Page 1

Series TSS2 Dual Stage Temperature Switch

°C

W

IRING DIAGRAM

B

LUE BUTTONS

3

[76.2]

1

-27/64

[

36.12]

1-9/64

[28.97]

2

-7/16

[

61.91]

MODEL CODE

DISPLAY COLOR

0=RED

UNITS

0 = °F

1 = °C

SUPPLY VOLTAGE

1 = 115 VAC

2 = 230 VAC

3 = 12 VAC/DC

4 = 23 VAC/DC

OUTPUTS

2 = 2 OUTPUTS

TSS2 –

Specifications - Installation and Operating Instructions

he TSS2 is an electronic temperature controller designed for ON/OFF control or

T

eutral Area Control. They can be provided with 1 or 2 probes (PTC or NTC)

N

ccording to parameter P5 and it provides two output relays plus an alarm buzzer.

a

The unit controls cooling, heating or both, since its relays can be setup for direct or

reverse operation. The user is able to program 34 different parameters including

set points, hysteresis, configuration of alarms and probe adjustment using the

silicone front keypad. The unit features error warning and password protection.

Each suffix can take the following values:

Bulletin E-90-TSS2

SPECIFICATIONS

Probe Range:

TC: -58 to 302°F (-50 to 150°C);

P

TC: -58 to 230°F (-50 to 110°C).

N

Input:

PTC: 1000Ω @ 25°C;

NTC: 10 kΩ @ 25°C.

Outputs: OUT1 - SPDT relay rated 16A @ 240 VAC resistive; OUT2 - SPDT

relay rated 8A @ 240 VAC resistive.

Horsepower Rating (HP): 1 HP (OUT1).

Power Requirements: 115 VAC, 230 VAC, 12 VAC/VDC or 24 VAC/VDC

(depending on model).

Accuracy: 1% FS.

Display: 3-digit and sign, red LED.

Resolution: 0.1° (<100°); 1° (≥100°).

Memory Backup: Nonvolatile memory.

Temperature Limit: Ambient: 32 to 158°F (0 to 70°C).

Storage Temperature: -4 to 176°F (-20 to 80°C).

Dimensions: 3 x 1-27/64 x 2-7/16 in.

Front Panel Rating: IP64.

Weight: 2.3 oz (65 g).

Agency Approvals: CE, cURus.

Note: Unit must be mounted away from vibration, impacts, water and corrosive

gases.

• Cut hole in panel 71 x 29 mm (2.80 x 1.14 inches).

• Apply silicone (or rubber gasket) around the perimeter of the hole to prevent

leakage.

• Insert unit into hole of panel.

• Slide removable fitting clips onto unit from the back until secure to panel.

• Wiring diagram is displayed on the top of the unit.

• Note: DO NOT INSTALL PROBE CABLE NEAR POWER CABLES.

LOVE CONTROLS DIVISION

DWYER INSTRUMENTS INC.

P.O. BOX 338 - MICHIGAN CITY, INDIANA 46360, U.S.A.

Maintenance, cleaning and repair

After final installation of the unit, no routine maintenance is required. Clean the

surface of the display controller with a soft and damp cloth. Never use abrasive

detergents, petrol, alcohol or solvents. All repairs must be made by authorized

personnel.

