Page 1

Series UL Transmitters

TM

Specifications - Installation and Operating Instructions

Bulletin L-UL

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

able of Contents

T

hapter 1. Introduction

C

pecifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

S

Measuring Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Chapter 2. Installation

recautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

P

nstalling the Unit on Threaded Flange/Thread-Free Flange . . . . . . . . . . . . . . . .3

I

nstalling the Unit via Extension Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

I

sing a Conduit Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

U

Non-Intrinsically Safe Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Power Supply and Load Resistance Recommendations . . . . . . . . . . . . . . . . . . .4

hapter 3. Set Up

C

eries UL Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

S

et Up and Function Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

S

Resetting the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Entering Distance to Empty Level (Tank Height) . . . . . . . . . . . . . . . . . . . . . . . . . .6

Defining Interfering Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Configuring 4 mA Current Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

onfiguring 20 mA Current Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

C

electing Low/High Dynamic Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

S

efining Working Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

D

Selecting Distance or Level Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Entering Factor for Gas Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Restoring the Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Shifting the Blocking Distance (SBD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

erifying the Version Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

V

efining 22 mA Signal Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

D

Chapter 4. Open Channels (ULF)

Selecting the Flow Measurement Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Open Channel Flow Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Flume/Weir Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Flumes/Weirs - European Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Rectangular Suppressed Sharp - Crested Weir (Type 1) . . . . . . . . . . . . . . . . . .11

Rectangular Contracted Sharp - Crested Weir (Type 2) . . . . . . . . . . . . . . . . . . .11

Trapezoidal (Cipolletti) Sharp - Crested Weir (Type 3) . . . . . . . . . . . . . . . . . . . .11

V-Notch (Triangular) Sharp - Crested Weir (Type 4) . . . . . . . . . . . . . . . . . . . . . .11

Khafagi-Venturi Flume (Type 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Parshall Flume (Type 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Palmer Bowlus Flume Trapezoidal Throat Cross-Selection (Type 7) . . . . . . . . .12

H Flume (Type 8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Neyrpic Venturi Flume/Long-Base Weir (Type 9) . . . . . . . . . . . . . . . . . . . . . . . .13

Flumes/Weirs – American Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Rectangular Suppressed Sharp - Crested Weir (Type 1) . . . . . . . . . . . . . . . . . .13

Rectangular Contracted Sharp - Crested Weir (Type 2) . . . . . . . . . . . . . . . . . .13

Trapezoidal (Cipolletti) Sharp - Crested Weir (Type 3) . . . . . . . . . . . . . . . . . . . .13

V-Notch (Triangular) Sharp - Crested Weir (Type 4) . . . . . . . . . . . . . . . . . . . . . .13

Parshall Flume (Type 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Palmer Bowlus Flume Trapezoidal Throat Cross-Selection (Type 6) . . . . . . . . .14

H Flume (Type 7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Leopold-Lagco Flume (Type 8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

able of Figures

T

igure 1: Front and Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

F

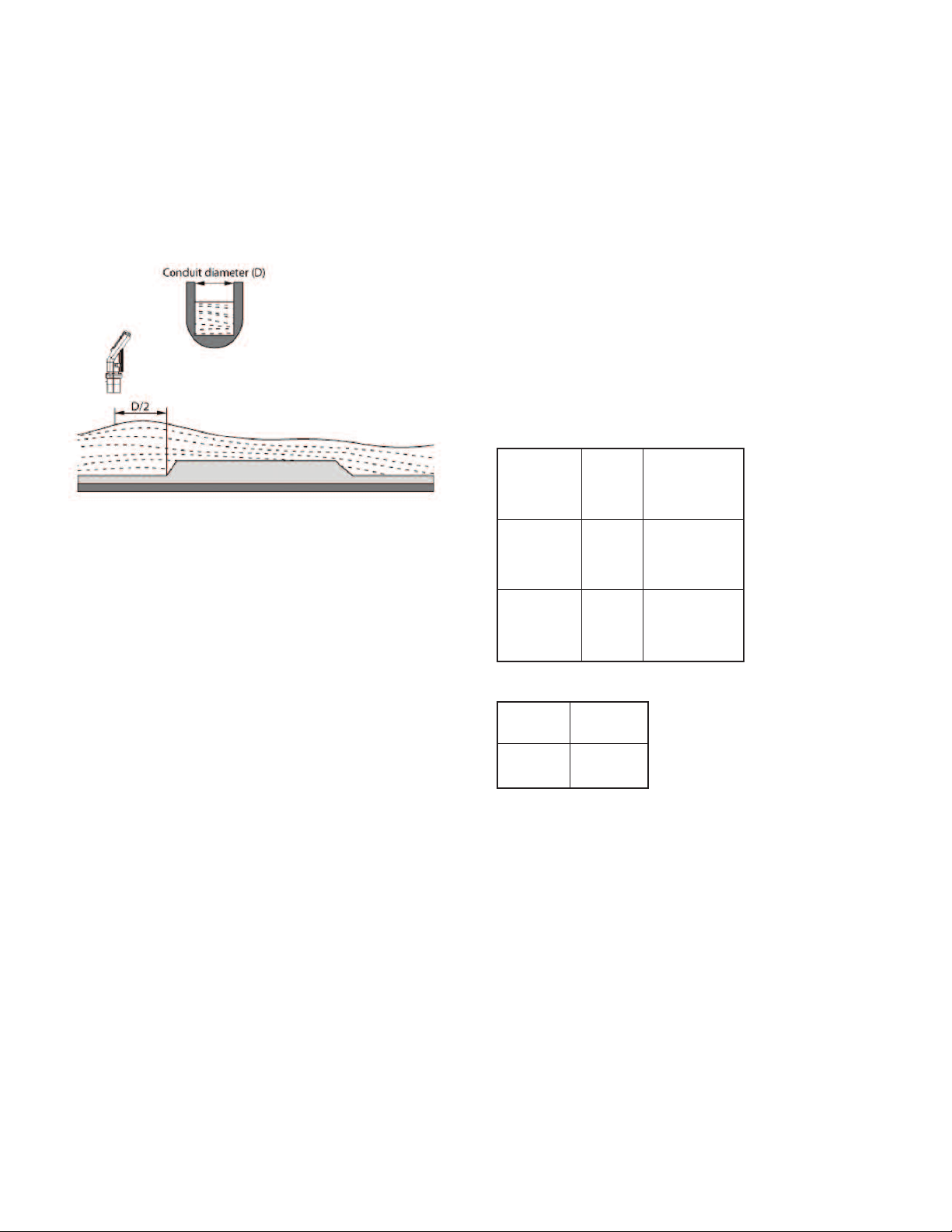

igure 2: Threaded Flange/ Thread - Free Flange Monitoring . . . . . . . . . . . . . . . . .3

F

Figure 3: Extension Pipe Recommendation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Figure 4: Conduit Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Figure 5: Non-Intrinsically Safe Positive Ground Connection . . . . . . . . . . . . . . . . . .4

igure 6: Non-Intrinsically Safe Negative Ground Connection . . . . . . . . . . . . . . . . .4

F

igure 7: Functions Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

F

igure 8: Display and Function Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

F

igure 9: Scan Distance Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

F

Figure 10: Defining Working Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Figure 11: Rectangular Suppressed Sharp - Crested Weir . . . . . . . . . . . . . . . . . . .11

Figure 12: Rectangular Contracted Sharp - Crested Weir . . . . . . . . . . . . . . . . . . . .11

igure 13: Trapezoidal (Cipolletti) Sharp - Crested Weir . . . . . . . . . . . . . . . . . . . . .11

