Page 1

Bulletin T-20-TSWB

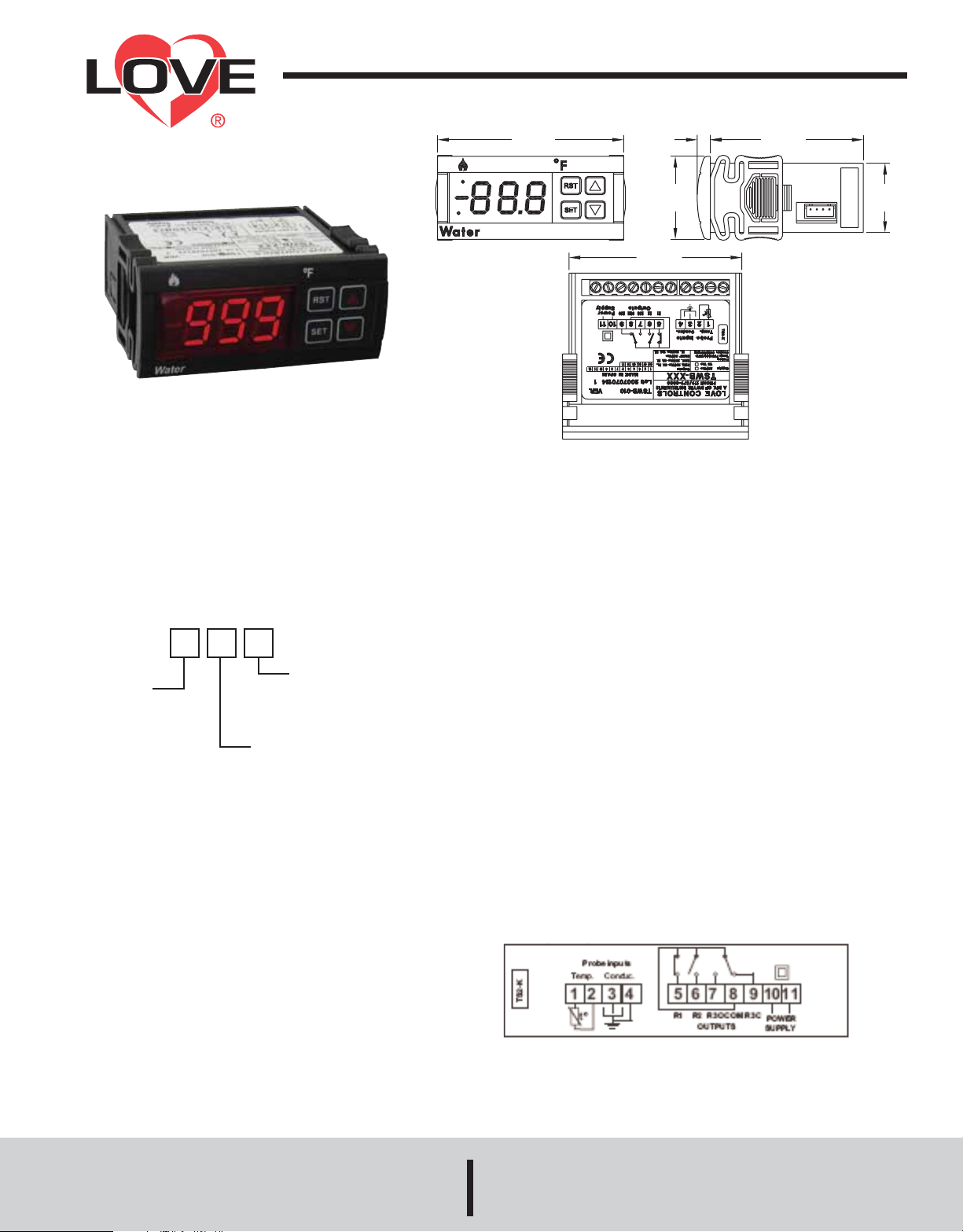

TSWB Digital Temperature/Water Level Switch

Specifications - Installation and Operating Instructions

The Series TSWB Digital Temperature Switch has a high and a low set

point for controlling the water temperature. The low set point can either be

manually or automatically reset. This control also has a conductivity probe

input. This input supplies12 VAC to the probe to check for low water condition. There are three relay outputs which can be assigned in the field to

the high temperature set point, low temperature set point or the low water

level input. The Model TS2-K configuration key can make configuring multiple controls quick and easy.

