Page 1

Series TPT Pressure Transmitter

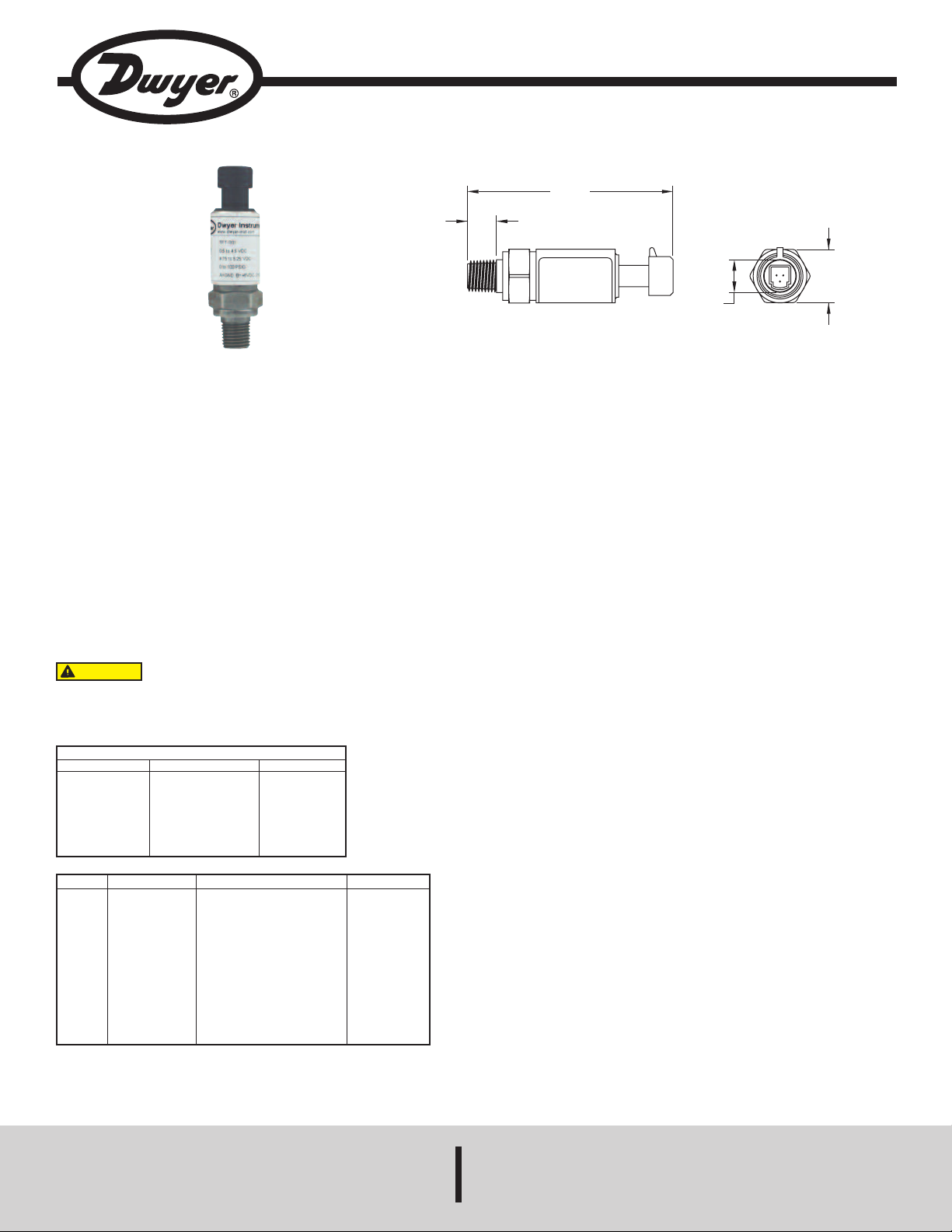

3-3/8

[85.88]

3

1/64

[

12.15]

35/64

[13.72]

7/8

[22.23]

Specifications - Installation and Operating Instructions

Bulletin P-TPT

he Series TPT Pressure Transmitter is the ideal choice for all types of industrial

T

pressure applications. Machined from a solid piece of 17-4PH SS, the TPT

provides a leak proof, all metal system without O-rings, welds, or organics exposed

to the pressure media. Its design allows for stable operation when subject to shock

and vibration. Utilizing piezoresistive technology with digital compensation and

emperature correction, the TPT gives high accuracy and stability under harsh

t

nvironmental conditions. Available in ratiometric and 4 to 20 mA outputs.

e

FEATURES

• Robust construction to withstand high vibration

• 17-4PH SS wetted material

• Standard packard connector

APPLICATIONS

• Process automation and control

• Test and measurement equipment

• Factory automation

• Energy management

CAUTION

designed for 120 or 240 volt AC operation. Use only 4.75 to 5.25 volts DC for

ratiometric outputs and 9 to 30 volts DC for 4 to 20 mA outputs.