F

igure 14: V-Notch (Triangular) Sharp - Crested Weir . . . . . . . . . . . . . . . . . . . . . . .11

F

igure 15: Khafagi-Venturi Flume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

F

Figure 16: Parshall Flume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Figure 17: Palmer Bowlus Flume Trapezoidal Throat

Figure 18: H Flume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

igure 19: Neyrpic Venture Flume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

F

igure 20: Long-Base Weir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

F

igure 21: Rectangular Suppresses Sharp - Crested Weir . . . . . . . . . . . . . . . . . . .13

F

Figure 22: Rectangular Contracted Sharp - Crested Weir . . . . . . . . . . . . . . . . . . .13

Figure 23: Trapeziodal (Cipolletti) Sharp - Crusted Weir . . . . . . . . . . . . . . . . . . . . .13

Figure 24: V-Notch (Triangular) Sharp - Crested Weir . . . . . . . . . . . . . . . . . . . . . .13

Figure 25: Parshall Flume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

igure 26: Palmer Boweus Flume Trapezoidal Throat

F

igure 27: H Flume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

F

Figure 28: Leopold Lagco Flume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Figure 29: Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Cross-Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

ross-Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

C

Chapter 5. Troubleshooting

22 mA Signal Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Appendix A – Gas Factor Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Appendix B – Installation Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Appendix C – Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Page 1

Page 3

hapter 1: Introduction

C

he unit is available in three separate series: The ULB for solids, the ULL for

T

iquids, and the ULF for open channel flow liquids.

l

Depending on the series, the unit can be used for the following measurement tasks:

• Dust-free tanks with solids (ULB)

• Open channel flow (ULF)

Liquid tanks with calm surfaces (ULL)

•

he ULF and ULL have a range of up to 49.21 ft (15 m) with an accuracy of 0.25%

T

f the maximum measuring range (version dependent).

o

The ULB has a range of up to 28 ft (8.5 m) with an accuracy of 0.25% of the

maximum measuring range (version dependent).

Figure 1 : Front and Side View

PECIFICATIONS

S

ervice: ULB: Bulk solids, ULF/ULL: Compatible liquids.

S

etted Materials: Sensor: Polypropylene or PVDF (upon request), Acoustic

W

indow: ECTFE.

W

Ranges: (see “Measuring Ranges”).

Accuracy: 0.25% of max range (at 20°C).

Resolution: 0.04˝ (1 mm).

lind Zone: (See “Blind Zone”).

B

eam Angle: 5° @ 3db point.

B

emperature Limits: -40 to 158°F (-40 to 70°C).

T

emperature Compensation: Automatic.

T

Pressure Limits: 13.5 psi (0.9 bar) to 30 psi (2 bar).

Power Requirement: 18 to 28 VDC.

Output Signal: 4 to 20 mA.

ax. Loop Resistance: 727 Ω at 28 VDC.

M

lectrical Connection: Screw terminal.

E

onduit Connection: 1/2˝ NPT conduit or cable gland (optional).

C

Process Connection: 2˝ NPT or 2˝ BSP (optional).

Enclosure Material: ABS and UV resistant.

Enclosure Rating: NEMA 4 (IP65).

Mounting Orientation: Vertical.

emory: Non-volatile.

M

isplay: 4 character LCD.

D

nits: ft, m (upon request).

U

Programming: 4 button.

Weight: 3.1 lb (1.4 kg).

Measuring Ranges

0.82 to 11.5 ft

0.25 to 3.5 m

1.96 to 28 ft

.6 to 8.5 m

0

.82 to 16.4 ft

0

0.25 to 5 m

1.96 to 49.2 ft

0.6 to 15 m

0.82 to 16.4 ft

0.25 to 5 m

1.96 to 49.2 ft

0.6 to 15 m

LB for solids

U

ULF for openchannel flow

ULL for liquids

tandard

S

Extended

Range

Short

Range

Standard

Short

Range

Standard

Blind Zone (Measured from the tip of the sensor)

ULB-11

ULL-1XXX

ULF-X1-XXX

ULB-12

ULL-2XXX

ULF-X2-XXX

0.8 ft (0.25 m)

1.96 ft (0.6 m)

Page 2

Page 4

hapter 2: Installing the Unit

C

recautions

P

Ensure that the unit is mounted in an area that meets the stated temperature,

•

pressure and technical specifications.

• Ensure that high-voltage sources or cables are at least 40˝ (1 m) away from the

sensor and its cable.

Use round cables with minimum diameter of 0.24 to 0.28˝ (6 to 7 mm) to ensure

•

hat the unit remains sealed per IP65 standards.

t

Ensure that cables are routed correctly and tightened along walls or pipes.

•

Installation and operation of this product should be performed according to the

•

Product Installation and Operating Instructions. Otherwise the use of this product

is prohibited.

hen installing the unit ensure that it is:

W

Mounted above the dead-zone area.

•

OTE: If the device enters the blocking distance (dead- zone

N

or blind zone), it will not measure correctly.

• Positioned at least 1.64 ft (0.5 m) away from the tank walls.

Add 4˝ (10 cm) spacing for each 40˝ (1 m) in range.

nstalling the Unit on Threaded Flange/Thread-Free Flange

I

he unit is available in 2˝ NPT or 2˝ BSP (upon request).

T

he unit can be installed with threaded-flange mounting or with thread-free flange

T

mounting, as shown below:

igure 2: Threaded Flange/Thread-Free Flange Mounting

F

OTE: When installing a thread-free flange mounted unit, you will need a 2˝

N

(50.8 mm) locking nut to secure the unit inside the tank.

To Install the Unit:

1. Insert the threaded end of the unit into the opening at the top of the tank or pipe.

. Bolt the unit into place in one of the following ways:

2

Threaded-flange mounting: Screw the unit into a flange with a threaded

•

˝ (50.8 mm) hole.

2

• Thread-free mounting: Place the unit in the flange, and bolt it from within

the tank with a 2˝ (50.8 mm) locking nut.

• Perpendicular to the surface of the target.

NOTE: Even the slightest difference in angle may affect echo

quality.

• Placed as far as possible from noisy areas, such as a filling

inlet.

NOTE: When installed in a humid environment it is

recommended to position the sensor on a tripod on top of the

vessel.

NOTE: Tighten the locking nut hand tight only. When tightening the nut, hold the

lower part of the unit, and make sure that the seal is leak proof.

Page 3

Page 5

nstalling the Unit Via Extension Pipes

I

f the level of the measured surface falls within the dead-zone, (blind zone) area,

I

ou should use an extension pipe to mount the unit.

y

When using an extension pipe, ensure that:

• The sensor is positioned in the center of the pipe.

• The pipe extension is exactly perpendicular to the surface

f the target.

o

The internal pipe diameter is at least 3.0˝ (76.2 mm) wide.

•

The pipe is preferably made of plastic and must have a

•

mooth interior surface.

s

• The pipe should not protrude inside the tank.

