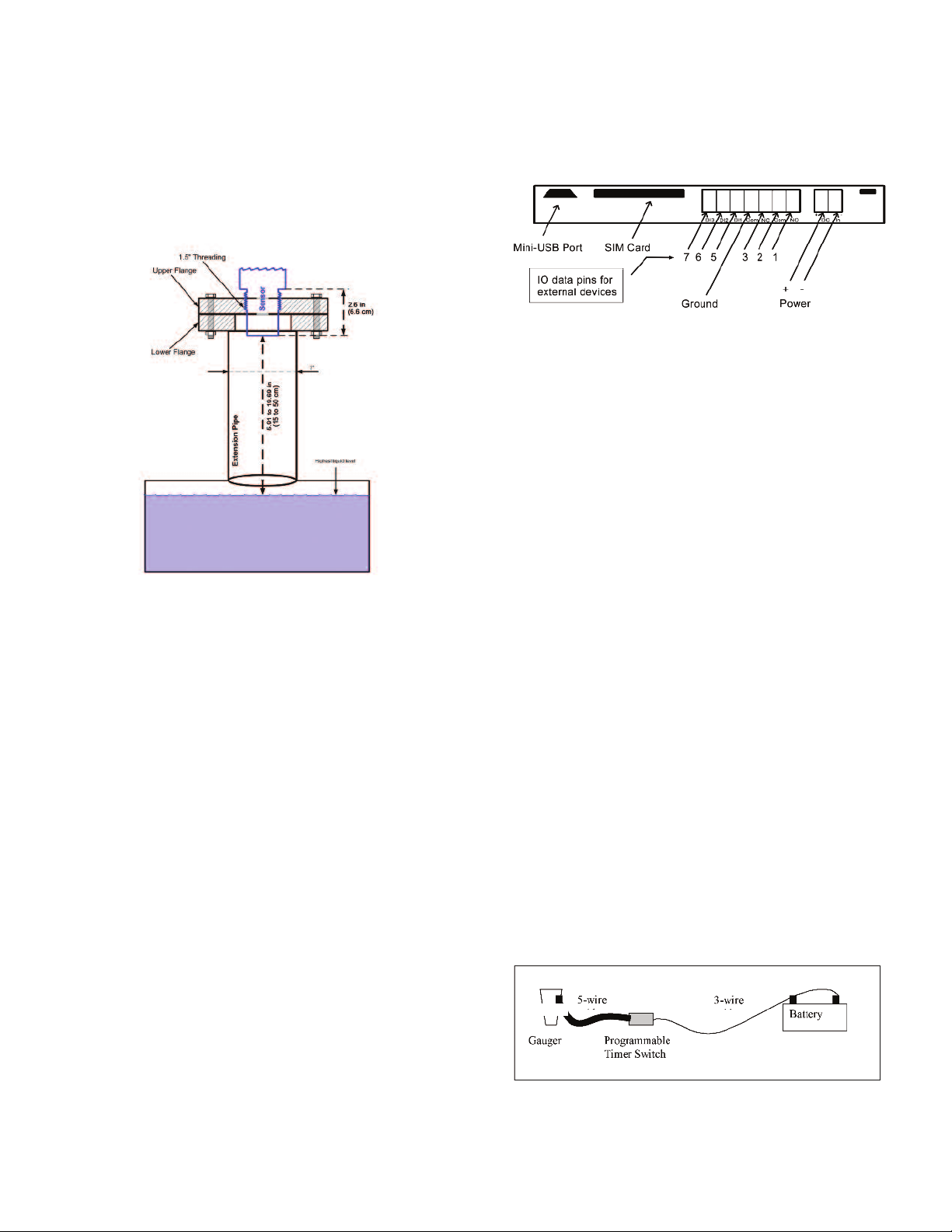

. Extension Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

4

5. Temperature Considerations and Temperature Sensors . . . . . . . . . . . . . . . . . .4

6. Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

7. Low Power Mode and Programmable Timer Switch (PTS) . . . . . . . . . . . . . . . .4

8. SIM Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

. MUST BE Pamphlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

9

hapter 3. Operating Instructions

C

1. Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.1 Navigation Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2 Execution Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2. Navigation Through Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

.1 Sub-Menu Style . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2

.2 Numeric Menu Style . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2

.3 Menu and Sub-Menu Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2

3. Measurement Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.1 Status Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.2 Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.3 Main Menu/Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.4 Temperature Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.5 Ultrasonic Echo Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.6 Product Identification Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4. Quick Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

5. False Echo Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

6. Advanced Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

7. Settings Available in PC Configuration Only . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Chapter 4. Configuration with a PC

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2. Preparing a Configuration Text File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.1 A Simple Sample File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.2 Multi Value Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3. Download Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.1 General Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.2 Launching and Setting Up HyperTerminal . . . . . . . . . . . . . . . . . . . . . . . .8

3.3 Downloading a Configuration File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4. Responses from Series ULTM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.1 Good Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.2 Erroneous Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.3 Communication Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

5. Reference Guide for Configuration from a PC . . . . . . . . . . . . . . . . . . . . . . . . .9

5.1 List of Configuration Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

5.2 Lists for Metric Unit System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5.3 List of American Unit System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5.4 Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

6. Useful Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

6.1 Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

6.2 Advanced Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

List of Figures

igure 1: Series ULTM Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

F

igure 2: Series ULTM Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

F

igure 3: Minimum Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

F

igure 4: Threaded Flange (left) Thread-Free Flange (right) . . . . . . . . . . . . . . . . . . .3

F

Figure 5: Possible Extension Pipe Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Figure 6: Possible Extension Pipe Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Figure 7: Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

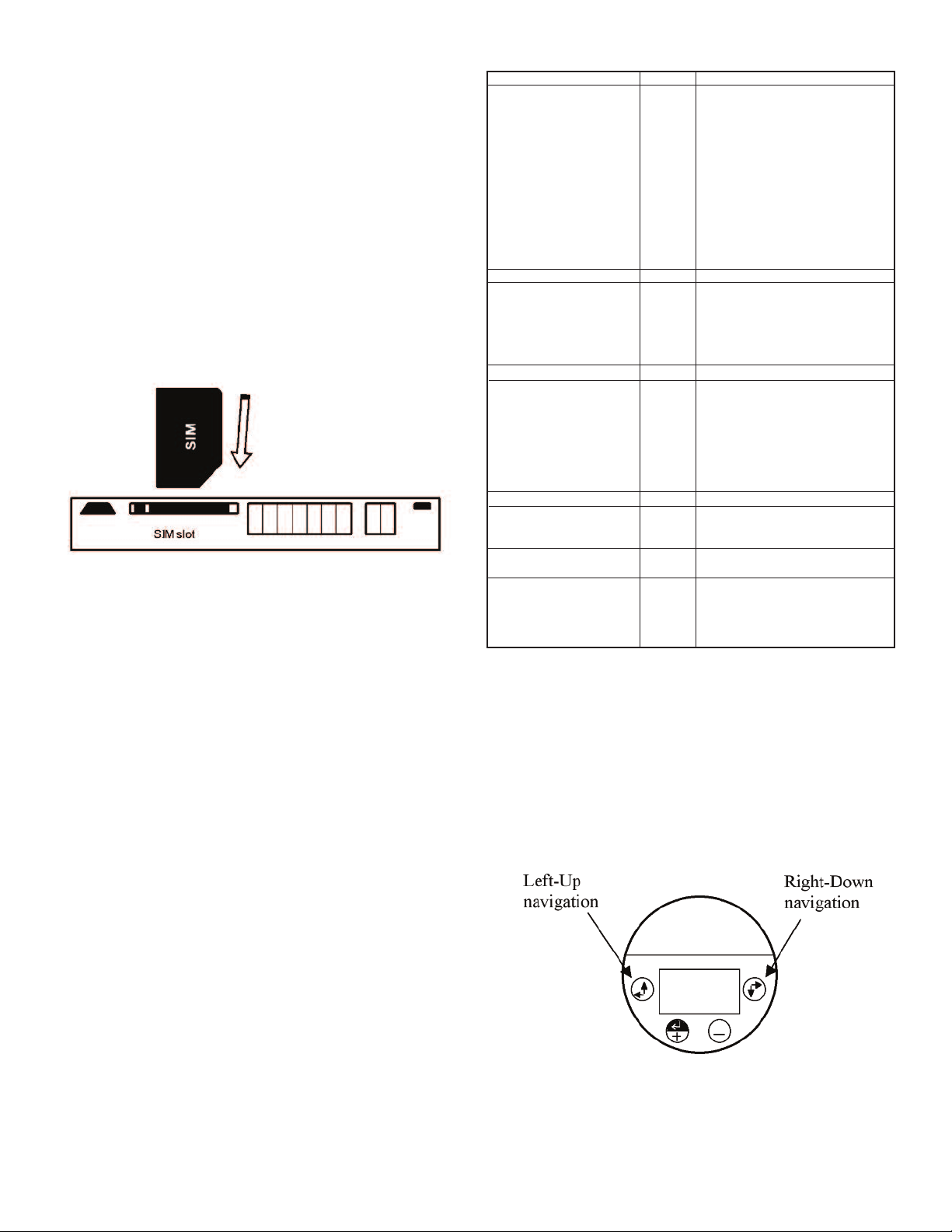

igure 8: Programmable Timer Switch Connections . . . . . . . . . . . . . . . . . . . . . . . . .4