Pressure Range

0 to 100 psig

0 to 250 psig

0 to 500 psig

0 to 1000 psig

0 to 2500 psig

0 to 5000 psig

Do not exceed specified supply voltage ratings. Permanent

damage not covered by warranty will result. This device is not

Pressure Ranges

Maximum Pressure

200 psig

500 psig

1000 psig

2000 psig

5000 psig

10000 psig

Burst Pressure

300 psig

750 psig

1500 psig

3000 psig

7500 psig

15000 psig

SPECIFICATIONS

ervice: Compatible liquids and gases.

S

etted Materials: 17-4PH SS.

W

ccuracy: ±1% FS (RMS).

A

Stability: < ±0.25% FS per year.

Temperature Limits: -13° to 185°F (-20° to 85°C).

Compensated Temperature Range: -13° to 185°F (-20 to 85°C).

Pressure Limits: Proof pressure: 2x FS; Burst pressure: 3x FS.

hermal Effect:

T

ero shift: ±0.01% FS per 1°C;

Z

pan error: ±0.02% FS per 1°C.

S

Power Requirements: See table.

Output Signal: See table.

Loop Resistance: < 100Ω.

Electrical Connection: Packard connector.

Process Connections: 1/4˝-18 male NPT.

Shock: ±20 g.

Vibration: 50 g @ 20 to 2000 Hz.

Weight: 0.20 lb (0.09 kg).

Power Requirements (VDC)

4.75 to 5.25

4.75 to 5.25

4.75 to 5.25

4.75 to 5.25

4.75 to 5.25

4.75 to 5.25

9 to 30

9 to 30

9 to 30

9 to 30

9 to 30

Output Signal

0.5 to 4.5 VDC

0.5 to 4.5 VDC

0.5 to 4.5 VDC

0.5 to 4.5 VDC

0.5 to 4.5 VDC

0.5 to 4.5 VDC

4 to 20 mA

4 to 20 mA

4 to 20 mA

4 to 20 mA

4 to 20 mA

Phone: 219/879-8000 www.dwyer-inst.com

Range psi (bar)

100 (6.89)

250 (17.24)

500 (34.47)

1000 (68.95)

2500 (172.37)

5000 (344.74)

100 (6.89)

250 (17.24)

500 (34.47)

1000 (68.95)

2500 (172.37)

Model

TPT-R01

TPT-R02

TPT-R03

TPT-R04

TPT-R05

TPT-R06

TPT-C01

TPT-C02

TPT-C03

TPT-C04

TPT-C05

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

nstallation

I

. Location: Select a location where temperatures will not exceed recommended

1

imits. Distance from the receiver is limited only by the total loop resistance. Longer

l

iring distances will slightly increase response time.

w

2. Position and Connection: The transmitter is not position sensitive. When

installing pressure connection, use a small amount of sealant tape or other suitable

sealant to prevent leaks. Make sure that male and female threads are clean and free

f any debris and ensure that the pressure passage inside the port is not blocked.

o

. Electrical Connections: The maximum length of wire connecting the transmitter

3

nd receiver is a function of the wire size and receiver resistance to total loop

a

esistance. Wiring should not contribute more than 10% of the receiver resistance to

r

total loop resistance. For extremely long runs (over 1000 feet), choose receivers with

higher resistance to minimize the size and cost of connecting leads.

