Page 1

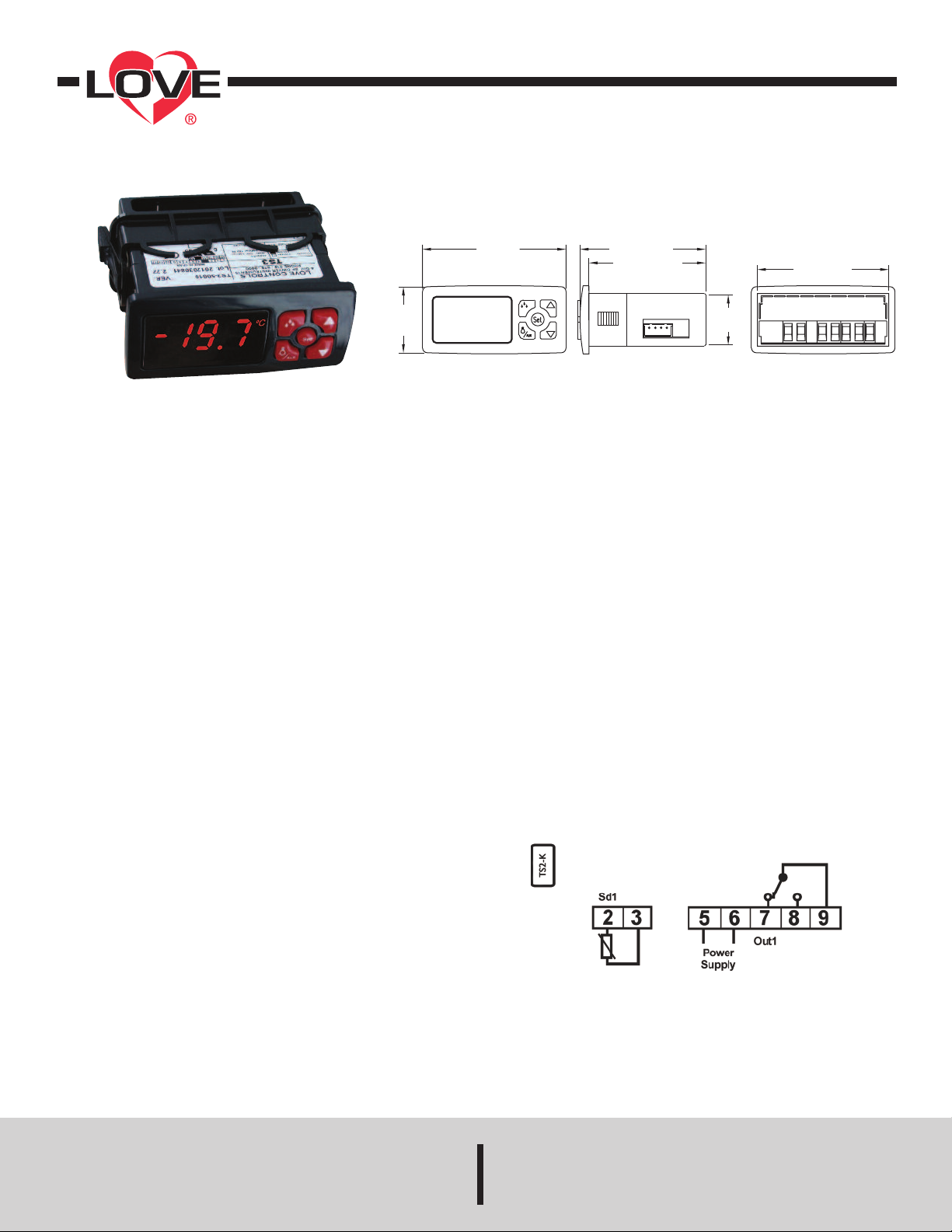

Series TS3 Digital Temperature Switch

3 [76.20]

1-3/8

[35.08]

1-3/64

[26.67]

2-3/4 [69.85]

2

-5/8 [66.74]

2

-7/16 [61.98]

Specifications - Installation and Operating Instructions

Bulletin T-TS3

The Series TS3 Digital Temperature Switch is the ideal control for

on/off heating or cooling applications. This generation of controls has

field selectable engineering units and temperature probe types in order

to reduce the combination of parts that need to be stocked. A built in real

time clock is used for HACCP logging of temperature alarms caused by

temperatures outside of their set limits or loss of power. For refrigeration

applications, the defrost cycle can be initiated based on time or using the

front panel keys. For programming multiple units, the model TS2-K

configuration key can be used to quickly download parameter settings.

INSTALLATION

NOTE: Unit must be mounted away from vibration, impacts, water and

corrosive gases.