F

igure 9: SIM Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

F

igure 10: Navigation Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

F

Figure 11: Execution Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Figure 12: Sub Menu Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Figure 13: Numeric Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Figure 14: Menu and Sub-Menu Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

igure 15: Measurement Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

F

igure 16: Temperature Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

F

igure 17: False Echo Scan Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

F

This manual is delivered subject to the following conditions and restrictions:

• The manual contains proprietary information belonging to Dwyer Instruments, Inc.

he information is published solely for the purpose of assisting authorized users of

T

eries ULTM.

S

No part of this manual may be used for any other purpose, or disclosed to any

•

person or firm, or reproduced by any means, without the prior written permission of

Dwyer Instruments, Inc.

• The text and graphics in this manual are for the purpose of illustration and

reference only.

• Information included in this manual is subject to change without notice. Information

in the manual may contain inaccuracies. We always welcome suggestions and

recommendations from the users of our manuals.

• All company names, brand products and service names that may appear in this

manual are trademarks or registered trademarks of their respective holders.

• Dwyer Instruments, Inc. shall not be liable for any loss or damage caused by

the use of this manual or of products described in the manual. Dwyer Instruments,

Inc. sole warranty is that products sold by the company shall be free of defects in

material and in workmanship for a period of 12 months.

• Series ULTM must be installed, connected and operated in accordance with the

instructions of this manual and with the Series ULTM certifications. Specific local

regulations may also apply.

• Do not open or disassemble Series ULTM except as required for electrical

connections.

• Any type of modifications and repairs are permissible only upon the manufacturer

or re-seller written approval and by pre-qualified personnel. Never reuse defective

parts.

Chapter 5. Firmware Dates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2. You Will Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3. Installation of Firmware Upgrade Tool and USB Driver . . . . . . . . . . . . . . . . .12

4. Upgrade Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5. Troubleshooting the Firmware Upgrade Process . . . . . . . . . . . . . . . . . . . . . .13

Chapter 6. Serial Data Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2. Installation and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3. Record Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Page 1

Page 3

hapter 1: Introduction

C

. Description

1

Series ULTM is an ultrasonic level meter with integrated GSM cellular modem

and USB interface. Optional items include external temperature sensor and

programmable timer switch.

eries ULTM measures distance for targets such as liquid or solids.

S

easurement is continuous and does not require contact with the target. The

M

ystem can accurately measure steady or agitated target surfaces. The system can

s

lso rapidly track filling and emptying of vessels. The system measurement

a

distance spans 5.9 in (15 cm) to 26 ft (8 m). In addition to distance, the ULTM can

also measure temperature of the environment.

Series ULTM makes use of the measured distance to calculate additional

nformation such as target level and volume.

i

eries ULTM operates at an ultrasonic frequency of 75 kHz, making it perfect for

S

oisy conditions. The sensor is made of PVDF, therefore providing good chemical

n

resistance to corrosive targets.

Series ULTM may be used with 8 to 33 VDC power. The low power mode is

available for use with batteries and is supported using a Programmable Timer

Switch (PTS).

eries ULTM is equipped with a large graphic display and keypad allowing a

S

imple wizard-driven setup of the system. The keypad and display allow

s

onfiguration of many ULTM configuration parameters. Complete setup of all ULTM

c

parameters can be executed using a USB equipped PC or laptop. This method of

configuration allows for rapid cloning of multiple ULTM systems.

Series ULTM transmits measurement information to a predefined destination –

(either cellular phone or cellular PC modem) via SMS with user-programmable

eporting intervals. The system also identifies and sends an alert in boundary

r

vents such as full and empty situations. The system can also be programmed to

e

dentify or alert for rapid changes of level, indicating theft and refuel quantities. The

i

system can also transmit on/off contact state information.

This user manual is intended for users and operators of Series ULTM. The

manual covers system description, installation, operation and troubleshooting for

the Series ULTM.

PECIFICATIONS

S

easuring range

M

aximum Range for Liquids: 26.25´ (8 m);

M

Maximum Range for Solids: 19.69´ (6 m).

Accuracy – Precision – Resolution -Tracking

ccuracy:

A

5 cm<range<60 cm: 0.59˝ (1.5 mm);

1

0 cm<range<5 m: 0.3% of measured range;

6

m<range<8 m: 0.2% of maximum range.

5

Repeatability: 0.2% of measured range.

Display Resolution: 0.04˝ (1 mm).

SMS Resolution: 0.04˝ (1 mm).

ax Tracking Rate: 0.55 ft/sec (10 m/min).

M

eam Angle: 5° @ 3 dB point.

B

Electrical Specifications

Power Supply: 8 to 33 VDC on ULTM ports.

Low Power Mode: Programmable sleep mode.

Current Consumption @ 24 VDC:

ontinuous: Less than 10 mA;

C

uring SMS transmission: Less than 40 mA;

D

hort spikes at switch and SMS: Less than 160 mA.

S

Data Interface: Serial COM over USB at 115,200 bps.

USB Port: Firmware upgrade.

Display: 64X128 graphic LCD, viewing size 50X25 mm

ellular Modem Specifications

C

and: Quad band 850/900/1800/1900 mHz.

B

utput Power: Class 4 (33dBm) for EGSM850/EGSM900.

O

2

.

Class 1 (30dBm) for GSM1800/GSM1900.

SMS: Point-to-point MO and MT.

GPRS: Multi-slot class 10.

Reports

Displayed: Level and percentage level;

Distance and percentage distance;

Volume;

Temperature (internal and external);

Echo strength;

Global operating hours;

Resettable operating hours.

Data Sent by SMS: Level, distance, volume, temperature, status.

Alerts Sent by SMS: Full, empty, over consumption, refill, custom.

Figure 1: Series ULTM Parts.

Temperature Characteristics

Operational Temperature Range: -4 to 158°F (-20°C to 70°C).

Temperature Sensors: Internal and optional external.

Temperature Compensation: Built-in based on internal sensor, external sensor or

average of the two.

Temperature Display: Internal and external temperature; Instantaneous and

recorded high/low.

Mechanical Specifications

Enclosure Material: Plastic PC/ABS+UV.

Sensor Material: PVDF.

Sealing Rating: IP65/IP67; IP68 - 96 hours at 5.91´ (1.8 m) depth in water.

Mounting Orientation: Vertical.

Mounting Threads: 1.5˝ BSP or 1.5˝ NPT.

Cable Entries: Conduit 1/2˝ NPT.

Weight: 1.95 lb (884.51 g).

*To measure external temperature, contact factory for ULTM-EXT for external

temperature sensor.

Page 2

Page 4

Figure 2: Series ULTM Dimensions.

Chapter 2. Physical and Electrical Installation Guidelines

his chapter is a list of guidelines for proper physical installation of the Series ULTM

T

n tanks, including electrical connections. In the final section of this chapter, there

o

s a short and concise list of instructions–the “Must-Be pamphlet”. Always ensure

i

that the Series ULTM is installed in an area that meets the stated ratings of this

product including temperature and technical specifications.

1. Physical Guidelines

• ULTM systems are installed above the target (e.g. water, fuel) being measured

and should not make contact with the target at any time. Typically, the unit is

installed on top of a tank through a hole on the roof of the

tank. In outdoor applications, the ULTM may be attached to a metal arm

extending above the target attached nearby.