• The tank opening should be at least the size of the internal

pipe diameter and have a smooth edge.

hen installing the unit with extension pipes, measure from sensor’s lower edge

W

nd follow these specifications:

a

ipe Length

P

1.64 ft (0.5 m)

OTE:

N

. It is always recommended to use the interference signal feature (Pr03) to locate

1

nterfering signals when using an extension pipe.

i

2. The sensor's lower edge may be

a) aligned with the extension pipe's upper edge or

b) protrude it by up to 2.56˝ (6.5 cm). See Figure 3 below:

Internal Pipe Diameter

≥ 3.0˝ (76.2 mm)

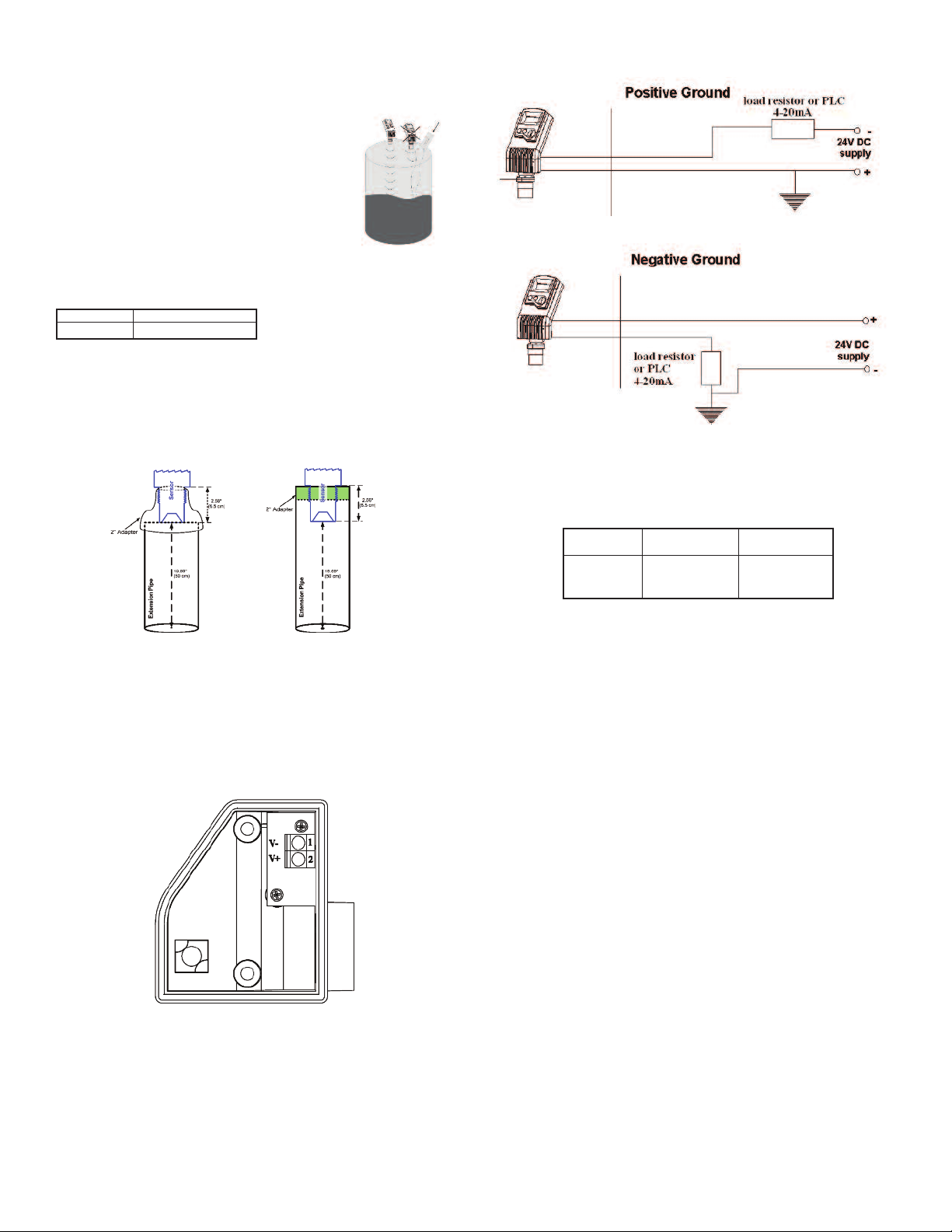

on-Intrinsically Safe Connections

N

Figure 5: Non-Intrinsically Safe Positive Ground Connection

Figure 6: Non-Intrinsically Safe Negative Ground Connection

ower Supply and Load Resistance Recommendations

P

The following table specifies the recommended resistance range for each power

supply voltage (Non-Intrinsically Safe).

Power Supply

Voltage

18 V

24 V

28 V

Minimum

Resistance Value

0 Ω

41 Ω

68 Ω

Maximum

Resistance Value

272 Ω

545 Ω

727 Ω

a

Figure 3: Extension Pipe Recommendation

Using a Conduit Adapter

1. Remove the four retaining screws from the conduit adapter cover.

2. Pull the electrical wires through the 1/2˝ NPT conduit connection or gland.

3. Connect the -24 V wire to Terminal 1, connect the +24 V wire to Terminal 2 on

the wiring block.

4. Return the adapter's cover to its place properly. Make sure that the O-ring is

placed correctly. Fasten the four retaining screws.

Figure 4: Conduit Adapter

NOTE: The conduit adapter should not exceed a torque of 50 lb-in.

To maintain a proper seal, make sure that conduit is firmly screwed to the conduit's

adaptor.

b

NOTE: The resistance value is the total sum of the series resistor (or PLC

resistance) and the lines resistance. The minimum voltage level on terminals

should not be less that 18 VDC.

To maintain a proper seal, make sure that conduit is firmly screwed to the conduit's

adaptor.

Ripple/Noise Parameters Recommended for the Power Supply

The following ripple/noise parameter is recommended for the power supply:

• 100 mV p-p max.

Power Supply Types Recommendations

• Prefer a regulated switching power supply.

• A rectified power supply is not recommended.

• When powering by a battery, avoid the using of switched charger.

Feeding Via PLC

• Verify that the voltage level on the unit’s terminals is at least 18 VDC.

• Check PLC specifications for grounding options.

• It is good practice to add a 150 Ω series resistor between the unit's positive

terminal and the PLC.

