Page 1

Bulletin E-90-TTE

Series TTE Explosion-Proof RTD Temperature Transmitter

Installation and Operation Instructions

4-9/32

[108.74]

10-23/64

[263.13]

[113.51]

1/2 NPT

4-15/32

2-23/32

[69.06]

The Series TTE Explosion-Proof RTD Temperature

Transmitter is the ideal product for hazardous

temperature measurement applications. The TTE series has

seven pre-programmed temperature ranges that are

selectable via an internal dip switch. For those applications

that need a custom range, the transmitter can be easily

configured for any range between -30 to 250°F with a

minimum span of 40°F. The span and zero can be quickly

adjusted with a simple push button design. The compact

housing allows for the transmitter to be mounted in virtually

any application.

The Series TTE is ideally suited for refrigeration, building

automation, commercial hot water heaters and boilers, and

water chillers applications.

3-29/32

[99.22]

1/2 NPT

1/2 NPT

ø1/4

[ø6.35]

SPECIFICATIONS

Temperature Sensor: Pt1000, 0.00385 DIN.

Output Temperature Ranges: User selectable – any range

between –30 to 250°F with a minimum span of 40°F.

Temperature Limits: Ambient: 0 – 158°F (-18 to 70°C).

Process: -30 to 250°F (-34.4 to 121.1°C).

Accuracy: Transmitter +/0.1% F.S. Probe +/-0.3% F.S.

Thermal Drift Effects: +/-0.02%/°C max.

Response Time: 250 ms.

Wetted Materials: 316 stainless steel.

Process Connection: 1/2˝ male NPT.

Conduit Connection: 1/2˝ female NPT.

Probe Length: 2˝ to 18˝ (depending on model).

Pressure Limits: 2000 PSI.

Power Requirements: 10 to 35 VDC.

Output Signal: 4-20 mA (two wire loop powered).

Optional Display: 2 lines X 8 character LCD.

Enclosure Rating: NEMA 4X (IP66) and explosion-proof

for Class I, Groups B, C, D; Class II, Groups E, F, G; Class

III.

Weight: 2 lb 8 oz (1134 g).

Agency Approvals:FM, CE.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

INSTALLATION

1. Location: Select a location where the temperature of the

transmitter will be between 0 and 158°F. Distance from

the receiver is limited only by total loop resistance.

2. Position: The transmitter is not position sensitive. Units

with the optional display should be mounted for ease of

viewing the display.

3. Electrical Connection:

Wire Length - The maximum length of wire connecting

the transmitter and receiver is a function of wire size and

receiver resistance. Wiring should not contribute more

than 10% of the receiver resistance to total loop

resistance. For extremely long runs (over 1000 feet),

choose receivers with lower resistance to minimize the

size and cost of connecting leads.