Phone: 219/879-8000 www.love-controls.com

Fax: 219/872-9057 e-mail:love@love-controls.com

Page 2

ist of parameters

L

S

S

r0 Dependency SP1-SP2 Range ind/dep

r1 Differential for SP1 Degrees 0.1 to 20.0

r2 Differential for SP2 Degrees 0.1 to 20.0

r

r

r

r

r7 Highest value for SP2 Degrees r5 to 302

r8 Regulation or operating mode Range On1/On2/nEU

A0 Alarm differential Degrees 0.1 to 20.0

A

A

A

A4 Minimum alarm probe 2 (2) Degrees 0.1 to 99.9

A5 Alarm verification time h-m (*) 0.0 to 18.0

A6 Alarm probe 1 selection Range AHL/Ano/AH/AL

A7 Alarm probe 2 selection Range AHL/Ano/AH/AL

c

c

c

c3 Default operation relay 1 Range Opn/Clo

c4 Default operation relay 2 Range Opn/Clo

P0 Temperature scale selection Range ºC/ºF

P1 Calibration of probe 1 Degrees -20.0 to 20.0

P

P

P

P5 Number of probes Range 1/2

H0 Reprogramming Range 0

H1 Keyboard protection Range no/yes

H2 Operation LED OUT1 Range dir/inv

H3 Operation LED OUT2 Range dir/inv

H4 Address for serial communication Numeric 0 to 999

H5 Access code to parameters Numeric 0 to 999

H6 Probe type Range Ptc/Ntc

(*)h-m are data in format XX.Y where XX are hours and Y tens of minutes.

(1)referred to set 1.

(2)referred to set 2.

Parameter descriptions

SP1 = Operation order of relay 1. Specifies the ON/OFF point of relay 1. Variable

between r4 and r6.

SP2 = Operation order of relay 2. Specifies the ON/OFF point of relay 2. Variable

between r5 and r7.

r0 = Dependency between SP1 and SP2. Only for mode ONOFF1

ind = order for relay 2, SP2.

dep = order for relay 2, SP1+SP2.

r1 = Differential or hysteresis for relay 1. Temperature differential between ON/OFF

of relay 1 in ON/OFF control.

r2 = Differential or hysteresis for relay 2. Temperature differential between ON/OFF

of relay 2 in ON/OFF control.

r3 = Band differential. Temperature differential between ON/OFF of relays 1 and 2

in neutral area control. For relay 1 it is added to SP1 and for relay 2 it is subtracted

from SP1.

r4 = Lowest value for SP1.

r5 = Lowest value for SP2.

r6 = Highest value for SP1.

r7 = Highest value for SP2.

r8 = Regulation or operating mode. Selection of the operating mode.

A0 = Alarm differential. It is the temperature differential between the alarm On and

Off cycle.

A1 = Maximum alarm probe1.

A2 = Maximum alarm probe2.

A3 = Minimum alarm probe1.