Page 4

Page 6

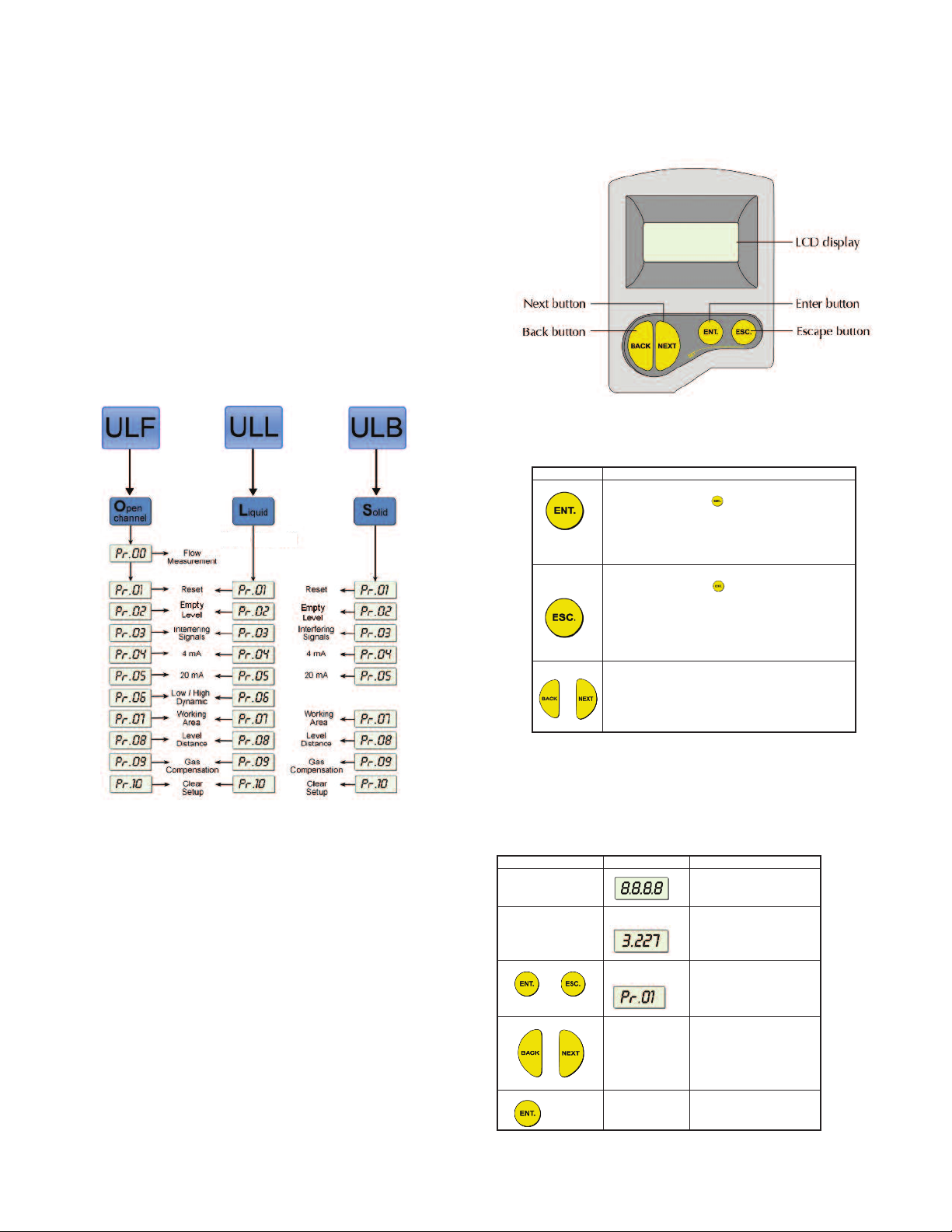

hapter 3: Setting Up and Calibrating the Unit

C

his chapter explains how to set up and calibrate the unit for accurate

T

easurement monitoring.

m

he unit is supplied with preprogrammed default settings, making it ready for

T

immediate operation. There is no need to change the default settings, unless you

wish to calibrate the unit for your specific requirements; however, it is

recommended that you replace the default tank height value with the actual tank

eight, as described on page 6. When using the unit, the tank height is calculated

h

s the distance from the surface of the sensor to the bottom of the tank. You should

a

nter this value whenever tank height is required. (For flow measurement, enter the

e

recise flume height.)

p

The ULF, ULL and ULB units contain eleven, ten and nine programs respectively.

These programs are referred to as functions, which enable you to change the

efault settings and calibrate as required. These functions are accessed from a

d

unctions menu. The functions Pr01, Pr02, Pr04 and Pr05 are the most important

f

o ensure correct usage of your device (with the addition of Pr00 if using the

t

appropriate ULF series). Function Pr03 may be used if there are interfering signals.

The remaining functions (Pr06, Pr07, Pr08, Pr09 and Pr10) enable you to

customize the unit for your monitoring requirements or to restore factory default

settings.

he diagram below shows the functions available in the functions menus for the

T

eries ULF, ULL and ULB. Some functions are only relevant for particular series.

S

sing Series UL Functions

U

he LCD display screen, functioning in "normal" mode, provides continuously

T

pdated measurement readings. The display screen is also used to view the

u

enu options, function settings and data values, accessed by using the function

m

buttons.

The picture below shows the upper part of the unit.

Figure 8: Display and Function Buttons

The function buttons are used to perform various operations, summarized in the

ollowing table.

f

utton

B

Uses Include:

• Accessing the functions menu (when pressed

simultaneously with )

Selecting functions

•

Progressing to the next step of a function

•

• Moving from left to right between displayed digits

• Saving changes to data

• Accessing the functions menu (when pressed

simultaneously with )

• Exiting the functions menu to restore the

distance reading

• Moving from right to left between displayed digits

• Exiting a function without saving changes

• Clearing error messages

• Scrolling through the functions menu

• Scrolling through available data values in

functions

• NEXT button only: Recording interfering signals

or

Figure 7: Function Menus

Setting flow measurement parameters (function Pr00) for the Series ULF (Open

Channels) is described in Chapter 4, Open Channels (ULF). Setting parameters

for all other functions and accessing the functions are described in this chapter.

NOTE: Within some functions, the digits in the displayed value can be individually

modified. This is indicated by a flashing digit (flashing digits are shown in gray in

the display illustrations. In this case, the ENT and ESC buttons enable you to move

between the digits. Each flashing digit can be modified using the BACK and NEXT

buttons.

Start Up and Function Access:

Page 5

Press/Action

Connect unit to

power supply

After a brief pause

and

(simultaneously)

or

Display:

For example:

For example:

Explanation

Temporary display while

unit takes a reading.

Distance reading.

Enters the functions

menu.

Used to search for the

required menu selection.

Accesses the selected

function.

Page 7

OTE: If an error message appears, press the ESC button to return to the

N

ain menu.

m

alues are displayed in feet and inches or meters and centimeters (model

V

ependent).

d

Resetting the Unit

he Pr01 function enables you to do a reset by refreshing the measurement

T

eading. (Other saved function settings are not changed.) After resetting, the actual

r

eading is displayed on the LCD, and the unit begins to scan (same as in turning

r

he unit on/off).

t

The reset function may sometimes be required after changing one of the settings

or after receiving an error message.

OTE: During reset the unit will display 8.8.8.8 followed by 22 mA current output.

N

To Reset The Unit:

Press/Action

and

(simultaneously)

fter a brief pause

A

and

simultaneously)

(

Display

or example:

F

Explanation

Required menu selection.

Temporary display while

unit takes a reading.

Distance reading.

Returns to the functions

menu.

efining Interfering Signals

he Pr03 function enables you to locate and store up to six interfering signals (false

T

choes) in the unit’s memory to avoid having obstructions, such as a tank agitator

e

or a sidewall, interfering with the measurement of the contents. Defining interfering

signals is done while the tank is empty.

Each reading (scan distance) taken using the Pr03 function is stored as an

interfering signal, until a reading is achieved that indicates the real echo. If six

interfering signals are already stored, the next read values will not be saved.

OTE: The reading of the actual target height may not be exact, for example, a

N

arget height of 19.69 ft (6 m) may give a reading in the range 19.62 to 19.75 ft (5.98

t

to 6.02 m).

The displayed values are in distance units.

D

igure 9: Scan Distance Process

F

Use Pr02 function to enter the distance from sensor face to empty level of the tank.

When sensor face coincides with tank top, enter the height of the tank. Default

value is the maximum range for your model. If you enter a value that exceeds this

highest value, an Err error message is displayed and the value is not saved.

NOTE: For flow measurements, enter the precise distance from the sensor to the

bottom of the flume.

Modified to read between 0 and 5 (feet) U.S. Standard Units or between 0 and 1

(meters) metric units (model dependent).