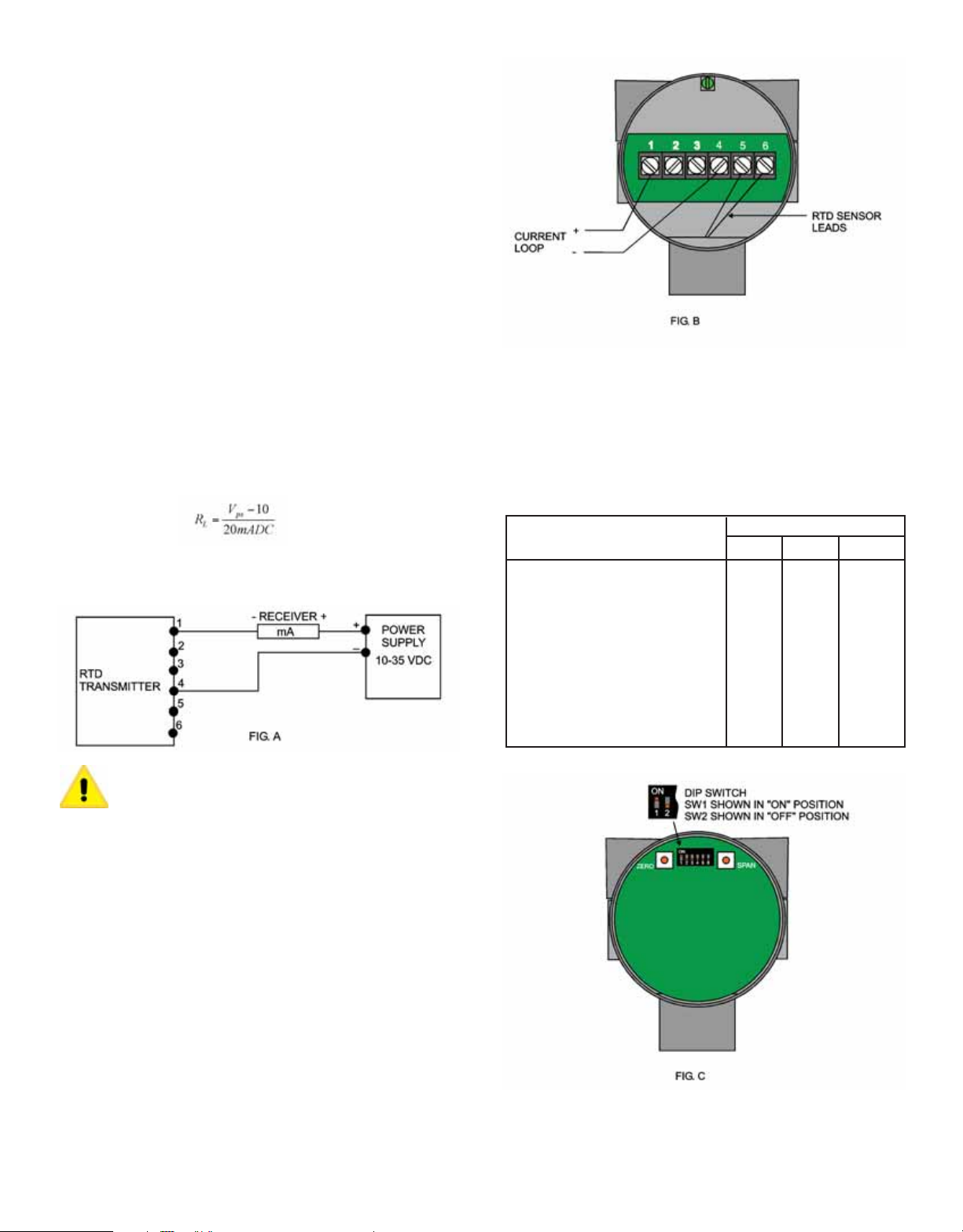

Current (4-20 mA) Output Operation

An external power supply is required. See Fig. A for diagram

of the connection of the power supply, transmitter and

receiver. The range of appropriate receiver load resistance

(RL) for the DC power supply voltage available is expressed

by the formula:

Shielded cable is recommended for control loop wiring.

Explosion-Proof Installation Notes:

1. Install in accordance with any applicable national electric

code.

2. Plug unused conduit openings. Plug must engage a

minimum of 5 threads.

3. Use a conduit seal within 18 inches of conduit entry.

4. Disconnect power before servicing.

Temperature Range Selection

The RTD Transmitter has 7 built in temperature ranges and

a user settable range that are selectable by setting the Dip

Switch located inside the housing (Fig C). Switches 2, 3,

and 4 are used to set the range. To set the desired range,

unscrew and remove the cover and set the Dip Switch

according to the following table:

DIP SWITCH

Selectable Ranges 2 3 4

40 to 90°F (4.4 to 32.2°C) OFF OFF OFF

-20 to 140°F (-28.9 to 60°C) ON OFF OFF

0 to 100°F (-17.8 to 37.8°C) OFF ON OFF

30 to 240°F (-1.1 to 115.6°C) ON ON OFF

32 to 212°F (0 to 100°C) OFF OFF ON

32 to 122°F (0 to 50°C) ON OFF ON

-30 to 65°C (-1.1 to 18.3°C) OFF ON ON

User Settable ON ON ON

Electrical connections to the RTD Transmitter are made to

the terminal block located inside the housing. Unscrew and

remove the cover. W ire as shown in FIG. B.

Page 3

Setting and Calibrating the User Settable Range

By setting SWITCH 2, 3, and 4 on, the RTD T ransmitter may

be adjusted to a custom user specified range. The range

may be any values between –30°F and +250°F (-34 to

+121°C) with a MINIMUM SPAN of 40°F (22°C).

Equipment Required

In order to calibrate the unit for a custom range, a precision

RTD simulator that can simulate a 1000 OHM DIN type RTD

or precision decade box is required. The device must be

capable of generating the correct RTD resistance to 0.1% or

better.

Calibration Procedure

1. Set DIP SWITCHES 2, 3 and 4 ON.

2. Remove the RTD sensor leads from terminals 5 and 6

(Fig. B). Connect the precision RTD simulator or

decade box to terminals 5 and 6.