escription Units Range

D

P1 Set Point 1 Degrees r4 to r6

P2 Set Point 2 Degrees r5 to r7

3 Band differential Degrees 0.1 to 20.0

4 Lowest value for SP1 Degrees -99.9 to r6

5 Lowest value for SP2 Degrees -99.9 to r7

6 Highest value for SP1 Degrees r4 to 302

1 Maximum alarm probe 1 (1) Degrees 0.1 to 99.9

2 Maximum alarm probe 2 (2) Degrees 0.1 to 99.9

3 Minimum alarm probe 1 (1) Degrees 0.1 to 99.9

0 Minimum relay stop time Minutes 0 to 240

1 Operation relay 1 Range dir/inv

2 Operation relay 2 Range dir/inv

2 Calibration of probe 2 Degrees -20.0 to 20.0

3 Decimal point Range no/yes

4 Probe to be displayed Range sd1/sd2

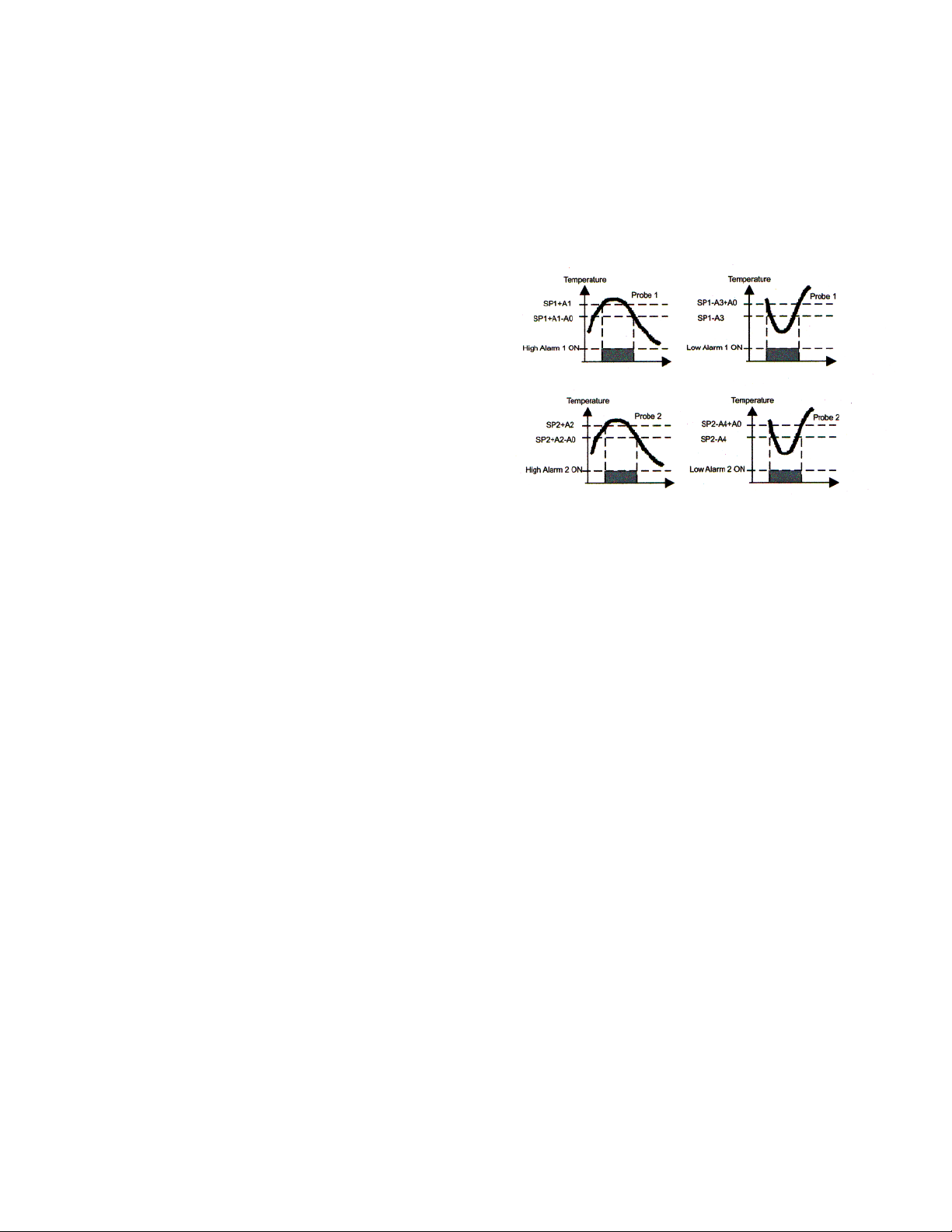

Maximum alarm ON when probe 2 higher than SP2+A2

Maximum alarm OFF when probe 2 lower than SP2+A2-A0.

Minimum alarm ON when probe 1 lower than SP1-A3

Minimum alarm OFF when probe 1 higher than SP1-A3+A0.

4 = Minimum alarm probe2.

A

inimum alarm ON when probe 2 lower than SP2-A4

M

inimum alarm OFF when probe 2 higher than SP2-A4+A0.

M

5 = Alarm verification time. Time from the alarm event until it trips.

A

A6 = Alarm probe 1 selection.

AHL=Maximum and minimum alarm probe 1 enabled.

Ano=No alarms probe 1.

H=Maximum alarm probe 1 enabled.

A

L=Minimum alarm probe 1 enabled.

A

7 = Alarm probe 2 selection.

A

HL=Maximum and minimum alarm probe 2 enabled.

A

Ano=No alarms probe 2.

AH=Maximum alarm probe 2 enabled.

AL=Minimum alarm probe 2 enabled.

c0 = Minimum relay stop time. Minimum time from the disconnection of a relay until

it can be switched on again.

c1 = Operation relay 1. Selection between direct or reverse operation for relay 1.

c2 = Operation relay 2. Selection between direct or reverse operation for relay 2.

c3 = Default operation relay 1. In case of failure of probe 1:

oPn= relay 1 will remain open.

Clo= relay 1 will remain closed.

c4 = Default operation relay 2. In case of failure of probe 1 (for all modes excepting

ON OFF2) or in case of failure of probe 2 (for mode ON OFF2):

oPn= relay 2 will remain open.