To Enter Tank Height Value:

Press/Action

Entering Distance to Empty Level (Tank Height)

Display

For example:

or

or

OR

Explanation

Required menu selection.

Indicates the measurement unit in feet

(F) or meters (M) (upon request).

Displays last saved tank height or

default value (maximum value in range).

Used to enter a new value.

To save the new value, press when

standing on the far right digit. After YES

is displayed, the display returns to the

functions menu.

To return to the main menu without

saving, press when standing on the

far left digit.

To Define Interfering Signals:

Press/Action

or

After a brief pause

NOTE: If the value represents an interference, false echo or false target: press

NEXT. If the value represents the real target, real distance: press ENT.

Display

For example:

For example:

Explanation

Required menu selection.

Select Search to locate acoustic

interferences, or Clear to delete stored

interferences.

Displayed after the selection for 3

seconds and then the menu returns to

Pr03.

Temporary display while the unit

searches for interfering signals.

Depth to interfering signal.

Saves the interfering signal, then

searches again and displays the next

reading. Continue to press this button to

save up to six interference readings.

Actual target height reading indicates

that there are no more interfering

signals.

Saves the entered values.

Page 6

Page 8

onfiguring 4 mA Current Output

C

r04 function enables you to enter values to be used as the 4 mA mark for remote

P

onitoring. You can define the 4 mA values for level, distance or flow

m

measurements (depending on series). The measurement value types should be

defined in Pr04. These definitions will be applicable as well for the 20 mA values

defined in Pr05.

o set 4 mA and 20 mA for level measurements you should configure Pr04 and

T

r05 for level values.

P

or example, if we measure a tank with tank height configured for 16.4 ft (5.0 m),

F

the 4 mA values will represent zero tank level and 20 mA values will represent full

tank level. Therefore, the value entered in Pr04 will be 0.0 ft (0.0 m) and the value

entered in Pr05 will be 16.4 ft (5.0 m).

hen setting 4 mA and 20 mA for distance measurements, 4 mA values will

W

epresent the minimal distance between the surface of the target and the sensor,

r

and 20 mA values will represent the maximal distance between the sensor and the

surface of the target. Therefore, 4 mA represents the full part of the tank and 20 mA

represents the empty part of the tank.

Press/Action

or

or

isplay

D

For example:

For example:

Explanation

Required menu selection.

elect the format for 4 mA and 20 mA

S

alues to level (L000), distance (d000)

v

or flow (F000) (depending on model).

Last saved 4 mA level or zero default

value.

Used to enter a new value.

onfiguring 20 mA Current Output

he Pr05 function enables you to enter values to be used as the 20 mA mark for

T

emote monitoring.

r

To Enter 20 mA Values:

P

NOTE: The type of measurement (level, distance or flow) selected in Pr04 is also

applicable for Pr05.

The values for 4 mA and 20 mA must be different; otherwise an Err (error message)

is displayed.

C

ress/Action

r

o

r

o

R

O

isplay

D

or example:

F

xplanation

E

equired menu selection.

R

ast saved 20 mA level or default value

L

maximum value in range).

(

Used to enter a new value.

o save the new value, press when

T

tanding on the far right digit. After YES

s

s displayed, the display returns to the

i

functions menu.

o return to the main menu without

T

aving, press when standing on the

s

ar left digit.

f

or

To save the new value, press when

standing on the far right digit. After YES

is displayed, the display returns to the

functions menu.

To return to the main menu without

saving, press when standing on the

far left digit.

NOTE: The values for 4 mA and 20 mA must be different, otherwise an Err (error

message) is displayed.

The values for 4 mA and 20 mA should not be greater than the value used for the

tank height (Pr02). Because of the dead-zone (blind zone), the distance between

the sensor and the surface of the target at its highest level should be a minimum of

0.82 ft (0.25 m) for ULB Standard Range as well as the ULL and ULF Short Range

models. There should be a 1.96 ft (0.6 m) minimum distance for the ULB Extended

Range as well as the ULL and ULF Standard Range models.

The first digit of the 4 mA value can be modified to read between 0 and 5 (feet) for

U.S. Standard Units or between 0 and 1 (meters) metric units (upon request).

After accessing the Pr04 function, the unit generates a fixed current of 22 mA on

the 4 to 20 mA line. When the unit reverts to regular scanning mode, the 4 to 20

mA line returns to regular functioning.

The default measurement values for 4 mA and 20 mA in both the ULB and ULL

models are level.

The default measurement values for 4 mA and 20 mA in ULF Open Channel Series

are flow. When changing from one measurement mode to another, the

measurement units will be changed automatically (for example, when changing

from (F) feet to (M) meters, the units will change from feet to GPM or meters to

M3/H (depending on the model).

The values for 4 mA and 20 mA should not be higher than the value used for the

tank height (Pr02).

The first digit of the 20 mA value can be modified to read between 0 and 5 for U.S.

Standard Units or between 0 and 1 for metric units (model dependent).

After accessing the Pr05 function, the unit generates a fixed current of 22 mA on

the 4 to 20 mA line. When the unit reverts to regular scanning mode, the 4 to 20

mA line returns to regular functioning.

Please refer to Chapter 5 Troubleshooting for 22 mA error indications.

The measurement mode selected for the 4 to 20 mA values will not influence the

measurement mode selected for the display (Pr08). In case of power rest,

measurement configuration (level, distance, flow) will be saved according to the

unit's last configuration.

Page 7

Page 9

electing Low/High Dynamic Speed (ULF and ULL Series Only)

S

he Pr06 function enables you to choose the required speed level. There are two

T

ettings available:

s

• SE 0: Low dynamic mode (default setting). This mode provides slower readings

with a greater degree of accuracy (rate of up to 31˝/80 cm per min).

• Fail-Safe: 10 minutes.

SE 1: High dynamic mode. This mode provides faster readings but with less

•

recision (rate of up to 39˝/100 cm per min).

p

Fail-Safe: 3 minutes.

•

NOTE: Fail-Safe timer determines the waiting period from an echo loss until a

transmission of an error signal.

o Select the Speed Mode:

T

ress/Action

P

isplay

D

xplanation

E

equired menu selection.

R

o Define a Working Area:

T

Press/Action

r

o

Display

For example:

Explanation

Required menu selection.

isplayed when entering the function.

D

Displays the value last saved in the tank

height (default). The entered value

hould not be more than double the tank

s

eight and should not exceed the unit's

h

aximum measuring range.

m

sed to enter a new value.

U

Displays the current

peration mode setting.

r

o

r

o

The Pr07 function allows you to add distance range that exceeds the tank's height,

thus enabling accurate readings of complicated tank shapes with conic ending. This

may be required when the vessel has a conical bottom shape, which is causing

false echoes and consequently faulty measurements. The minimal value can be the

entered tank height and the maximal value can be double the value of the entered

tank height. The default setting is the entered tank height.

Defining Working Area

o

Used to toggle between

the operations modes.

aves the selected

S

operation mode.

or

Saves the entered value.

Used to move on to the next function.

r

o

electing Distance or Level Display

The Pr08 function enables you to choose whether the unit displays either distance

or level measurements. There are two settings available:

• d000: Distance mode (default setting): In this mode, the unit displays the distance

• L000: Level mode: In this mode, the unit displays the level of the contents from

NOTE: The measurement mode selected for the display will not influence the

measurement mode selected for the 4 to 20 mA values (Pr04).

To Select Distance or Level Display:

S

from the sensor to the surface of the contents.

the bottom of the tank.