• Series ULTM should be located as far as possible from vertical tank walls and

from other physical obstructions such as filling inlets. Keep a minimum gap of: 12

in (30 cm) plus 4 in (10 cm) for each 3.3 ft (1 m) of measurement range.

• For best results, place the unit away from sources of acoustic noise or

sources of vibrations.

Proper physical installation is accompanied by software setup. Setup includes

•

efining parameters such as tank height, and may include additional parameters

d

uch as Near Blocking Distance (NBD), Far Blocking Distance (FBD), False echo

s

can and more. For additional information refer to the section in Chapter 8

s

reference guide: “Application Dimensions and Constraints” (p.14).

2. Tank Fitting

eries ULTM is equipped with a 1.5˝ BSP or 1.5˝ NPT thread allowing for two fitting

S

ptions: direct fitting in a threaded flange, or fastened with a 1.5˝ BSP / 1.5˝ NPT

o

ut through a thread-free flange.

n

or outdoor installations, use a stable arm and firmly attach the sensor to the arm

F

using a through-hole and threaded nut. Alternatively, it may be possible to attach

the sensor to a threaded hole which is built-in the arm.

lways verify thread compatibility between the Series ULTM and flange or nut. Do

A

ot use excessive force when using threads. Preferably, tighten by hand only. If a

n

rench is used, grip Series ULTM at the wrench grip surfaces only (see Figure 1

w

Series ULTM parts) and exert light force.

3. Dead Zone

Refer to Chapter 8 reference guide: “Application Dimensions and Constraints”

p.14). A gap must be kept between the face of sensor and the topmost level of the

(

arget. This gap must be at least the size of the specified “dead zone”. If the target

t

evel passes the dead zone, measurements may be unpredictable. Therefore, it is

l

recommended to keep a marginal gap between the expected topmost level and the

dead zone border. In the case where the top most level is too close to the tank roof,

an extension pipe is required for the installation of the unit as described below.

Figure 4: Threaded Flange (left) Thread-Free Flange (right).

4. Extension Pipe

Refer to Chapter 8 reference guide: “Application Dimensions and Constraints”

(p.14). An extension pipe is required for installation where the top most target level

is too close to the roof of the tank. In such cases, an extension pipe is installed on

the tank and the sensor is installed on top of the extension pipe at a safe distance

from the top most level of the target. The lower border of the dead zone may fall

inside the tank as seen in the right hand side of the figure below. In this case no

further software settings are required. The lower border of the dead zone may also

fall within the extension pipe as described in the left hand side of the figure below.

In such cases, the Near Blocking Distance (NBD) should be configured in the

software.

r

cm)

e

t

0

3

me

(

m)

2˝

ch

a

c

f 1

e

45

(

per

m)

4˝(10 c

To

17.72˝

l of

a

t

Minimum o

Figure 3: Minimum Gap.

• Series ULTM should be perpendicular to the surface of a liquid target. The angular

displacement should be less than 5° from the vertical axis.

Figure 5: Possible Extension Pipe Fittings.

Page 3

Page 5

typical structure of an extension pipe is shown in Figure 6 below. Closely follow

A

hese guidelines when using an extension pipe:

t

Internal pipe diameter should be at least 3˝ (7.62 cm) wide.

•

The diameter of the hole on the flange or tank should not be smaller than the pipe

•

diameter.

• Pipe length (measured from sensor face) should be no longer than 20˝ (50 cm).

• The pipe should not protrude into the tank.

Pipe should be exactly perpendicular to the surface of the target.

•

Sensor must be located at the center of the pipe.

•

Pipe should have a smooth interior surface.

•

The hole in the flange or tank should have a smooth edge and welding spots must

•

be avoided.

Figure 6: Possible Extension Pipe Fittings.

5. Temperature Considerations and Temperature Sensors

Also refer to Chapter 8 reference guide: “Temperature Sensors, Units and Display”

(p.17).

When using an external temperature sensor, place the sensor at a location that

best represents temperature of the air between the sensor face and the target.

Connect the sensor internally as described in the electrical connection section to

the Thermistor pins. External temperature sensors may be ordered from the

manufacturer or may be purchased independently. Use Thermistor NTC 10 K Ω 5%

(minimum), ULTM-EXT or equivalent.

When using the internal temperature sensor, avoid situations where the Series

ULTM is exposed to different thermal conditions other than its environment, such

as direct sunlight. Direct sunlight may overheat the system and cause

measurement inaccuracies, measurement variations in time, and even failure of the

system in extreme cases. If the Series ULTM is exposed to direct sunlight,

construct a local sunshade (“umbrella”) over the ULTM.

In areas of large temperature variations, take into consideration volume changes of

the target due to temperature expansion.

. Electrical Connections

6

arefully follow these steps when connecting a power supply to the Series ULTM.

C

ower supply must fulfill the proper rating requirements as defined in the

P

pecifications chapter above.

s

6.1 Turn off Series ULTM.

6.2 Turn the ULTM top cap counter-clockwise and expose the electrical

onnections board. Identify the elements as shown in the following figure.

c

Figure 7: Electrical Connections.

GROUND (Pin 4) is a ground and not a common.

*

Pins 1-3 are not used on this device.

*

.3 Insert power cables into the Series ULTM through one of the glands.

6

nsure that high voltage sources or cables are at least 3.28´ (1 m) away from

E

Series ULTM and cables.

Keep the electrical supply lines away from electromagnetic interference

sources.

When inserting a cable through the gland, use round cables with a minimum

iameter of 0.24˝ (6 mm) to ensure that the unit remains sealed to IP67 rating.

d

onnector terminals may be pulled up for easy wire connection and then re-

C

nserted back again.

i

6.4 Connect the power cables to the appropriate terminals.

Note: The Series ULTM operates from a DC power supply of 8 to 33 VDC.

Always make sure that sufficient voltage is present on the Series ULTM power

terminals, disregarding of any voltage drop along the supply lines.

6.5 When using an external temperature sensor or ULTM-EXT, connect the

thermistor to data pins 6 and 7. *Do not wire ULTM-PTS and ULTM-EXT at the

same time.

6.6 When using an external Programmable Timer Switch ULTM-PTS, connect the

switch to pins 6 and 7.

6.7 When using a contact alert, connect short/open between pins 5 and 4 (ground).

See the section about contact alerts in the Chapter 8 reference guide.

6.8 The mini-USB port is a USB device-side supporting virtual COM ports. The port

may be used for firmware upgrades, field monitoring and remote setup. Details

about firmware upgrade are provided in the Chapter 5: Firmware Updates

(p.12).

7. Low Power Mode and Programmable/Timer Switch (PTS), ULTM-PTS

Series ULTM supports low power mode for extended external battery lifetime. This

mode of operation requires the external Programmable Timer Switch (PTS) ULTMPTS to be connected between Series ULTM and battery.

PTS connections:

• First connect the 5-wire cable from the ULTM-PTS to Series ULTM through one

of the glands.

• Connect the Brown (+) wire to the power plus (+) on Series ULTM.

• Connect the Yellow (-) wire to the power minus (-) on Series ULTM.

• Connect the White wire to pin 6 on the electrical port panel (see Figure 7

above).

• Connect the Green wire to pin 7 on the electrical port panel.

• Connect the Blue (ground) wire to the ground port on Series ULTM.

• Then connect the 3-wire cable from the ULTM-PTS to the battery.

• Connect the Brown (+) wire to the battery plus (+).

• Connect the Yellow (-) wire to the battery minus (-).

• Connect the Blue wire to a local ground at or nearby the battery.

ULTM

Figure 8: Programmable Timer Switch Connections.

See PTS software configuration in Chapter 8: Reference Guide.

Page 4

Page 6

. SIM Card*

8

Mini-SIM card must be inserted in the Series ULTM to allow use of the cellular

A

eature. Never insert or take out a SIM card when Series ULTM power is on. Follow

f

these instructions regarding your SIM card:

8.1 The SIM card must support SMS services with your local cellular operator. You

o not need any voice or browser capabilities in your cellular service.

d

epending on your cellular operator – you might be required to use a USIM

D

ard.

c

.2 Deactivate the SIM PIN code if the PIN code is active before inserting in the

8

ULTM. Deactivation is preformed by inserting the SIM card into a cellular phone

and following the instructions of the phone manufacturer. PIN code

configuration is usually found in your phone Settings – Security Settings – PIN

ode Request or similar.