• Cut hold in panel 71 x 29 mm (2.80 x 1.14 in).

• Use the supplied gasket or apply silicone around the perimeter of the

hole to prevent leakage.

• Insert unit into hole from the front side of the panel.

• Slide the mounting bracket securely against the panel from the rear of

the unit.

• Wiring diagram is displayed on the top of the control.

Wiring

Avoid installing the temperature probe cables and the digital input wires

in close proximity of any power cables. If the length of the probe cables

is longer than 100 meters, a recalibration adjustment may be made

using the P1 parameter.

SPECIFICATIONS

Probe Range:

PTC: -58 to 302°F (-50 to 150°C)

NTC: -58 to 230°F (-50 to 110°C).

Input: PTC (1000Ω @ 25°C) / NTC (10KΩ @ 25°C).

Output: R1 SPDT Relay Resistive Load 16A, Inductive Load 10 FLA,

60 LRA @ 240 VAC.

Horsepower Rating: 1HP @ 240 VAC.

Control Type: On/Off.

Power Requirement: 115 VAC, 230 VAC, 12 VAC/VDC, 24 VAC/DC

(±10%) depending on model.

Power Consumption: 3.6VA (115/230/24 V), 1.5VA (12V).

Accuracy: ±1% FS.

Display: 3 Digits Plus Sign.

Resolution: 0.1°.

Memory Backup: Non-Volatile Memory.

Ambient Temperature: 32 to 131°F (0 to 55°C).

Weight: 2.3 oz (65 g).

Front Protection: IP65.

Agency Approvals: CE, UL.

LOVE CONTROLS DIVISION

DWYER INSTRUMENTS INC.

P.O. BOX 338 - MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000 www.love-controls.com

Fax: 219/872-9057 e-mail:love@love-controls.com

Page 2

Parameter List (ºC)

Operation

Compressor/

Set Point

(COn)

Defrost (dEF)

Display (PrO)

Alarm

(ALA)

Initial Setup

(Ini)