Press/Action

Display

or

Explanation

Required menu selection.

Displays the current

distance/level mode setting.

Figure 10: Defining Working Area

NOTE: It is recommended to use the Pr07 function only in distance mode.

Used to toggle between the

modes.

or

Saves the selected mode.

Page 8

Page 10

ntering Factor for Gas Compensation

E

unction Pr09 enables you to compensate for sound velocity changes in different

F

ypes of gasses. You can enter the appropriate factor for each type of gas listed on

t

the “Gas Factor Table” (Appendix A). For example, the sound velocity in air (at

room temperature) is 1125 ft/sec (343 m/sec) and for Methane (Ch

(445.82 m/sec). Therefore, a factor of 1463/1125 = 1.30 should be entered to

ompensate for this type of gas. This factor will compensate in cases when the gas

c

ompound consists of 100% Methane. In case the gas is not pure, the sound

c

elocity cannot be estimated and therefore a minor deviation could appear. It is

v

ecommended to use a reference measurement indicator (using a tape or other

r

) 1463 ft/sec

4

measuring device) and compare the measurement results between the unit and the

reference measurement indicator. If the result is correct, press ENT. If the accuracy

deviation is higher than expected, continue and calibrate the factor to meet the gas

aintained in the vessel. For example, if the gas composition consists of water and

m

as, you can add ± 0.01 to the factor figure already entered to meet your

g

pplication requirements.

a

The “Gas Factor Table” supports up to 32 different types of gasses. For any other

type of gas, not included in this table, please contact Dwyer Customer Support,

(www.dwyer-inst.com).

ress/Action

P

isplay

D

xplanation

E

equired menu selection.

R

Default screen.

efault value.

D

Choose a factor from the “Gas Factor

Table” (Appendix A).

or

or

For example:

This is the factor for Ethanol.

Saves the chosen gas factor.

NOTE: Repeat this procedure if the measurement results differ from the actual

material level measured with a reference tape (or other reference measurement

method). Add or reduce 0.01 to calibrate the factor figure already entered.

Updated on-screen results may take a few seconds to appear.

hifting the Blocking Distance (SBD)

S

his function enables you to define an area in which measurement results would

T

e ignored. This option is applicable for installations requiring extension pipes or

b

ozzles positioned above the material level. This area should approximately fit the

n

pipe/nozzle length to eliminate false echoes and to provide accurate and stable

measurement readings.

To Shift the Blocking Distance:

•

ollow the directions given for Entering Distance to Empty Level (Tank Height),

F

age 6. Instead of entering the tank height value, enter 00.01, and continue as

p

ollows:

f

ress/Action

P

isplay

D

xplanation

E

nsert this code to enter the blocking

I

istance area.

d

This message will flash for a few

seconds, indicating an entry to the

blocking distance area.

or example:

r

o

r

o

OTE: Shifting of the blocking distance is limited to 4.9 ft (1.5 m). The value

N

ntered to the SBD incorporates the dead zone (blind zone) Value.

e

F

hifts the blocking distance to 2.46 ft

S

0.75 m).

(

aves this entry and returns to Pr02.

S

Pr10 (Clear) reverts the blocking distance to its default.

Echo received from the defined blocking distance area will be ignored by the unit

and the measurement result will be based on the next echo.

When installing via extension pipe, it is recommended to keep approx. 2˝ (5 cm)

gap between the shortest distance to target (maximal level) and the lower pipe

edge. Set the SBD length to a value that is 2˝ (5 cm) smaller than the distance from

the sensor's lower edge to pipe's lower edge, in order to avoid second harmony

interference.

Verifying the Version Number

In addition to the functions described, you can verify the UL series version

number.

The Pr10 function allows clearing all user-defined settings and reverting to the

Restoring the Default Settings

default factory settings.

Default factory settings are:

Pr00: GPM 1U01 or M³/Hr 1E01

Pr02: Sbd 00.00, E000, Tank Height =default

Pr03: Resets all interfering signals

Pr04: Solid/Liquid device L000, 00.00 or

Flow device F000, 00.00

Pr05: Solid/Liquid device Tank Height = Pr02

Flow device 55500 M³/Hr or 244400 GPM

Pr06: SE 0 (Liquid and Flow)

Pr07: Tank Height = Pr02

Pr08: Solid/Liquid device d000

Pr09: 01.00

NOTE: If you decide not to revert to the default settings, press ESC when CLCL is

displayed. A redo option is not available when ENT has been pressed.

To Restore the Default Settings:

Press/Action

Display

Explanation

Required menu selection.

Reverts all settings to default factory

settings.

• To Verify the Version Number:

Follow the directions given for Entering Distance to Empty Level (Tank Height),

page 6. Instead of entering the tank height value, enter 00.17, and continue as

follows:

Press/Action

Display

Explanation

After a brief pause

Displays the version number.

Page 9

Page 11

efining 22 mA Signal Error Messages

D

he unit allows you to define if the following signal error indications: Near Zone and

T

ost Echo, will be active when the current output reaches 22 mA. The default

L

etting enables 22 mA analog current and error messages to appear on its LCD

s

display.

hapter 4: Open Channels (ULF)

C

his section describes how to set flow measurement parameters for open channels

T

nd explains the flume/weir codes methodology used when setting up flow

a

easurements.

m

Near Zone - Whenever the distance is below the defined Dead Zone (depending

n the series you are using) message will be displayed on the LCD.

o

ost Echo - Whenever the echo is lost, or in cases when the measurement results

L

xceed the tank height or when a returned echo is not received, message will

e

be displayed on the LCD.

You can choose to enable or disable these error messages and 22 mA analog

ignal as follows:

s

d000: Disable

•

E000: Enable (default setting)

•

Refer to Chapter 5, Troubleshooting for a detailed list of the 22 mA signal error

messages.

To Disable/Enable 22 mA Signal Error in the Unit:

•

ollow the directions given for Entering Distance to Empty Level (Tank Height),

F

age 6. Instead of entering the tank height value, enter 00.16, and continue as

p

follows:

Press/Action

Display

xplanation

E

hoose disable.

C

Used to toggle between the modes.

r

o

Disables the 22 mA error messages.

NOTE: When the error signals are disabled the following current outputs will be

displayed:

(Level or flow measurement): will indicate 20 mA and will indicate 4

mA.

(Distance measurement): will indicate 4 mA and will indicate

20 mA.

Selecting the Flow Measurement Settings

he Pr00 function enables you to select one of the preset flumes/weirs settings for

T

low measurements. This function is available only in the ULF Open Channel

f

eries. When setting flow measurement parameters in the Pr00 function, the

s

lume/weir type value (X) is entered first, followed by the letter (U) or (E) that

f

represents either American (USA) or European standard flume/weir. The code

value (YY) represents the appropriate flume/weir dimensions in the following

format: . The open channel types and codes are described in Open Channels

low Measurement.

F

OTE: Refer to Chapter 3, Setting Up and Calibrating the Unit, for an explanation

N

of accessing and using the functions menu.

All flow measurement values are displayed divided by 1000.

To Select the Flow Measurement Settings:

•

Press/Action

isplay

D

xplanation

E

Required menu selection.

For example:

Indicates the measurement unit for flow

in GPM (American standard) or M

3

/h

(metric standard) (upon request).

Displays last saved flow measurement

etting or default value, with first digit

s

lashing U – American standard or E –

f

uropean standard (upon request).

E

Use to select a new type value (X).

or

Last two digits of the display flash.