Clo= relay 2 will remain closed.

P0 = Temperature scale selection.

P1 = Calibration of probe 1. Offset degrees to be added to probe 1.

P2 = Calibration of probe 2. Offset degrees to be added to probe 2.

P3 = Decimal point. If the displayed value of the probes is desired with decimals or

not.

P4 = Probe to be displayed. Probe always on the display. The other probe can be

seen pressing the keys SET+UP.

sd1= probe 1.

sd2= probe 2.

P5 = Number of probes. If P5=1, there is not ON OFF2 mode. If selected, it will

operate as ONOFF1.

H0 = Reprogramming. Parameter to reprogram the thermostat.

H1 = Keyboard protection.

To change the sets, enter into parameter and exit again. The protection setting

is momentarily released. It switches on again 1 minute after the last time a key

was pressed.

Yes= Keyboard Protected.

No=Keyboard non protected.

H2 = Operation of LED OUT1.

dir = On when relay 1 is ON.

inv = On when relay 1 is OFF.

H3 = Operation of LED OUT2.

dir = On when relay 2 is ON.

inv = On when relay 2 is OFF.

H4 = Serial communication address. Address for computer connection.

H5 = Parameter entry code. Factory set as 0.

H6 = Input probe type selectable between PTC or NTC.

Page 3

essage display

M

nder normal operation, the temperature of the probe selected by P4 will be

U

isplayed, the following messages may also appear:

d

Err Memory reading error.

•

•ErP Error of the probe not shown on the display.

•AH1 Maximum temperature alarm, probe 1.

•AL1 Minimum temperature alarm, probe 1.

AH2 Maximum temperature alarm, probe 2.

•

AL2 Minimum temperature alarm, probe 2.

•

ooo Open probe.

•

--- Shorted probe.

•

Pressing SET with UP it displays the probe not selected by P4.

When the probe not selected by P4 is displayed, it alternates its value with

message Sd1 or Sd2 depending if it is probe 1 or probe 2.

he display blinks when waiting for a value confirmation.

T

ED indications

L

Out1: Indicates relay 1 On or Off as per parameter H2. If H2=dir, with relay 1 On,

LED lit, if H2=inv, with relay 1 On, LED off. It blinks when SP1 is displayed.

Out2: Indicates relay 2 On or Off as per parameter H3. If H3=dir, with relay 2 On,

LED lit, if H3=inv, with relay 2 On, LED off. It blinks when SP2 is displayed.

etting SP1 and SP2

S

Press and release SET. The current value of order 1 is displayed.

•

SP1 and led OUT1 blink.

• Press UP or DOWN to increase or decrease the value.

• Press SET to confirm the new value. The actual value of order 2 will be displayed,

SP2 and LED OUT2 blink.

Press UP or DOWN to increase or decrease the value.

•

Press SET to confirm the new value and exit.

•

Parameter setup

• Press SET for 8 seconds. Value 0 will blink.

• With UP and DOWN input the code (factory set as 0).

• Press SET to confirm the code. If correct, the label of the first parameter will be

displayed.

• With UP or DOWN go to the desired parameter in the parameter list.

• Press SET to see the value.

• With UP or DOWN change the value to the new value as desired.

• Press SET to confirm and exit again to the parameter list. (Also to exit to the list

without parameter modification.)

• Press SET + DOWN to exit setup or wait for 1 minute.

Resetting the keyboard code

You can setup to 0 the keyboard code switching the unit off and on while pressing

the SET key.

eprogramming factory values (H0)

R

Access to parameter H0 as explained in parameter setup.

•

Value 0 will be displayed.

•

Press SET for 8 seconds. Pro will be displayed if they have been setup correctly.

•

•Press SET + DOWN to exit setup or wait for 1 minute.