Model References

TSWB -

Display Color

0 = Red

Units

0 = °F

1 = °C

1 = Green

Power Supply

1 = 115 VAC

2 = 230 VAC

3 = 12 VAC/VDC

4 = 24 VAC/VDC

Installation

NOTE: Unit must be mounted away from vibration, impacts, water and

corrosive gases.

2-63/64

[75.69]

SPECIFICATIONS

Probe Range: PTC -58 to 302ºF (-50ºC to 150ºC); NTC -58 to 230ºF

(-50ºC to 110ºC).

Probe Temperature Input: (Selectable by parameter) PTC1000 probes

(25ºC-1000 Ohm) / NTC.

Probe Level Input: Conductivity Probe: max Voltage 12 VAC. Sensitivity

established from factory at 100KOhm.

Output: R1 SPST NO Relay Resistive load 5A @ 250 VAC.

R2 SPST NC Relay Resistive load 5A @ 250 VAC.

R3 SPDT Relay Resistive load 16A @ 240 VAC.

Horsepower Rating: 1HP -- 10FLA, 60LRA 250 VAC.

Control Type: On/Off.

Power Requirement: 115 VAC ± 10%, 230 VAC ± 10%, 24 VAC/DC ±

10%, 12 VAC/DC ± 10%.

Power Consumption: 4VA (230V/115V) 1.5VA (24V/12V).

Accuracy: Better than 1% of full scale.

Display: 3-digit, red 1/2˝ digits.

Resolution: 1º (3 digits).

Memory Backup: Nonvolatile memory.

Ambient Operating Temperature: 32 to 158ºF (-30 to 70ºC).

Storage Temperature: -4 to 176ºF (-30 to 80ºC).

Weight: 3.5 oz.

Front Protection: IP64.

Agency Approvals: CE, UL, cUL.

7/32

[5.33]

1-21/64

[33.73]

2-49/64

[70/36]

2-29/64

[62.23]

1-7/64

[28.19]

··

Cut hole in panel 2.80 x 1.14 inches).

··

Apply silicone (or rubber gasket) around the perimeter of the hole to pre-

vent leakage.

··

Insert unit into hole of panel.

··

Slide removable fitting clips onto unit from the back until secure to panel.

··

Wiring diagram is displayed on the top of the unit.

Note: DO NOT INSTALL PROBE CABLE NEAR POWER CABLES.

Wiring Diagram

LOVE CONTROLS DIVISION

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

List of parameters

Description Units Range

HSP High Set Point Degrees r1 to r2

LSP Low Set Point Degrees r3 to r4

r0h Differential or hysteresis for HS Degrees 1 to 99

roL Differential or hysteresis for LS Degrees 1 to 99

r1 Lower value for HS Degrees -58 to r2

r2 Higher value for HS Degrees r1 to 302

r3 Lower value for LS Degrees -58 to r4

r4 Higher value for LS Degrees r3 to 302

t1 Time for revalue LS condition Minutes 0 to 999

A0 Reset of alarms Range Auto/hoL/Bot

A1 LS is High or Low Set Point Range Low/High

Out Relay Output State Numeric 1 to 7

P1 Ambient probe adjustment Degrees -30 to 30

P5 Ambient probe type Range PTC/NTC

H5 Access code to parameters Numeric 0 to 255

H6 Blinking of Low Fuel LED Range On/Off

Parameters Descriptions

HSP = High Set Point. (variable from r1 to r2).

Temperature of probe > HSP -->relay excites.

Temperature of probe < HSP-r0 -->relay de-excites.

LSP = Low Set Point. (variable from r3 to r4).

Temperature of probe < LSP -->relay de-excites.