3. Wire instrument as previously discussed. A current

meter may be wired in series with the unit to verify the

correct current output, but this is not necessary for

calibration. Apply power to the unit.

4. If a precision RTD simulator is used, make sure it is set

to simulate a 1000 OHM DIN 0.00385 RTD. Then set it

to the desired minimum temperature. If a decade box is

used refer to the table in Appendix A (°F) or Appendix B

(°C) and set it to the resistance that represents the

desired minimum temperature.

5. Press the ZERO button. If the unit has the optional LCD,

the display will read ZERO OK momentarily. If a current

meter is wired, it will read 4.00mA.

6. Repeat step 4 using the value for the maximum desired

temperature.

7. Press the SPAN button. If the unit has the optional LCD,

the display will read SPAN OK momentarily. If a current

meter is wired, it will read 20.00mA.

8. Tur n off power to the unit. Disconnect the RTD simulator

or decade box and reconnect the RTD sensor to

terminals 5 and 6. Calibration is complete.

°F and °C Selection

If the unit has the optional LCD display, DIP SWITCH 1 sets

the display to read in °F or °C. SWITCH 1 “OFF” = °F

SWITCH 1 “ON” = °C.

Output Current Display

If the unit has the optional LCD display, the lower display will

show the output current if DIP SWITCH 5 is “ON”. Setting

DIP SWITCH 5 “OFF” causes the lower display to be blank.

Open RTD Protection

Upon detecting an open RTD, the unit may be set to force

the output to read 3.5mA or 21mA based upon the setting

of DIP SWITCH 6.

SWITCH 6 “OFF”, output forced to 3.5mA

SWITCH 6 “ON”, output forced to 21mA

Calibration

The unit requires no calibration. An internal precision resistor

continually self calibrates the unit. Calibration may be

verified by removing the sensor leads and testing the unit

against a precision RTD simulator or a precision decade

box. If the unit is found to out of calibration it must be

returned to the factory for service.

MAINTENANCE

Upon final installation of the Series TTE Explosion Proof RTD

Temperature Transmitter, no routine maintenance is

required. A periodic check of the system calibration is

recommended. The Series TTE is not field serviceable and

should be returned if repair is needed (field repair should not

be attempted and may void warranty). Be sure to include a

brief description of the problem plus any relevant application

notes. Contact customer service to receive a return goods

authorization number for shipping.

Note: The calibration procedure does not effect the

calibration of any of the built in ranges.