Description Factory value

P1 Set Point 1 10.0

S

P2 Set Point 2 10.0

S

0 Dependency SP1 - SP2 ind

r

1 Differential for SP1 1.0

r

r2 Differential for SP2 1.0

r3 Band differential 1.0 1.0

r4 Lower value for SP1 -99.9

5 Lower value for SP2 -99.9

r

6 Higher value for SP1 99.9

r

7 Higher value for SP2 99.9

r

r8 Regulation or operating mode On1

A0 Alarm differential 0.1

A1 Maximum alarm probe 1 99.9

A2 Maximum alarm probe 2 99.9

3 Minimum alarm probe 1 99.9

A

4 Minimum alarm probe 2 99.9

A

5 Alarm verification time 18.0

A

A6 Alarm probe 1 selection AHL

A7 Alarm probe 2 selection AHL

c0 Minimum relay stop time 0

c1 Operation relay 1 dir

2 Operation relay 2 dir

c

3 Default operation relay 1 Opn

c

4 Default operation relay 2 Opn

c

P0 Temperature scale selection ºC

P1 Calibration of probe 1 0.0

P2 Calibration of probe 2 0.0

P3 Decimal point yes

P4 Probe to be displayed sd1

P5 Number of probes 2

H0 Reprogramming 0

H1 Keyboard protection no

H2 Operation LED OUT1 dir

H3 Operation LED OUT2 dir

H4 Address for serial communication 0

H5 Access code to parameters 0

H6 Probe type Ptc

Buzzer disconnection

Pressing SET with DOWN turns off the buzzer alarm. The message of alarm

continue appearing in the display.

Page 4

perating modes

O

ode ON OFF1 (On1) with r0=ind.

M

elay 1 with c1=dir.

R

Relay 1 with c1=inv.

emperature of probe 1 >= SP1+r1 -->relay 1 ON

T

Temperature of probe 1 <= SP1 -->relay 1 OFF

Temperature of probe 1 <= SP1-r1 -->relay 1 ON

Temperature of probe 1 >= SP1 -->relay 1 OFF

elay 2 with c2=inv.

R

emperature of probe 1 <= SP1+SP2-r2 -->relay 2 ON

T

emperature of probe 1 >= SP1+SP2 -->relay 2 OFF

T

Mode ON OFF2 (On2)

utput 1 works as in independent ON/OFF control (Figure 1 and 2), but output 2

O

orks as follows:

w

elay 2 with c2=dir.

R

Temperature of probe 2 >= SP2+r2 -->relay 2 ON

Temperature of probe 2 <= SP2 -->relay 2 OFF

elay 2 with c2=inv.

R

emperature of probe 2 <= SP2-r2 -->relay 2 ON

T

Temperature of probe 2 >= SP2 -->relay 2 OFF

Relay 2 with c2=dir.

Temperature of probe 1 >= SP2+r2 -->relay 2 ON

Temperature of probe 1 <= SP2 -->relay 2 OFF

Relay 2 with c2=inv.

Temperature of probe 1 <= SP2-r2 -->relay 2 ON

Temperature of probe 1 >= SP2 -->relay 2 OFF

Mode ON OFF1 (On1) with r0=dep.

Output 1 works as in independent ON/OFF control (Figure 1 and 2), but output 2

works as follows:

Relay 2 with c2=dir.

Temperature of probe 1 >= SP1+SP2+r2 -->relay 2 ON

Temperature of probe 1 <= SP1+SP2 -->relay 2 OFF

Neutral Area Mode (nEU)

Relay 1

Temperature of probe 1 >= SP1+r3 -->relay 2 ON

Temperature of probe 1 <= SP1 -->relay 2 OFF

Relay 2

Temperature of probe 1 <= SP1-r3 -->relay 2 ON

Temperature of probe 1 >= SP1 -->relay 2 OFF

Operation in case of error.

If probe 1 fails, the operation is through c3. (See Parameter description.)

If probe 2 fails, the operation is through c4. (See Parameter description.)

In case of memory failure, both relays will remain open.

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 2/14 FR# R0-443509-00 Rev.3

LOVE CONTROLS DIVISION

DWYER INSTRUMENTS INC.

Phone: 219/879-8000 www.love-controls.com

Fax: 219/872-9057 e-mail:love@love-controls.com

P.O. BOX 338 - MICHIGAN CITY, INDIANA 46360, U.S.A.

Loading...

Loading...