Page 1

Bulletin F-41-TTM

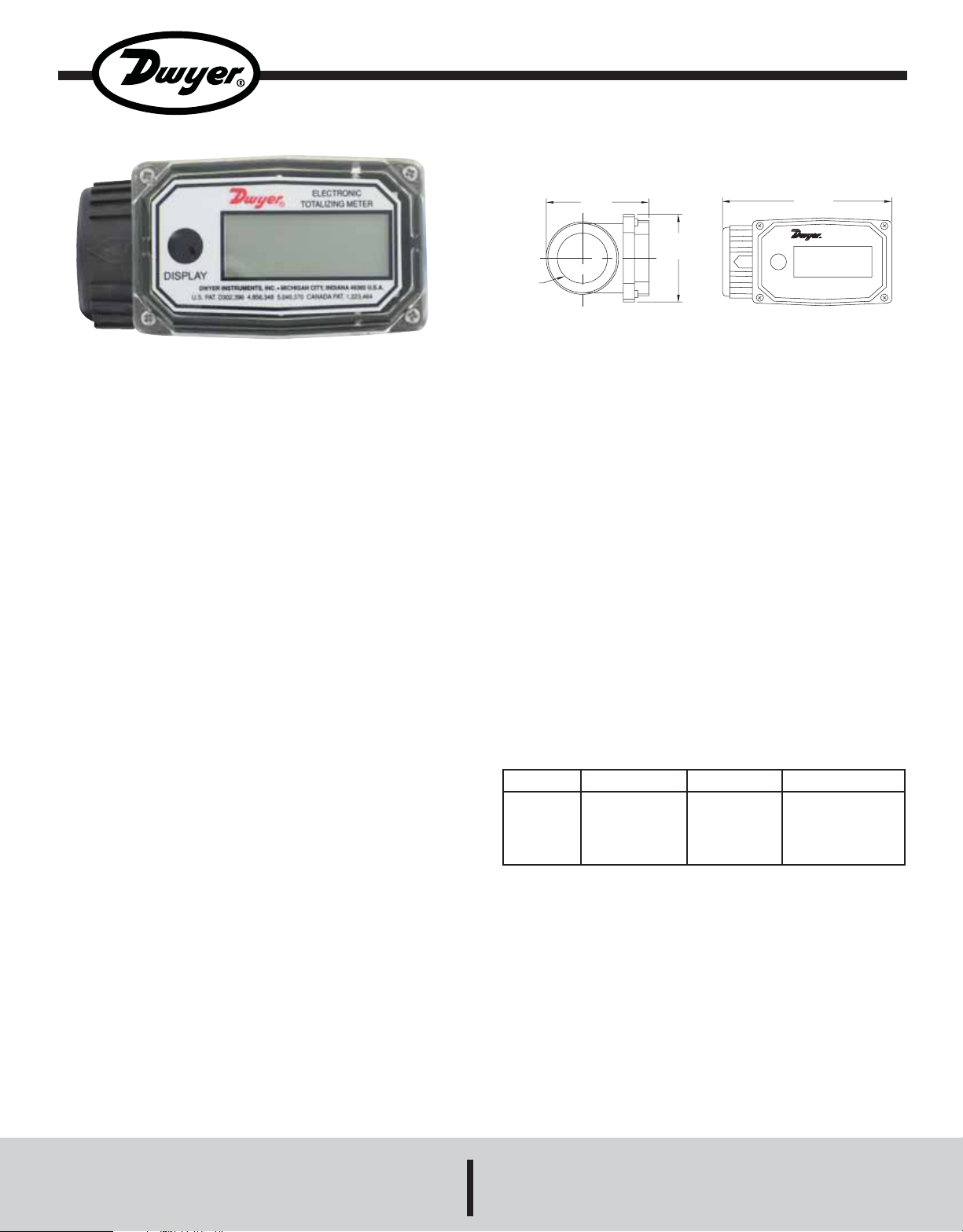

Series TTM Totalizing Flowmeter

Specifications - Installation and Operating Instructions

Measure batch and cumulative totals in liquid transfer systems

with the Series TTM Electronic totalizing Meter. The meter is

designed for any pump, pressure, or gravity feed system with a 3

to 30 GPM (10 to 100 LPM) flow range. View batch and

cumulative totals on the large 4-digit LCD display . Batch totals can

be reset to measure flow during a single use. The cumulative total

will automatically reset to zero when a maximum reading of 9999

is obtained. Models designed for use in water applications are

constructed of Nylon and rated to 150 psig (10.3 bar). Aluminum

models are calibrated for fuels and rated to 300 psig (20.7 bar).

GENERAL INSTALLATION

Battery Connections

1. Remove the four Phillips-head scr ews and lift the faceplate from

meter.

2. Remove tape from the end of one battery.

3. Replace the battery. Make sure the positive post is in the

correct position.

4. Make sure the O-ring is fully seated and secure the faceplate

with the four screws.

Calibration

The meter is permanently factory calibrated for measuring water or

fuels depending on model. If installed and used correctly,

inaccuracies of no greater than ±5% will be obtained.

Installation

This meter may be installed in-line either vertically or horizontally or

at the end of a hose adjacent to a nozzle if present.

4-1/8

[104.78]

TOTALIZING METER

DISPLAY

DWYER INSTRUMENTS, INC.