Use to select a new flume/weir length

code (YY).

or

Selected values are saved.

Open Channels Flow Measurements

The flume/weir type code methodology used when setting up open channels is

based on three digits: X(U/E)YY

Where:

X refers to the particular flume/weir type

U/E refers to either American or European standard flumes/weirs

YY refers to the specific flume/weir dimensions

The types of flumes/weirs are available in American standard or European standard

(upon request). When working in American standard the default flow measurement

units will be GPM, and in European standard the default flow measurement units

will be M³/Hr.

Page 10

Page 12

lume/Weir Types

F

his is the first value (X) entered for the Pr00 function. The following flume/weir

T

ypes are available both in European and American standard:

t

uropean Standard

T

Flumes/Weirs - European Standard

ectangular Suppressed

R

1

harp-Crested Weir, Page 11

S

Rectangular Contracted Sharp-

2

Crested Weir, Page 11

Trapezoidal (Cipolletti) Sharp-

3

rested Weir, Page 11

C

-notch (Triangular) Sharp-

V

4

rested Weir, Page 11

C

hafagi-Venturi Flume, Page 12

K

5

Parshall Flume, Page 12

6

Palmer Bowlus Flume

7

rapezoidal Throat Cross-

T

election, Page 12

S

Flume, Page 12

H

8

Neyrpic Venturi Flume/Long-

9

Base Weir, Page 13

E

ages 11-13

P

ype (X)

American Standard

ages 13-14

P

ectangular Suppressed Sharp-

R

rested Weir, Page 13

C

ectangular Contracted Sharp-

R

Crested Weir, Page 13

Trapezoidal (Cipolletti) SharpCrested Weir, Page 13

-notch (Triangular) Sharp-Crested

V

eir, Page 13

W

arshall Flume, Page 14

P

almer Bowlus Flume Trapezoidal

P

Throat Cross-Selection, Page 14

H Flume, Page 14

eopold-Lagco Flume,

L

age 14

P

Rectangular Suppressed Sharp-Crested Weir (Type 1)

Code (YY)

Figure 11: Rectangular Suppressed Sharp-Crested Weir

Rectangular Contracted Sharp-Crested Weir (Type 2 )

Code (YY)

Crest Length (cm)

1

0

2

0

3

0

04

05

06

07

08

Crest Length (cm)

01

02

03

04

05

06

07

08

09

10

20

40

60

8

1

1

200

300

20

30

40

50

60

80

100

150

200

300

0

00

50

Trapezoidal (Cipolletti) Sharp-Crested Weir (Type 3)

ode (YY)

C

Figure 13: Trapezoidal (Cipolletti) Sharp-Crested Weir

V-Notch (Triangular) Sharp-Crested Weir (Type 4)

Code (YY)

rest Length (cm)

C

1

0

2

0

03

04

05

06

07

08

V-Notch Angle (°)

01

02

03

04

05

06

07

British Standard

08

09

10

3

4

60

80

100

150

200

300

53.8

28.4

22.5

22.5

0

5

90

60

45

30

90

45

Figure 12: Rectangular Contracted Sharp-Crested Weir

Figure 14: V-Notch (Triangular) Sharp-Crested Weir

Page 11

Page 13

hafagi-Venturi Flume (Type 5)

K

C

igure 15: Khafagi-Venturi Flume

F

Parshall Flume (Type 6)

Code (YY)

ode (YY)

1

0

2

0

3

0

04

05

06

7

0

8

0

9

0

01

02

03

4

0

5

0

06

07

08

09

10

11

12

13

14

15

Flume Type

QV 302

QV 303

V 304

Q

V 305

Q

V 306

Q

V 308

Q

QV 310

QV 313

QV 316

hroat Width (in)

T

1

2

3

6

9

12

18

24

36

48

60

72

96

120

144

0 (cm)

b

1

3

40

50

60

8

1

1

1

almer Bowlus Flume Trapezoidal Throat Cross-Selection (Type 7)

P

01

2

0

3

0

4

0

05

06

07

08

Code (YY)

Flume Size (ft)

2

0

0

00

30

60

igure 17: Palmer Bowlus Flume Trapezoidal Throat Cross-Selection

F

Flume (Type 8)

H

Code (YY)

onduit Diameter (in) D

C

01

2

0

3

0

4

0

5

0

06

07

08

9

0

0

1

0.5

0.75

1

2.5

4.5

Measurement Point (cm)

1

.5

2

3

6

8

10

2

1

5

1

8

1

1

2

24

27

30

5

7

9

4

1

18

23

28

41

Figure 16: Parshall Flume

Figure 18: H Flume

Page 12

Page 14

eyrpic Venturi Flume/Long-Base Weir (Type 9)

N

ode (YY)

C

igure 19: Neyrpic Venturi Flume

F

Code (YY)

Figure 20: Long-Base Weir

Flumes/Weirs - American Standard

Rectagular Suppressed Sharp-Crested Weir (Type 1)

Code (YY)

Venturi Flume Type

01

02

03

4

0

5

0

6

0

7

0

08

09

ong Base Weir Type

L

10

11

12

3

1

Crest Length (in)

01

02

03

04

05

06

07

08

09

253AX

1

253AY

1

253AZ

1

253A

1

1253B

1253C

1253D

253E

1

253F

1

1

1

1245C

1245D

12.00

18.00

24.00

30.00

36.00

48.00

60.00

72.00

96.00

245A

245B

ectangular Contracted Sharp-Crested Weir (Type 2)

R

ode (YY)

C

Figure 22: Rectangular Contracted Sharp-Crested Weir

Trapezoidal (Cipolletti) Sharp-Crested Weir (Type 3)

Code (YY)

1

0

2

0

3

0

04

05

06

7

0

8

0

9

0

01

02

3

0

4

0

5

0

06

07

08

09

Crest Length (in)

12.00

8.00

1

4.00

2

0.00

3

6.00

3

48.00

60.00

72.00

6.00

9

Crest Length (in)

12.00

18.00

4.00

2

0.00

3

6.00

3

48.00

60.00

72.00

96.00

Figure 21: Rectangular Suppressed Sharp-Crested Weir

Figure 23: Trapezoidal (Cipolletti) Sharp-Crested Weir

V-Notch (Triangular) Sharp-Crested Weir (Type 4)

Code (YY)

01

02

03

04

05

Figure 24: V-Notch (Triangular) Sharp-Crested Weir

Page 13

V-Notch Angle (°)

90

60

45

30

22.5

Page 15

arshall Flume (Type 5)

P

Code (YY)

0

0

0

0

05

06

07

0

0

1

1

12

13

14

1

1

igure 25: Parshall Flume

F

Palmer Bowlus Flume Trapezoidal Throat Cross-Selection (Type 6)

Code (YY)

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

hroat Width (in)

T

1

2

3

4

8

9

0

1

5

6

1

2

3

6

9

1

1

2

30

36

48

6

7

9

20

1

144

Conduit Diameter (in) D

2

8

4

0

2

6

4

6

8

10

12

15

18

21

24

27

30

36

42

48

60

72

Flume (Type 7)

H

Code (YY)

eopold-Lagco Flume (Type 8)

L

lume Size (in)

F

01

2

0

3

0

4

0

5

0

06

07

08

Figure 28: Leopold-Lagco Flume

Measurement Point (in)

6

9

12

18

24

0

3

6

3

4

5

Figure 27: H Flume

Code (YY)

01

02

03

04

05

06

0

0

0

10

11

12

13

14

15

16

17

7

8

9

rest Length (in)

C

1.96

2.75

.54

3

.51

5

.08

7

.05

9

11.02

16.14

4

6

8

10

12

15

8

1

1

2

4

2

30

36

42

48

54

60

66

72

Figure 26: Palmer Bowlus Flume Trapezoidal Throat Cross-Selection

Page 14

Page 16

hapter 5 Troubleshooting

C

his chapter describes how to resolve problems that may occur when calibrating

T

he unit as follows:

t

Error

escription

D

1. Noise in area.

(Indicated by 22 mA if the

Error Signals are Enabled).