Parameter

SEt

r0

r1

r2

c0

c1

c2

c3

c4

c5

d0

d1

d2

d3

d4

d5

d6

d7

d8

d11

d14

HdE

ndE

P0

P1

P4

A0

A1

A2

A3

A4

A6

A7

Hor

nin

E0

H0

H1

H2

H3

H4

H5

H6

H11

dAt

td

Description

Set Point

Differential or Hysteresis

Minimum Value for Set Point

Maximum Value for Set Point

Minimum Compressor

Stoppage Time

Continuous Cycle Time

On Time of Fault Cycle

Off Time of Fault Cycle

Minimum On Time of Compressor

Minimum Time Between

Compressor Starts

Heating or Cooling

Temperature to Stop Defrosting

Maximum Defrosting Time

First Hour of Day for Defrost

Delay of First Defrost

Display During Defrost

Display Return Limit

Compressor Drip Time

Interval Between Defrosts

Minimum Defrosting Time

Units to Count Defrost Cycle

Next Defrost Time

Next Defrost Time

Temperature Scale

Ambient Probe Adjustment

Decimal Point

Alarm Differential

Maximum Alarm Temperature

Minimum Alarm Temperature

Time without alarm after

Continuous Cycle

Time Without Alarm After Defrost

Time Without Alarm After Power On

Alarm Verification Time

Real Time Hours

Real Time Minutes

Configure Digital Input

Factory Default

Assign Master/Slave

Keypad Protection

Delay Time on Connecting

Serial Communication Address

Keypad Code

Type of Probe

HACCP Activated

Real Time Date

Display Refresh Rate

Units

Degrees

Degrees

Degrees

Degrees

Minutes

H-M

Minutes

Minutes

Minutes

Minutes

Range

Degrees

Minutes

H-M

Minutes

Range

Minutes

Minutes

H-M

Minutes

Option

Hours

Minutes

Option

Degrees

Option

Degrees

Degrees

Degrees

H-M

H-M

H-M

H-M

Hours

Minutes

Option

Range

Option

Option

Seconds

Range

Range

Option

Option

Range

Seconds

Range

R1 to R2

0.1 to 20

-99.9 to R2

R1 to 302

0 to 240

0.0 to 18

0 to 999

0 to 999

0 to 240

0 to 240

Re/In

99.9 to 302

0 to 240

00.0 to 18.0

0 to 999

Off/on/-d0 to 240

0 to 240

00.0 to 18.0

0 to 240

CT/RT

Read only

Read only

F/C

-20.0 to 20.0

0.1 to 20.0

0.1 to 99.9

0.1 to 99.0

0.0 to 18.0

0.0 to 18.0

0.0 to 18.0

0.0 to 18.0

0.0 to 18.0

0 to 23

00 to 59

Off/A1/In/DEF/Rst

0 to 2

Mst/Slv

yes/No

0 to 240

0 to 999

0 to 999

PTC/NTC

Yes/No

dxx, nxx, yxx

0-999

Factory Setting

3.0

1.0

-50.0

150

1

1.0

5

5

0

1

Re

80

30

00.0

0

-d15

0

8.0

0

RT

C

0.0

No

4.0

8.0

8.0

1.1

1.1

1.1

1.1

0

00

Def

0

Mst

No

0

0

0

PTC

No

d01, n01, y00

0

Page 3

Parameter Description

Compressor / Set Point Menu

SEt Sets the Ambient Temperature set point between r1 and r2

r0 Differential or hysteresis for set point

(For d0 = re)

Ambient temperature ≥ SEt + r0 Output On

Ambient temperature ≤ SEt Output Off

(For d0 = in)

Ambient temperature ≤ SEt - r0 Output On

Ambient temperature ≥ SEt Output Off

r1 Minimum value for set point

r2 Maximum value for set point

c0 Minimum time compressor must remain off before being

restarted

c1 Duration of cold cycle

c2 During probe error, time that output is engaged

c3 During probe error, time that output is disengaged

c4 Minimum time compressor must stay on

c5 Minimum time between compressors starts

Defrost Menu

d0 Selection for Heating or Cooling Operation

re = Cooling

in = Heating

d2 Maximum time the control will be in defrost cycle. If set to zero,

control will not defrost.

d3 Hour of the day for the first defrost. No defrost cycles will take

place before this time.

d4 Upon powering on the control, delay time before first defrost

cycle.

d5 Display during defrost cycle.

Off = Current temperature displayed.

On = Temperature at start of defrost cycle displayed until

defrost cycle ends and the temperature is less than or equal

to starting temperature or after the time is set in d6.

d6 Maximum time before the display returns to normal reading

after a defrost cycle.

d7 Time after defrost cycle before the compressor can be started.

d8 Time between defrost cycles. If set to 0, defrost must be

manually actuated.

d11 Minimum duration the control remains in defrost cycle.

d14 Units to count the defrost cycle

rt = according to the time the controller was on.

ct = according to the time the compressor was on.

HdE Hours until next defrost cycle.

ndE Minutes until next defrost cycle.

Display Menu

P0 Selection of Engineering Unit (F or C)

P1 Ambient Probe Calibration Adjustment

P4 Decimal Point Present

Alarm Menu

A0 Alarm Differential or hysteresis

A1 High Alarm Set Point (Deviation Value)

On when temperature reaches Set + A1 and off at Set +

A1 - A0

A2 Low Alarm Set Point (Deviation Value)

A3 Time of Alarm Inhibit after Continuous Cool Cycle

A4 Time of Alarm Inhibit after Defrost Cycle

A6 Time of Alarm Inhibit after Power Up

A7 Time since Alarm Initiated until Validated

Initial Setup Menu

Hor Real Time Hours

nin Real Time Minutes

H0 Restore Factory Configuration

H2 Keypad Password Protected

Yes = code is necessary to start/stop defrost or continuous

cold cycle. One minute after entering the code, keypad is

locked again

No = Keypad not protected

H3 Compressor delay time upon power up

H4 Address for serial communications (Need Model TS485

communication module)

H5 Input code to Parameters (factory set at 0)

H6 Input Probe Types: PTC or NTC

H11 HACCP Alarm recording enabled or disabled

dAt Real Time Date can be programmed by holding the set key for

3 seconds. Then, use arrows to select day. Press set to store

day; use arrows to access month and year

td The display refreshes at 1 degree if actual temperature is

greater than 1 degree higher td seconds before during defrost

and open door conditions

Front Panel Operation

Set Point Setup

• Press the Set key once and Set will be displayed.

• Press Set key again and set point value will be shown.

• Uses the Up and Down arrows to adjust set point.

• Press the Set key to save the new set point.

• Press Set and Down arrow at same time to exit.

Time Setup

• Press the Set Key once and Set will be displayed.

• Use the Up and Down arrow until Hor is displayed for adjusting the

hours.

• Press the Set key to view the current value.

• Use the Up and Down arrow to adjust to current time.

• Press the Set key for 8 seconds to save the new time (Pro will flash

on display once the value is saved).

• Press the Set key to return to the previous menu.

• Use the Up and Down arrow until Nin is displayed for adjusting the

minutes.

• Repeat steps 3 through 6.

• Press the Set and Down arrow at the same time to exit.