C

.3 Always test your SIM card before inserting into Series ULTM. Test the SIM card

8

y inserting the card into a cellular phone and sending an SMS. Verify that no

b

PIN code is required, that the proper operator serves the cellular link and that

the SMS reaches its destination.

8.4 Turn off Series ULTM. Turn the Series ULTM top cap counter-clockwise and

expose the electrical connections board. Insert the SIM card into the proper slot

s described in the following figure. The SIM may be pulled out by pressing it

a

ownward again. Insert as shown in Figure 9 below.

d

Figure 9: SIM Card.

8.5 Aim Series ULTM to proper target (e.g. floor), turn on Series ULTM and closely

observe the lower status line on the display (status lines are explained in the

Operating Instructions Chapter 3- Measurement Screen sub-chapter).

You should observe the report “GSM Initializing” for 30 to 60 seconds. Then you

should observe several additional status reports including “GSM Active”. This

indicates proper SIM card operation.

*Series ULTM only supports AT&T and T-Mobile mini-SIM cards. Make sure unit will

work with carrier.

. Must Be Pamphlet

9

. Choosing Location

1

istance to Tank Walls

D

Flange

Acoustic Noises

lectrical Interference

E

ank Installation

T

Sensor

xternal Thermistor

E

. Handling Dead Zone

2

xtension Pipes (1)

E

Extension Pipes (2)

xtension Pipes (3)

E

. Power Source

3

Voltage

Battery (Internal/External)

Ripple and Noise

ype

T

SB Power Source

U

4. Cellular Communications

SIM Card with SMS Service

Destination Phone Number

SMS Alerts

5. Measurement

Configuration

Full/Empty, Level/Distance

Filling Rate

False Echo Scan

Near Blocking Distance (NBD)

Chapter 3. Operating Instructions

This chapter describes the keypad and display of the Series ULTM. The keypad

and display add the following functionality to Series ULTM:

• Viewing measurement results and viewing information related to the system

• Configuring Series ULTM

This chapter focuses on the structure and operation of the keypad and display.

Configuration of the system via a PC is described in following chapters. Expose the

keypad by turning the cap counterclockwise all the way.

UST BE

M

UST BE

M

MUST BE

MUST BE

UST BE

M

UST BE

M

MUST BE

UST BE

M

MUST BE

MUST BE

UST BE

M

UST BE

M

MUST BE

UST BE

M

MUST BE

MUST BE

UST BE

M

MUST BE

MUST BE

MUST BE

MUST BE

MUST BE

t least 11.81˝ (30 cm) from walls

A

3.94/39.37˝ (+10 cm /1 m) range.

+

ixed on a horizontal surface.

F

Far away from acoustic noises and

vibrations.

Shielded away from power and sensor

ables.

c

ar away from tank inlets, outlets,

F

hysical obstacles.

p

xactly perpendicular to the surface of

E

the target.

In shaded location, attached to the tank

body.

f at least 3˝ (7.62 cm) internal

O

iameter and 5.91˝ (15 cm) above

d

target (from sensor face).

With completely smooth interior surface.

Installed with a flange/not protruding

into the tank.

t least 8 VDC on unit terminals.

A

ated higher than 8 VDC due to

R

voltage drop.

Not exceeding 100 mV.

referably regulated switching power

P

upply.

s

Accompanied by power source for field

operations.

Inserted in the SIM card slot.

et and formatted correctly.

S

Defined using correct limits.

Configured correctly.

Defined (consider the application).

Executed when the tank is empty.

Set up in flange and extension pipe

installations.

1. Keypad

1.1 Navigation Keys

Use the navigation keys to scroll through the display.

Figure 10: Navigation Keys.

Page 5

Page 7

.2 Execution Keys

1

se the execution keys to change a digit or to execute a command (Back, Next or

U

ub-menu).

S

o change a digit: navigate to the digit and press the plus (+) key or the minus (-)

T

key.

To execute a command: navigate to the command and press the enter (+) key.

Remember–some changes are saved only after returning to the measurement

creen. If you shut down Series ULTM before you return to the measurement

s

creen, your changes may be lost.

s

igure 11: Execution Keys.

F

2. Navigation Through Menus

Series ULTM supports two menu styles that are used throughout the setup

perations and are described below. False echo scan employs a third menu style

o

nd is described in the relevant section below.

a

2.1 Sub-Menu Style

The Sub-Menu style presents a list of vertical choices. An arrow may appear on the

right hand side of the screen if additional items can be reached when scrolling

down. The scrolling is cyclic, meaning that when you reach the last (first) item, the

next step will lead you to the first (last) item. Scroll up or down, using the navigation

keys, to your selected choice and press Enter (+). This action will lead you to the

next sub-menu.

The last item in the list of choices is **back**. Select **back** to return to the

previous menu. The previous menu will be displayed such that your last selection

will appear first on the menu. For example:

fter pressing Next, ULTM will check the validity of your numerical entry. If your

A

ntry is outside the acceptable boundaries, an ILLEGAL VALUE screen will be

e

resented. You need to press any key to return to the previous screen. A default

p

alue will replace your wrong entry. If so needed, modify the numerical entry and

v

press Next again.

The top line presents the current measurement information.

.3. Menu and Sub-Menu Organization

2

LTM menus and submenus are organized in a tree-like format. The organization

U

s described in the following figure:

i

igure 14: Menu and Sub-Menu Organization.

F

3 Measurement Screen

±XX

setup

°

T

dB

ID

Figure 12: Sub Menu Screens.

2.2 Numeric Menu Style

The numeric menu style presents you with a multi-digit number which may be

modified. Navigate to each digit and modify the digit as required by using the plus

(+) or minus (-) keys.

When you are done with all digits, select Next to move on. Select Back to ignore

the changes and return to the previous sub-menu. Modifications will become

permanent (survive a reset) when you navigate back to the measurement screen.

For example:

By repeatedly pressing the Right-Down navigation key, you will follow this route:

Figure 13: Numeric Menu.

X1 → X2 → X3 → X4 → Next → Back → X1→ X2 →…

Conversely, by repeatedly pressing the Left-Up navigation key, you will follow the

opposite route.

Figure 15: Measurement Screen.

3.1 Status Reports

Status reports appear beneath the measurement result. On the first line, reports

related to ultrasonic monitoring issues are presented. On the next line, cellular

communication related reports are displayed. Ultrasonic reports include messages

such as: FULL LEVEL, EMPTY LEVEL, ECHO SEARCH, THEFT, START FILL,

END FILL and others. Cellular related reports include messages such as SMS

SENT, SMS ACTIVE, REGISTRATION FAILED and more.

The bottom line on the screen presents a toolbar with choices. Navigate through

the toolbar and select an action or report. ULTM halts any operations (including

measurements) during navigation. ULTM will automatically resume operations 30

seconds after last key has been pressed.

3.2 Contrast

Press the plus (+) or minus (-) keys to change visual contrast of the display.

3.3 Main Menu / Setup

Navigate to setup and press Enter (+) to configure ULTM. The actual configuration

process is explained in a following chapter.

Page 6

Page 8

.4 Temperature Readings

3

avigate to the T° symbol on the toolbar and press Enter (+). The following table

N

ill be displayed:

w

he table is explained in the Chapter 8 reference guide section: “Temperature

T

Sensors, Units and Display” (p.17). Press reset to reset recorded high / low

temperatures, or press done to return to the measurement screen.

ow

High

31.0

32

L

6

2

23.3

Done

Cur

Sens:

29.5

Int

29.4

xt

E

eset

R

igure 16: Temperature Readings.

F

3.5 Ultrasonic Echo Conditions

avigate to the dB symbol and press enter (+). You will be presented with the

N

easured echo amplitude and the maximum amplitude available. The amplitudes

m

re presented in dB relative to a system threshold amplitude. Echo amplitude

a

should be above threshold amplitude for reliable measurement. Echo strength

between 3 dB and 8 dB (maximum) is reliable. Echo amplitude refers to the echo

measured just prior to navigating through the toolbar. Press done to return to the

measurement screen.