. Inappropriate power

2

upply/no grounding.

s

aulty power supply.

F

ensor disconnected.

S

ny combination of three 8s and

A

one 1: Indicates an electrical

shortage caused by depressing

the buttons for too long.

ppears for several seconds

A

after restarting the unit. If it is

displayed for more than several

seconds, it may be due to one

of the following:

Power supply voltage is too

•

low

• Load resistor resistance is too

high or unnecessary

A random pulse that causes

•

he unit to automatically restart

t

easurement value is greater

M

than 9999.

In flow mode, appears when the

entered tank height is incorrect.

olution

S

. Get away from noise source.

1

. Check that the power supply is

2

ppropriate/ check grounding

a

connection.

Make sure that the power supply

orresponds with the specifications

c

escribed in Chapter 2, Installing

d

he Unit. If the problem persists,

t

eplace the power supply.

r

Contact Dwyer Technical Support.

Contact Dwyer Technical Support.

Make sure that the power supply

corresponds with the specifications

described in Chapter 2, Installing

the Unit. If the problem persists,

eplace the power supply.

r

Double check the unit configuration

(Tank h, type of flume, 4 to 20 mA

settings.)

Decrease the tank height value.

2 mA Signal Error Messages

2

he following list of messages will appear on the display and coincides with a 22

T

A analog current error output signal (when the error signals messages are

m

nables):

e

Error

escription

D

ensor disconnected.

S

Near dead zone (blind zone).

(Depends on the measurement

efinitions).

d

ank empty. (Depends on the

T

easurement definitions).

m

. Noise in area.

1

(indicated by 22 mA if the

error signals are enabled).

2. Inappropriate power supply/

o grounding.

n

aulty power supply.

F

indicated by 22 mA if the error

(

signals are enabled).

Solution

ontact Dwyer Technical Support.

C

ove the sensor farther from the

M

ead zone (blind zone) area.

d

Check the level of material in the

tank.

1. Get away from noise source.

. Check that the power supply is

2

ppropriate/check grounding

a

onnection.

c

Make sure that the power supply

corresponds with the specifications

described in Chapter 2, Installing

he Unit. If the problem persists,

t

replace the power supply.

Page 15

Page 17

ppendix A

A

ppendix B

A

as Factor Table

G

he following table contains 32 different types of gasses and their factor for

T

compensating the sound velocity:

actor

F

.62

0

.63

0

0.74

0.54

0.99

.26

1

.92

0

.53

0

.41

0

0.37

0.56

0.77

.01

1

.38

0

.68

0

0.71

0.90

0.71

0.95

.93

2

.79

3

0.89

.62

0

.29

1

.71

0

1.30

1.01

0.63

1.02

0.72

0.61

0.57

ymbol

S

C

2h4o2

C3h6o

C

o

2h4

C

2h3c1

C

2h2

H3n

r

A

C

6H6

Br

2

Cbrclf

H

C

C

3

O

C

2

O

C

CCI

4

Cl

2

C2h6o

C

2h6

C2h6o

C

2h4

e

H

H

2

H2S

C

o

3h8

H

C

4

Ch6n

Ne

N

2

CH3NO

O

2

C3H

8

C3H8O

C

4H8

o

2

OCH

2

O

2

Gas

Acetic Acid

cetone

A

cetaldehyde

A

cetyl Chloride

A

cetylene

A

Ammonia

Argon

Benzene

romine

B

romochlorodifluoromrthane

B

utanone

B

H

C

2

3

Carbon Dioxide

Carbon Monoxide

Carbon Tetrachloride

Chlorine

Dimethyl Ether

thane

E

thanol

E

thylene

E

Helium

Hydrogen

ydrogen Sulfide

H

Isopropyl Alcohol

Methane

Methyl Hydrazine

Neon

itrogen

N

itromethane

N

Oxygen

Propane

Propanol

Tetrahydrofuran

nstallation Tips

I

istance to tank walls

D

urface

S

Acoustic noises

Electrical interference

ank installation

T

ank installation

T

Sensor

Extension pipes (1)

xtension pipes (2)

E

Extension pipes (3)

Voltage

A battery

ipple and noise

R

Type

Rechargeable supply

PLC Connections

Barrier

Tank Height,

Level/Distance

4 to 20 settings

5 cm margin

Scan distance (1)

Scan distance (2)

Scan distance (3)

SBD (1)

SBD (2)

1) Choosing Location

ust Be

M

ust Be

M

Must Be

t least 19.69˝ (50 cm) from

A

alls + 3.94˝/3.28 ft (10 cm/1

w

) range.

m

ixed on a horizontal surface.

F

Far away from acoustic

noises and vibrations.

Must Be

ust Be

M

ust Be

M

Shielded away from power

nd sensor cables.

a

ar away from tank inlets,

F

utlets, physical obstacles.

o

ar away from tank inlets,

F

outlets, physical obstacles.

Must Be

Exactly perpendicular to the

surface of the target.

2) Handling Dead Zone

Must Be

Must Be

At least 3˝ (7.62 cm) internal

iameter and 19.69˝ (50 cm)

d

ong (from sensor low edge to

l

ipe low edge).

p

With completely smooth

interior surface.

Must Be

) Power Source

3

Must Be

Installed with a flange/not

rotruding into the tank.

p

At least 12 VDC on unit

terminals.

Must Be

Rated higher than 12 volts

due to normal voltage drop.

ot exceeding 100 mV.

ust Be

M

Must Be

N

Preferably regulated switching

PS (avoid rectified PS).

Must Be

Non operational when

switched to recharge.

4) 2-Wire Interface

Must Be

As specified in the user

manual, preferably grounded.

Must Be

Connected in EX zones,

grounded.

5) Configuration

Must Be

Must Be

Configured correctly.

Defined (consider the

extension pipe).

Must Be

Kept between pipe low edge

and full level.

Must Be

Preferably be executed in all

applications.

Must Be

Executed when the tank is

empty.

Must Be

Performed after the old stored

data is cleared.

Must Be

Set up in flange and

extension pipe installations.

Must Be

At least 1.97˝ (5 cm) before

the pipe edge.

Page 16

Page 18

ppendix C

A

igure 29: Nomenclature

F

MAINTENANCE/REPAIR

Upon final installation of the Series UL, no routine maintenance is required. The

Series UL is not field serviceable and should be returned if repair is needed (field

repair should not be attempted and may void warranty).

WARRANTY/RETURN

Refer to “Terms and Conditions of Sale” in our catalog or on our website. Contact

customer service to receive a Return Goods Authorization number before shipping

your product back for repair. Be sure to include a brief description of the problem

plus any relevant application notes.

Page 17

©Copyright 2013 Dwyer Instruments, Inc. Printed in U.S.A. 6/13 FR# R4-443852-00 Rev. 3

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...