Parameter Programming

The parameters are organized into 6 programming menus (COn, dEF,

PrO, ALA, HAC, and Ini) (HAC is only accessible when H11 = yes).

• Press the Set key for 8 seconds until 0 is displayed.

• Use the Up and Down arrows to reach the assigned security code

(factory setting for this code is 0).

• Press the Set key to accept the code.

• Use the Up and Down Arrows to select programming menu to

enter.

• Press the Set key to reach the parameters under each

programming menu.

• Use the Up and Down Arrows to scroll through the parameters.

• Press the Set key to view the value of the parameters.

• Use the Up and Down Arrows to change the values of the

parameters.

• Press the Set key to save the changes.

• Press the Set and Down Arrow to go back to the programming

menu selection.

• Press the Set and Down Arrow a second time to exit.

Page 4

Date Setup

• Access the Data Parameter (dAt) in the Initial Setup Menu.

• Press the Set key once to display the day (dXX).

• Press and hold the Set button for 8 seconds will cause the digits to

flash and allow the value to be changed.

• Use the Up or Down arrow to adjust the value for the day.

• Press and hold the Set button for 8 seconds to store the value (Pro

will flash when the value has been stored).

• Use the Up or Down arrows to switch from day (dxx) to month (nxx)

or year (yxx).

• Follow the same steps to adjust the month and year values.

Factory Default

• Go to H0 menu in the Initial Setup Menu.

• Adjust value to 0.

• Press the Set key for 8 seconds.

Manual Default

Press the key for 8 seconds to activate / deactivate defrost cycle.

Continuous Cold Cycle

Press the Down key for 8 seconds to activate or deactivate a continuous

cold cycle. (CON will flash upon starting cycle and COF will flash upon

completion of cold cycle).

Resetting Keypad Security Code

Press the Set key during power up will reset the security code to 0.

Alarm Validation

Pressing the Down Arrow and the Set Key simultaneously will

acknowledge an alarm condition. The Alarm indicator and the buzzer will

turn off after acknowledging the alarm condition.

LED Indicators

Indicates that the Compressor is engaged. It will blink when

there is a call for the compressor to turn on during minimum

compressor stoppage.

Indicates defrost cycle is active.

Indicates an error or Alarm or error condition.

HACCP Indicates that a HACCP event is being recorded.

Display Messages

In normal operation the probe temperature will be displayed. The display

blinks when waiting for a parameter to be saved or when there is an error

saving a parameter to memory. The following messages can also

appear:

Err Memory Reading Error

ERP1 Probe Error (check wiring or replace probe)

Eri Internal Parameter Error (factory default programming)

ALH High Temperature Alarm

ALL Low Temperature Alarm

ooo Open Probe Error

--- Short Circuited Probe Error

DON Defrosting Activated

DOF Defrosting Finished

CON Continuous Cold Cycle Activated

COF Continuous Cold Cycle Finished

-d- Defrosting Cycle

During memory error, the compressor will be cycled 5 minutes on and 5

minutes off. Manual defrosting and manual continuous cold cycle

operations can not be activated.

HACCP

If this option is activated, the digital temperature switch can register up

to 5 alarms which could be high, low, or blackout. These alarms can be

seen in the menu registry of alarms (HAC).

This first value that appears is the number of registered alarms.

Afterwards, for each alarm (if any have occurred), the value of the

temperature and time the alarm occurred will be displayed. Once the

alarm returns to normal state, the temperature will be recorded along

with the amount of time it took to return to this temperature will be

displayed.

When the elapsed time is shown, it will appear as xxd for the number of

days. Pressing the Up arrow will display xxH for the number of hours,

followed by xxn for the number of minutes. Pressing the Up and Down

Arrows together for 2 seconds will delete the current record being

displayed. If the Up and Down arrows are pressed for 2 seconds while

in the HAC menu, all of the records will be erased.

Defrosting Cycles

The amount time between defrost can be based off the total time that the

instrument is on or it can be limited to the amount of time the

compressor is running. The first defrost will be performed at the hour of

the day set with d3 and the following cycles will occur in intervals of d8

after the initial defrost.