MICHIGAN CITY, INDIANA 46360 U.S.A.

ELECTRONIC

1˝ NPT

TYP

2-1/2

[63.5]

2-9/64

[54.37]

SPECIFICATIONS

Service: Compatible liquids.

Flow Range: 3 to 30 GPM (10 to 100 LPM).

Wetted Materials: Bearings: Ceramic; Shaft: Tungsten Carbide;

Rotor: Nylon 6-6; Rings: 316 SS; Body: TTM10, 11: Nylon 6-6,

TTM20, 21: Aluminum; Other: TTM20, 21: Ceramic Magnet.

Accuracy: ±5%.

Batch Total Maximum: 9,999.

Cumulative Total Maximum: 9,999.

Temperature Limits: 14 to 130°F (-10 to 54°C).

Pressure Limits: Nylon models: 150 psig (10 bar); Aluminum

models: 300 psig (20 bar).

Pressure Drop: 2 psi (0.14 bar) @ 30 GPM (100 LPM).

Maximum Particulate Size: 350 microns.

Display: 4-digit LCD, 5/8˝ H.

Auto Shut-off: After 1 minute.

Connections: 1˝ female NPT.

Power: Two AAA alkaline batteries (included).

Battery Life: Approx. 9,000 hours.

Weight: Nylon models: 0.4 lb

(190 g); Aluminum models: 0.7 lb (340 g).

Agency Approvals: CE.

Model No. Application Body Material Units

TTM10 Water* Nylon Gallons

TTM11 Water* Nylon Liters

TTM20 Fuels

TTM21 Fuels

*Calibrated for use with water; †Calibrated for use with gasoline, diesel fuel and kerosene

†

†

Aluminum Gallons

Aluminum Liters

NOTE: If using the Nylon meter for measuring water, it is not

recommended to install with metal connection or fittings. Install as

follows:

1. If necessary, remove nozzle from hose.

2. Wrap all connections with 3 to 4 wraps of Pipe Thread Sealant

Tape. Ensure the tape does not intrude into the flow path.

3. Attach meter to hose or plumbing with the arrow on the outlet

port pointed in the direction of flow.

4. If necessary, attach nozzle to meter.

5. hand tighten the meter at the housing ends. Do not use a

wrench or similar tools to tighten the meter housing. The housing

may be damaged.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.DWYER-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@DWYER-inst.com

Page 2

OPERATION

Batch and Cumulative Totals

The meter maintains two totals. The batch total may be reset to

measure flow during a single use. The cumulative total provides

continuous measurement and my not be manually reset. The

batch total is labeled TTL 1. The cumulative total is labeled TTL2.

When the cumulative total reaches a maximum reading of 9999, it

will automatically reset to zero.

Press the DISPLAY button briefly to switch between the batch and

cumulative totals.

Activate the Meter

Turn the meter ON by starting flow or briefly pressing the DISPLAY

button. The meter will display the batch or cumulative total from

last use.

Press DISPLA Y briefly to display the batch total. Hold the DISPLAY

button down for three seconds to reset the batch total to zero.

Battery Replacement

The meter is powered by two AAA alkaline batteries which may be

replaced while the meter is installed. When batteries are removed

or lose power , the batch and cumulative totals reset to zer o but the

factor calibration is retained.

If the meter display becomes dim or blank, replace the batteries as

follows:

1. Remove the four Phillips-head scr ews and lift the faceplate from

meter.

2. Remove the old batteries and clean any corrosion from the

terminals.

3 Install new batteries. Make sure the positive post is in the

correct position.

4. When batteries are replaced, the faceplate will power ON.

Check the display to ensure normal functions have resumed

before assembling again.

The meter is programmed to turn off automatically if not used for

more than one minute.

MAINTENANCE

Proper handling and care will extend the life and service of the

meter.

Turbine Rotor

The meter is virtually maintenance-free. However, it is important

the rotor moves freely. Keep the meter clean and free of

contaminants.

If the rotor does not turn freely, apply a penetrating lubricant on the

rotor, shaft, and bearings. Remove any debris or deposits from the

rotor using a soft brush or small probe. Be careful not to damage

the turbine rotor or supports.

CAUTION: Blowing compressed air through the turbine

assembly could damage the rotor.

5. Reseat the batteries, if necessary , and position the faceplate on

the turbine housing. To avoid moisture damage, make sure the Oring is fully seated. Tighten the four screws on the faceplate.

If the unit should need repairs, please contact Dwyer Instruments,

Inc. before returning unit to review information relative to your

application and obtain a return authorization number. When

returning a product to the factory, carefully package and ship

freight prepaid. Be sure to include a complete description of the

application and problem and identify any hazardous material used

with the product.

MAINTENANCE

Upon final installation of the Series TTM Totalizing Flowmeter, no

routine maintenance is required. A periodic check of the system

calibration is recommended. The Series TTM is not field

serviceable and should be returned if repair is needed (field repair

should not be attempted and may void warranty). Be sure to

include a brief description of the problem plus any relevant

application notes. Contact customer service to receive a return

goods authorization number before shipping.

©Copyright 2007 DYER Instruments, Inc. Printed in U.S.A. 2/07 FR# R2-443088-00 Rev 1

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.DWYER-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@DWYER-inst.com

Loading...

Loading...