Page 1

Bulletin T-TSCC

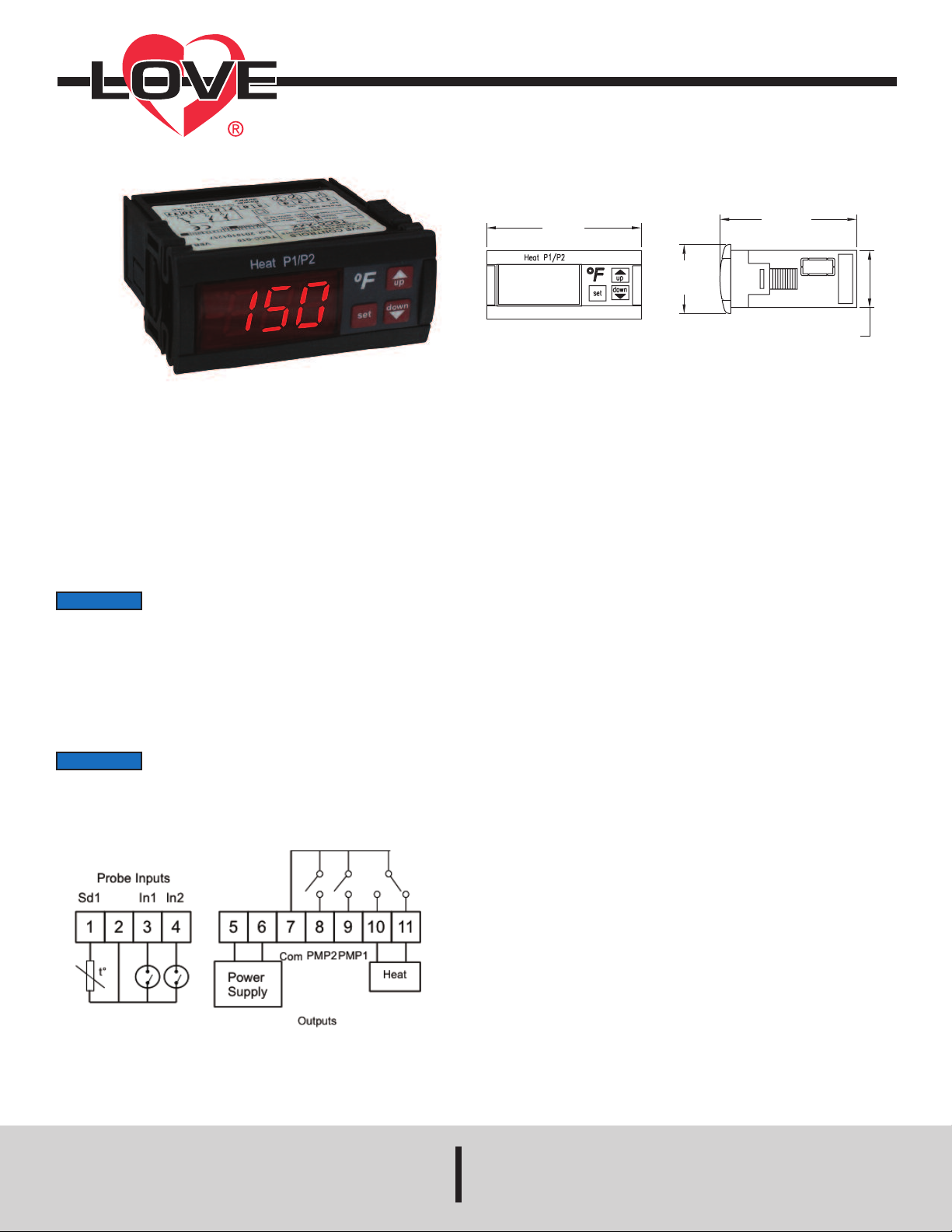

3

[

76.20]

2

-21/32

[67.39]

UNIT

1-7/64

[28.19]

1-11/32

[34.04]

Series TSCC Digital Dispensing Temperature Control

Specifications - Installation and Operating Instructions

The Series TSCC Digital Dispensing Temperature Control is used to

monitor and control product temperature and dispensing rate in the

production of melted cheese, chili, or other heated food products. One

selectable PTC or NTC thermistor is used to monitor the product

temperature while a SPDT relay is used to control the temperature. Two

SPST relays are used for controlling two dispensing rates for either

different size containers or different products. A three digit, easy-to-read

display is included on the controller. The buttons on the face of the

controller enable the user to program the desired control parameters.