.6 Product Identification Details

3

rom the measurement screen, navigate to the ID symbol on the toolbar and press

F

Enter (+). Product information will be displayed: serial number and part number.

Press Back to return to the measurement screen or navigate to one of the options:

Software Information (SW), Hardware Information (HW), or Manufacturing Date

Information (Date). SW screen will display firmware versions of the embedded

pplication and of the embedded boot-loader. Press Back to return to the previous

a

enu. HW screen will display product information regarding sensor type and model

m

ype. Press Back to return to the previous menu. Date screen will present the date

t

of manufacturing. Press Back to return to the previous menu.

4. Quick Setup

Set ULTM for operation by a quick 7-step wizard-driven procedure using the basic

menu option.

Note: Configuration using the display and keypad supports metric units only. For

English units, use the PC configuration method as described in the Chapter 5

describing Configuration with a PC (p.9).

A. Turn on ULTM and wait for the measurement screen to show up. Navigate

through the toolbar and select setup.

B. Scroll and select Basic Setup from the Main Menu.

C. Scroll and select application (Low power or High power). For additional details

about the application type refer to the reference guide under Chapter 8:

“Application Type” (p.15).

D. Determine distance to empty level. For additional details about the empty level,

see the reference guide section Chapter 8: “Application Dimensions and

Constraints” (p.14). When you are done press Done.

E. Determine distance to the full level. For additional details about the full level, see

the reference guide section Chapter 8: “Application Dimensions and

Constraints” (p.14). When you are done press Done.

F. Scroll and select value to display. For additional details about value-to-display,

see the reference guide section: Chapter 8: “Distance Units and Value to

Display” (p.15).

G. Skip or perform false echo search. See the section “False Echo Scan” in

Chapter 8, the reference guide chapter (p.16).

5. False Echo Scan

Perform a false echo scan when obstructions are nearby the target or sensor.

Preferably, false echo scan should be performed when the tank is empty. If you

choose to perform false echo scan, wait for about a minute and then you will be

presented with a list of echoes.

elect an echo, scroll to that echo and press Enter (+) again. If you choose to

s

erform false echo scan a second time, new echoes which were not identified

p

uring the first scan will be reported as “new”.

d

The ULTM is now ready for measurements.

Parameters which are not determined during quick setup procedure will take their

efault value and may be modified later using the Advanced Setup menu.

d

ote: Always verify then re-verify that your basic settings are correct including

N

istance to empty level, distance to full level, level or distance choice. Most wrong

d

eadings originate from incorrect basic setup.

r

. Advanced Settings

6

LTM supports a set of advanced settings. These settings are classified under

U

hree categories: GSM, Algorithm and Device state. The following items may be

t

modified under each category:

ub Menu Items

ategory

C

SM

G

lgorithm

A

Device state

To execute any of the advanced settings, follow these steps: Turn ON ULTM and

wait for the Measurement screen to show up. Navigate and select Setup. Then

scroll and select Advanced Setup from the Main Menu. Now select the required

category (GSM, Algorithm or Device state) and follow the screen instructions.

When done, scroll and press **back** to return to the Main Menu, then scroll and

select the measurement display.

Each item may either present a selection of sub-items to choose from or may

require entry of a numeric field.

If you are not sure what sub-item to select or how the numeric field should be

modified, leave the default values as is.

7. Settings Available in PC Configuration Only

Some advanced settings are available in a PC configuration only and cannot be

configured with the display/keypad. These settings are defined in the following

table.

Setting

Units

Value to Display

USB Monitoring

Tank Shape and Dimensions

Theft and Refill Alerts for Volume

Programmable Timer Switch

S

estination phone number

D

eporting interval

R

Full and empty alerts

Theft/Refill alerts active

once value is set for rate

nd level

a

ar blocking distance

F

Near blocking distance

Filling rate

Temperature units

Reset to defaults

Operating hours

See Section in Chapter 8

Reference Guide…

Destination Phone

“

umber”

N

GSM reporting Interval”

“

“Theft Alerts”

“Refill Alerts”

Application Dimensions &

“

Constraints”

“Application Dimensions &

Constraints”

“Filling Rate”

“Temperature Sensors,

Units and Display”

“Reset and Operating

Hours”

“Reset and Operating

Hours”

Options

Meter, feet, liter, gallon

Volume

Enable and disable

Cubic, cylindrical

Level and duration

PC Command

UNT

VAL

ENDT, DSDT

CUB, CYLV, CYLH

ATF, ARF

LPST

Notes

1-Enable

0-Disable

-Enable

1

-Disable

0

Figure 17: False Echo Scan Screen.

Scroll through the listed echoes and press Enter (+) on each echo you would like

to ignore during measurement. Each such echo will be designated by a √ sign. The

number of selected echoes is presented on the top-right edge of the screen. Press

Save to store your selection and Next to proceed to the next sub-menu. To un-

Page 7

Page 9

hapter 4. Configuration with a PC

C

. Introduction

1

LTM is pre-configured at the factory to default settings. See reference guide

U

section in Chapter 8: “Default Values” (p.15). The system is delivered to the user

ready for operation. Some configuration parameters should be re-configured by the

user for proper field application. ULTM can be configured by a simple PC tool.

onfiguration by PC may be used in lieu of configuring with the integral keypad and

C

isplay. PC configuration provides the user with the full set of configuration items.

d

urthermore, configuration by PC allows the user to clone fielded ULTM systems.

F

For this cloning process, the user is required to prepare one text file and download

that file into all relevant ULTM systems. Once this configuration file is prepared, the

downloading process takes a few seconds and makes redundant any manual

eypad based operation.

k

ection 2 below begins by demonstrating a sample configuration text file.

S

Section 3 handles the downloading operation. The download process involves use

of a standard Windows application – HyperTerminal. The setup of HyperTerminal is

explained in the second section, and parts of it may be skipped by those who are

lready familiar with this tool. Section 4 presents possible responses from

a

LTM–whether good or erroneous responses. Section 5 is a list of all configuration

U

tems. Section 6 provides some configuration file example.

i

2. Preparing a Configuration Text File

he next example looks fine but the Enter button was not pressed. This will cause

T

n error.

a

2.2 Multi Value Commands

ome configuration items are assembled from two values or more. For example,

S

he dimensions of a vertical cylindrical tank (prefix CYLV) are height and diameter.

t

hese two values are both included with a comma between the two values. The

T

next figure illustrates the use of the comma.

2.1 A Simple Sample File

he following text file was created using Windows Notepad application and

T

emonstrates the essence of the configuration file:

d

Digest:

• The first line resets ULTM to its default values.

• The second line instructs ULTM to set its EMPTY LEVEL to a distance of 6.0

meters.

• The third line instructs ULTM to set its FULL LEVEL to a distance of 0.70 meters.

If you are unfamiliar with terms such as empty level or full level, read reference

guide section Chapter 8: “Application Dimensions and Constraints” (p.14). Next is

a slightly more complex configuration file:

Digest:

• The first line instructs ULTM to set its EMPTY LEVEL to a distance of

18 ft (5.5 m).

• The second line instructs ULTM to set its FULL LEVEL to a distance of

1.5 ft (0.45 m).

• The third line instructs ULTM to set up the destination phone number to

+49-1-1234567 (10 digits only).

• The forth and last line instructs ULTM to set up SMS interval time to 1800

seconds.

• Each instruction is implemented as a specific command such as EMP or FUL.

he third line instructs ULTM to set the tank as a vertical cylindrical tank with height

T

f 4.5 meter and diameter of 3.00 meters. The last item instructs ULTM to display

o

olume results (rather then level or distance). The comma should always separate

v

between values.

3. Download Operation

3.1 General Procedure

ULTM can be configured by downloading the text configuration file from your PC

into ULTM. The previous chapter described the making of the configuration file.

This chapter describes the download procedure. The download process can be

preformed using HyperTerminal – a Microsoft

most operating systems such as Windows XP

®

standard application which is part of

®

.

Prior to using the HyperTerminal, you must connect ULTM to the PC and install a

USB-Serial driver on the PC. You can do that by following the instructions in the

Chapter 8: “USB driver installation on a PC” (p.13).