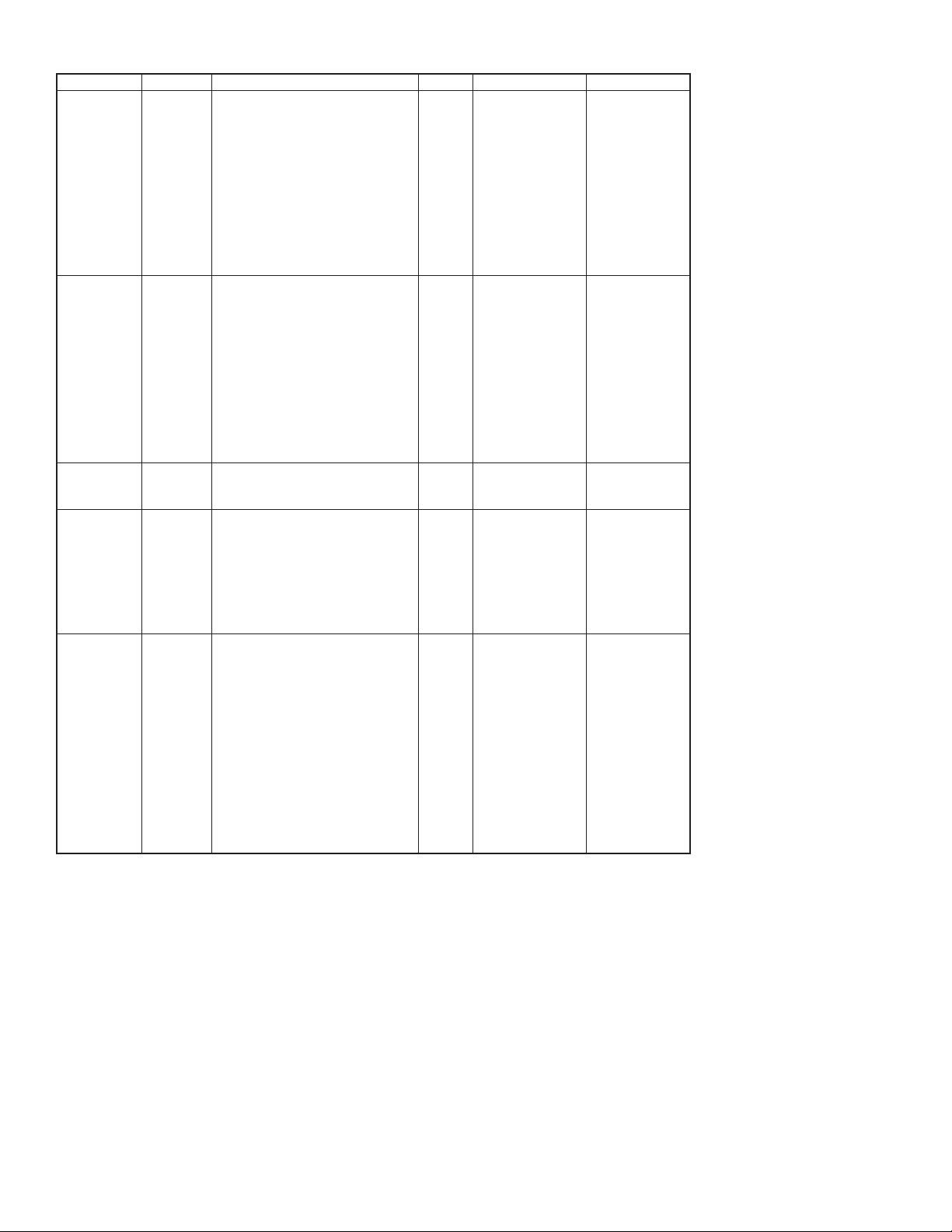

Communication Connector

The communication connector can be used with the TS2-K to read or

write the parameter configuration to the Series TS3. The connector can

also be used with a TS485 module to communicate with a computer or

other device.

MAINTENANCE

Upon final installation of the Series TS3 Digital Temperature Switch, no

routine maintenance is required. Clean the surface of the display

controller with a soft and damp cloth. Never use abrasive detergents,

petrol, alcohol or solvents. Upon final installation of the TS3 Temperature

Digital Controller, no routine maintenance is required. A periodic check

of the system calibration is recommended. The Series TS3 is not field

serviceable and should be returned if repair is needed (field repair

should not be attempted and may void warranty). Be sure to include a

brief description of the problem plus any relevant application notes.

Contact customer service to receive a return goods authorization

number before shipping.

During Probe error, the compressor will be cycled according to

parameters c2 and c3. Manual defrosting and manual continuous cold

cycle operations can be activated.

©Copyright 2013 Dwyer Instruments, Inc. Printed in U.S.A. 5/13 FR# R7-443719-00 Rev.1

LOVE CONTROLS DIVISION

DWYER INSTRUMENTS INC.

Phone: 219/879-8000 www.love-controls.com

Fax: 219/872-9057 e-mail:love@love-controls.com

P.O. BOX 338 - MICHIGAN CITY, INDIANA 46360, U.S.A.

Loading...

Loading...