Parameters can be copied from one device to another using our TS2-K

configuration key. Security protection is offered using a password code.

NOTICE

Cut hole in panel 2.80 x 1.14 in (71 X 29 mm).

Apply silicone or use the included rubber gasket around the perimeter of

the hole to prevent leakage.

Insert unit into the hole of panel.

NOTICE

controller. Do not exceed the specified power supply voltage.

WIRING DIAGRAM

Unit must be mounted away from vibration, impacts,

water and corrosive gases.

POWER SUPPLY VOLTAGE

Take note of the power supply voltage marked on the

SPECIFICATIONS

Probe Range:

PTC: -58 to 302°F (-50 to 150°C);

NTC: -58 to 230°F (-50 to 110°C).

Input: 2 free voltage contact input, 1 PTC thermistor 1000Ω @ 25°C

or 1 NTC thermistor 10K Ω @ 25°C.

Output:

1 each relay SPDT 16 A @ 240 VAC resistive, 5 A inductive;

2 each relay SPST 5 A @ 240 VAC resistive.

Control Type: ON/OFF.

Power Requirements: 115 VAC ±10%; 230 VAC ±10% (depending on

model).

Power Consumption: 4 VA.

Accuracy: ±1% FS.

Display: 3-digit and sign, 1/2˝ red LED digits.

Resolution: 1°.

Memory Backup: Nonvolatile memory.

Temperature Limits:

Operating: 32 to 158°F (0 to 70°C);

Storage: -4 to 176°F (-20 to 80°C).

Weight: 8.8 oz (250 g).

Front Panel Rating: IP64.

Agency Approvals: CE, cUL, UL.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