You should find out the COM port number that ULTM is using on the PC. ULTM

must be in the measurement screen during download procedure. Two PC

applications trying to access ULTM will conflict with each other. Avoid having two

such applications running at the same time.

3.2 Launching and Setting Up HyperTerminal

This section assumes you are using Windows XP

®

. Similar procedures apply to

other operating systems.

3.2.1 Go to Start Menu and then Open Programs.

3.2.2 Open Accessories, then Open Communications then Open HyperTerminal.

3.2.3 Press NO when asked about “default telnet program”.

3.2.4 When prompt for a name, choose any name and press OK.

3.2.5 In the next window “Connect to”, select the COM port that you intend to use

for ULTM. This part is described in the next figure:

Notes:

• Each line begins, and ends, with a $ sign.

• All commands are made of capital letters.

• Each command is immediately adjacent to the first $ sign.

• There is a blank between the command and the related parameter.

• There is a blank between the parameter and the ending $ sign.

• Do not forget to press Enter after the last line.

Windows® and Windows® Xp are registered trademarks of Microsoft Corporation

Page 8

Page 10

.2.6 In the next window “COM properties - port settings”, set the parameters as

3

escribed below:

d

.2.10 Press OK and then OK again – you are all set to configure ULTM.

3

.3 Downloading a Configuration File

3

.3.1 From the HyperTerminal screen select transfer (top right side tab) and then

3

select “Send File”.

3.3.2 Browse to the directory where you stored the configuration text file (the one

you prepared in the previous section) and select that file. Double click on the

ile to transmit it.

f

.3.3 Alternatively, you can key each configuration item line by line directly from the

3

yperTerminal screen. As a quick test of this configuration, key the following

H

ommand:

c

$VAL 1 $

Watch ULTM integral display and verify that measured data is level.

Now key the following command:

VAL 2 $

$

atch ULTM integral display and verify that measured data is distance.

W

3.2.7 Now you should see the HyperTerminal screen:

.2.8 Select the File tab (on the top left side) and choose Properties, then Settings,

3

nd set the parameters as described below:

a

3.2.9 Now press on ASCII setup (bottom right side) and set the parameters as

described below:

4. Responses from Series ULTM

4.1 Good Response

ULTM should reply with an OK response to each configuration item:

4.2 Erroneous Responses

ULTM will reply with an ERROR or NOTE response to a wrong configuration item.

For example:

The ERROR or NOTE response will be followed by the causing item (in this case

EMP) and is accompanied by an error number (5 in this case). Possible error codes

are listed in the following table:

Error Code

1, 2

3

4

5

6

7

8

9

4.3 Communication Errors

The erroneous responses described indicate that the link between PC and ULTM

is operating fine and that the commands are of wrong nature.

Most probable cause

Configuration item is too long

$ sign is probably missing

Wrong command name or command not adjacent to $ sign

Value is exceeds upper legal limit

Value is below lower legal limit

Value is illegal

(NOTE) Command was already sent

(NOTE) Value is below minimum value and redefined to

minimum value

Especially note the “Line Delay” and the “Character Delay”, which are not the

default values of HyperTerminal.

Note: When using the USB port for local serial data monitoring (see appropriate

chapter), you should return to the default values of the screen above and

specifically uncheck “Append Line Feeds to Incoming Line Ends”. And vice verse,

if you revert to configuration of ULTM through the USB interface, make sure to set

the parameters of the screen above correctly.

If no responses are received from ULTM, or if the responses carry unfamiliar

characters, the communication link between the PC and ULTM is not performing.

In this case, you need to check the physical cabling, verify the HyperTerminal

settings and then restart this application again.

5. Reference Guide for Configuration from a PC

5.1 List of Configuration Items

The following conventions apply for the list of commands. These conventions refer

to the values allowed for each parameter.

5.1.1 Range of Number Values

A range of number values is presented with a hyphen. For example: 0.150-8.000.

This entry means that the value may be any number between 0.150 and 8.000.

Always use the decimal point. The number of decimal digits may be less than three.

Page 9

Page 11

.1.2 Range of Whole Number Values

5

range of whole number values is presented with a hyphen. For example: 1 - 99.

A

his entry means that the value may be any whole number between 1 and 99.

T

5.1.3 Several Distinct Values

When a parameter can be one of a few distinct values, each value is listed on

separate lines with an explanation. For example:

ommand

C

AL (3)

V

Command Description

alue to display

V

Possible Values

1

2

3

Value Description

Level

Distance

olume (set also tank

V

hape)

s

5.2 List for Metric Unit System

tem

I

PP (

A

EMP (

FUL (

VAL (

NT (

U

UNT (

FBD (

NBD (

RAT (

TMP (

SNS (

RSD (

RSC (

RST (

GMAN

ENDT (

DSDT (

CUB (

CYLV (

CYLV (

CYLH (

CYLH (

TEL1 (9)

TEL1 (

SMST (

AFE (

ATF (

ATF (

ARF (

ARF (

Description

1

pplication type

A

)

2

mpty level

E

)

2

Full level

)

3

Value to display

)

3

Units for VAL=1,2,4,5

)

3

Units for VAL=3,6

)

2

ar blocking distance

F

)

2

Near blocking distance

)

4

Filling (tracking) rate

)

5

Temperature unit system

)

5

Temperature sensor

)

6

Reset to factory defaults

)

6

Reset hour counter

)

6

Restart ULTM

)

Get manufacturer data

8

Enable USB monitoring

)

8

Disable USB monitoring

)

7

Cubic tank

)

7

Vertical cylindrical tank

)

7

Vertical cylindrical tank

)

with concave bottom

7

Horizontal cylindrical tank

)

with curved sides

7

Horizontal cylindrical tank

)

with flat sides

9

Cell-phone destination

)

10

SMS periodic interval

)

11

Full / Empty alerts

)

12

Theft alert for VAL=1,2,4,5

)

12

Theft alerts for VAL=3,6

)

13

Refill alerts for

)

VAL=1,2,4,5

13

Refill alerts for VAL=3,6

)

ossible values

P

Basic Setup (Metric)

0

1

.150 – 8.000

0

.150 – 8.000

0

1

2

3

4

5

6

1

2

3

4

Advanced Setup (Metric)

0.150 – 8.000

0.150 – 8.000

0

1

2

3

3

4

0

1

2

Resetting and ID Options (Metric)

None

None

None

None

None

None

Tank Shapes and Dimensions (Metric)

0.00-99.99, 0.00-99.99

0.00-99.99, 0.00-99.99, 0

0.00-99.99, 0.00-99.99,

0.00-99.99

0.000-99.99, 0.000-99.99,

0.001-99.99

0.000-99.99, 0.000-99.99, 0

XXXXXXXXXXXXXX

Communication and Alert Items (Metric)

XXXXXXXXXXXXXX

0

180-3999999

0

1

0, 0

4-99, 0

0, 0

4-99, 0

0, 5-500

0, 0, 1

4-99, 0, 1-3

0, 0, 1

4-99, 0, 1-3

0, 3-500, 1-3

alue description

V

High power

Low power

istance in meters

D

istance in meters

D

Level

Distance

Volume (set also tank shape)

% Level

Distance

%

% Volume (set also tank shape)

Meter

Feet (see list for English units)

iter

L

S Gallons (see list for English units)

U

Distance in meters

Distance in meters

1 meter / minute

2 meter / minute

5 meter / minute

10 meter / minute

Celsius

Fahrenheit

Internal sensor

External sensor

Average of both

Response is serial number and manufacturer date: dd-mm-yyyy

Width and depth (horizontal dimensions) in meter

Height of tank = EMP value in meter

Diameter of tank in meter

Height of tank = EMP value in meter

Diameter of tank in meter

Breadth of bottom in meter

Length, diameter and curved breadth in meter.

Length and diameter in meter

Exactly 14 digits where X is any digit 0-9 or *,+,No periodic reports

Interval in seconds

No alerts

Alerts activate

No alerts

Normal consumption in mm/minute

No alerts

Normal consumption in mm/minute

Normal consumption in liter/minute

No alerts

Minimal alerted level change in mm and minimum fill duration in minutes

No alerts

Minimal alerted level change in mm and minimum fill duration in minutes

Minimal alerted level change in liters and minimum fill duration in minutes

.1.4 Two Parameters for the Same Command

5

n entry such as 1-9999, 0.150-8.000 means that the command is made of two

A

arameters and requires two values. A comma separates the two values. In this

p

xample the first value may be any whole number between 1 and 9999. The

e

second value may be any number between 0.150 and 8.000.