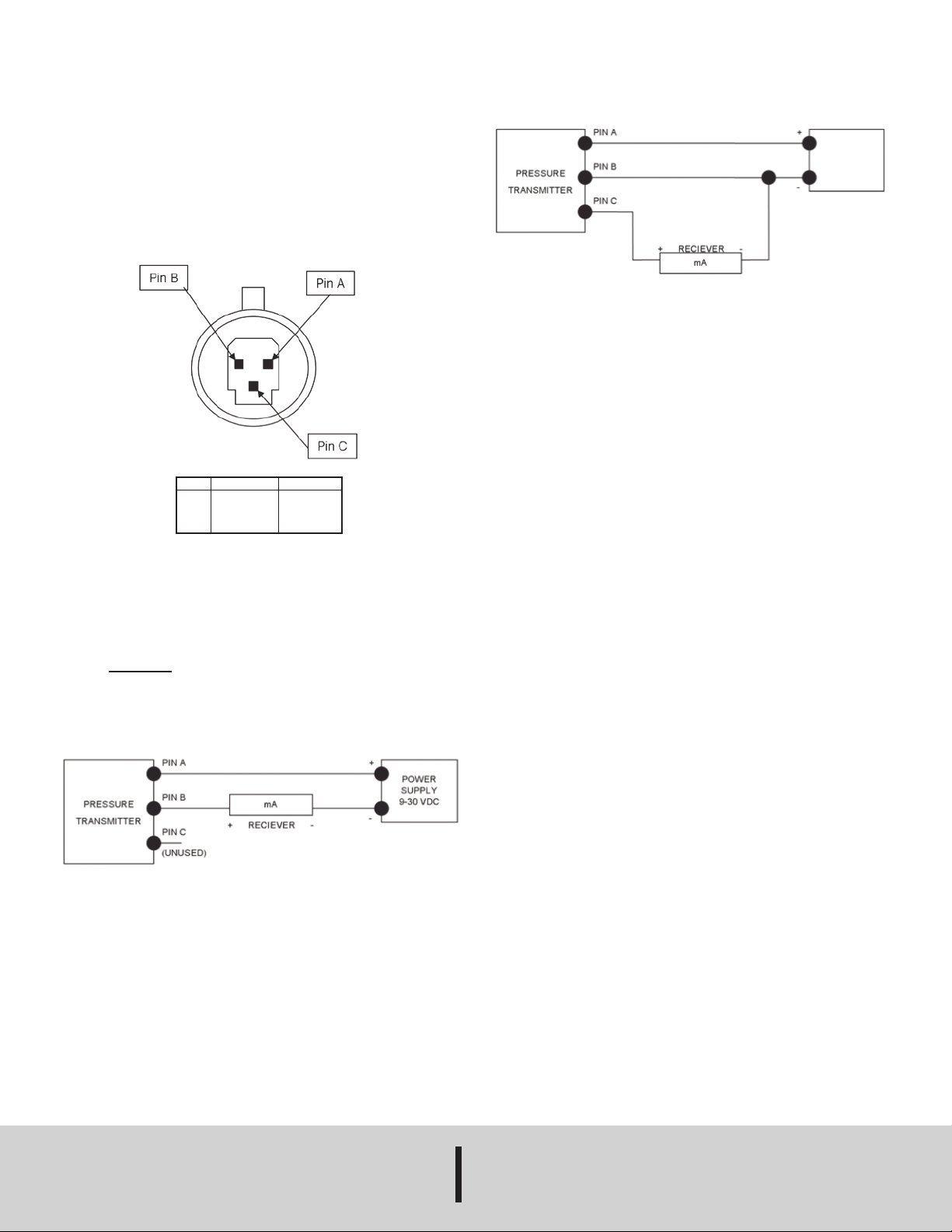

P

P

P

in A

in B

in C

Ratiometric

5 VDC

+

round

G

utput

O

4 to 20 mA

upply+

S

round

G

nused

U

ATIOMETRIC (0.5 to 4.5 VDC) OUTPUT OPERATION

R

ee Fig. C for connection of the power supply, transmitter and receiver.

S

atiometric Output

R

POWER

SUPPLY

VDC ±10%

5

igure C: Ratiometric Output Connection

F

MAINTENANCE/REPAIR

pon final installation of the Series TPT no routine maintenance is required. The

U

eries TPT is not field serviceable and should be returned if repair is needed. Field

S

epair should not be attempted and may void warranty.

r

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping the

roduct back for repair. Be sure to include a brief description of the problem plus any

p

dditional application notes.

a

CURRENT (4 to 20 mA) OUTPUT OPERATION

An external power supply delivering 9 to 30 VDC with minimum current capability of

40 mA DC (per transmitter) is required to power the control loop. See Fig. B for

connection of the power supply, transmitter and receiver. The range of appropriate

receiver load resistance (RL) for the DC power supply voltage available is expressed

by the formula:

RL Max = Vps – 10V

Shielded cable is recommended for control loop wiring.

20 mA DC

Current Output

Figure B: Current Output Connection

©Copyright 2013 Dwyer Instruments, Inc. Printed in U.S.A. 4/13 FR# RA-444069-00 Rev. 1

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...