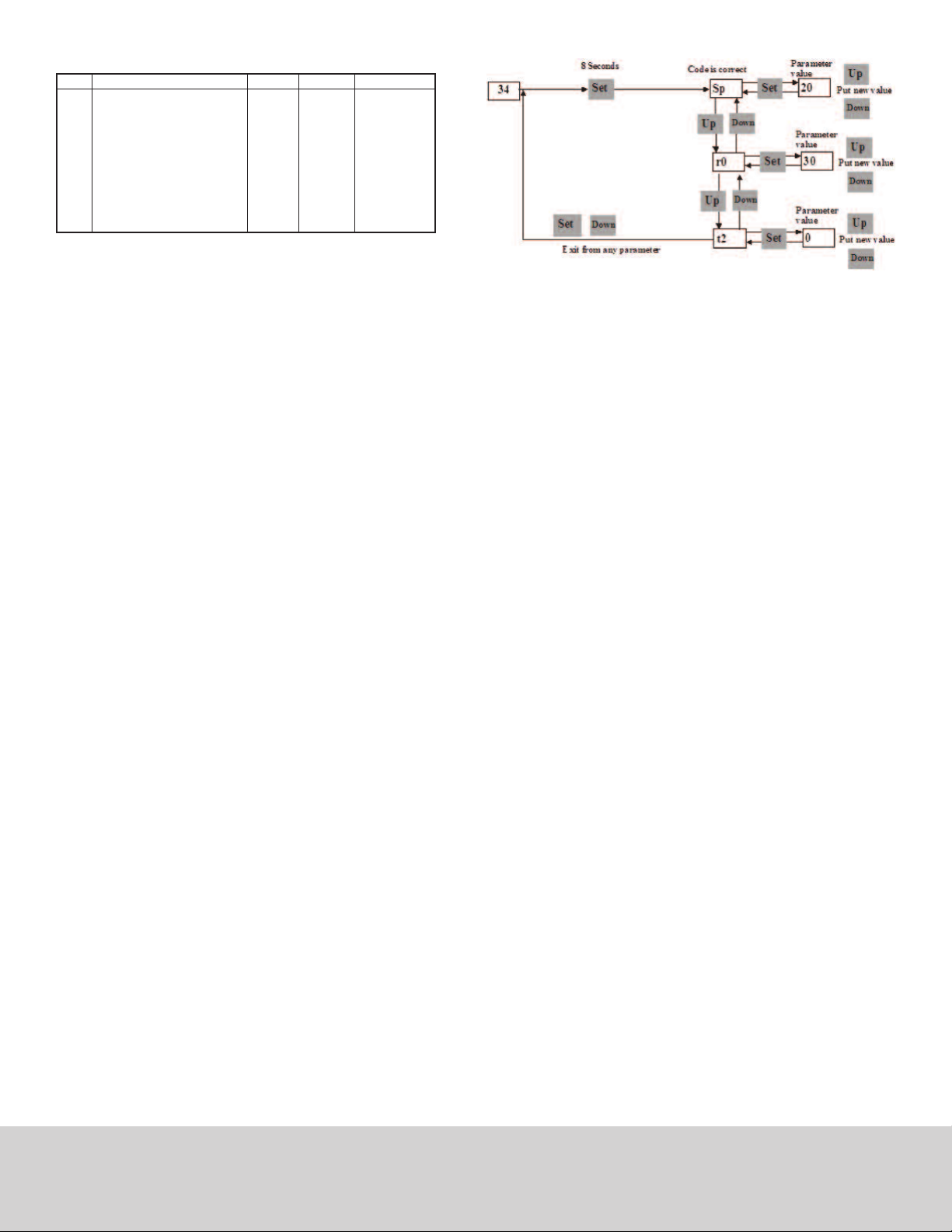

PARAMETERS

abel

escription

L

D

P

et Point

S

S

r0

Differential or Hysteresis

r1

Lower Value for SP

r2

Higher Value for SP

0

utput Status with Probe Error

c

O

1

mbient Probe Adjustment

P

A

5

ccess Code to Parameters

H

A

6

mbient Probe Type

H

A

t1

Time of Relay P1 Close

t2

Time of Relay P2 Close

nits

U

egrees

D

Degrees

Degrees

Degrees

ange

R

egrees

D

umeric

N

ange

R

Seconds

Seconds

ange

R

1 to r2

r

1 to 99

0 to r2

r1 to 999

FF/ON

O

-30 to 30

.

to 999

0

TC/NTC

P

0 to 99.9

0 to 99.9

efault Values

D

0

1

0

999

FF

O

0

0

TC

P

0

0

Parameter Descriptions

SP: Set point. Desired Product Regulation Temperature

r0: Differential or Hysteresis

if temperature < SP – r0, load is connected

if temperature ≥ SP, load is disconnected

r1: Lowest Value for SP

r2: Highest Value for SP

c0: Output Status with Probe Error

P1: Ambient Probe Adjustment

H5: Access Code to Parameters (Set to 00 from factory)

H6: Ambient Probe Type (PTC, NTC)

t1: Time that relay PMP1 is engaged after input 1 is closed to GND

t2: Time that relay PMP2 is engaged after input 2 is closed to GND

LED INDICATIONS

HEAT: Indicates that heat relay is active.

P1/P2: Indicates that either Pump 1 relay or Pump 2 relay is active.

DISPLAY MESSAGES

In normal operation, the probe temperature will be shown on the display. In

case of an error, the following messages will be shown:

• Er = Memory Error

• oo = Open Probe

• - - - = Short Probe

PARAMETER PROGRAMMING

Set Point (SP), t1, and t2 are the only parameters the user can access

without code protection.

• Press SET. SP text will appear on the display.

• With the UP and DOWN arrows, select SP, t1, or t2.

• Press SET again. The value of the parameter appears on the display.

• The value can be modified with the UP and DOWN arrows.

• Press SET to enter any new values.

• Press SET and DOWN at the same time to quit programming or wait one

minute and the display will automatically exit programming mode.

Access to all code protected parameters

• Press SET for 8 seconds. The access code value 00 is shown on the

display. (Unit comes with code set at 00 from factory).

• With the UP and DOWN arrows, code can be set to user needs

• Press SET to enter the code. If code is correct, the first parameter label

is shown on the display (SP).

• Move to the desired parameter with the UP and DOWN arrows.

• Press SET to view the value on the display.

• The value can be modified using the UP and DOWN arrows.

• Press SET to enter the value and exit.

• Repeat until all necessary parameters are modified.

• Press SET and DOWN at the same time to quit programming or wait one

minute and the display will automatically exit programming mode.

RESET TO DEFAULT KEYPAD CODE

The parameter H5 (keypad code) can be reset to ZERO by turning off the

controller and turning it on again while keeping the SET key depressed.

FACTORY DEFAULT PROCEDURE

Press UP and DOWN while turning the controller on, all parameters will be

reset to factory values.

MAINTENANCE/REPAIR

Upon final installation of the Series TSCC no routine maintenance is

required. The Series TSCC is not field serviceable and should be returned

if repair is needed. Field repair should not be attempted and may void

warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website.

Contact customer service to receive a Return Goods Authorization number

before shipping the product back for repair. Be sure to include a brief

description of the problem plus any additional application notes.

©Copyright 2013 Dwyer Instruments, Inc. Printed in U.S.A. 8/13 FR# R7-444066-00 Rev.2

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...