5.1.5 Two Parameters with One Parameter Fixed

n entry such as 1-99, 0 means that the configuration item requires two values, but

A

he second value must be 0. The first value in this example may be any whole

t

umber between 1 and 99.

n

The user may select one of two units systems: Metric or English. A separate

command list is provided below for each unit system. The user can select their

preferred unit system with the UNT command.

Page 10

Page 12

4

1

PST (

L

Low power timer

)

1-99999, 0.150 – 8.000,

1-99999, 0.150 – 8.000, 0-1, 0-1

ll notes are explained in section 5.4.

A

.3 List for English Unit System

5

Item

PP (

A

MP (

E

FUL (

VAL (

UNT (

UNT (

FBD (

BD (

N

AT (

R

TMP (

SNS (

RSD (

RSC (

RST (

GMAN

ENDT (

DSDT (

CUB (

CYLV (

CYLV (

Description

1

pplication type

A

)

2

mpty level

E

)

2

Full level

)

3

Value to display

)

3

nits for VAL=1,2,4,5

U

)

3

Units for VAL=3,6

)

2

Far blocking distance

)

2

ear blocking distance

N

)

4

illing (tracking) rate

F

)

5

Temperature unit system

)

5

Temperature sensor

)

6

Reset to factory defaults

)

6

Reset hour counter

)

6

Restart ULTM

)

Get manufacturer data

8

Enable USB monitoring

)

8

Disable USB monitoring

)

7

Cubic tank

)

7

Vertical cylindrical tank

)

7

Vertical cylindrical tank

)

with concave bottom

7

CYLH (

CYLH (

Horizontal cylindrical tank

)

with curved sides

7

Horizontal cylindrical tank

)

with flat sides

TEL1 (9)

9

TEL1 (

SMST (

AFE (

ATF (

ATF (

ARF (

Cell-phone destination

)

10

SMS periodic interval

)

11

Full / Empty alerts

)

12

Theft alert for VAL=1,2,4,5

)

12

Theft alerts for VAL=3,6

)

13

Refill alerts for

)

VAL=1,2,4,5

13

ARF (

Refill alerts for VAL=3,6

)

ommunication and Alert Items (Metric)

C

ossible values

P

Basic Setup (English)

0

1

0.50 – 26.00

0.50 – 26.00

1

2

3

4

5

6

1

2

3

4

Advanced Setup (English)

0.50 – 26.00

0.50 – 26.00

0

1

2

3

3

4

0

1

2

Resetting and ID Options (English)

None

None

None

None

None

None

Tank Shapes and Dimensions (English)

0.00-300.00, 0.00-300.00

0.00-300.00, 0.00-300.00, 0

0.00-300.00, 0.00-300.00,

0.01-300.00

0.000-99.99, 0.000-99.99,

0.001-99.99

0.000-99.99, 0.000-99.99, 0

XXXXXXXXXXXXXX

Communication and Alert Items (English)

XXXXXXXXXXXXXX

0

180-3999999

0

1

0, 0

0.16-4.00, 0

0, 0

0.16-4.00, 0

0, 1.4-26.00

0, 0, 1

0.16-4.00, 0, 1-3

0, 0, 1

0.16-4.00, 0, 1-3

0, 0.8-26, 1-3

Long standby interval in minutes

Distance to low level in meters

Short standby interval in minutes

istance to high level in meters

D

isable (0) or enable (1)

D

- No SMS are sent when in the “Long Standby Mode”. 1 – SMS are sent

0

hen in “Long Standby Mode”.

w

alue description

V

igh power

H

Low power

Distance in feet

Distance in feet

evel

L

istance

D

olume (set also tank shape)

V

% Level

% Distance

% Volume (set also tank shape)

Meter (see list for metric units)

eet

F

iter (see list for metric units)

L

allons (US)

G

Distance in feet

Distance in feet

3 feet / minute

feet / minute

6

5 feet / minute

1

30 feet / minute

Celsius

Fahrenheit

Internal sensor

External sensor

Average of both

Response is serial number and manufacturer date: dd-mm-yyyy

Width and depth (horizontal dimensions) in feet

Height of tank = EMP value in feet

Diameter of tank in feet

Height of tank = EMP value in feet

Diameter of tank in feet

Breadth of bottom in feet

Length, diameter and curved breadth in feet

Length and diameter in feet

Exactly 14 digits where X is any digit 0-9 or *,+,No periodic reports

Interval in seconds

No alerts

Alerts activate

No alerts

Normal consumption in inch/minute

No alerts

Normal consumption in inch/minute

Normal consumption in gallon/minute

No alerts

Minimal alerted level change in inch and minimum fill duration in minutes

No alerts

Minimal alerted level change in inch and minimum fill duration in minutes

Minimal alerted level change in gallons and minimum fill duration in minutes

Page 11

Page 13

4

1

PST (

L

Low power timer

)

1-99999, 0.50 – 26.00,

1-99999, 0.50 – 26.00, 0-1, 0-1

ll notes are explained in sections 5.4.

A

ommunication and Alert Items (English)

C

Long standby interval in minutes

Distance to low level in feet

Short standby interval in minutes

istance to high level in feet

D

isable (0) or enable (1)

D

- No SMS are sent when in the “Long Standby Mode”. 1 – SMS are sent

0

hen in “Long Standby Mode”.

w

Perform firmware upgrade only when authorized to do so by the manufacturer.

•

5.4 Notes

ote Number

N

(1)

(2)

(3)

4)

(

5)

(

6)

(

(7)

(8)

(9)

(10)

11)

(

12)

(

13)

(

(14)

15)

(

16)

(

. Useful Examples

6

See Detailed Information in Reference Guide Chapter…

ection: “Application Type”

S

ection: “Application Dimensions and Constraints”

S

ection: “Distance Units and Value to Display“

S

ection: “Filling Rate”

S

Section: “Temperature Sensors, Units and Temperature Display”

Section: “Reset and Operating Hours”

ection: “Volume Measurement”

S

ee Chapter 6: “Serial Data Monitoring”

S

ection: “Destination Phone Number”

S

Section: “GSM Reporting Interval”

Section: “Full and Empty Alerts”

Section: “Refill Alerts”

Section: “Theft Alerts”

Section: “PTS Configuration”

Section: “Trigger Alerts”

Section: “GPRS Architecture”

6.1 Basic Setup

$RSD $

$APP 0 $

$EMP 8.0 $

$FUL 0.15 $

$VAL 1 $

Reset to factory defaults

Application is high power

Distance to empty level is 8 meter

Distance to full level is 0.15 meter

Value to display is level

6.1 Advanced Setup

$DATA D $

$VAL 1 $

$FBD 8.0 $

$NBD 0.4 $

$RAT 3 $

$TMP 3 $

$SNS 0 $

$TEL1 +49-25-4678911- $

$SMST 1800 $

$AFE 1 $

$ATF 4, 0 $

$ARF 8, 0, 2 $

$CYLV 5.0, 2.0 $

SMS messaging

Value to display is level

Far blocking distance is 8 meters

Near blocking distance is 0.4 meters

Tracking rate is 10 meters per minute

Temperature unit is Celsius

Temperature sensor is the internal

Cell-phone destination is +49-25-4678911

Interval between periodic SMS messages is 1800

second

Empty and full event alerts are on

Theft alerts ON and for rate above 4 mm per minute

(for VAL=1)

Refill alerts ON for minimum refill of 8 mm during 2

minutes

Tank is vertical cylindrical, height 5 m and diameter 2

m

• While upgrading ULTM, record your steps and also record any messages that

appear on-screen. This will aid in troubleshooting a defective upgrade process.

• Most stored settings will usually not be lost when upgrading the firmware.

Use only the updated firmware provided by the manufacturer or re-seller.

•

. You Will Need

2

(A) PC with minimum requirements: Windows XP

7/16 /bit, CD drive, USB port, and administrator rights. The firmware upgrade

tool was also tested on Windows

®

7/32 bit.

®

Service Pack 2 or Windows

®

(B) ULTM Installation CD.