Temperature of probe > LSP+r0 -->relay excites.

r0h = Differential or hysteresis for HSP.

l01 = Differential or hysteresis for LSP.

r1 = Lower value for HSP.

r2 = Higher value for HSP.

r3 = Lower value for HSP.

r4 = Higher value for LSP.

t1 = Time for revalue LSP condition.

If A0 = HoL when reset button is pressed the relay LSP is excited for t1

minutes. The process of the user pressing the manual reset button would

continue until the process temperature is above LSP.

A0 = Reset of alarms.

Aut = Disabled manual reset.

Bot = Enable manual reset and automatic reset.

HoL = Enabled manual reset.

Out = Relay Output State.

Profile

1

2

3

4

5

6

7

P1 = Ambient probe adjustment. Offset degrees to be added to probe.

P5 = Ambient probe type. PTC or NTC.

H5 = Access code to parameters. (It is set to 00 from factory).

H6 = Blinking of fuel LED.

High Set Point

SPST NC (R1)

SPST NO (R2)

SPST NC (R1)

SPST NO (R2)

SPDT (R3)

SPDT (R3)

SPDT (R3)

ON = If temperature of probe < LSP the fuel LED on the display

starts to blink. When Temperature of probe > LSP+r0 the fuel LED

is turned off.

OFF = fuel LED blinking disabled.

Low Set Point

SPST NO (R2)

SPST NC (R1)

SPDT (R3)

SPDT (R3)

SPST NO (R2)

SPDT NC (R1)

-

Water Probe

SPDT (R3)

SPDT (R3)

SPST NO (R2)

SPST NC (R1)

SPST NC (R1)

SPST NO (R2)

SPST NO (R2) + SPST

NC (R1)

Parameter Programming

Programming the High and Low Set Point (HSP and LSP).

• Press SET HSP text will appear on the display.

• Press SET again. The value of HSP is shown on the display.

• The value can be modified with the UP and DOWN arrows.

• Press SET to enter any new value and exit to HSP label.

• Press the UP or DOWN arrows to go a LSP label.

• Press SET again. The value of LSP is shown on the display.

• The value can be modified with the UP and DOWN arrows.

• Press SET to enter any new value and exit to LSP label.

• Press SET and DOWN at the same time to exit programming or wait one

minute and the display will automatically exit programming mode.

Access to all code protected parameters.

• Press SET for 8 seconds. The access code value 0 is shown on the display (unit comes with code set at 0 from factor).

• With the UP and DOWN arrows, code can be set to user needs.

• Press SET to enter code. If code correct, the first parameter label is

shown on the display (HSP).

• Move to the desired parameter with the UP and DOWN Keys.

• Press SET to view the value on the display.

• The value can be modified with the UP and DOWN arrows.

• Press SET to enter the value and exit.

• Repeat until all necessary parameters are modified.

• Press SET and DOWN at the same time to quit programming or wait one

minute and the display will automatically exit programming mode.

* The keyboard code can be reset to ZERO by turning off the controller and

turning it on again while keeping the SET pressed.

Water Control

A water level sensor can be connected to the digital input. When the control detects an open signal, the unit is low on water. In this case the water

LED on the face of the control lights and the relay given by Out is excited.

When the control detects a closed signal, it indicates the presence of water

and the water LED is switched off and the correspondent relay is de-excited.

Default Working

In case of probe error or memory error:

the relay output R1 will remain Open.

the relay outout R2 will remain Close.

the relay outout R3 will remain Open.

LED Indication and Display Messages

Fuel LED indicates the stove is out of wood or corn.

Water LED indicates the unit is low on water.

In normal operation, the probe temperature will be shown on the display.

In case of alarm or error, the following messages can be shown:

•

Erl

= Memory Error

•

ooo

= Open Probe Error

• --- = Short Circuit Probe Error

Maintenance, Cleaning and Repair

After final installation of the unit, no routine maintenance is required.

Clean the surface of the display controller with a soft and damp cloth.

Never use abrasive detergents, petrol, alcohol or solvents. All repairs must

be made by authorized personnel.

(*) Relay selection given by Out paramter.

©Copyright 2008 Dwyer Instruments, Inc. Printed in U.S.A. 3/08 FR# R7-443608-00

LOVE CONTROLS DIVISION

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...