Page 4

Appendix A - RTD Table, ˚F PIt 1000 DIN 0.00385

Values are in ohms

TEMP, °F -0 -1 -2 -3 -4 -5 -6 -7 -8 -9

-30 864.7

-20 886.6 884.4 882.2 880.0 877.8 875.6 873.5 871.3 869.1 866.9

-10 908.5 906.3 904.1 901.9 899.7 897.6 895.4 893.2 891.0 888.8

-0 930.3 928.2 926.0 923.8 921.6 919.4 917.2 915.0 912.9 910.7

TEMP, °F 0 1 2 3 4 5 6 7 8 9

0 930.3 932.5 934.7 936.9 939.1 941.2 943.4 945.6 947.8 950.0

10 952.1 954.3 956.5 958.7 960.9 963.0 965.2 967.4 969.6 971.7

20 973.9 976.1 978.3 980.4 982.6 984.8 987.0 989.1 991.3 993.5

30 995.7 997.8 1000.0 1002.2 1004.3 1006.5 1008.7 1010.9 1013.0 1015.2

40 1017.4 1019.5 1021.7 1023.9 1026.0 1028.2 1030.4 1032.5 1034.7 1036.9

50 1039.0 1041.2 1043.4 1045.5 1047.7 1049.9 1052.0 1054.2 1056.3 1058.5

60 1060.7 1062.8 1065.0 1067.1 1069.3 1071.5 1073.6 1075.8 1077.9 1080.1

70 1082.3 1984.4 1086.6 1088.7 1090.9 1093.0 1095.2 1097.4 1099.5 1101.6

80 1103.8 1106.0 1108.1 1110.3 1112.4 1114.6 1116.7 1118.9 1121.0 1123.2

90 1125.3 1127.5 1129.6 1131.8 1133.9 1136.1 1138.2 1040.4 1142.5 1144.7

TEMP, °F 0 1 2 3 4 5 6 7 8 9

100 1146.8 1149.0 1151.1 1153.3 1155.4 1157.6 1159.7 1161.8 1164.0 1166.1

110 1168.3 1170.4 1172.6 1174.7 1176.9 1179.0 1181.1 1183.3 1185.4 1187.6

120 1189.7 1191.8 1194.0 1196.1 1198.3 1200.4 1202.5 1204.7 1207.0 1208.9

130 1211.1 1213.2 1215.4 1217.5 1219.6 1221.8 1223.9 1226.0 1228.2 1230.3

140 1232.4 1234.6 1236.7 1238.8 1241.0 1243.1 1245.2 1247.3 1249.5 1251.6

150 1253.7 1255.9 1258.0 1260.1 1262.2 1264.4 1266.5 1268.6 1270.8 1272.9

160 1275.0 1277.1 1279.3 1281.4 1283.5 1285.6 1287.8 1289.9 1292.0 1294.1

170 1296.2 1298.4 1300.5 1302.6 1304.7 1306.9 1309.0 1311.1 1313.2 1315.3

180 1317.5 1319.6 1321.7 1323.8 1325.9 1328.0 1330.2 1332.3 1334.4 1336.5

190 1338.6 1340.7 1342.8 1345.0 1347.1 1349.2 1351.3 1353.4 1355.5 1357.6

TEMP, °F 0 1 2 3 4 5 6 7 8 9

200.0 1359.7 1361.9 1364.0 1366.1 1368.2 1370.3 1372.4 1374.5 1376.6 1378.7

210.0 1380.8 1383.0 1385.1 1387.2 1389.3 1391.4 1393.5 1395.6 1397.7 1399.8

220.0 1401.9 1404.0 1406.1 1408.2 1410.3 1412.4 1414.5 1416.6 1418.7 1420.8

230.0 1422.9 1425.0 1427.1 1429.2 1431.3 1433.4 1435.5 1437.6 1439.7 1441.8

240.0 1443.9 1446.0 1448.1 1450.2 1452.3 1454.4 1456.5 1458.6 1460.7 1462.8

250.0 1464.9

Appendix B - RTD Table, ˚C PIt 1000 DIN 0.00385

Values are in ohms

TEMP, °C -0 -1 -2 -3 -4 -5 -6 -7 -8 -9

-30 888.2 878.3 874.3 870.4 866.4

-20 921.6 917.7 913.7 909.8 905.9 901.9 898.0 894.0 890.1 886.2

-10 960.9 956.9 953.0 949.1 945.2 941.2 937.3 933.4 929.5 925.5

-0 1000.0 996.1 992.2 988.3 984.4 980.4 976.5 972.6 968.7 964.8

TEMP, °C 0 1 2 3 4 5 6 7 8 9

0 1000.0 1003.9 1007.8 1011.7 1015.6 1019.5 1023.4 1027.3 1031.2 1035.1

10 1039.0 1042.9 1046.8 1050.7 1054.6 1058.5 1062.4 1066.3 1070.2 1074.1

20 1077.9 1081.8 1085.7 1089.6 1093.5 1097.4 1101.2 1105.1 1109.0 1112.9

30 1116.7 1120.6 1124.5 1128.3 1132.2 1136.1 1140.0 1143.8 1147.7 1151.5

40 1155.4 1159.3 1163.1 1167.0 1170.9 1174.7 1178.6 1182.4 1186.3 1190.1

50 1194.0 1197.8 1201.7 1205.5 1209.4 1213.2 1217.1 1220.9 1224.7 1228.6

60 1232.4 1236.3 1240.1 1243.9 1247.8 1251.6 1255.4 1259.3 1263.1 1266.9

70 1270.8 1274.6 1278.4 1282.2 1286.1 1289.9 1293.7 1297.5 1301.3 1305.2

80 1309.0 1312.8 1316.6 1320.4 1324.2 1328.0 1331.8 1335.7 1339.5 1343.3

90 1347.1 1350.9 1354.7 1358.5 1362.3 1366.1 1369.9 1373.7 1377.5 1381.3

TEMP, °C 0 1 2 3 4 5 6 7 8 9

100 1385.1 1388.9 1392.6 1396.4 1400.2 1404.0 1407.8 1411.6 1415.4 1419.1

110 1422.9 1426.7 1430.5 1434.3 1438.0 1441.8 1445.6 1449.4 1453.1 1456.9

120 1460.7 1464.5

©Copyright 2008 Dwyer Instruments, Inc. Printed in U.S.A. 12/08 FR# 02-443554-00 Rev.1

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...