C) New ULTM firmware which is authorized for upgrading your ULTM.

(

. Installation of Firmware Upgrade Tool and USB Driver

3

(A) Insert the installation CD, select and run Setup.exe in the main directory of the

CD.

(B) Follow the on-screen instructions. When prompted for an installation directory,

keep the default installation directory:

“c:\program files\solidat\ULTMFirmwareUpgradeTool” or choose another

(

irectory).

d

C) When complete, check for new icon on your desktop and new program entry in

(

the programs list.

(D) Install ULTM USB driver by following instructions in Chapter 7: “USB driver

installation on a PC”.

4. Upgrade Procedure

(A) Copy the new ULTM firmware (e.g. xyz.bin) to a directory of your choice.

(B) Run ULTM Firmware Upgrade Tool by clicking on the proper desktop icon.

(C) Wait until the proper COM port is identified (the port connected with ULTM) then

press OK on the pop-up window.

Verify that current firmware version is displayed on the top line.

(D) Click on the

“…” button, browse and select the new firmware (e.g. xyz.bin).

When the new name appears on the windows, you can press the “upgrade new

firmware” button. Follow the progress and instructions on-screen. After some

time, ULTM display will be turned off – this is normal.

During the upgrade, you will see a progressive bar on the window as follows:

$LPST 60, 6, 10, 3, 1 $

Low power timer is ON: Low level sleep time of 60

minutes when the distance to target above emptylevel and longer than 6 meters. High level sleep time

is 10 minutes and occurs when distance to target is

more than 3 meters, but still less than 6 meters.

ULTM will operate continuously when the distance to

target is less than 3 meters.

Note: Always verify then re-verify that your basic settings are correct including

distance to empty level, distance to full level, level or distance choice. Most wrong

readings originate from incorrect setup.

Chapter 5. Firmware Updates

1. Introduction

ULTM firmware can be upgraded in the field. The upgrade procedure takes less

than 5 minutes, but should be done carefully to avoid damage to the system. This

feature is useful for adding new features to your ULTM system and for fixing

bugs.

If you do not see the bar starting, or if the bar has stopped moving – just wait! If

Be patient!

you disconnect the ULTM while in the middle of the upgrade process, the internal

software may be impaired and may require returning to the factory. If the bar has

not started or has stopped, wait for at least 10 minutes before reconnecting and

restarting the process.

Page 12

Page 14

E) Wait for the upgrade process to complete. The process is complete when you

(

ee the following window:

s

ow click OK and restart ULTM.

N

. Troubleshooting the Firmware Upgrade Process

5

ecommendation

Symptom

R

Installing Upgrade Tool

nstall .NET Framework on you PC (2.0 or

Installation of the upgrade tool

halts due to .NET Framework

issing.

m

Installation of the upgrade tool

halts due to user permissions

I

above). See

http://www.microsoft.com/downloads/details.as

x?familyid=0856eacb-4362-4b0d-8edd-

p

ab15c5e04f5&displaylang=en

a

erify that you are a local administrator on the

V

PC.

Upgrading the Firmware

1) Make sure ULTM is turned on. Disconnect

COM port is not found

r Current firmware version is

o

ot displayed

n

(

nd then connect again the USB cable.

a

(2) Select the Communication tab. Try

automatic port selection then try manual

port selection.

(3) Shut off the Upgrade Tool, then verify with

he Windows

t

®

ask Manager that a ULTM

T

process is not running. Run the Upgrade

Tool again.

Upgrade process has halted

Wait for 10 minutes. Restart the application.

Restart your PC and try again.

ULTM display stays blank after

Restart your PC and try again.

installation and restart

Chapter 6. Serial Data Monitoring

1. Introduction

ULTM may be monitored locally. ULTM may be configured to send information to

a PC over the USB interface and that information may be viewed with a

HyperTerminal application. This feature is useful for field monitoring and for

debugging purposes.

E) Information may be simply viewed or gathered into a text file by using the

(

ransfer/Capture Text tab of HyperTerminal. You can define this file as .txt or

T

csv. You can also define the file as txt and later rename it to .csv. A .csv file

.

an then be conveniently viewed with an excel application.

c

Other data logging programs include Log & Forward and SMS Management Center

found on the ULTM software CD. These programs use SMS messages sent directly

o a PC to organize and display data from the ULTM. This requires a PC equipped

t

ith a cellular modem and a separate SIM card. Instructions for installing and

w

unning these programs are also found on the software CD in the folder, “ULTM

r

ocuments”.

D

3. Record Format

typical record on the HyperTerminal screen or text file may appear as follows:

A

20 1.53 1.53 2 1 27.67 29.8 2 32 6 0 50 62 1.53 0.02 0 3880 0 3

2

222,1.532,1.531,2,1,27.667,29.800,2,32,6,0,50,64,0.000,0.000,0, 3417, 0, 3

A .csv file will appear as follows:

n these recordings the third column from the left is the measured data (after

I

rocessing) and the sixth column from the left is the measured temperature. Other

p

columns are internal equipment variables applicable for manufacturer debugging

purposes. Fields may change between software versions. Check with the

manufacturer about the fields in your recording.

hapter 7. USB Driver Installation on a PC

C

his chapter describes the installation of ULTM USB drivers on a PC. The driver

T

installation is required when using the PC / laptop for:

• Configuration of ULTM

• Serial monitoring

• Firmware upgrade

The drivers were tested on Windows XP

®

and Windows®7/32 bit systems.

(A) Copy the directory “ULTM Drivers XP” from the CD to your PC.

(B) Connect the PC to ULTM using a USB cable. Keep cable length to less than two

meters. Turn ULTM on (if not already powered by the USB).

(C) Follow the standard driver installation instructions on the PC. Whenever

prompted for a driver, select the location of “ULTM Drivers XP”.

(D) The following set of windows may aid you when following with the installation.

Information being sent by ULTM includes measured data such as distance and

temperature and internal system variables.

2. Installation and Operation

(A) Install the USB driver for ULTM as described in the chapter 7: “USB Driver

Installation on a PC” (p.13). You may have done so already for the “PC

Configuration Utility” or for the “Firmware Upgrade Application”. In that case,

there is no need to do it again.

(B) Connect ULTM to your PC using a USB cable terminated with a mini-USB

connector. Refrain from utilizing USB power supply alone. It is advisable to

connect a regular DC power supply to ULTM.

(C) Launch the HyperTerminal application on the PC. To do so, follow the

instructions included in Chapter 4 “Configuration with a PC” under the subsection “Launching and Setting up HyperTerminal”.

(D) You need to enable the monitoring function using the ENDT command from the

HyperTerminal. The command may be keyed manually or sent as text

configuration file. Review the “Configuration with PC” chapter for this procedure.

The settings of HyperTerminal for configuring ULTM and for serial monitoring are

identical, except for the item “Append Line Feed”. When monitoring, you should

uncheck the “Append Line Feed” item in the ASCII setup to avoid extra lines.

When you want to halt the monitoring function, you must prepare a configuration

file with the DSDT command and send it from the HyperTerminal application. In this

case the manual procedure is not applicable because ULTM is constantly

transmitting its own monitoring data.

Windows® is a registered trademark of Microsoft Corporation

Page 13

Page 15

Choose “Continue Anyway”...

You should also check proper installation by viewing the device manager.

If the USB driver installation failed, a “?” sign may be listed at the “Ports” item. In

other cases, the driver may be listed under “Other Devices” item. In both cases,

uninstall the device and than re-install it again.

Chapter 8. Reference Guide

Application Dimensions and Constraints

A) Basic Dimensions

• Distance • Distance to full level (FULL)

• Level • Distance to empty level (EMPTY)

• Dead zone • Maximum range

• Full level • Near blocking distance (NBD)

• Empty level • Far blocking distance (FBD)

Figure 17: Application Dimensions.

These variables are shown on the following figure along with the “Fundamental

Interdependency Equation”.

15 cm=Dead Zone < NBD < Full < Empty < FBD < Maximum range=8 meter

See also the section: Interdependencies in this chapter.

Page 14

Page 16

) Distance to Empty Level

B

istance to empty level is defined as the distance from the face of the sensor to the

D

ottom-most surface of the target to be measured. For typical installation in tanks,

b

he bottom-most surface is usually the floor of the tank.